Page 5

Installation

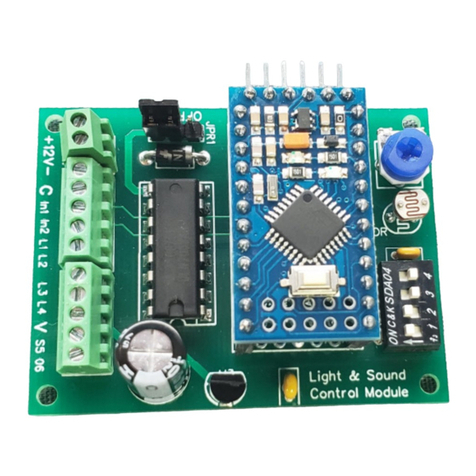

The Trackside base station can be mounted anywhere between the power supply and the track. All wiring

(power supply to Trackside base station , and Trackside base station to track, should be as short as possible

to minimize voltage drops. For long runs, wire gauge should be at least 16 gauge or better. 12 gauge Landscape

wiring works well.

The Trackside base station wires are not terminated, just tinned, for you to make connections as needed in your

setup. Final connections can be made using wire nuts,

crimp terminals, or soldering.

Power Input

Connect 7 to 25 VDC to the Red and Black wires. Reverse

polarity will not cause damage, but the control will not oper-

ate. Red is Plus (+), Black is Minus (-). The Trackside base

station will not function below 7vdc input. When proper

power is supplied, a small green LED inside the box will be

visible (ON) through the ventilated cover.

Warning! Most train “Power Packs” with a knob on them

(e.g. the MRC 6200) are very poor power sources. Their

“DC” output is unregulated and unfiltered. The large AC

component of their output may cause damage to the Trackside R/C electronics. If you can measure more than 1

volt AC on the “DC” output of your power pack, it is not suitable!

It is assumed that power to the system will be switched on/off at the power supply.

Any DC power supply with a regulated output between 7 and 25 VDC will work. The greater the voltage, the faster

your top speed will be. There is nothing special about power supplies made specifically for trains, other than they

may have some built-in meters. Industrial power supplies are much bet-

ter, lower cost, and smaller.

ome common fixed output train supplies:

Crest (Aristo-Craft), Elite Dual, 22V/13.8V, 13A/20A, CRE55465, $206

Crest (Aristo-Craft), Elite ingle, 24V,15A, CRE55468, $242

Aristo-Craft, Ultima, 18-21V, 10A, ART-5460, obsolete and not suitable.

Industrial witching Power upplies:

Meanwell, 24V,6.5A, NE -150-24

Meanwell, 24V,10A, P-240-24

and many other models by Meanwell, most under $50.

Click here for more info.

Must supply your own AC cord/connection to the terminal block.

Track Output

A maximum of 7 amps continuous current (10 amps peak) is

available from the board. An in-line 7.5 amp automotive fuse is

located in black plastic case of the output wiring. If you have a

derailment or other catastrophe causing a short on your track, it

is highly likely that this fuse will blow.

Keep the ventilation holes in the cover of the box open.

At power-up the track output will provide a voltage to the track

that is positive on the output wire containing the in-line fuse, and

negative on the other. This is intended to be the forward direc-

tion of the locomotive. If it is not, just swap the track output

wires.

Meanwell Industrial Power Supply

SP-240-24