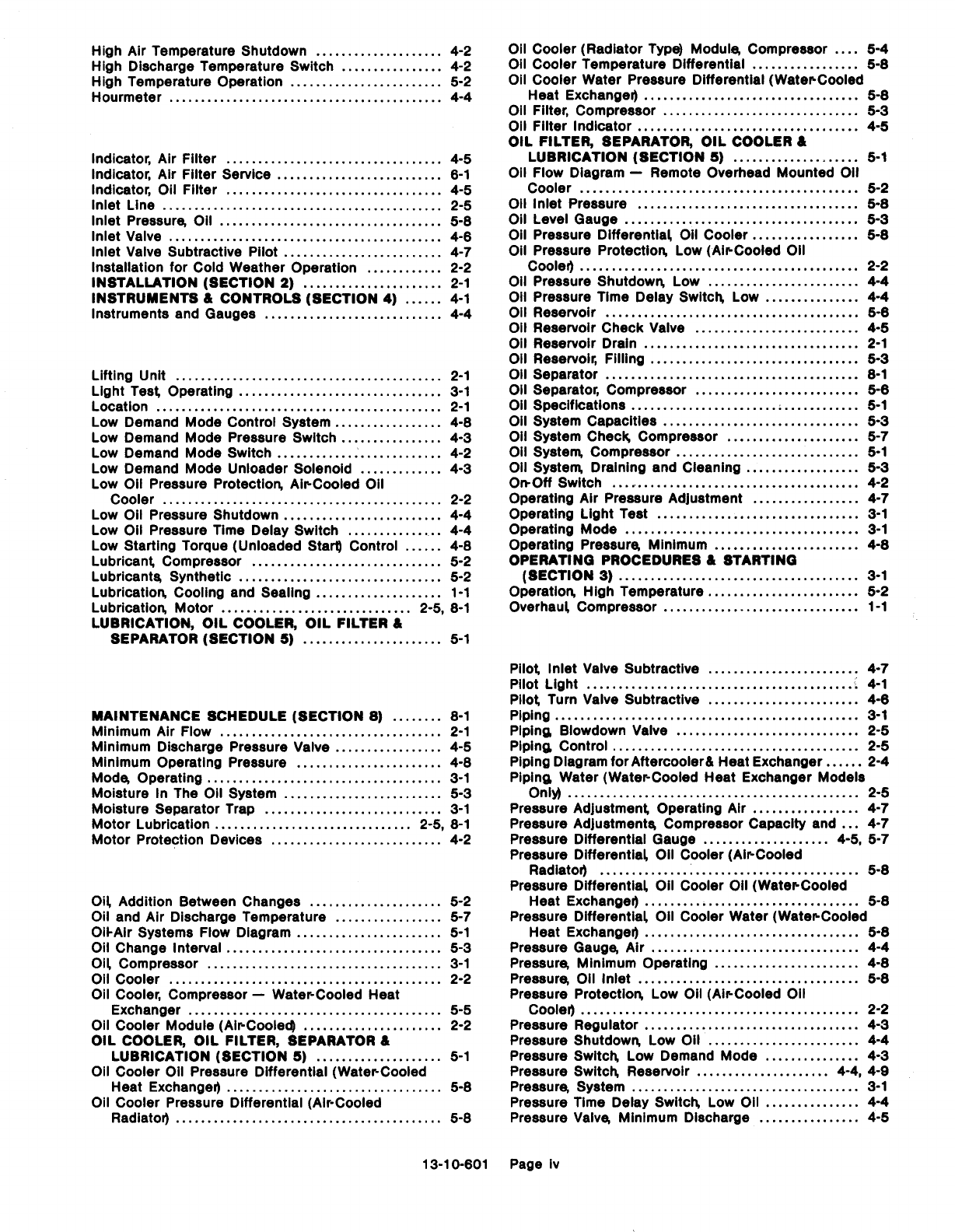

High Air Temperature Shutdown .................... 4-2

High Discharge Temperature Switch ................ 4-2

High Temperature Operation ........................ 5-2

Hourmeter ........................................... 4-4

Indicator, Air Filter .................................. 4-5

indicator, Air Filter Service .......................... 6-1

Indicator, Oil Filter .................................. 4-5

Inlet Line ............................................ 2-5

Inlet Pressure Oil ................................... 5-8

Inlet Valve ........................................... 4-6

inlet Valve Subtractive Pilot ......................... 4-7

Installation for Cold Weather Operation ............ 2-2

INSTALLATION (SECTION 2) ...................... 2-1

INSTRUMENTS &CONTROLS (SECTION 4) ...... 4-1

Instruments and Gauges ............................ 4-4

Lifting Unit .......................................... 2-1

Light Test Operating ................................ 3-1

Location ............................................. 2-1

Low Demand Mode Control System ................. 4-8

Low Demand Mode Pressure Switch ................ 4-3

Low Demand Mode Switch .......................... 4-2

Low Demand Mode Unloader Solenoid ............. 4-3

Low Oil Pressure Protection Air-Cooled Oil

Cooler ............................................ 2-2

Low Oil Pressure Shutdown ......................... 4-4

Low Oil Pressure Time Delay Switch ............... 4-4

Low Starting Torque (Unloaded Start) Control ...... 4-8

Lubricant Compressor .............................. 5-2

Lubricants Synthetic ................................ 5-2

Lubrication Cooling and Sealing .................... 1-1

Lubrication Motor .............................. 2-5, 8-1

LUBRICATION, OIL COOLER, OIL FILTER &

SEPARATOR (SECTION 5) ...................... 5-1

MAINTENANCE SCHEDULE (SECTION 8) ........ 8-1

Minimum Air Flow ................................... 2-1

Minimum Discharge Pressure Valve ................. 4-5

Minimum Operating Pressure ....................... 4-8

Mode, Operating ..................................... 3-1

Moisture lnThe Oil System ......................... 5-3

Moisture Separator Trap ............................ 3-1

Motor Lubrication ............................... 2-5, 8-1

Motor Protection Devices ........................... 4-2

Oil Addition Between Changes ..................... 5-2

Oil and Air Discharge Temperature ................. 5-7

Oil-Air Systems Flow Diagram ....................... 5-1

Oil Change interval .................................. 5-3

Oil Compressor ..................................... 3-1

Oil Cooler ........................................... 2-2

Oil Cooler, Compressor –Water-Cooled Heat

Exchanger ........................................ 5-5

Oil Cooler Module (Air-Cooled) ...................... 2-2

OIL COOLER, OIL FILTER, SEPARATOR &

LUBRICATION (SECTION 5) .................... 5-1

Oil Cooler Oil Pressure Differential (Water-Cooled

Heat Exchanger) .................................. 5-8

Oil Cooler Pressure Differential (Air-Cooled

Radiator) .......................................... 5-8

Oil Cooler (Radiator Type) Module, Compressor .... 5-4

Oil Cooler Temperature Differential ................. 5-8

Oil Cooler Water Pressure Differential (Watercooled

Heat Exchanger) .................................. 5-8

Oil Filter, Compressor ............................... 5-3

Oil Filter Indicator ................................... 4-5

OIL FILTER, SEPARATOR, OIL COOLER &

LUBRICATION (SECTION 5) .................... 5-1

Oil Flow Diagram –Remote Overhead Mounted Oil

Cooler ............................................ 5-2

Oil Inlet Pressure ................................... 5-8

Oil Level Gauge ..................................... 5-3

Oil Pressure Differential Oil Cooler ................. 5-8

Oil Pressure Protection Low (Air-Cooled Oil

Cooler) ............................................ 2-2

Oil Pressure Shutdown Low ........................ 4-4

Oil Pressure Time Delay Switch Low ............... 4-4

Oil Reservoir ........................................ 5-8

Oil Reservoir Check Valve .......................... 4-5

Oil Resevoir Drain .................................. 2-1

Oil Reservoir Filling ................................. 5-3

Oil Separator ........................................ 8-1

Oil Separator, Compressor .......................... 5-8

Oil Specifications .................................... 5-1

Oil System Capacities ............................... 5-3

Oil System Check Compressor ..................... 5-7

Oil System Compressor ............................. 5-1

Oil System Draining and Cleaning .................. 5-3

O* Off Switch ........................................ 4-2

Operating Air Pressure Adjustment ................. 4-7

Operating Light Test ................................ 3-1

Operating Mode ..................................... 3-1

Operating Pressure Minimum ....................... 4-8

OPERATING PROCEDURES &STARTING

(SECTION 3) ............................... 3-1

Operation High Temperature ....................... . 5-2

Overhaul Compressor ............................... 1-1

Pilot, Inlet Valve Subtractive ........................ 4-7

Pilot Light ........................................... 4-1

Pilot, Turn Valve Subtractive ........................ 4-6

Piping ................................................ 3-1

Piping Blowdown Valve ............................. 2-5

Piping Control ....................................... 2-5

Piping Diagram for Aftercooler &Heat Exchanger ...... 2-4

Piping Water (Water-Cooled Heat Exchanger Models

Only) .............................................. 2-5

Pressure Adjustment Operating Air ................. 4-7

Pressure Adjustments Compressor Capacity and . . . 4-7

Pressure Differential Gauge .................... 4-5, 5-7

Pressure Differential Oil Cooler (Air-Cooled

Radiator) ......................................... 5-8

Pressure Differential Oil Cooler Oil (Watercooled

Heat Exchanger) .................................. 5-8

Pressure Differential Oil Cooler Water (Watercooled

Heat Exchanger) .................................. 5-8

Pressure Gauge, Air ................................. 4-4

Pressure, Minimum Operating ....................... 4-8

Pressure Oil Inlet ................................... 5-8

Pressure Protection Low Oil (Air-Cooled Oil

Cooler) ............................................ 2-2

Pressure Regulator .................................. 4-3

Pressure Shutdown, Low Oil ........................ 4-4

Pressure Switch, Low Demand Mode ............... 4-3

Pressure Switch, Reservoir ..................... 4-4, 4-9

Pressure System .................................... 3-1

Pressure Time Delay Switch, Low Oil ............... 4-4

Pressure Valve, Minimum Discharge ................ 4-5

13-10-601 Page iv