6

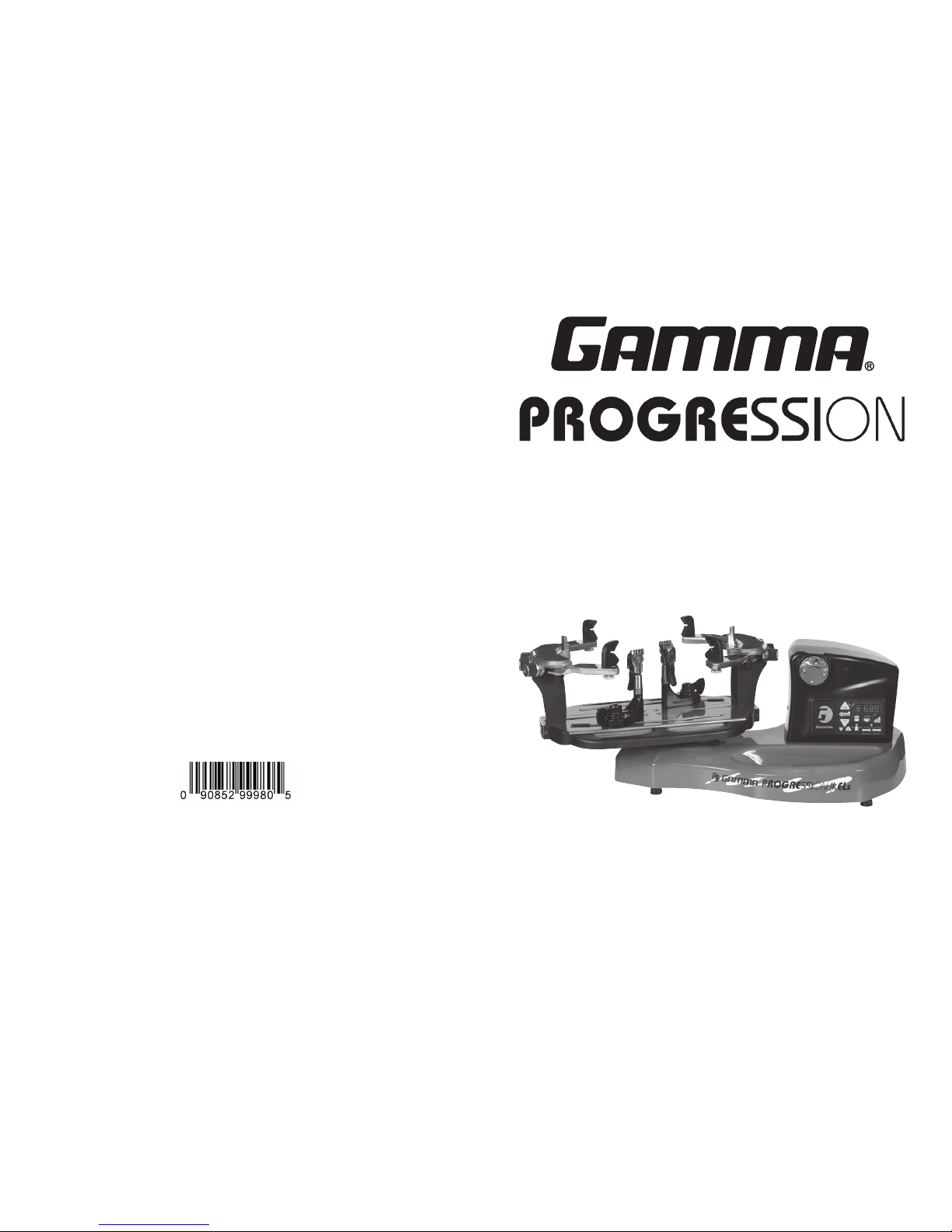

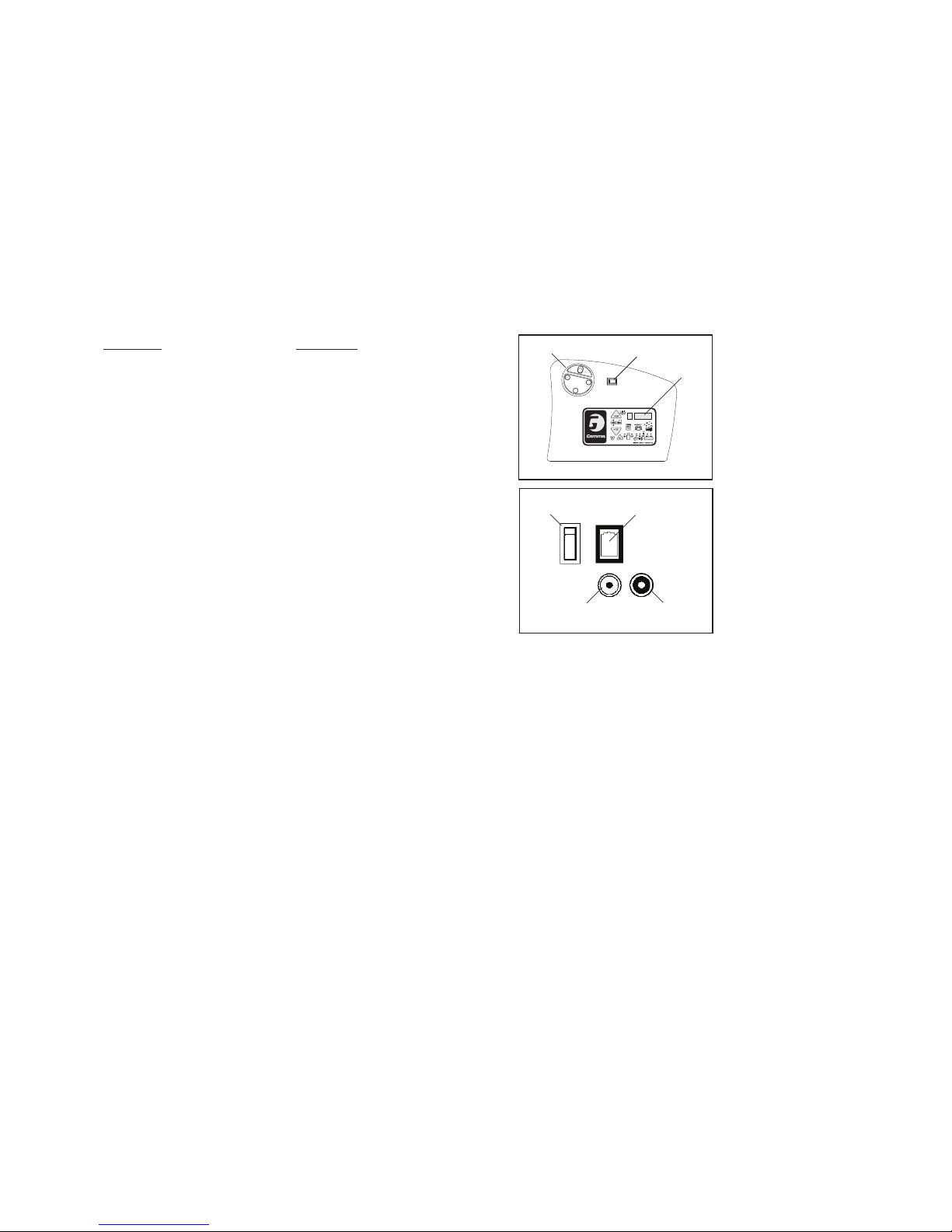

CONTROL PANEL FUNCTIONS

AND FEATURES

Single Digit (1-9)

Memory LED Display

Three Digit (XX.X)

Tension Setting Display

or String Length LED

Display

String Length Meter Button - feature is

currently not available.

Lbs/Kgs Button - Changes tension

display from Lbs to Kgs. Each press

of the button toggles back and forth

between Lbs and Kgs.

Speed Button - Changes pulling speed

of winder from Fast (default) to Medium

to Slow. Slow speed is recommended

for low stretch strings, such as Kevlar.

Each press of the button toggles be-

tween Fast, Medium and Slow speeds.

Pre-Stretch Function - Pulls string 10%

or 20% over the tension setting (up to 90

lbs / 40.8 kgs), releases the string, and

repulls to the tension setting. Each press

of the button toggles between 10%, 20%

or no pre-stretch.

Clear Button - Clears display to enter

a new tension or to reset String Length

Meter measurement.

Knot Function - Increases pulling ten-

sion by 10% over the setting value (max

90 lbs / 40.8 kgs) for one pull. During the

pull the LED stays lit to indicate the Knot

function is enabled.

Tension Index Buttons - Changes

tension setting in +/- 1.0 or +/- 0.1 Lb or

Kg increments. Holding the button down

will scroll the tension setting values up

or down. Tension settings entered with

the tension index buttons are placed into

temporary memory setting “0”.

Memory Button - Indexes from 9 preset

tension settings that can be stored in

memory. Settings are retained even if

machine is turned off. Each press of

the button indexes to the next memory

setting. Memory settings 1-9 must be

entered using the keypad followed by

pressing the “ENT” button.

Enter Button - Saves displayed tension

for Memory setting - when tension is en-

tered using the keypad display flashes

until this button is pressed to save the

setting. Also Clears display for String

Length Meter measurements.

Test Button & Racquet Strung -

Press once for approximate number of

racquets strung. Press again to return.

Press and hold for 5 seconds and the

machine does an internal diagnostic

check, such as the one performed at

start-up.

15

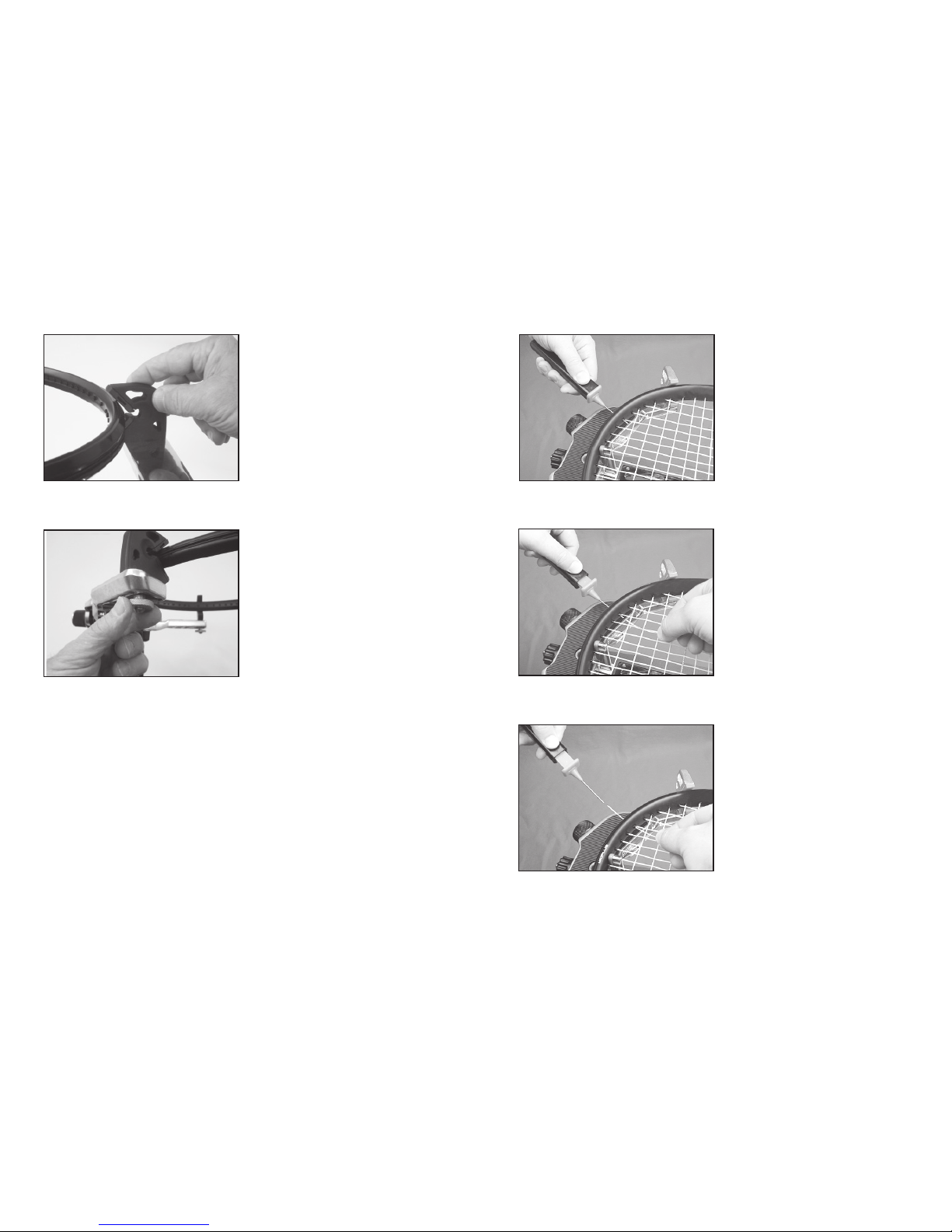

Adjusting the String Clamp Jaw

Spacing

The string clamps will need minor adjust-

ments according to what string type, con-

struction, and gauge you are using.

To adjust the gap (clamping pressure)

between the clamp jaws, insert the string

through the racquet as if you were begin-

ning the main strings. Clamp the strings

and pull tension. If the string slips through

the jaws of the clamp, tighten the clamp

by squeezing the clamp jaws together by

hand while turning the Adjustment Knob, in

the clockwise direction. If the clamp leaves

impressions or damages the string, it may be excessively tight and should be adjusted by

turning the Adjustment Knob counter clockwise to open the gap between the jaws. The clamp

jaws should be cleaned periodically to be free from dirt, oil, and any string coating residue

to grip properly. Knife sharpening stones are excellent for removing build-up on the diamond

coated surfaces and are available.

Adjustment

Knob

MAINTENANCE & ADJUSTMENTS

Clamp Base Locking NutAdjustment

In the event the Locking Lever rotation is

insufficient to ensure smooth operation of the

clamp base, very minor adjustments to the

Clamp Base Locking Nut can be made with

the supplied 17mm socket. Tighten or loosen

the locking nut in very small increments to

provide more clamping pressure or running

clearance as needed.

Quick Action Clamp Base Removal

Quick Action clamp bases can be removed

from the turntable for maintenance or clean-

ing by removing clamp stop located at the

end of the slot in the turntable. To remove the

clamp stop, remove the two screws holding

the clamp stop in place from the underside of

the turntable. Lift the clamp stop out of the

slot, slide the clamp base to the end of the

slot and lift it out. Replace the clamp base and

clamp stop in reverse order.