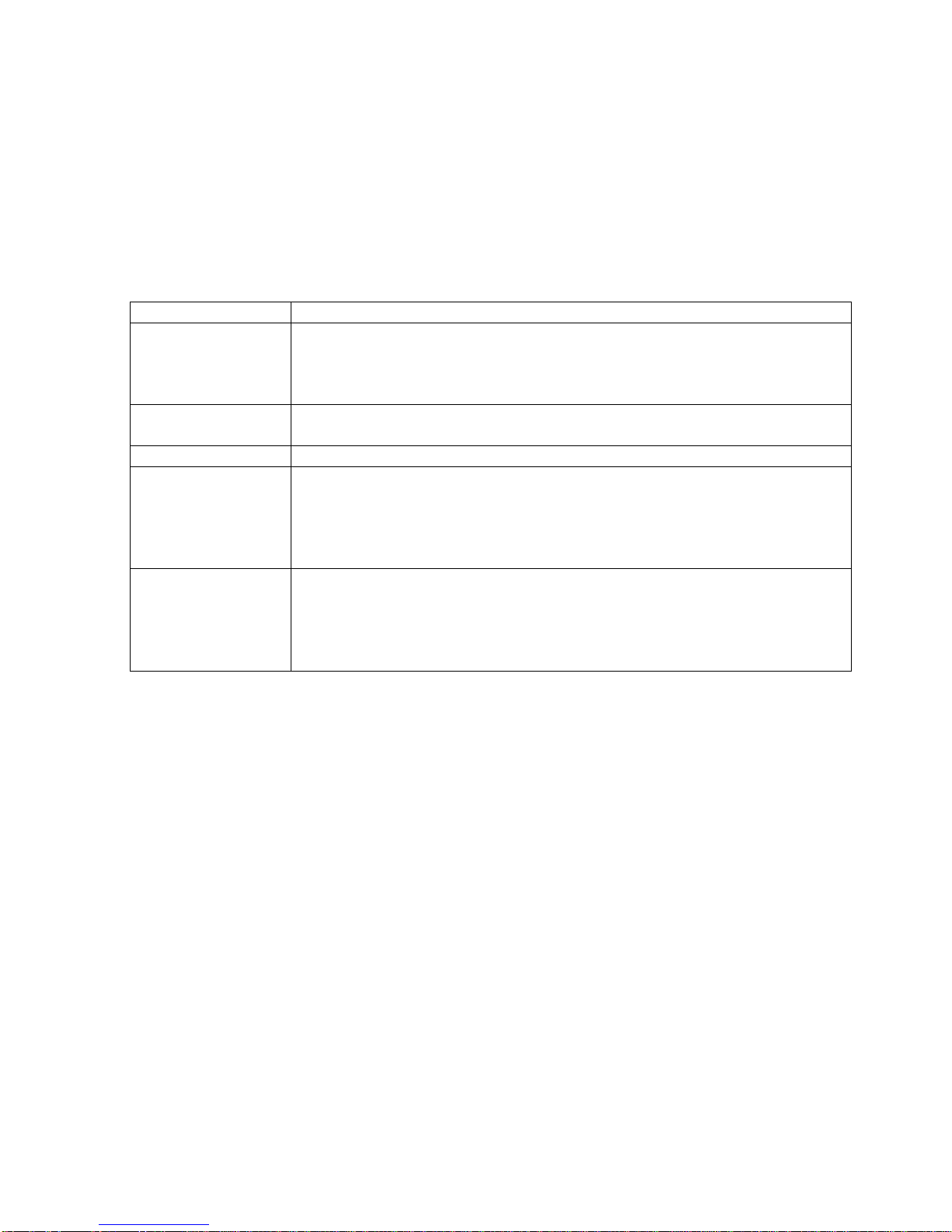

CONTENTS

1.GENERAL.........................................................................................................1-1

1.1 POWER SUPPLY......................................................................................1-1

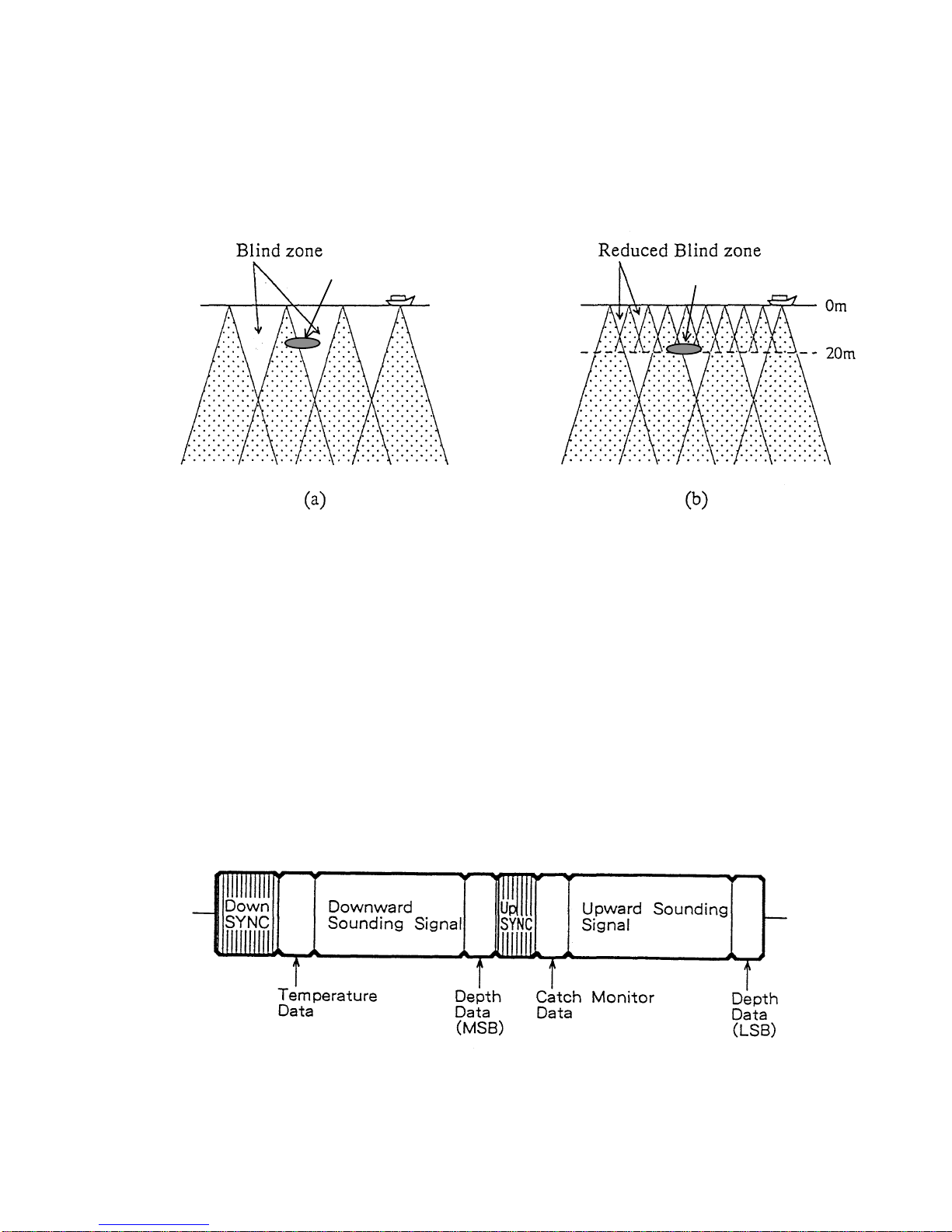

1.2 UPWARD AND DOWNWARD SOUNDING .............................................1-1

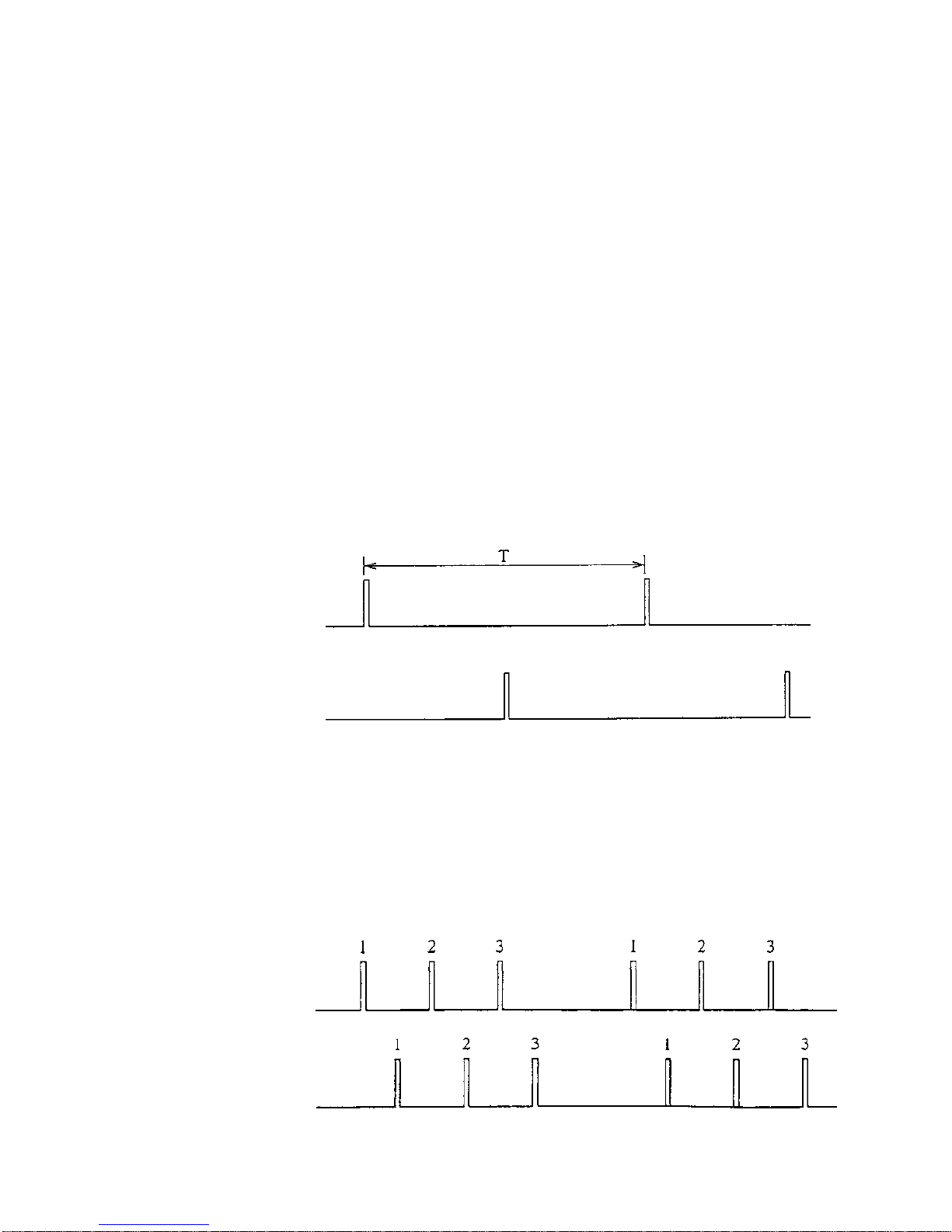

1.2.1 Sounding Rate ................................................................................1-1

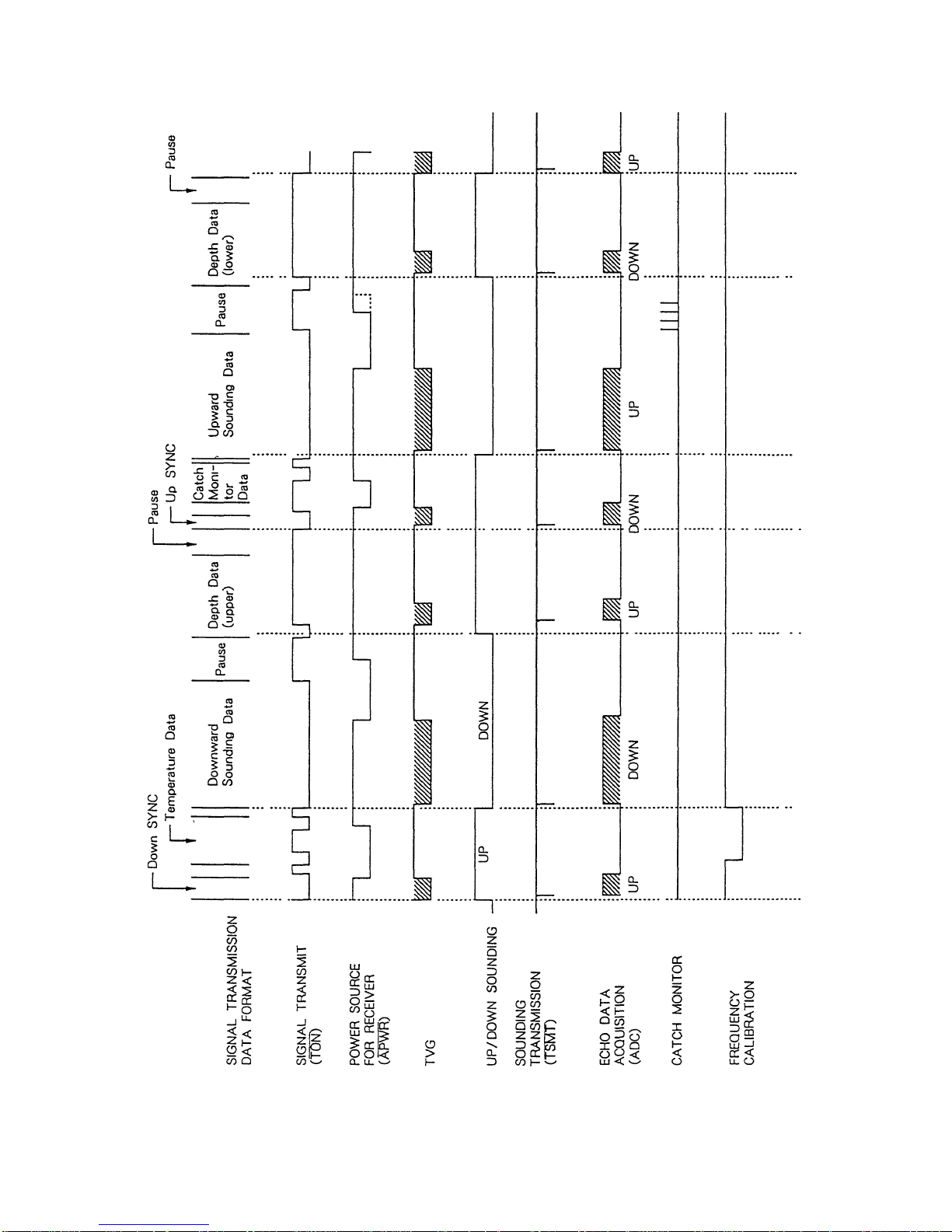

1.3 DATA FORMAT FROM TRANSMITTER UNIT ..........................................1-2

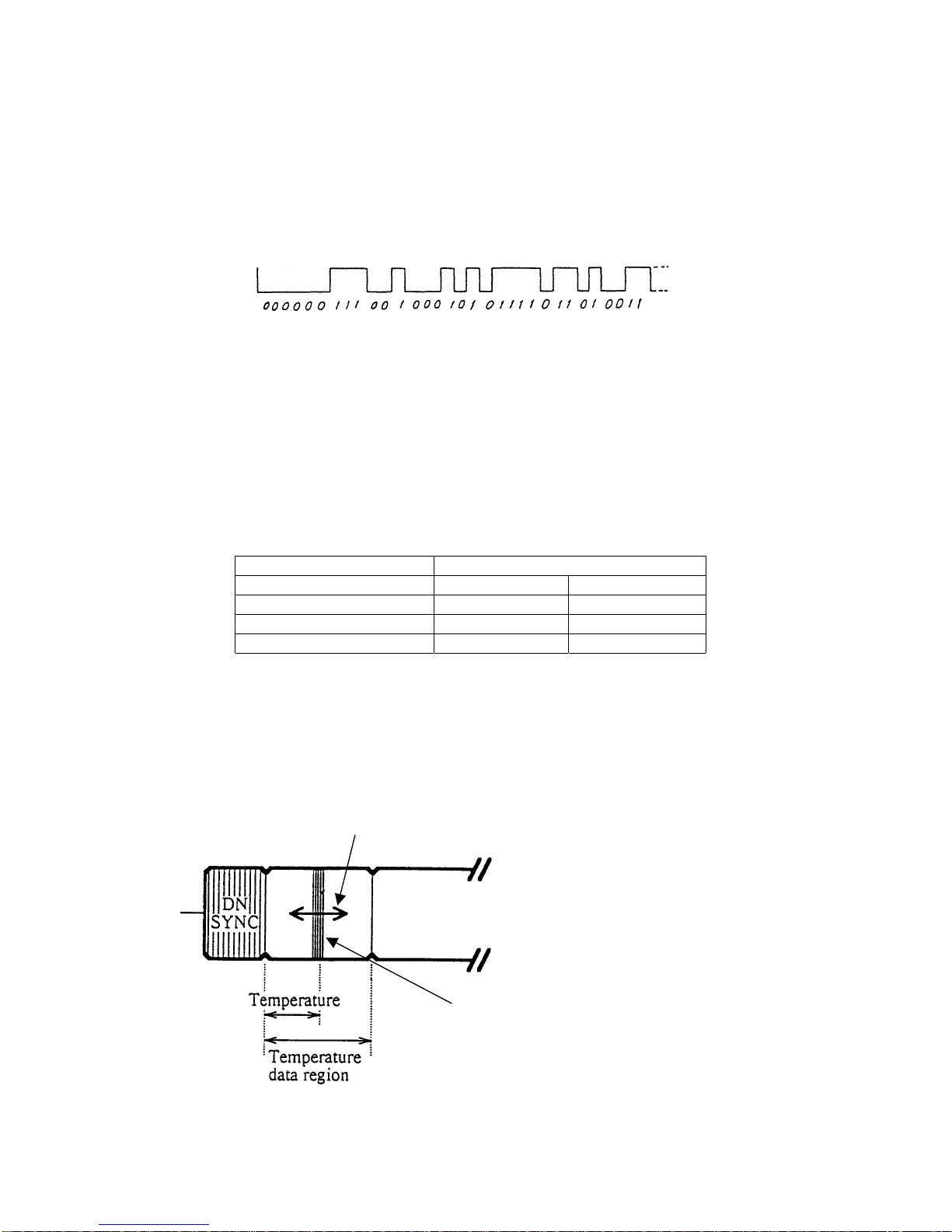

1.3.1 SYNC Code ....................................................................................1-3

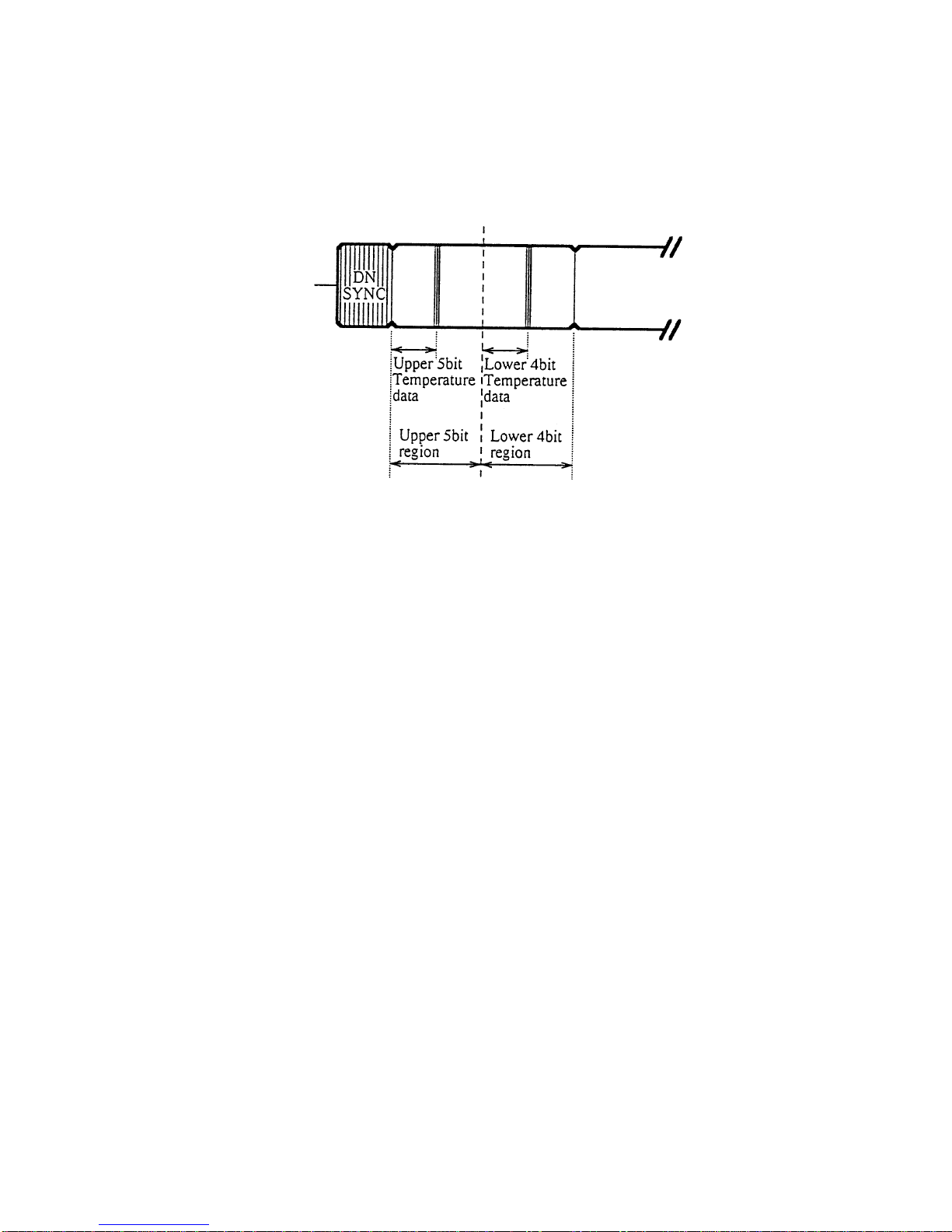

1.3.2Temperature Data ............................................................................1-3

1.3.3 Upward/Downward Sounding ..........................................................1-4

1.3.4 Depth Data ......................................................................................1-4

2.CIRCUIT DESCRIPTION ................................................................................2-1

2.1TRANSMITTER UNIT ..............................................................................2-1

2.1.1 Board Function ................................................................................2-1

2.1.2 Power ON/OFF Control ...................................................................2-1

2.1.3 Upward and Downward Soundings ..................................................2-1

2.1.4 Depth/Temperature Measurement (SEN Board) ..............................2-5

2.1.5 Signal Transmission (CONT-A, CONT-B Boards) .............................2-7

2.2 DISPLAY UNIT ........................................................................................2-10

2.2.1 Power Supply (POW 01P5727) .......................................................2-10

2.2.2 Receiver Board (AMP 01P5725) .....................................................2-12

2.2.3 Display and Signal Processor Board (DISP 01P5726) .....................2-12

3.CHECK AND ADJUSTMENT ..........................................................................3-1

3.1 DISPLAY UNIT CHECK ......................................................................

3-1

3.1.1Self-Check ................................................................................

3-1

3.1.2 Power Supply Circuit (POW Board 01P5737) ................................

3-2

3.2 TESTING FUNCTION IN AIR ..............................................................

3-2

3.2.1 Testing Transmitter Unit and Display Unit with Receiving Transducer. 3-2

3.2.2TestinginAirwithoutParavaneReceiver........................................

3-3

3.3ADJUSTINGTRANSMITTERUNIT

.......................................................

3-4

3.3.1GainAdjustment..........................................................................

3-4

3.3.2 Depth Indication Adjustment.........................................................

3-4

3.3.3 Adjusting Transmission Frequency on CONT.B Board......................

3-5

3.4ADJUSTMENTOFDISPLAYUNIT.......................................................

3-7

3.4.1ColorMonitorAdjustment.............................................................

3-7

3.4.2 DISP Board (01P5726).................................................................

3-8

4.CHANGE OF SPECIFICATIONS .....................................................................4-1

4.1DISPLAYUNIT ..................................................................................

4-1

4.1.1 Range Unit, Sounding Range, Data Format, etc ............................

4-1

4.2TRANSMITTERUNIT ........................................................................

4-3

4.2.1 Sounding Range..........................................................................

4-3

4.2.2SoundingRate ...........................................................................

4-4

4.2.3SignalTransmittingPower ...........................................................

4-4

4.2.4AdjustmentMode

.........................................................................

4-5

5.PARTS LOCATION............................................................................................

5-1

5.1DISPLAYUNIT....................................................................................

5-1

5.2 TRANSMITTER UNIT (CN-2220)..........................................................

5-6

6.BOARD INTERCHANGEABILITY.....................................................................6-1

6.1DISPLAYUNIT....................................................................................

6-1

6.2TRANSMITTERUNIT..........................................................................

6-2