Installation Manual

COLOR SCANNING SONAR CSH-8L

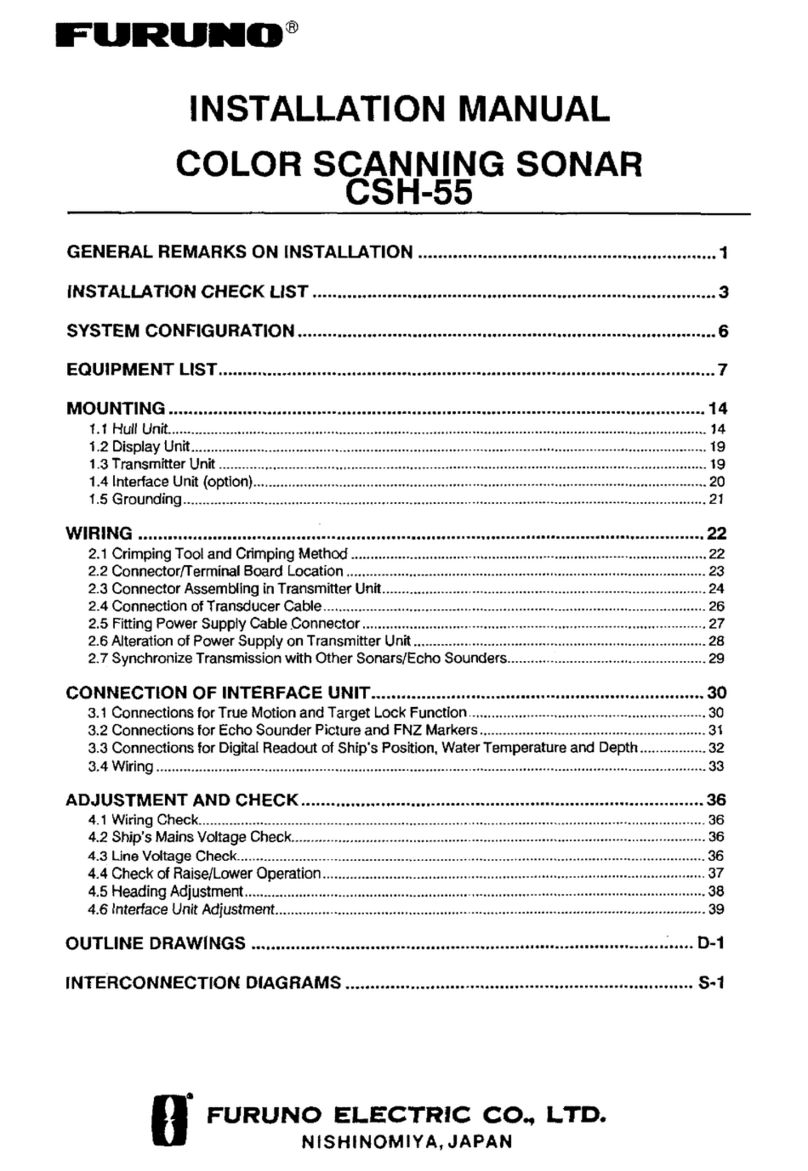

SAFETY INSTRUCTIONS.................................................................................................................... i

SYSTEM CONFIGURATION .............................................................................................................. iii

EQUIPMENT LISTS ........................................................................................................................... iv

1. MOUNTING ................................................................................................................................1-1

1.1 Hull Unit ................................................................................................................................1-2

1.2 Transceiver Unit..................................................................................................................1-15

1.3 Processor Unit ....................................................................................................................1-16

1.4 Control Unit.........................................................................................................................1-16

1.5 Ground................................................................................................................................1-19

1.6 Transducer Cable Extension Kit CSH-1700 (Optional Junction Box)..................................1-20

1.7 Motion Sensor MS-100 (option) ..........................................................................................1-21

1.8 DC-AC Inverter (option) ......................................................................................................1-22

2. WIRING ......................................................................................................................................2-1

2.1 Cabling Outline .....................................................................................................................2-1

2.2 Hull Unit ................................................................................................................................2-3

2.3 Transceiver Unit....................................................................................................................2-5

2.4 Processor Unit ......................................................................................................................2-8

2.5 Synchronizing Transmission with Other Equipment............................................................2-15

2.6 Transducer Cable Extension Kit (option).............................................................................2-19

2.7 DC-AC Inverter (option) ......................................................................................................2-20

3. ADJUSTMENT............................................................................................................................3-1

3.1 Measuring TX Output............................................................................................................3-1

3.2 Heading Alignment................................................................................................................3-3

3.3 Setting for External Equipment .............................................................................................3-4

3.4 Smoothing the GPS Data......................................................................................................3-7

3.5 NMEA Version Setting...........................................................................................................3-8

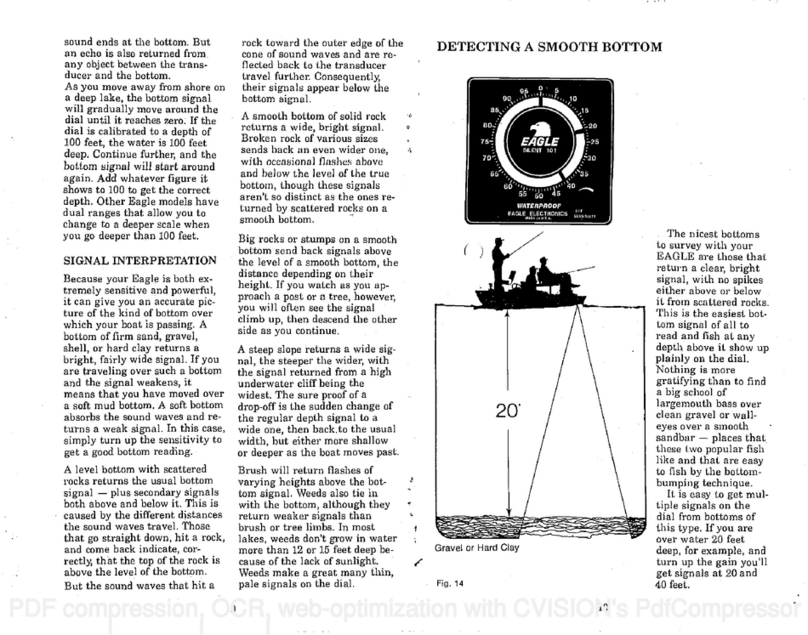

3.6 Adjusting Echo Sounder Video .............................................................................................3-9

3.7 Sea Trial..............................................................................................................................3-10

APPENDIX

INSTALLATION OF CSH-8L ON RETRACTION TANK OF CH/FH SERIES SONAR,

OR 1800/3500 MM TANK ..............................................................................................................AP-1

PACKING LISTS.............................................................................................................................. A-1

OUTLINE DRAWINGS .................................................................................................................... D-1

INTERCONNECTION DIAGRAMS.................................................................................................. S-1

All brand and product names are trademarks, registered trademarks or service marks of their respective holders.

www.furuno.com