16

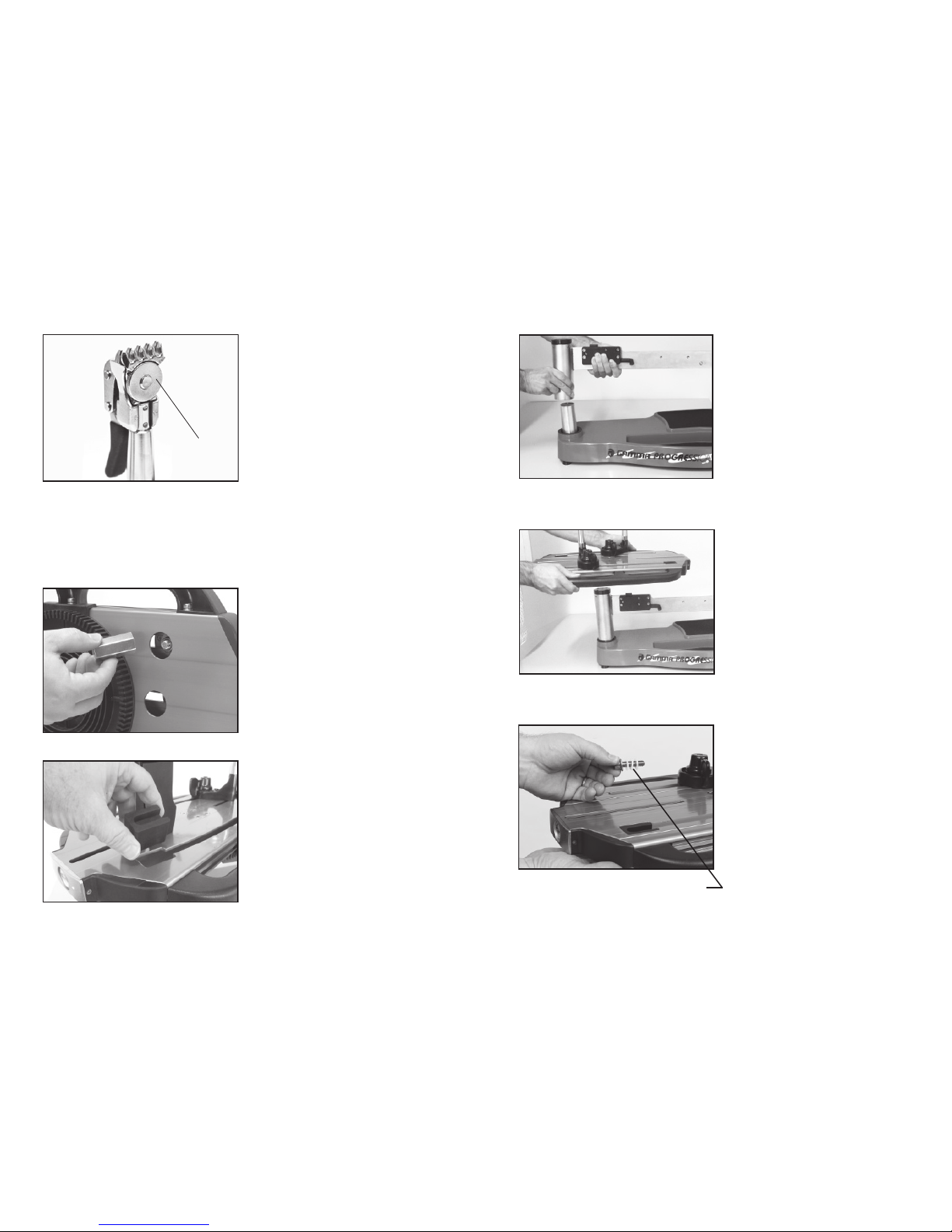

Adjusting the String Clamp Jaw

Spacing

The string clamps will need minor adjust-

ments according to what string type, construc-

tion, and gauge you are using.

To adjust the gap (clamping pressure)

between the clamp jaws, insert the string

through the racquet as if you were begin-

ning the main strings. Clamp the strings

and pull tension. If the string slips through

the jaws of the clamp, tighten the clamp

by squeezing the clamp jaws together by

hand while turning the Adjustment Knob, in

the clockwise direction. If the clamp leaves

impressions or damages the string, it may be excessively tight and should be adjusted by

turning the Adjustment Knob counter clockwise to open the gap between the jaws. The clamp

jaws should be cleaned periodically to be free from dirt, oil, and any string coating residue

to grip properly. Knife sharpening stones are excellent for removing build-up on the diamond

coated surfaces and are available.

Adjustment

Knob

MAINTENANCE & ADJUSTMENTS

Clamp Base Locking NutAdjustment

In the event the Locking Lever rotation is

insufficient to ensure smooth operation of the

clamp base, very minor adjustments to the

Clamp Base Locking Nut can be made with

the supplied 17mm socket. Tighten or loosen

the locking nut in very small increments to

provide more clamping pressure or running

clearance as needed.

Quick Action Clamp Base Removal

Quick Action clamp bases can be removed

from the turntable for maintenance or cleaning

by removing clamp stop located at the end

of the slot in the turntable. To remove the

clamp stop, remove the two screws holding

the clamp stop in place from the underside of

the turntable. Lift the clamp stop out of the

slot, slide the clamp base to the end of the

slot and lift it out. Replace the clamp base

and clamp stop in reverse order.

5

Support Post Installation

To install the support posts you must first

remove the mounting bolt from the mounting

plate that sets inside the central cavity of the

turntable. There are large holes stamped on

the underside of the turntable that allow you

to support the mounting plate with your fingers

while removing the mounting bolt.

After removing the mounting bolt, remove

and discard the plastic washers that are

installed for shipping purposes.

Remove and Discard Plastic Washers

ASSEMBLY INSTRUCTIONS

Turntable Installation

To install the turntable position it over the

turntable pin and align the bolts (included in

separate bag) with the holes in the flange.

Secure them with the included 6mm allen

wrench.

Winder Bar Installation

To install the winder bar, slide over the post

on the base and secure it with the 2 allen

set screws.

Note: When purchased with the optional floor

stand, it is most convenient to attach the base

to the floor stand at this point. See instruc-

tions provided with the optional floor stand.