Table of Contents RTCSmp Built-In Temperature Controlled Hold-Line

Part # 4532286 Rev 3 (6/10/14) 3

WARRANTY .......................................................................................................................................................2

UNPACKING and PACKING SLIP ......................................................................................................................2

USING THIS MANUAL .......................................................................................................................................2

DESCRIPTION OF WARNING SYMBOLS...........................................................................................................2

CONTACTS.........................................................................................................................................................2

1Safety Requirements................................................................................................................................4

1.1Risk Involved By Disregarding Safety Information...........................................................................................................4

1.2Safety Instructions for Operator .............................................................................................................................................4

1.3Improper Use of the Equipment.............................................................................................................................................5

1.4Unauthorized Modification and Use of Spare Parts.........................................................................................................5

1.5Pan Detection................................................................................................................................................................................5

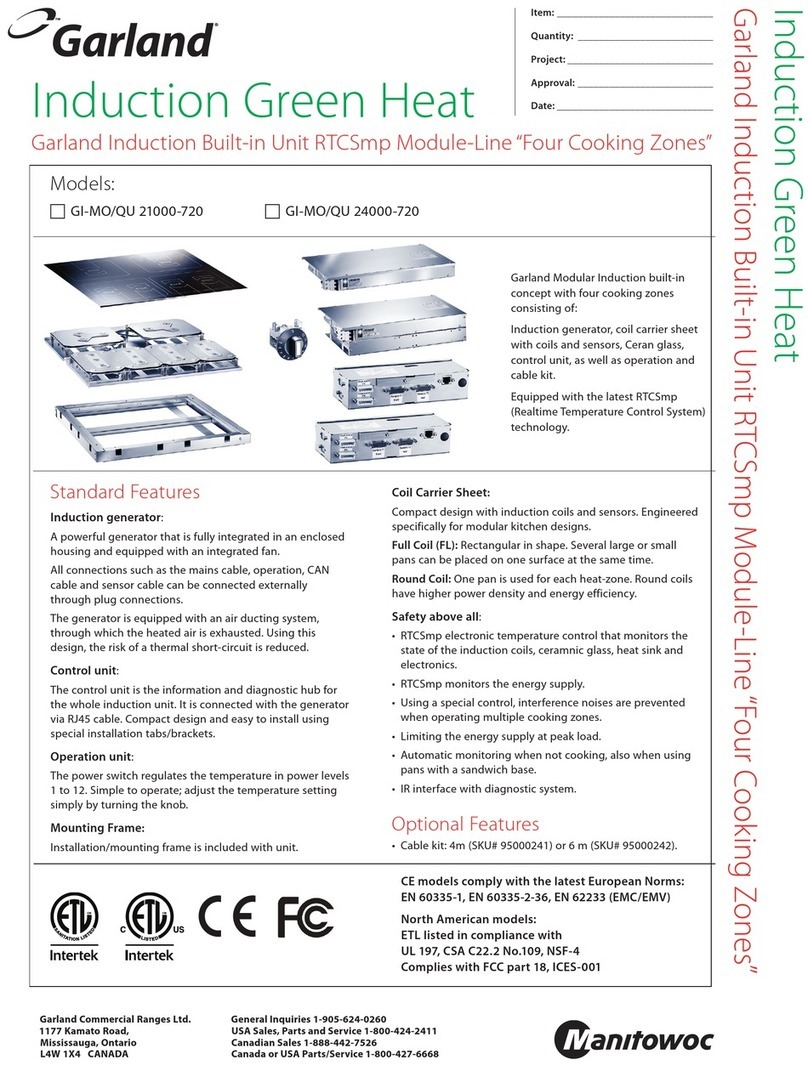

2Components and Features.......................................................................................................................6

2.1Application.....................................................................................................................................................................................6

2.1Components and Features .......................................................................................................................................................6

3Dimensions and Technical Specifications ..............................................................................................7

3.1Rating Plate....................................................................................................................................................................................7

3.2Nomenclature and Models.......................................................................................................................................................7

3.3Dimensions ....................................................................................................................................................................................7

3.4Electrical Specifications .............................................................................................................................................................7

3.5Operating Conditions.................................................................................................................................................................7

3.6Compliances ..................................................................................................................................................................................7

4Installation ................................................................................................................................................8

4.1Location...........................................................................................................................................................................................8

4.2Ventilation ......................................................................................................................................................................................8

4.3Electrical Compartment Protection.......................................................................................................................................9

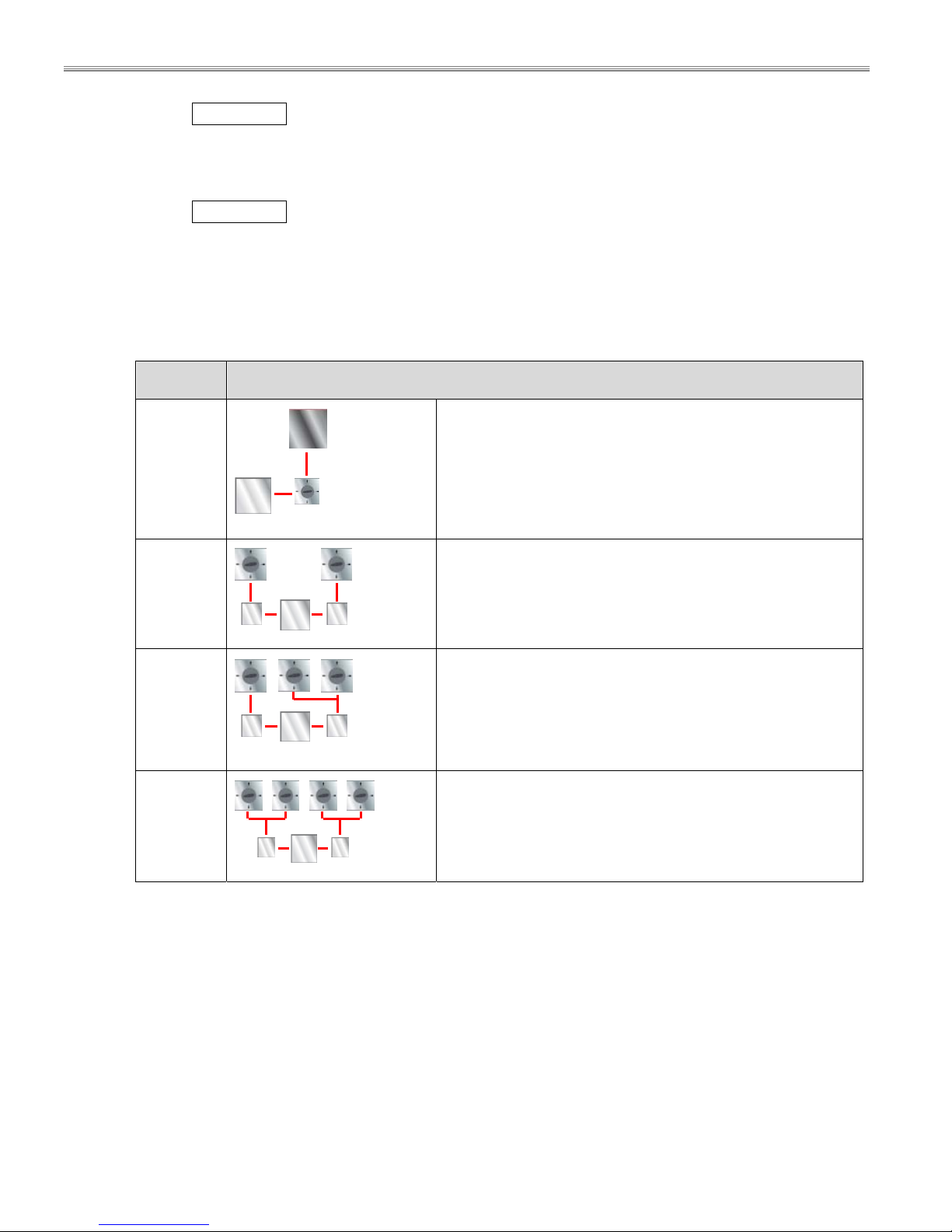

4.4Configurations ........................................................................................................................................................................... 10

4.5Dimensions and Installation.................................................................................................................................................. 11

4.5.1Heat Retaining Plate Installation ......................................................................................................................... 11

4.5.1.1Dimensions: RTCSmp HOIN450/900/1350/1800 Heat Retaining Plate 11

4.5.1.2Cut-Out Dimensions 11

4.5.1.3Parallel Installation and Clearance 12

4.5.1.4Installation Steps 13

4.5.2Control Unit Installation ......................................................................................................................................... 14

4.5.2.1Dimensions: Control Unit RTCSmp HOIN450/900/1350/1800 14

4.5.2.2Front-Mount 15

4.5.2.3Back-Mount 15

4.5.3Induction Generator Installation ......................................................................................................................... 15

4.5.3.1Orientation 16

4.5.3.2Mounting Methods 16

4.5.3.3Dimensions: Induction Generator RTCSmp HOIN450/900/1350/1800 16

4.6Electrical Installation................................................................................................................................................................ 17

5Function Test ..........................................................................................................................................19

6Operating Instructions...........................................................................................................................20

6.1Proper Induction Chafing Dish or Pan............................................................................................................................... 20

6.2Proper Placement of Chafing Dish or Pan on Single Hob........................................................................................... 21

6.3Temperature Control and Display....................................................................................................................................... 22

6.3.1Configurations and Temperature Control ....................................................................................................... 22

6.3.2Set and Current Temperatures............................................................................................................................. 23

6.3.3Digital Display............................................................................................................................................................ 23

6.4No Pan No Heat ......................................................................................................................................................................... 23

6.5When Unit is Not In Use.......................................................................................................................................................... 23

7Cleaning...................................................................................................................................................24

8Maintenance ...........................................................................................................................................25

9Important Rules ......................................................................................................................................25

10Troubleshooting.....................................................................................................................................26

10.1Common causes for induction unit failure ...................................................................................................................... 26

10.2Problems and Possible Causes............................................................................................................................................. 27

10.3Troubleshooting with Error Codes (for Service Technicians) .................................................................................... 28