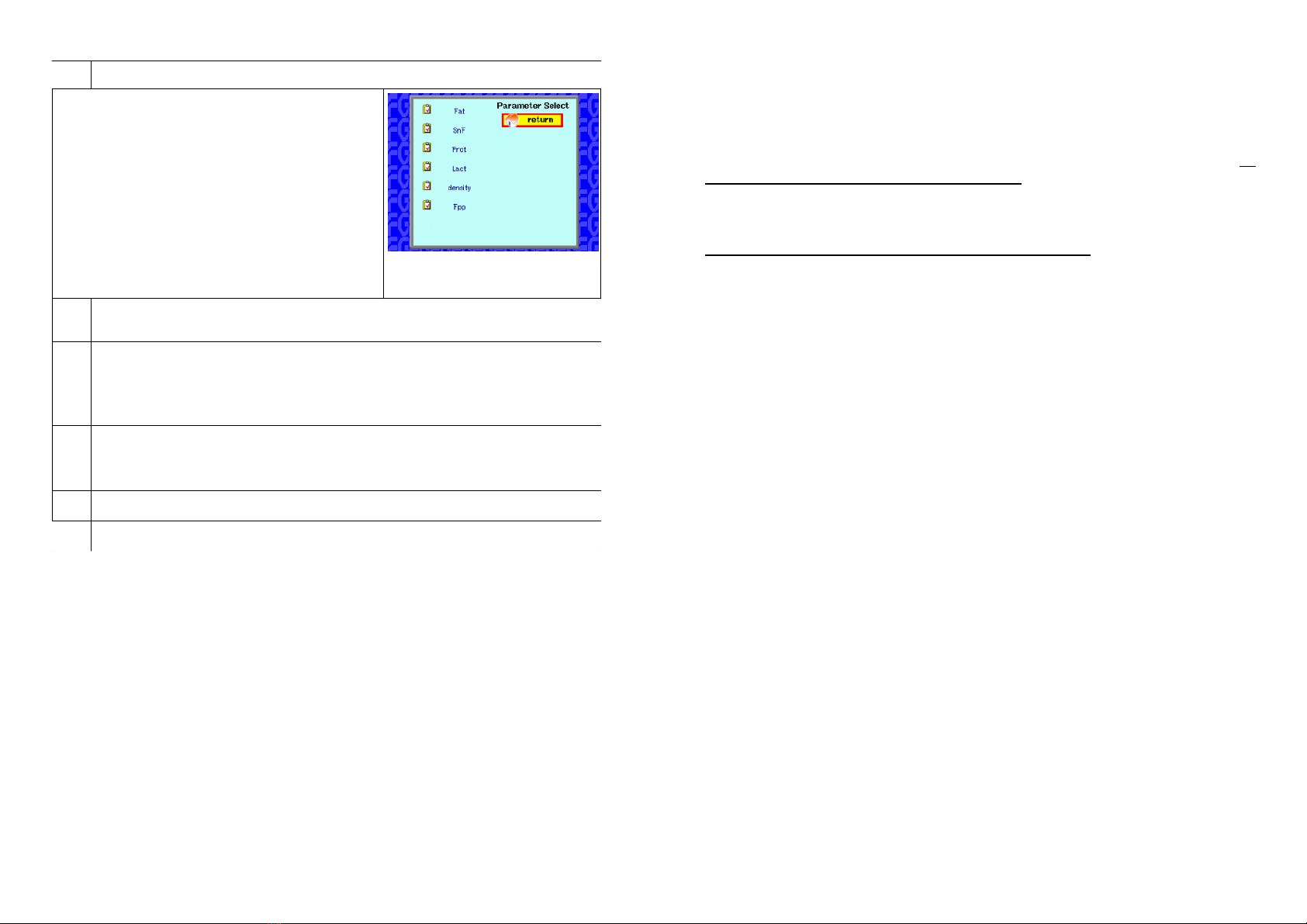

5.4. Configure parameters

Configure Parameters: After the Enter button

has been pressed, the following image

appears:

From this list you can select the relevant

parameters. The selected parameters are

shown by a tick, those that are not selected by

an X. Selected parameters are printed out and

shown on the display, while those that are not

selected are disabled.

5.5. English: Language selection: the desired language can be selected

(“Deutsch” or “English”).

5.6. Adjust Pump: You can adjust the sample pump in such a way that the

sample quantity displayed is the same as the actual sample volume.

This is necessary because the sample quantity can vary according to

how the hose pump is used and may therefore have to be adjusted.

5.7. Measurements per Sample: You can set the number of measurements

from 1 up to 9. Please ensure that in the case of very many repeat

measurements there is enough sample volume present.

5.8. Date: The date can be set here.

5.9. Time: The time can be set here.

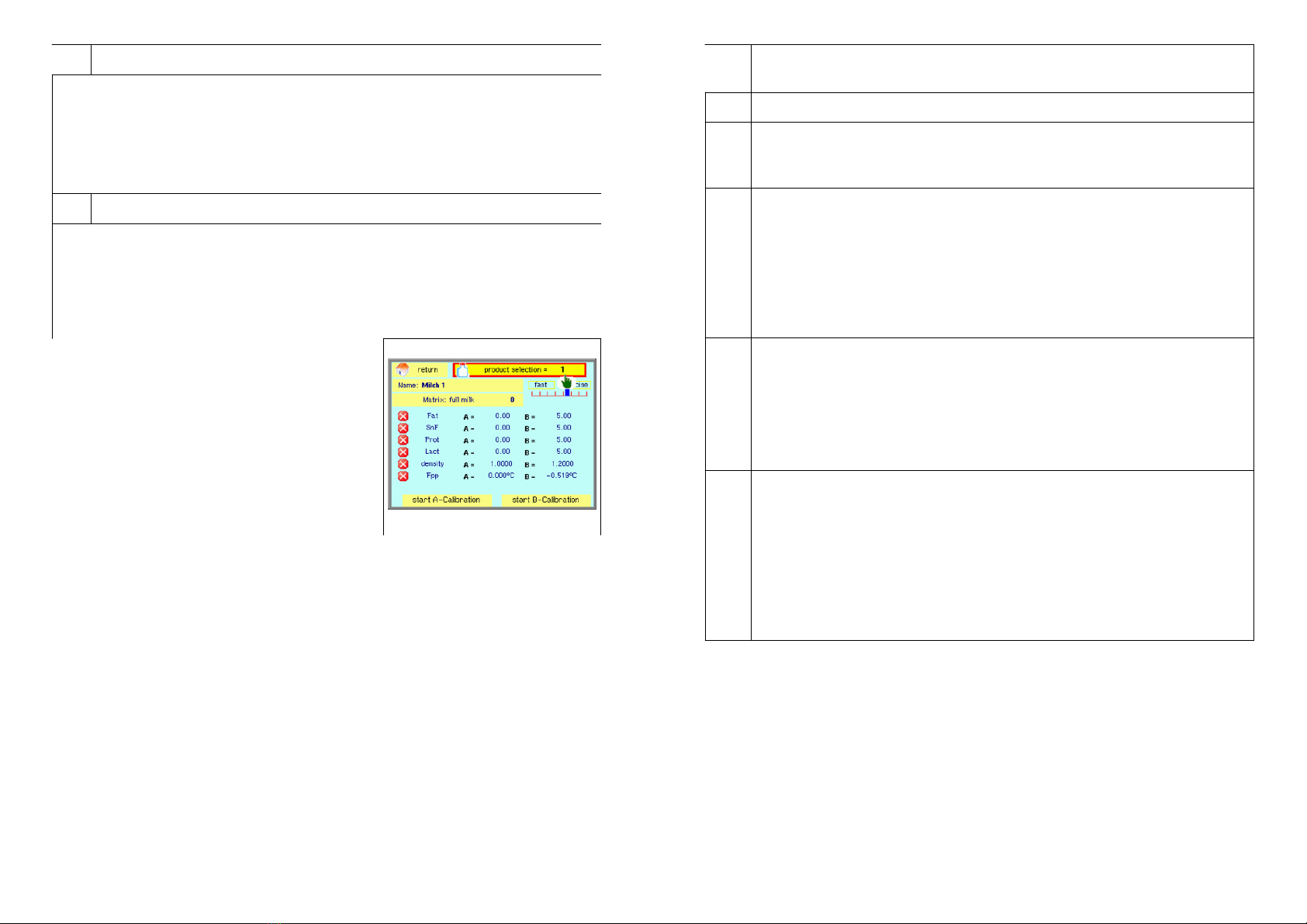

Calibration

Before it left the factory the LactoFlash was equipped with a fundamental

calibration system based on various reference milks. This fundamental

calibration possesses a fairly high level of accuracy for the matrix “raw

milk/cow’s milk”. Quite often this calibration is fully sufficient for the required

demands. In these cases the device does not have to be calibrated, as the daily

zero calibration with “-

--

-FUNKE GERBER

FUNKE GERBERFUNKE GERBER

FUNKE GERBER Zero-Diluent“ is enough this can be

performed at any time.

In other cases it may be necessary to calibrate only a single substance, e.g. fat.

This is made possible by the parameter selection (see 6.1., page 12, selection of

the substance parameters to be calibrated).

However, in principle it is possible to calibrate all substance parameters in one

calibration procedure. Only one reference milk is required for which all of the

substance parameters are known. In this manner the device can be adapted or

corrected by the user to the corresponding type of milk (e.g. raw milk, cheese-

10 LactoFlash 31. Januar 2013

making milk, skimmed milk, sheep’s milk, goat’s milk, etc.). The LactoFlash

stores a total of 18 different calibration data sets for the various types of product.

Accordingly it is possible (after appropriate calibration) to switch between

various types of product without recalibrating the device - e.g. from skimmed

milk to cream and back.

Product-specific substance calibration usually consists of B calibration. A-

type calibration is not normally necessary. Only in the case of special

milks, e.g. flavoured milks (strawberry milk, vanilla milk etc.) do you need

two-point calibration , i.e. A calibration and B calibration.

B Calibration (typical method for “normal” types of milk)

For this you require a reference milk. A reference milk is a milk which has

previously been analysed with the known reference procedures (e.g. Röse-

Gottlieb, Kjeldahl etc.). This reference milk should fulfil certain requirements. It

must be similar to the milks that are to be measured in terms of its important

ingredients or have a similar matrix.

These product-specific calibrations only have to be performed once. Afterwards

only the daily zero calibration is sufficient to compensate for drifting and ageing.

Note: The substance calibration is based on zero calibration. For this reason it is

advisable to perform zero calibration shortly beforehand.

Special Case : Two-Point Calibration

Only in the case of special milks, e.g. flavoured milks (strawberry milk, vanilla

milk etc.) do you require two-point calibration, i.e. A-type calibration and B

calibration.

Two-point calibration (A / B calibration):

(This is not normally required!)

A-type calibration is performed with a type of milk (A-type milk) that has lower

levels of substances in all parameters, while the B calibration is performed with a

reference milk (B milk) that is richer in terms of the substances it contains. The

A- type milk is acquired from the B milk by diluting the B milk with water. It is

important that this dilution is carried out with an accurate balance and is

thoroughly mixed in order to prevent errors with the calibration.

We suggest a dilution of e.g. 20% (80% reference milk / 20% distilled water). In

principle the two reference milks, the A milk and B milk, should cover the

expected measurement range.

The device places certain requirements on the B milk in that this milk should be

similar to the milks to be measured in terms of the important substances that

they contain or have a similar matrix. The differences between the A and B milk

with respect to the substances they contain should not be too small, i.e. the

dilution should be between 20% and 50%.

LactoFlash 31. Januar 2013 11