Page.1

Safety Precautions Symbols

Protect yourself and others f rom inj ury,

read and follow these precaut ions be fore

installation and operatio n.

Ex p lo d ing p art s c an in jur e .Al w ays w ear a f a ce

sh i el d a nd lo ng sl e eve s。

St ati c ca n dam ag e P C bo ard s

1、Pu t on gr ou nde d wr i st s tra p be f or e

ha ndi ng b oar ds o r p ar ts。

2、Us e pro pe r sta ti c -p roo f ba g s an d box es t o

st ore,move or s hip P C bo ard s。

1、We ar ap pr ove d fa c e sh iel d or s a fe ty go gg l es

wi th si de s hie ld s。

2、We ar pr op er bo dy p r ot ect io n t o pr ote ct s k in。

Do n ot we ld i n the h ei g ht!

Read instructions.

1、Read owner's Ma nua l be for e us i ng o r ser vi c in g

un it。

2、Use only manufacturer’s supplied replacement。

Fl yin g me t al c an i n ju re ey es。

1) Wea r sa f et y gl a ss es wi th s i de s hie ld s o r fa ce

sh iel d。

1、Ma gne ti c fie ld s c an a ffe ct p a ce mak er s .

Pa cem ak er we ar e rs k eep a wa y .

2、We are rs s hou ld c o ns ult t he i r do cto r be f or e

go ing n ea r pla sm a a rc c utt in g o pe rat io n s。

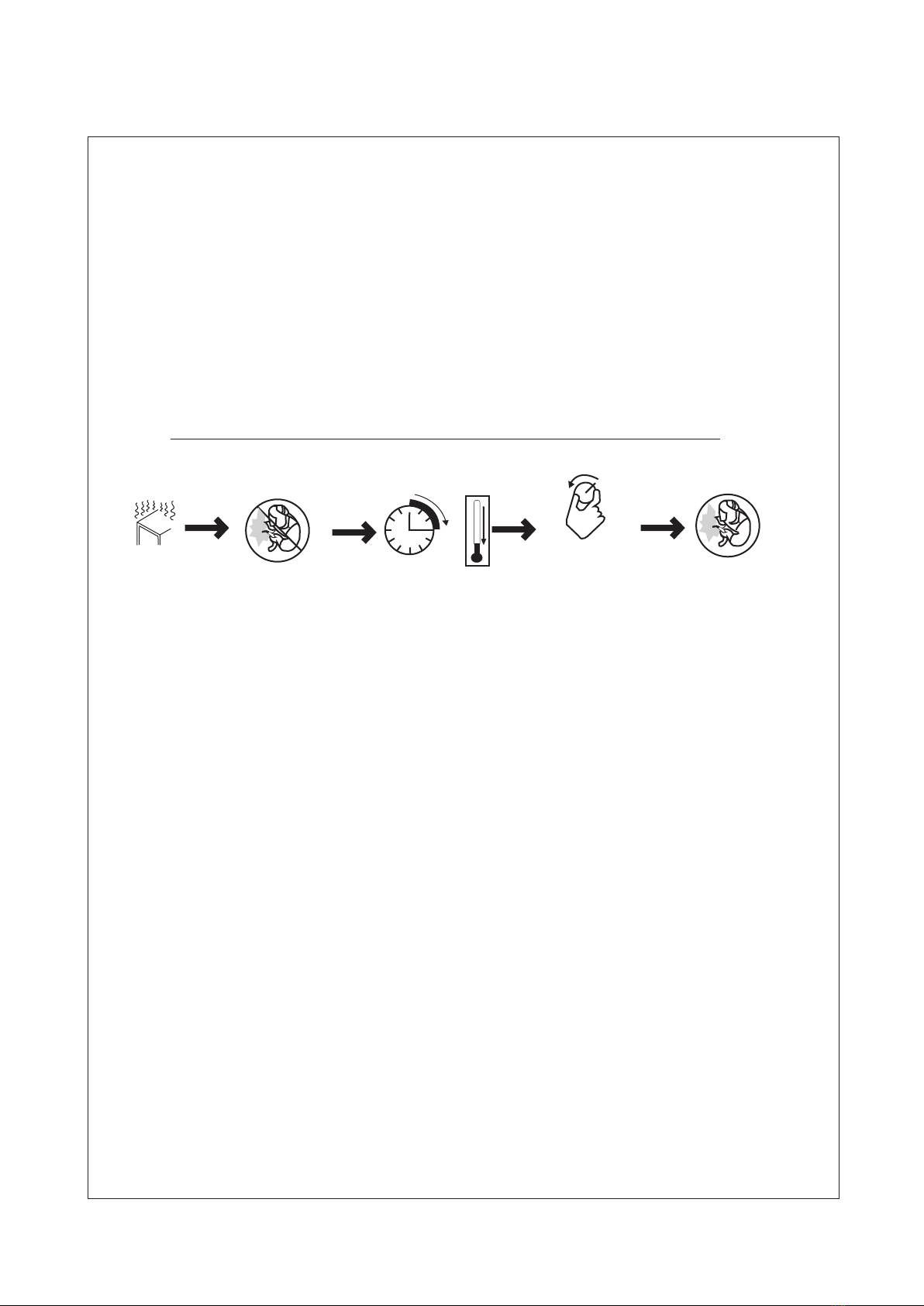

Ov e ru s e can c aus e o ver hea t in g

Al l ow c o oli ng pe r iod , fol l ow r a ted d uty c y cle

before starting to we ld ag a in.

El ect ri c sho ck c a n ki ll:

1、Do n ot to uc h liv e el e ct ric al p a rt s。

2、We ar dr y, hol e- f re e ins ul a ti ng gl ov e s an d

bo dy pr ot ect io n .

3、Do n ot wr ap e lec tr i ca l cab le a r ou nd yo ur

bo dy.

4、Gr oun d th e wor kp i ec e wit h a go o d el ect r-

ic al gr ou nd。

Ey e pro te cti on f o r we ldi ng :

Cu rre nt l eve l in a m pe rag e Mi n im um sh ad e

Nu mbe r

30-150A---------- - -- -- --- -- --- -- --- # 8

150-300A--------------------------- # 10

30 0-5 00 A-- -- ----------------------- #12

Nev er cut o n pres suri zed cy lind er.

Maintenance regularly!

Fa cto ry s afe ty!

Fi re or e xp los io n h az ard .

Do n ot lo ca te un it o n ,o ver ,o r n ea r com bu s ti be

su rfa ce s.D o no t i ns tal l un i t ne ar fl am m ab les .

Re mov e al l fla mm a bl es of t he w e ld ing a re a .

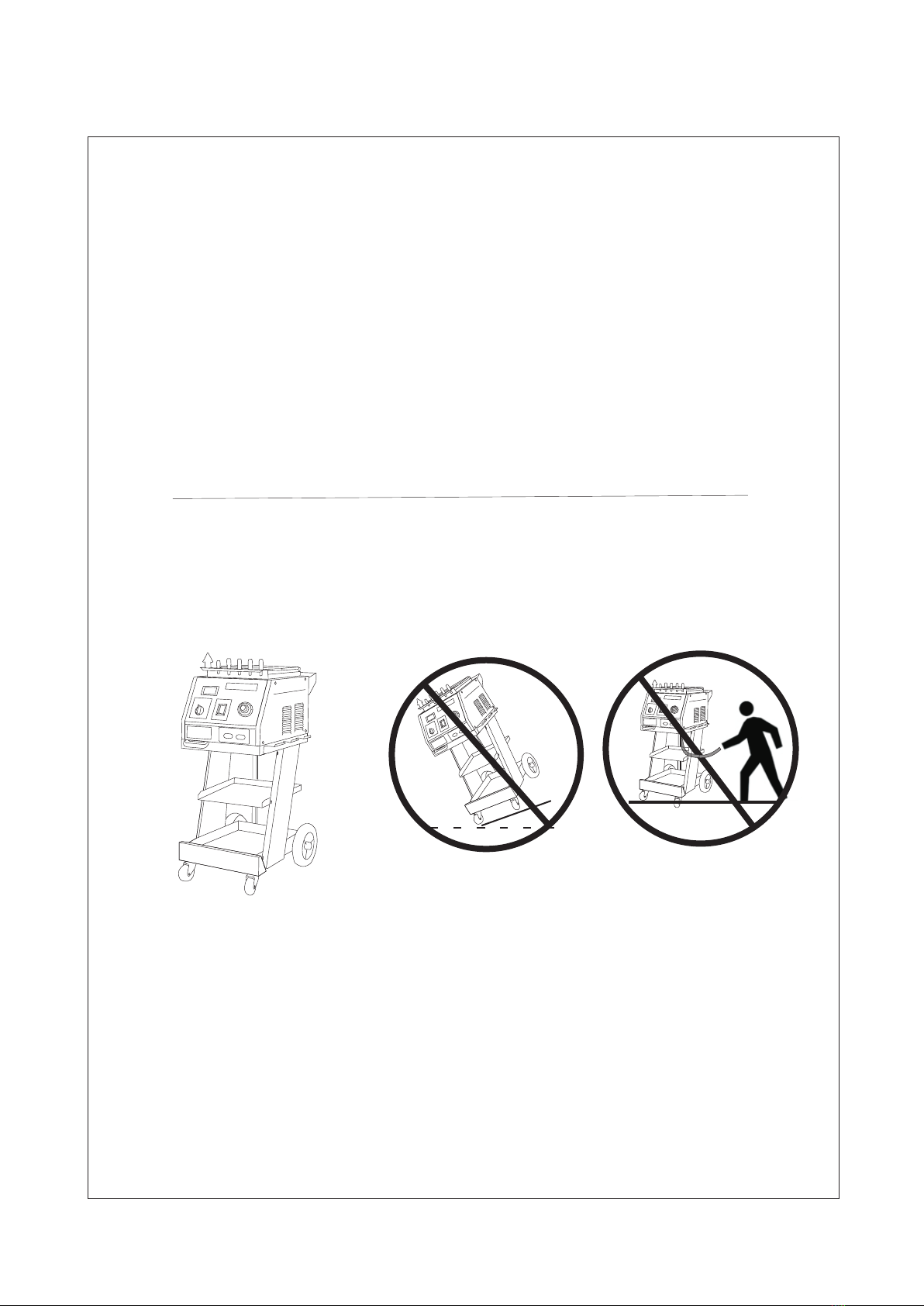

Fa lli ng u nit c an c a us e inj ur y .

Th e hea t fr om th e wo r kp iec e ca n c au se se ri o us

bu rns。

Fu mes a nd g ase s ca n b e ha zar do u s

we ldi ng p rod uc e s fu mes a nd g a se s. Breathing

th ese f um es an d ga s es c an be h az a rd ous

to y our h ea lth .

If inside,ventilate the area.

Do n ot we ld i n a con fi n ed s pac e on l y if i t

is w ell v en til at e d.

Pr ote ct y our se l f Warn others