Flexbar

21-1-2009

edda

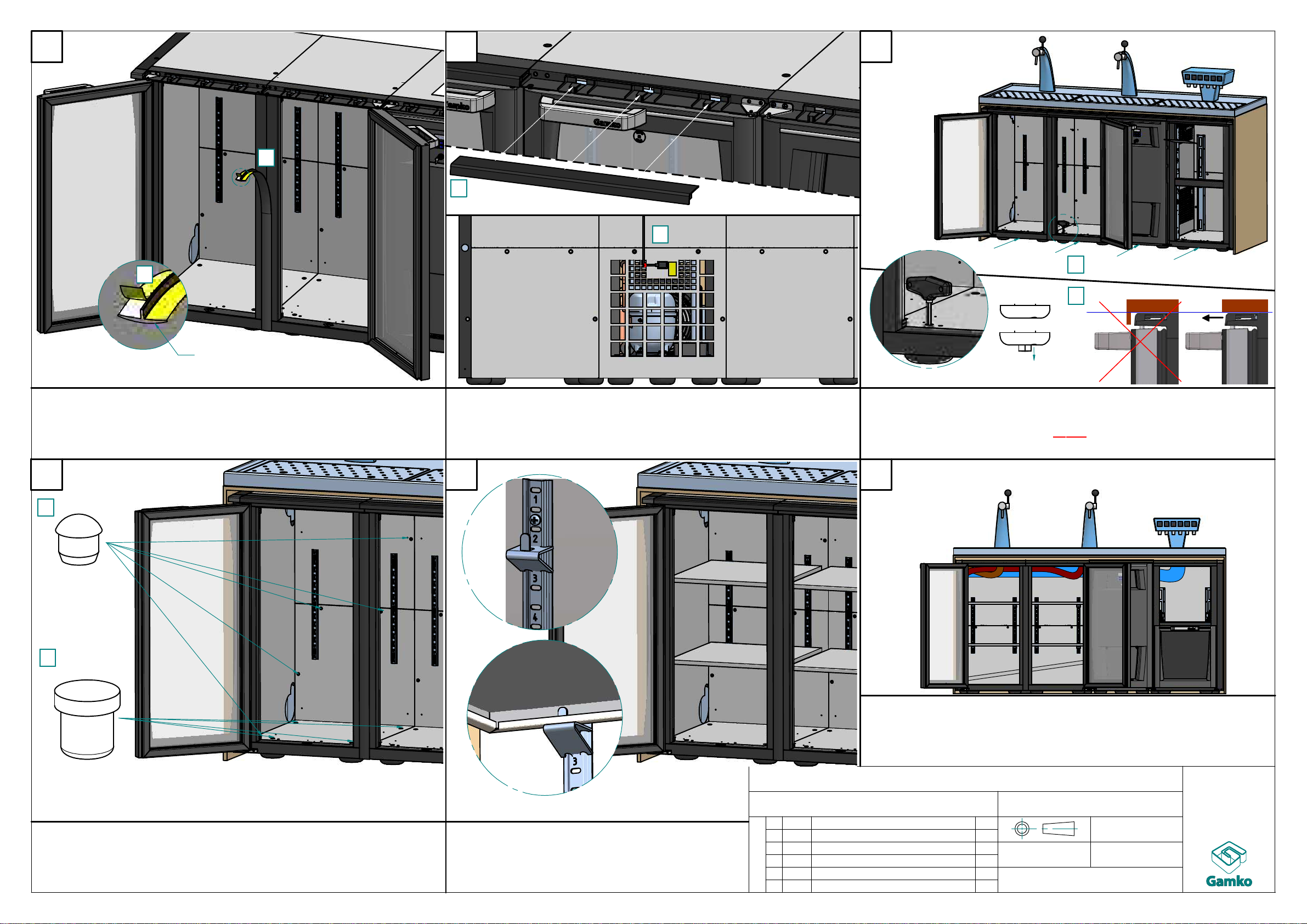

Algemene installatie instructie

modifications

destination

Gamko Holding BV

Mon Plaisir 75

4879 AL Etten-Leur

Tel.(0)76-5087500

The Netherlands

name

drawing nr.

draftsman date

196169

1 02/09 DMX + CELS 5611

1 02/09 DMX + CELS 5611

Blad 9 van 13

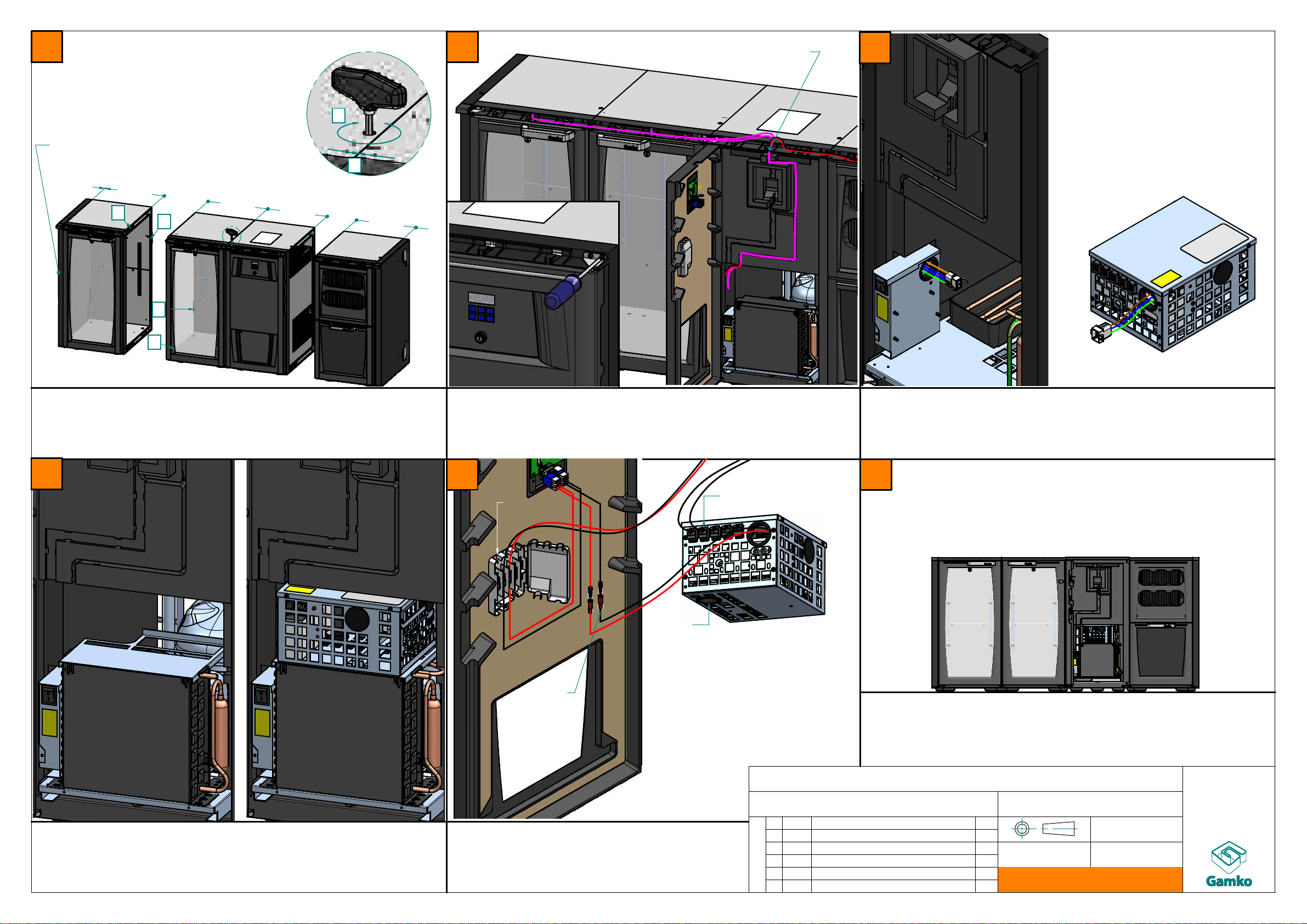

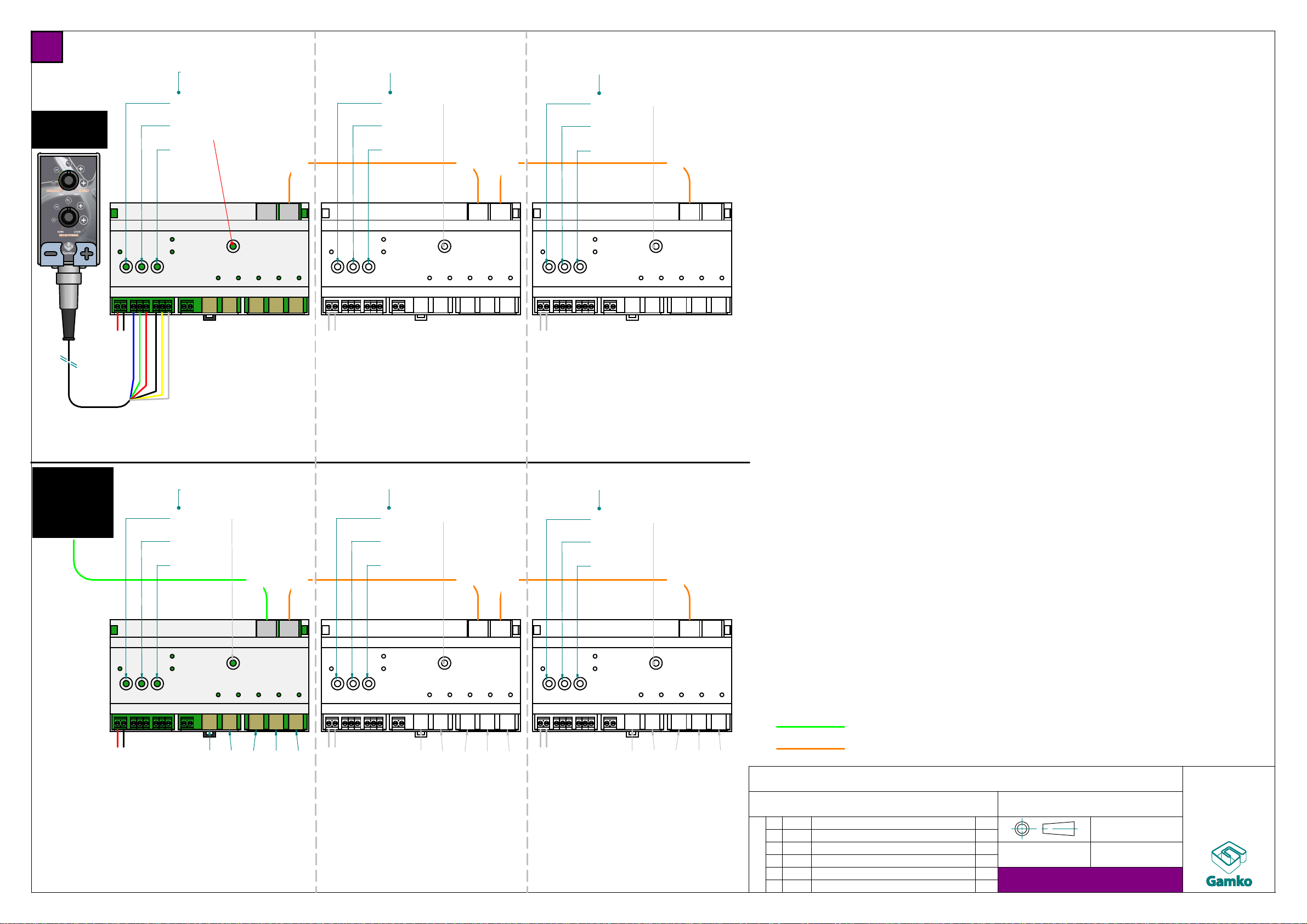

Driver Bar 1

(master) Driver Bar 2

(slave) Driver Bar 3

(slave)

Mode = 0

Mode = 0

1

0

0

Mode = 1

Mode = 0

1

0

0

1

0

0

6

1

0

1

0

0

1

0

0

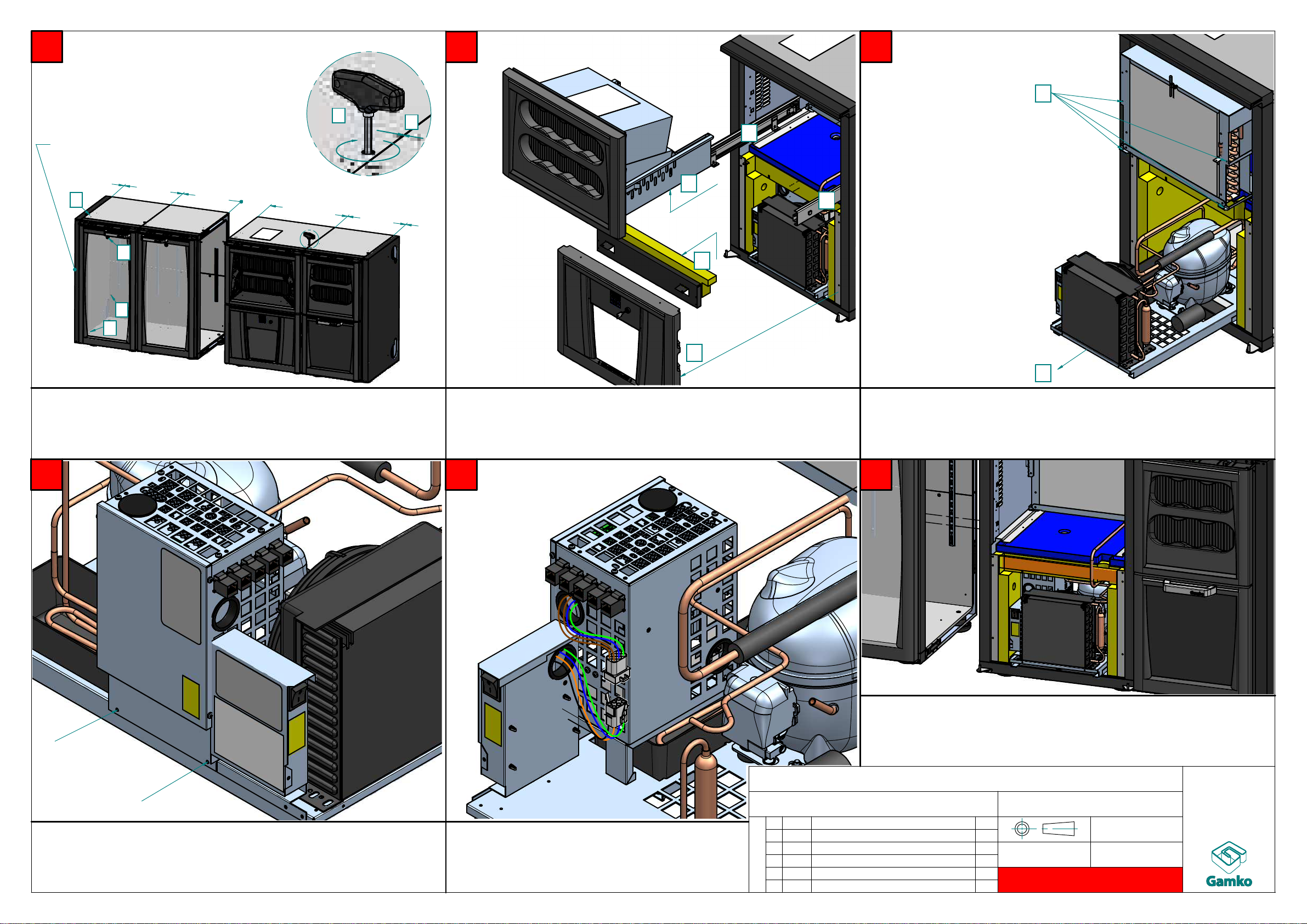

Driver Bar 1

(slave 0)

LED output 1

(DMX R=001, G=002, B=003)

LED output 2

(DMX R=004, G=005, B=006)

LED output 3

(DMX R=007, G=008, B=009)

LED output 4

(DMX R=010, G=011, B=012)

LED output 5

(DMX R=013, G=014, B=015)

LED output 6

(DMX R=016, G=017, B=018)

LED output 7

(DMX R=019, G=020, B=021)

LED output 8

(DMX R=022, G=023, B=024)

LED output 9

(DMX R=025, G=026, B=027)

LED output 10

(DMX R=028, G=029, B=030)

LED output 11

(DMX R=001, G=002, B=003)

LED output 12

(DMX R=001, G=002, B=003)

LED output 13

(DMX R=001, G=002, B=003)

LED output 14

(DMX R=001, G=002, B=003)

LED output 15

(DMX R=001, G=002, B=003)

LED output 1

LED output 2

LED output 3

LED output 4

LED output 5

LED output 1

LED output 2

LED output 3

LED output 4

LED output 5

LED output 1

LED output 2

LED output 3

LED output 4

LED output 5

Mode = 0

24V DC

41

24V DC

24V DC 24V DC

24V DC 24V DC

DMX in

DMX out

DMX address 0-0-1 DMX address 0-0-1

DMX address 0-0-1

DMX address 0-1-6 DMX address 0-0-1

DMX address 0-0-1

Controller

Gamko

example:

Driver Bar 2

(slave 0)

example:

Driver Bar 3

(slave 1)

External

DMX-

device

(master)

DMX in

DMX out

DMX in

DMX out

DMX in

DMX out

DMX in

DMX out

DMX in

DMX out

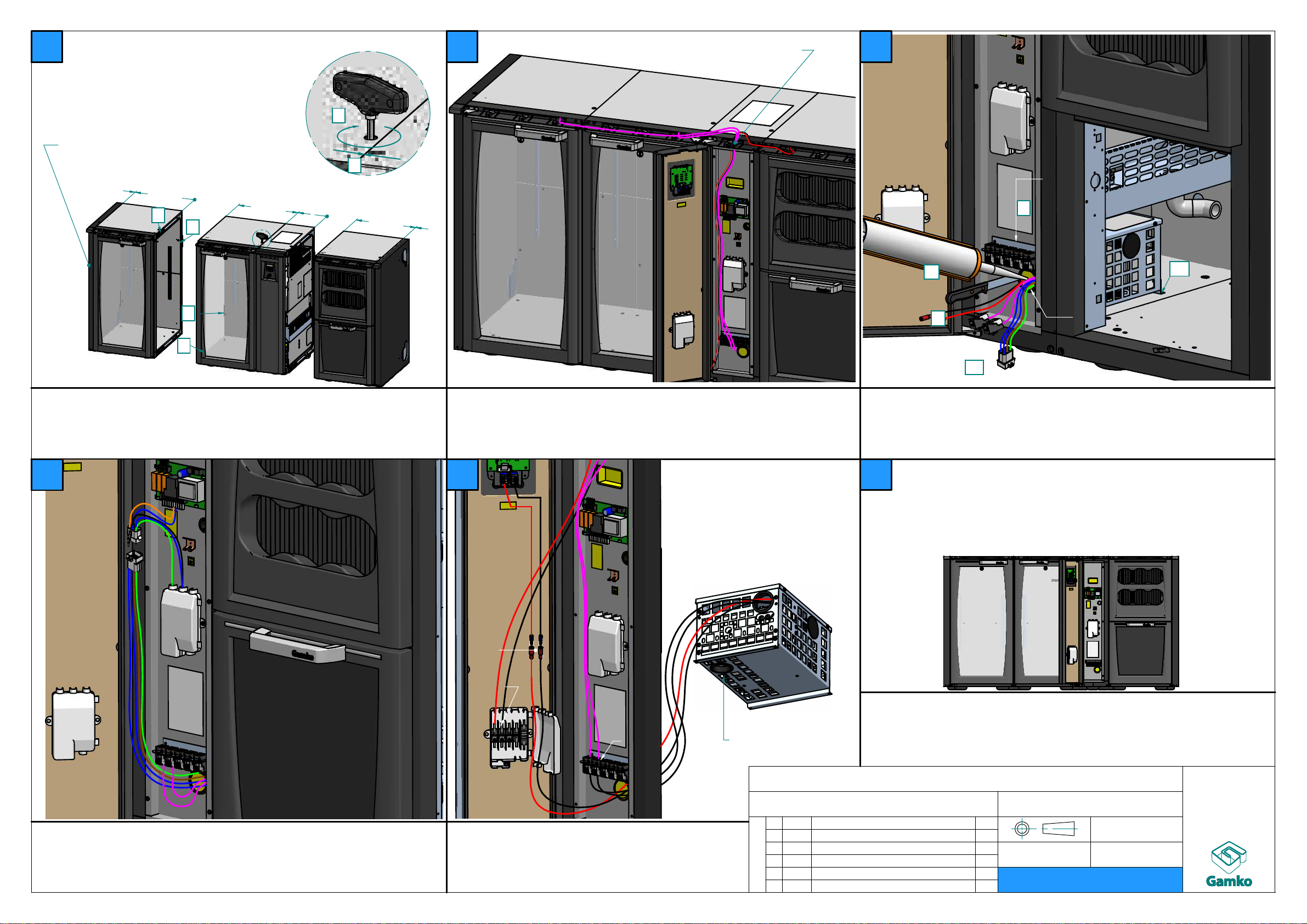

RJ45-RJ45 Ethernet patch cable (Cat5e)

XLR-RJ45 connection cable (008110192)

Mode switch

(see list)

Default = 5

Gamko controller mode

X/ACLED1-A = mode 4 - manual colour lapse (master)

controller controls colour and brightness

X/ACLED1-B = mode 5 - automatic colour lapse (master)

controller controls cycle speed and brightness

Demo mode

X/ACLED1-C = mode 6 - different colour (static) per segment (master)

switch dmx address to 0-0-1 to select output nr1

use controller to set colour

switch dmx address to 0-0-2 to select output nr2

use controller to set colour

controller controls brightness

X/ACLED1-D = mode 7 - chasing light RGB (master)

dmx address 0-0-1 fast cycle speed

dmx address 9-9-9 slow cycle speed, etc.

controller controls brightness

X/ACLED1-F = mode 8 - chasing light rainbow (master)

dmx address 0-1-0 slow colourchange

dmx address 9-9-0 fast colourchange, etc.

controller regelt intensiteit

Slave mode

X/ACLED1-E = mode 0 - DMX15 (each segment individual) (slave)

to synchronise colours of 2nd, 3rd, etc bars

with first bar (master)

or to manipulate colours with lighting computer

no controller

X/ACLED1-E = mode 1 - DMX3 (all segments equal) (slave)

to synchronise colours of 2nd, 3rd, etc bars

with first bar (master)

or to manipulate colours with lighting computer

no controller

Connecting and settings

RGB driver(s)

GB

RGB settings