Humidity Sensor FK80J

and

Humidity-Temperature Sensor TFK80J

with capacitive measuring element

with current or voltage output,

0...20mA / 0...10VDC or 4...20mA to determine relative air hu-

midity and temperature, duct version

Technical Data

measuring range humidity ........................................ 0..100%rh

measuring element ............................................ capacitive FE09

accuracy at 23°C (73,4°F) ................ ±2.0%rh (40...60%rh)

at 23°C (73,4°F) ................... ±2.5%rh (otherwise)

includes linearity and repeatability

inuence of temperature ................................. < 0.15%rh per K

working range ............................................................. 5...95%rh

measuring medium ................. air, pressureless, non-aggressive

Response time (at calm air) ............................................... < 20 s

output humidity ..............................0...10V or 0...20mA (4wire)

................................... or 4...20mA (2wire)

measuring range temperature

..................0...+50°C,-10...90°C1),-30...60°C,0...100°C1)

measuring element .............................................. Pt100 class B

accuracy at 0...10V .................................. ±0.2 K ±0.36 °F

at (0)4...20mA ........................... ±0.3 K ±0.54 °F

working range .................................... -30...+80°C (-22...176°F)

output temperature .........................0...10V or 0...20mA (4wire)

................................... or 4...20mA (2wire)

0ther temperature outputs

NTC; PTC; KTY; LMx35; Pt100; Pt1000; Ni1000; AD592; LM34;

BALKO 1kΩ; SILICON 2kΩ;

SEMICONDUCTOR 559 mVDC @23°C (75°F)

Thermistors @ 25°C (77°F) 1,8kΩ; 2,252kΩ; 3kΩ; 5kΩ; 10kΩ;

1,8kΩ (Type II; III, CSI); 20kΩ; 100kΩ

power supply ..................................... 15..30V DC / 24VAC± 10%

electromagnetic compatibility EMC

resistance to interference ............................... EN 50 082-2

interference emission ................................... EN 50 081-2

max. load ...........................

(current output only)

min load (voltage output only) ............................................ 10 kΩ

power consumption ....................................................... < 5 mA

permissible ambient temperature ...... -40...+80°C (-40...176°F)

at the housing ....... -10....+60°C (14...140°F)

admitted air speed ........................................ 15 m/sec (50 ft/sec)

Minimum air speed (across the sensor):

output 0...10V, 2x 0...1V ................................................ ≥0.5m/s

4...20mA, 2x 0...10V .............................................. ≥1m/s

2x 4...20mA ........................................................ ≥1.5m/s

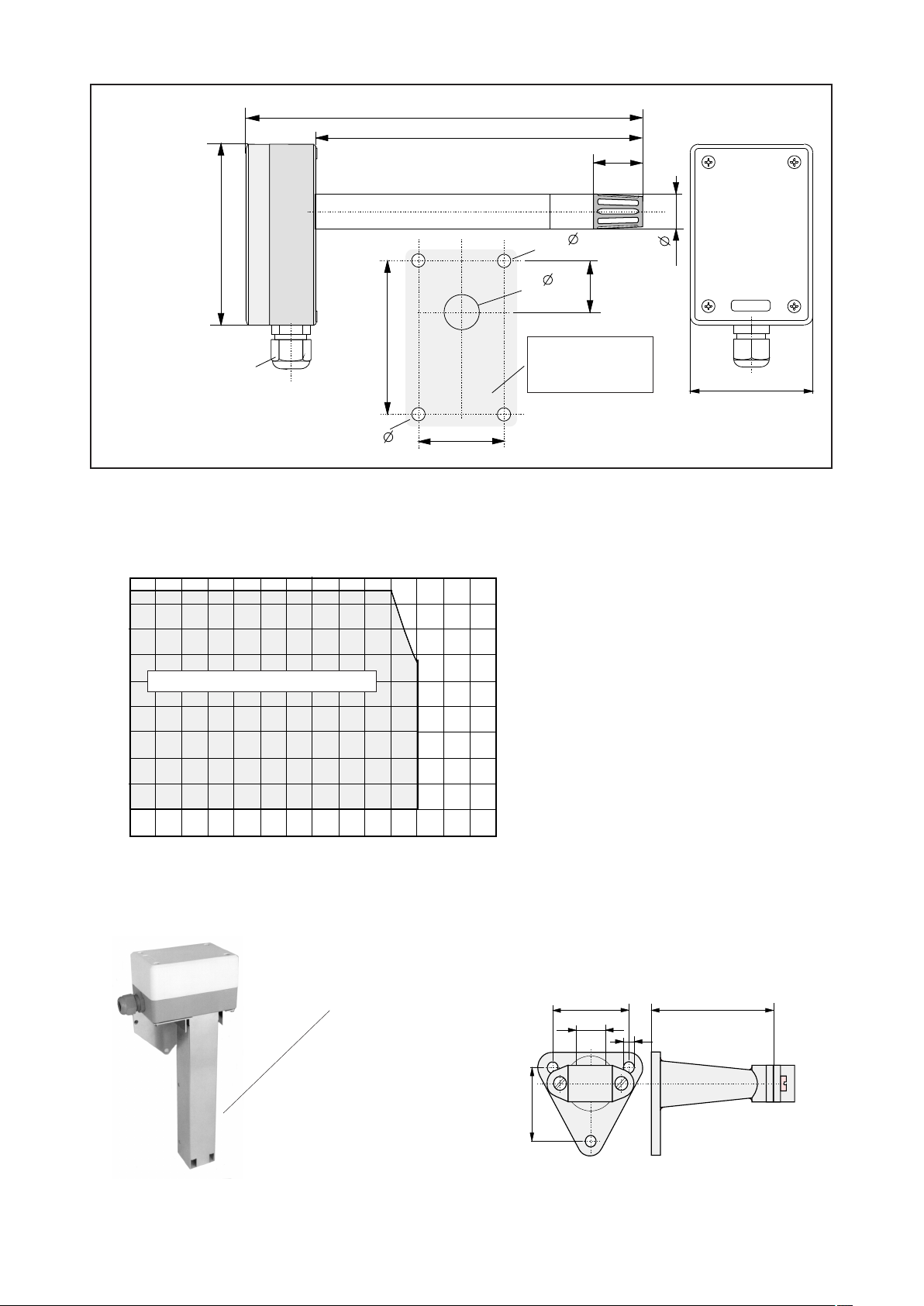

probe length ....................................................... 200mm (7,87")

probe material ..................... aluminium, electrolytically oxidized

for channel mounting ................................ perforation in the case

mounting position ...................................................... as you like

contacting ............................ connecting terminals in the housing

connecting terminal conductor cross sections

...... 1.5mm2(0,023"2)

housing .............................................................. polystyrol-ABS

protective system ............................................................... IP64

weight ..................................................... approx. 0.3 kg (0.6 lbs)

1) please observe working range

Description of the sensors

The sensors FK80J (humidity only) / TFK80J (humidity

and temperature) measure the air humidity by means

of a humidiy-dependant condenser. The capacitive

humidity measuring element, produced using thinlm

technology, consists of a base plate, on which the

electrodes are housed and a hygroscopic polymer

layer avove it. The hygroscopic polymer layer absorbs

water molecules from the medium to be measured (air)

or releases them, thereby altering the capacity of the

condenser. In a tandem-arranged electronic device, the

change in capacity is processed via integrated signal

preprocessing into signals 0..20mA or 0..10VDC or

4..20mA.

The measuring element is protected by a protective

guard. The sensors are designed for pressureless

systems - the measuring medium is non-corrosive air.

The TFK80J sensors also contain a semi-conductor

temperature sensor for simultaneous temperature

measurement. Its measured values are likewise con-

verted into standardised signals 0..20mA or 0..10VDC

or 4..20mA

The temperature coefcient as well as the self-heating

of the electronic may vary according to the location and

the application (especially with sensors where electronic

and measuring system are integrated in one housing.

Maintenance - Application instructions -

Inuence of dirt

In a clean environment, the measuring element is main-

tenance-free. Depending on their type and concentra-

tion, aggressive media containing solvents can cause

incorrect readings or cause the sensor to fail. Direct

sunlight should be avoided. Substances deposited on

the sensor element (e. g. resin aerosols, paint aerosols,

smoke deposits etc.) are harmful as they eventually

form a water-repellent lm (this applies to all humidity

sensors with hygroscopic measuring elements).

Please consult "application instructions for the

sensing elements" (product info sheet no. A 1) or

check with the manufacturer for further information

which you need to bear in mind when using humidity

sensors with capacitive sensing elements.

This information is based on current knowledge and is intended to provide details of our products and their possible applications. It does not, therefore, act as a guarantee of specic

properties of the products described or of their suitability for a particular application. It is our experience that the equipment may be used across a broad spectrum of applications under

the most varied conditions and loads. We cannot appraise every individual case. Purchasers and/or users are responsible for checking the equipment for suitability for any particular

application. Any existing industrial rights of protection must be observed. The perfect quality of our products is guaranteed under our General Conditions of Sale. Issue : November

2014 FK80_E. Subject to modications.

supply - 10 VDC

0.02 amps

RL(Ω) =

Galltec Mess- und Regeltechnik GmbH MELA Sensortechnik GmbH

D-71145 Bondorf . Germany D-07987 Mohlsdorf-Teichwolframsdorf . Germany

Tel. +49 (0)7457-9453-0 .Fax +49 (0)7457-3758 Tel. +49(0)3661-62704-0 .Fax +49(0)3661-62704-20

E-Mail:

[email protected] . Internet:www

.galltec-mela.de

E-mail:mela@melasensor

.de

. Internet: www

.galltec-mela.de