i

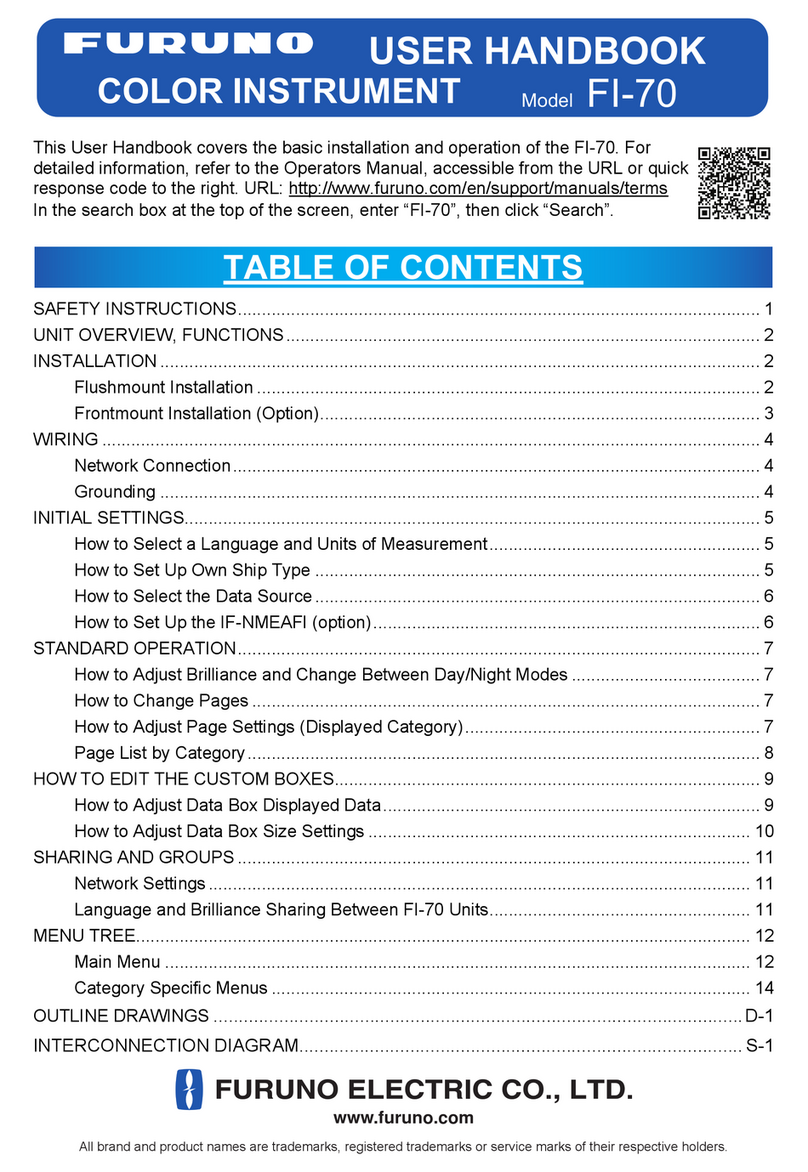

SAFETY INSTRUCTIONS

WARNING

WARNING

To avoid electrical shock, do not

remove cover. No user-serviceable

parts inside.

WARNING

CAUTION

MU-201C

Standard Steering

compass compass

0.55 m 0.30 m

The TFT LCD is constructed using the

latest LCD techniques, and displays

99.99% of its pixels. The remaining 0.01%

of the pixels may drop out or blink, how-

ever this is not an indication of malfunc-

tion.

Name: Warning Label (1)

Type: 86-003-1011-1

Code No.: 100-236-231

Do not open the equipment.

Only qualified personnel should

work inside the equipment.

Do not disassemble or modify the

equipment.

Fire, electrical shock or serious injury can

result.

Use the proper fuse.

Fuse rating is shown on the equipment.

Use of a wrong fuse can result in damage

to the equipment.

Immediately turn off the power at the

switchboard if the equipment is emitting

smoke or fire.

Continued use of the equipment can cause

fire or electrical shock. Contact a FURUNO

agent for service.

Safety Instructions for the Operator Safety Instructions for the Installer

Do not open the cover unless

totally familiar with electrical

circuits and service manual.

Improper handling can result in

electrical shock.

Turn off the power at the switchboard

before beginning the installation.

Fire or electrical shock can result if the

power is left on.

Do not install the equipment where it may

get

wet

from

rain

or

water

splash.

Water in the equipment can result in fire,

electrical shock or damage to the

equipment.

Ground the equipment to

prevent mutual interference.

A warning label is attached to the

equipment. Do not remove the label.

If the label is missing or damaged,

contact a FURUNO agent or dealer.

About the TFT LCD

Observe the following compass safe

distances to prevent interference to a

magnetic compass:

The face of the LCD monitor is made of

glass. Handle it with care.