Page 4

While holding the button down, set the desired minimum speed. Release the button to save.

Program Button

A momentar press at an time will enter program mode and cause an emergenc stop if pressed while running.

In program mode, the LED will blink the Option Code of the Parameter currentl selected b the DIP switch. A

momentar button press after the code will increment the Option Code. When the desired option has been

reached, hold down the Program Button for about 3 seconds until the LED starts flashing rapidl , indicating the

new option has been saved. Change more options b changing the DIP switch to the desired parameter, and re-

peat above. To exit program mode, power down and restart.

LED

Power: LED should be ON when power is applied.

Diagnostics: LED will turn OFF while a button is pressed: Start, Stop, Dir

LED will turn OFF while the Start input, or Stop input goes low (connected to common).

Programming: LED will turn start blinking Option Codes when the Program button is pressed.

LED will flash rapidl while the Program button is held down to save the option.

While Running ...

Automated station stops can be done using a track mounted reed switch, and a magnet located on the locomo-

tive. When the loco passes over the reed switch, a station stop will be performed as programmed b Station Stop

Percentage Parameter 2; i.e. it will onl stop a certain percentage of the time, or with the use of two reed switch-

es, one at each end of a track, and Parameter 2 Option 6, it will run in back and forth trolle mode.

Stopping the train

A running train can be stopped automaticall after running for One Lap or after a Time Period of X minutes (See

Run Mode Parameter 3.) If a station stop reed switch in used, the train will stop at the station and wait for the next

start command. Otherwise it will just stop wherever it is when time runs out.

The train can also be stopped at an time b holding down the Stop Button.

Installation

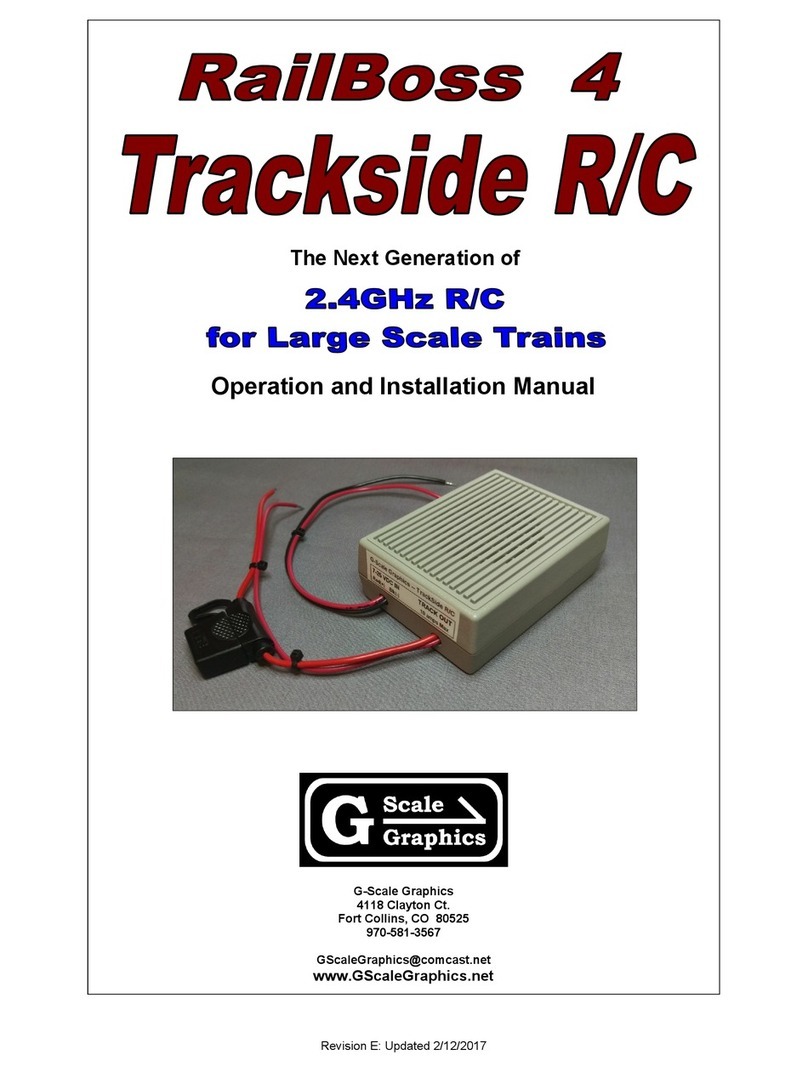

Power Input

Power input to the APTC can be an DC power source, 7-25 VDC, connected to the Vin +,- terminals. The most

economical and best power source is an industrial power suppl ; e.g. the Meanwell LRS-150-24, which is rated

for 24 VDC, 6.5 amps, and can be purchased on-line for around $19.

You can also use an train power

pack with suitable voltage and cur-

rent ratings, b setting the throttle for

up to 25 VDC max.

Track Output

Connect the “Track Out” terminals to

the track. The APTC output is rated

for up to 10 amps. Output voltage will

be determined b the power input

source and the speed pot on the

APTC. Voltage can be adjusted from

0 to 100% of the power input voltage.

To change the direction the train runs

at power up, swap the Track Out

wires.

Remote Controls

Remote Start Pushbutton - Con-

nect a momentar push button, nor-

mall open, across the Start and

Com terminals. Momentar contact closure initiates a start.

Track Mounted Reed Switch - Connect this to the Stop and Com terminals to initiate an automated station stop.

Motion Detector - An optional PIR Motion Detector Module can be used to start the train when a visitor’s pres-