2 of 13

1 Introduction

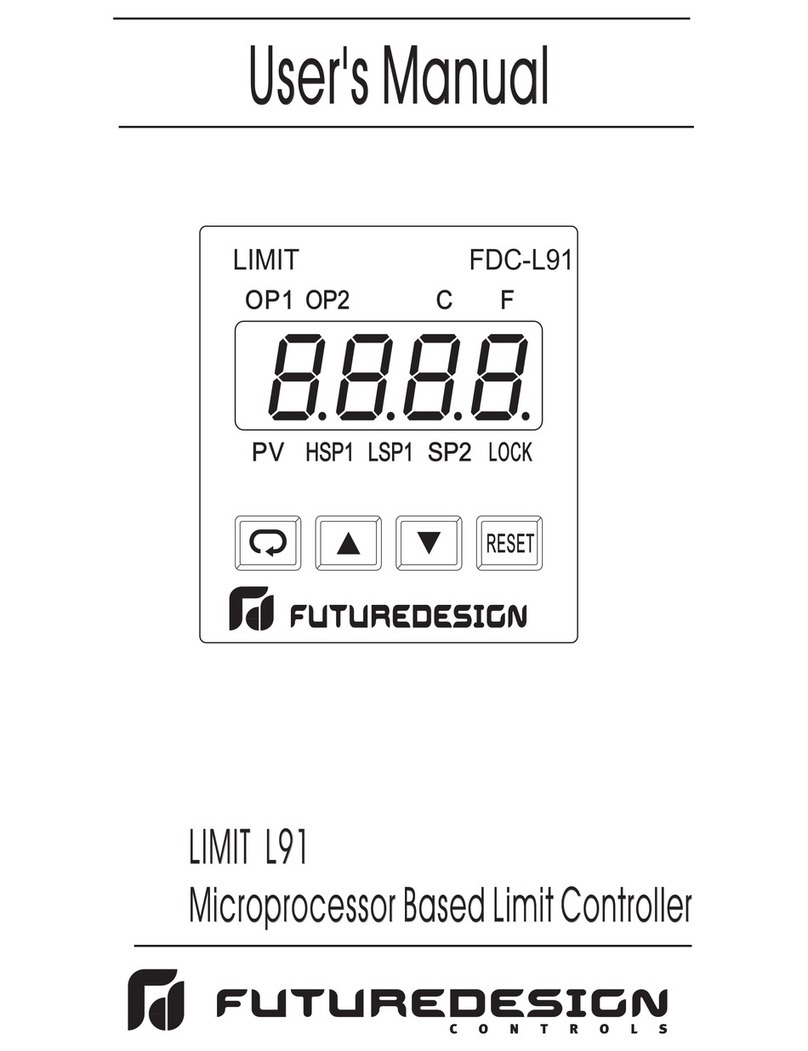

This new generation of low-cost, microprocessor-based control incorporates two bright, easy to read LCD

displays which indicate process value (PV) and set point (SP). The control is powered by an 11-26 VDC

supply and incorporates a 2 Amp control relay output as a standard. The control is fully programmable for

PT100 RTD and thermocouple types J, K, T, E, B, R, S, N, L, U, P, C, and D. The input provides high

accuracy via an 18-bit A to D converter and when coupled with the fast-sampling rate, allows control of fast

processes.

1.1 Features

•LCD display

•Simple operation

•Universal input (thermocouple/RTD) with high accuracy 18-bit A-D conversion

•Fast sampling rate

•Degrees F or C operation

•Low voltage operation

•Programmable deadband alarm

•Power failure alarm

•Low battery indication

•Adjustable hysteresis for control and alarm outputs

•Process value calibration offset adjustment

•Control and alarm relay (SPST) output contacts

•Audible alarm with silence (utilizing external relay)

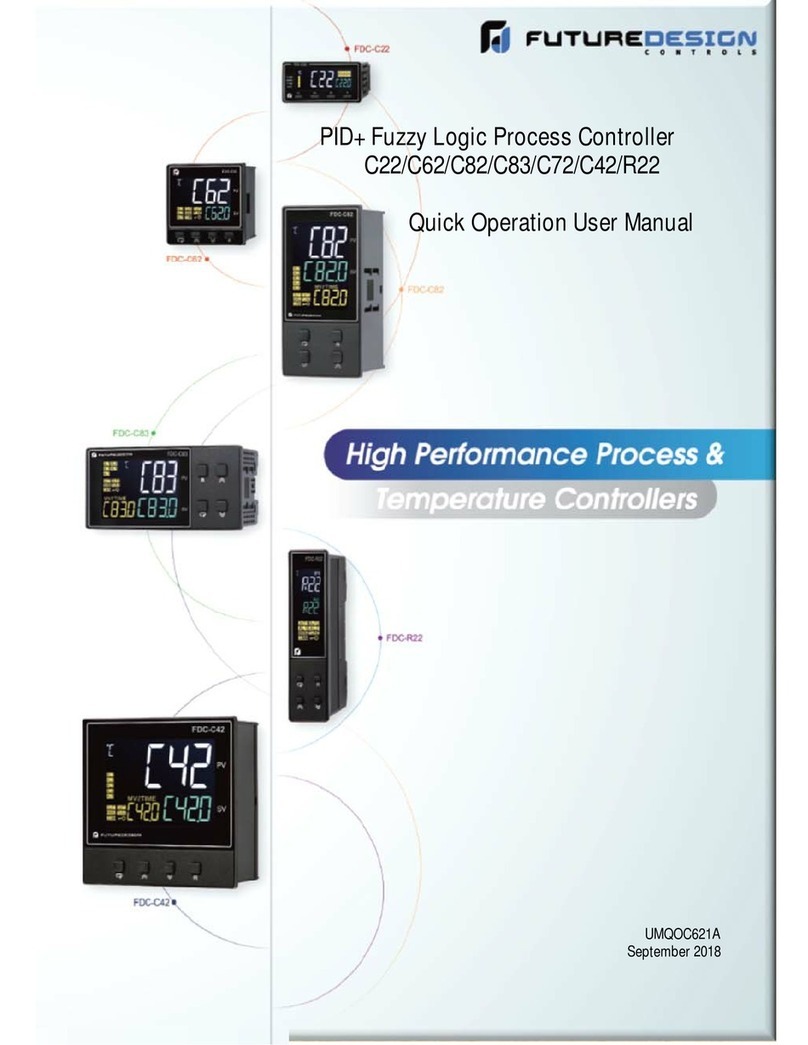

The FDC-C42 microprocessor-based controller, incorporates dual, easy to read 4-digit LCD readouts to

indicate process value and set point, as well as other controller operations. The unit features keys to select

the various operator views as well as control parameters. The FDC-C42 chamber controller is provided

pre-configured, specifically for low temperature chamber operation, providing simple to use, “hassle” free

operation for startup and operation of the chamber.

The FDC-C42 incorporates a (SPST) control relay output and three (SPST) alarm relay outputs. Two of

the alarm relays (AL1 for temperature and AL2 for power failure) are prewired together in order to facilitate

faster installation and connection to external alarm relays for remote indication and sounding the on-board

audible alarm (wired separately). A programmable deadband alarm set point allows the operator to

monitor/indicate alarm conditions above and below chamber operational settings.

The FDC-C42 provides digital inputs which are utilized for the power failure and low battery indicators

(compatible with MEAN WELL DRC-40/60 series power supplies). When main power is lost, the external

12Vdc backup battery will maintain power to the FDC-C42; however, the “power OK” input will be

deactivated causing the second alarm relay output (AL2) to activate and sound the audible alarm. Asilence

push-button is provided for the audible alarm, so that when a temperature and/or power failure alarm

occurs, the operator can silence the alarm.