Page.1

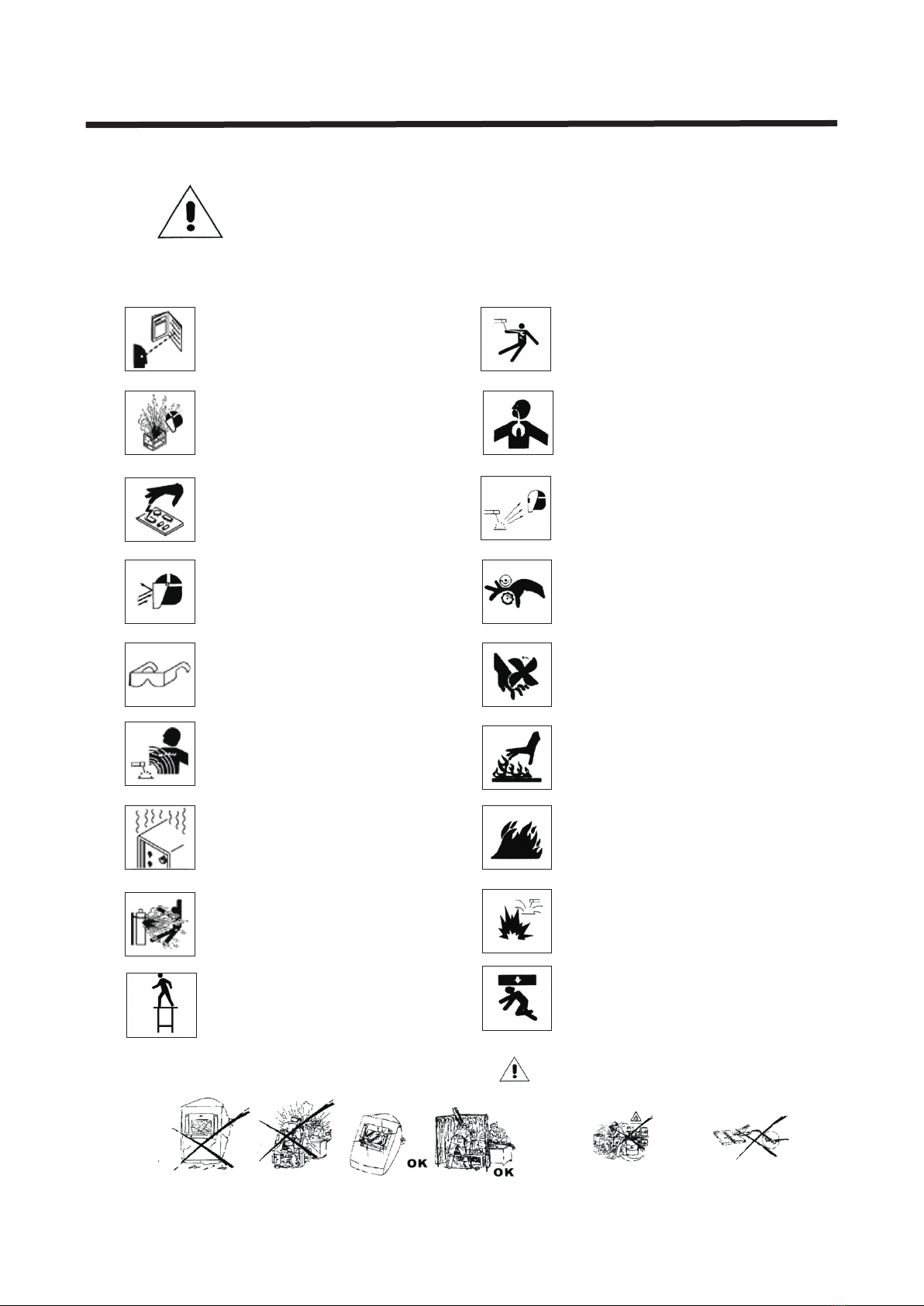

Pro tect you rself and others from injury,

rea d and foll ow these p recautions before

ins tallat ion and operation.

Exploding p a r t s c a n i n j u re.Always wear a face

shield and lo n g s l e e v e s。

Static can damage PC boards

1、Put on grounded wrist strap before

ha n d i n g b o a r d s o r p a rts。

2、Us e p r o p e r s t a t i c - proof bags and bo x e s t o

st o r e,move or s h i p P C b o a r d s。

1、We a r a p p r o v e d f a c e s h ield or safety go g g l e s

wi t h s i d e s h i e l d s。

2、We a r p r o p e r b o d y p r o t ection to prote c t s k i n。

Pa y a t t e n t i o n n o t t o b e crushed by the wh e e l o f

th e w i r e f e e d e r w h e n i nstalling wel d i n g w i r e s

an d c l e a n i n g t h e i n s ide of the machin e .

Pa y a t t e n t i o n n o t t o b e scratched by th e f a n

wh e n i n s t a l l i n g w e l ding wires and cl e a n i n g t h e

in s i d e o f t h e m a c h i n e.

Do n o t w e l d i n t h e h e i g h t!

Read instructions.

1、Read owner's M a n u al before using o r s e r v i c i n g

un i t。

2、Use only manufacturer’s supplied replacement。

Fl y i n g m e t a l c a n i n j u re eyes。

1) W e a r s a f e t y g l a s s es with side shie l d s o r f a c e

sh i e l d。

1、Ma g n e t i c f i e l d s c a n a ffect pacemak e r s .

Pa c e m a k e r w e a r e r s k eep away.

2、We a r e r s s h o u l d c o n s ult their docto r b e f o r e

go i n g n e a r p l a s m a a r c cutting opera t i o n s。

Overuse can c a u s e o v e r h e atin g

Allow cooli n g p e r i o d , f o llow r a t e d d u t y c y c le

before starting t o w e l d a g a i n.

Check the int e g r i t y o f t h e g as cyl i n d e r b e f o r e

use. Any dama g e i n t h e g a s c y l inde r c o u l d c a u s e

explosions.

El e c t r i c s h o c k c a n k ill:

1、Do n o t t o u c h l i v e e l e c trical parts。

2、We a r d r y , h o l e - f r ee insulating gl o v e s a n d

bo d y p r o t e c t i o n .

3、Do n o t w r a p e l e c t r i c al cable around y o u r

bo d y .

4、Gr o u n d t h e w o r k p i e ce with a good elec t r -

ic a l g r o u n d。

Ey e p r o t e c t i o n f o r w elding:

Cu r r e n t l e v e l i n a m p erage Minimum s h a d e

Nu m b e r

30-150A---------- - -- - -- - - -- - -- - --- - # 8

150-300A--------------------------- #1 0

30 0 - 5 0 0 A - - - - ----------------------- #12

Pr e v e n t f i r e o r e x p l osion hazard.

Do n o t l o c a t e u n i t o n , o ver or near combu s t i b l e

su r f a c e s . D o n o t i n s tall unit near fl a m m a b l e s .

Re m o v e a l l f l a m m a b les away from the w e l d i n g a r e a .

Fa l l i n g u n i t c a n c a u se injury.

Th e h e a t f r o m t h e w o r k piece can cause s e r i o u s

bu r n s .

Fu m e s a n d g a s e s c a n b e h azardous

we l d i n g p r o d u c e s f umes and gases. Breathing

th e s e f u m e s a n d g a s e s can be hazardous

to y o u r h e a l t h .

If inside,ventilate the area.

Do n o t w e l d i n a c o n f i n e d space only if it

is w e l l v e n t i l a t e d .

Maintenance regularly!

Fa c t o r y s a f e t y!

Pr o t e c t y o u r s e l f Warn others

Ne ver cut o n pr essur iz ed cyli nd er.

Safety Precaution Symbols