■Installation and maintenance rules

The appliance must be installed and maintained

by an approved professional in accordance with

current regulations and codes of practice.

• Warning, hydraulic unit should not be installed

in an air current.

■Handling

The outdoor unit must not be placed in a horizontal

position during transport.

If not kept upright during transport, the appliance

could be damaged through displacement of

the refrigerant and damage to the compressor

suspension.

Any damage caused by transportation in a horizontal

position is not covered by the warranty.

If necessary, the outdoor unit may be tilted only

during manual handling (to go through a door or up

a staircase). This operation must be conducted very

carefully and the appliance must be immediately

restored to the upright position.

■Containment of refrigeration circuits

All refrigeration circuits are sensitive to contamination

from dust and moisture. If such pollutants penetrate

the refrigeration circuit, they can aect the reliability

of the heat pump.

Make sure that the connections and refrigeration

circuits (hydraulic unit, outdoor unit) are

protected correctly.

In the event of a subsequent failure and following

an inspection, the presence of moisture or

foreign bodies in the compressor oil would

automatically void the warranty.

- Check upon receipt that the ttings and refrigeration

circuit caps mounted on hydraulic unit and outdoor

unit are properly seated and secured (cannot be

loosened with bare hands). If this is not the case,

tighten them using a C spanner.

- Check also that the refrigeration connections are

sealed (plastic caps or tubes crimped at the ends

and brazed). If the caps must be removed during

the installation (tubes to be re-cut for example),

put them back as soon as possible.

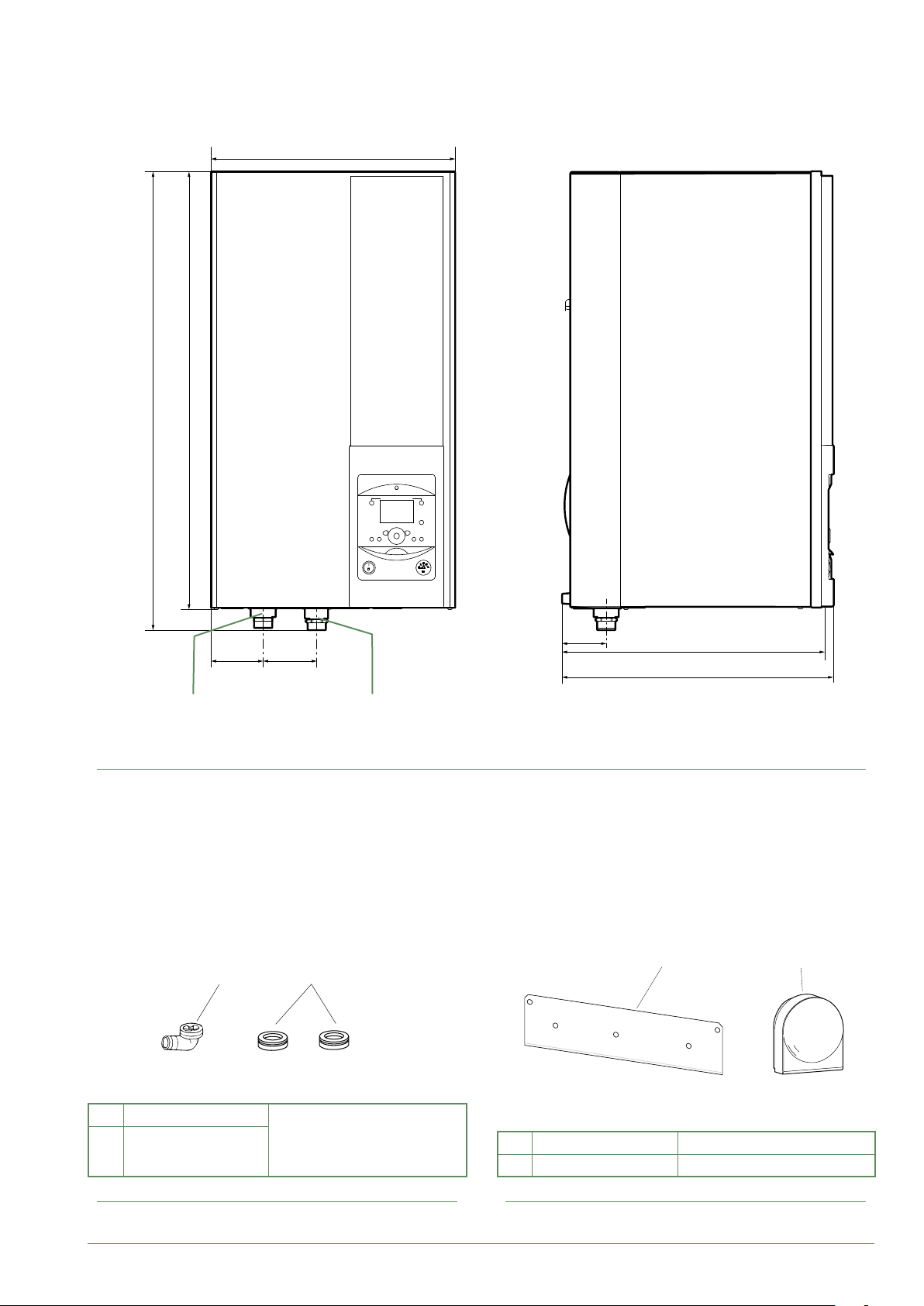

■Hydraulic connections

The connection must comply with industry standard

practice according to current regulations.

Remember: Seal everything when tting in

accordance with industry standard practice for

plumbing work:

- Use suitable seals (bre gasket, O-ring).

- Use Teon or hemp tape.

- Use sealing paste (synthetic depending on the

case).

Use glycol/water mix if the minimum ow

temperature is set below 10°C. If you are using a

glycol/water mix, arrange for an annual check on the

quality of the glycol. Use monopropylene glycol only.

The recommended concentration is 30% minimum.

Never use monoethylene glycol.

• In some installations, the presence of dierent

metals can cause corrosion problems; the

formation of metal particles and sludge can

appear in the hydraulic circuit.

• In this case, it is advisable to use a corrosion

inhibitor in the proportions indicated by the

manufacturer.

• You must also ensure that treated water does

not become corrosive.