W ebsite

:

www.kyowa-ei.com

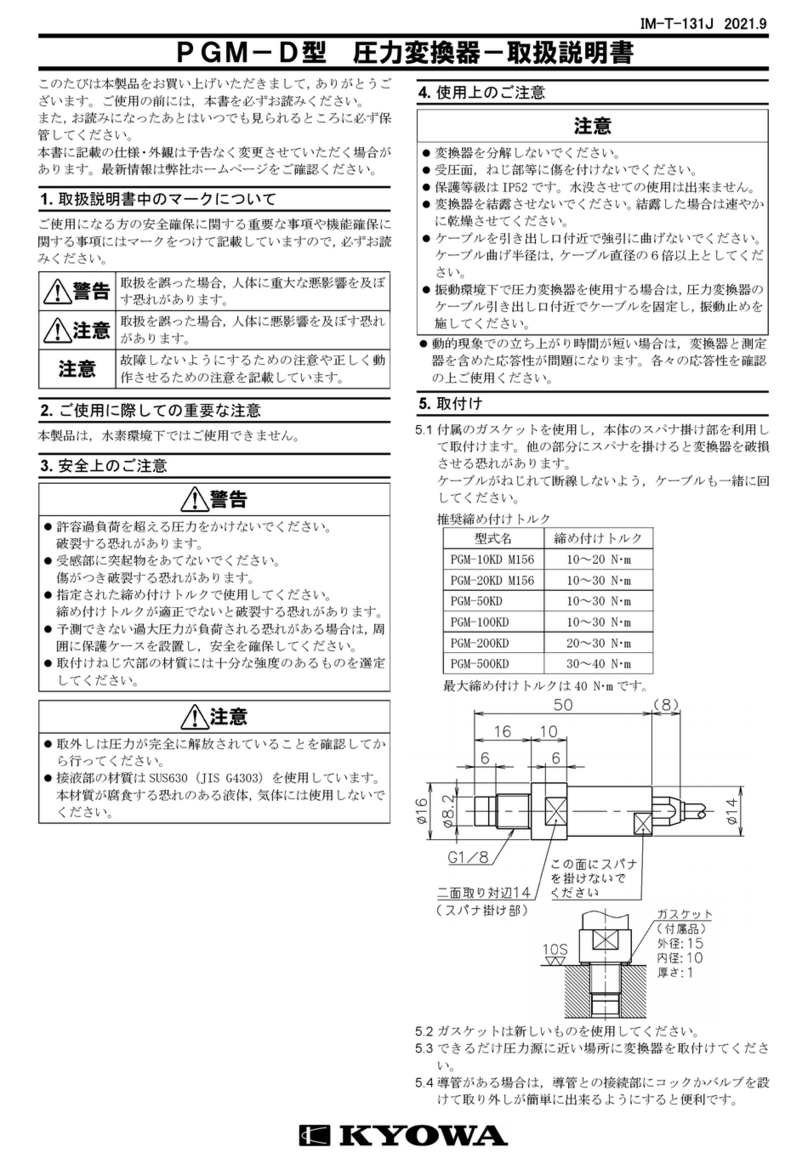

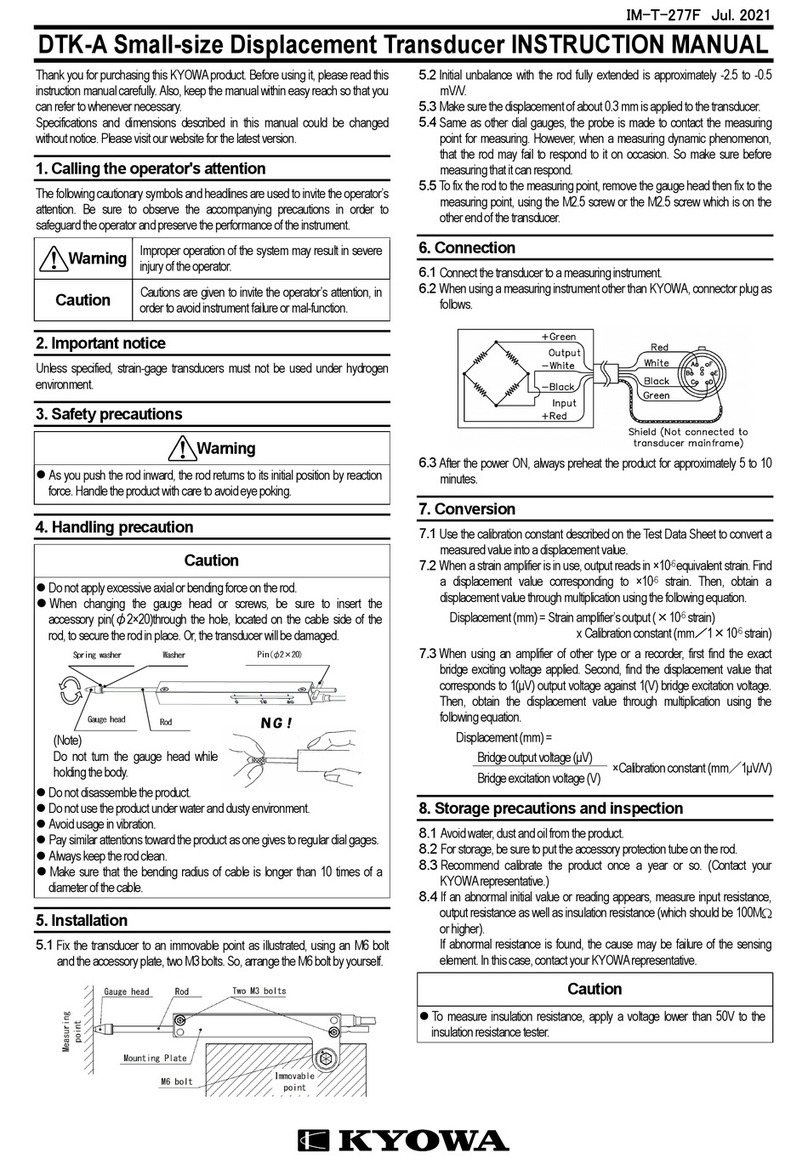

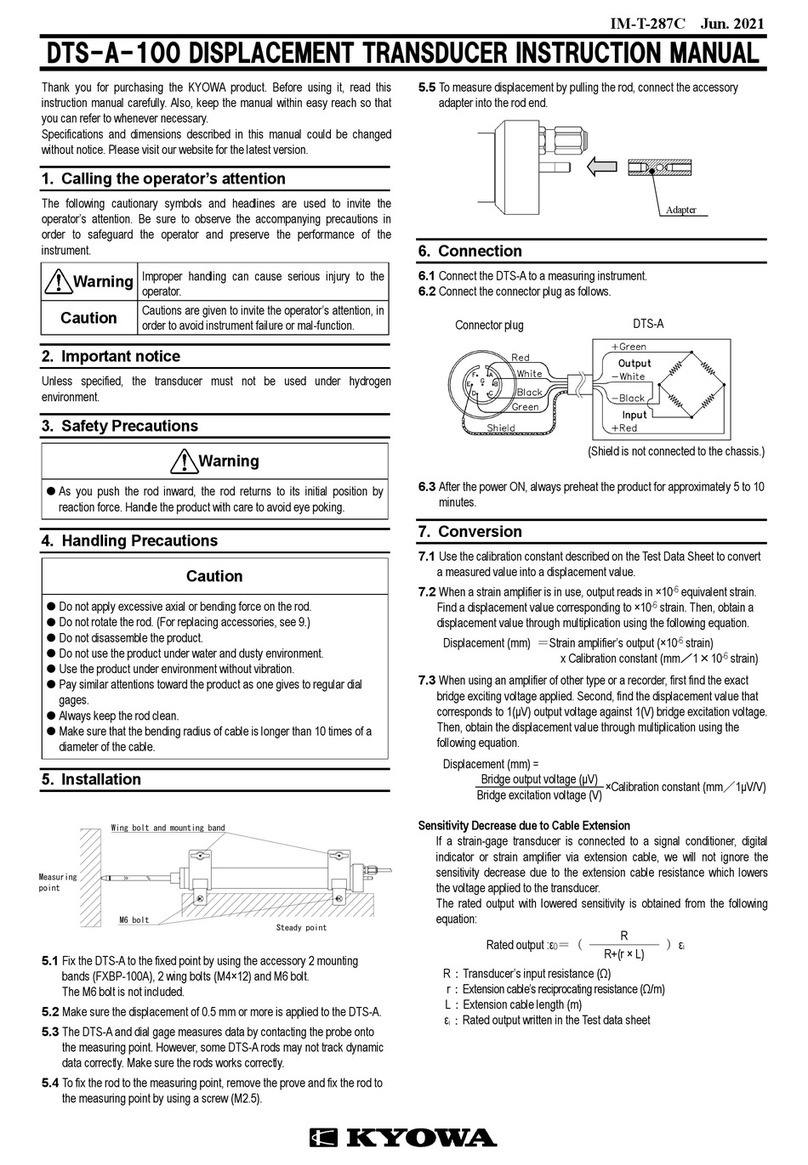

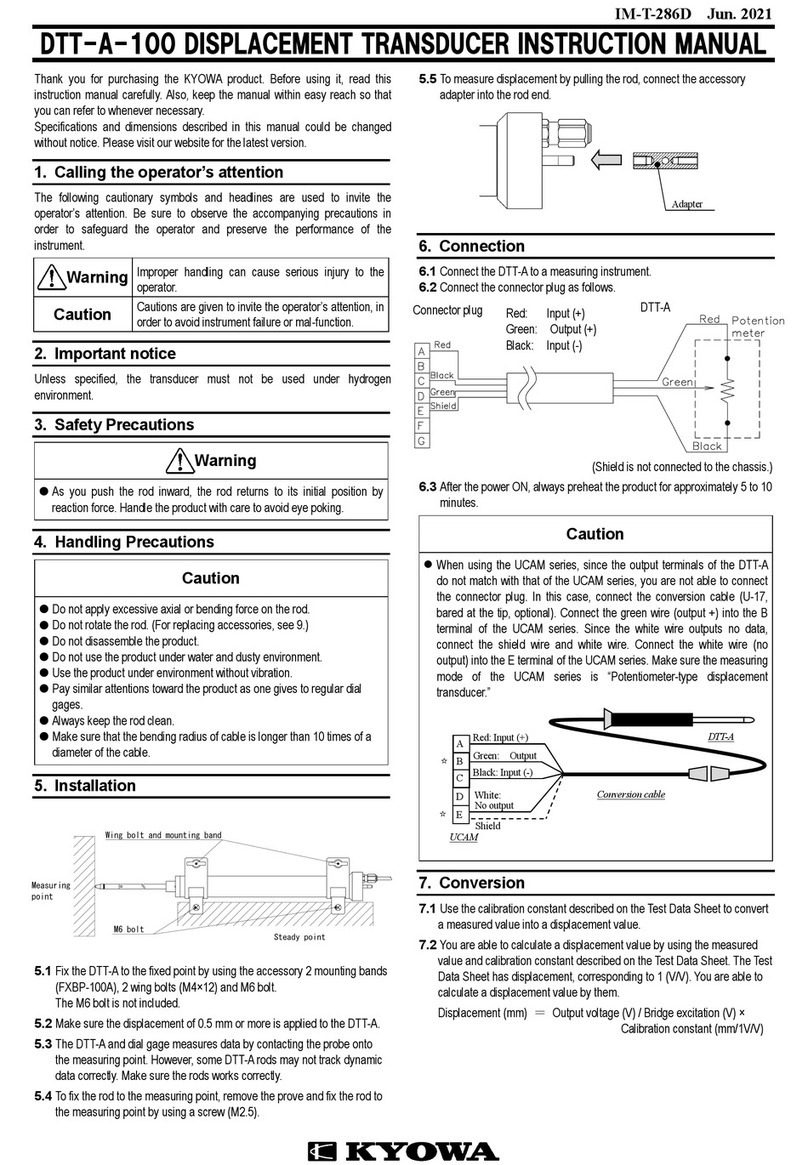

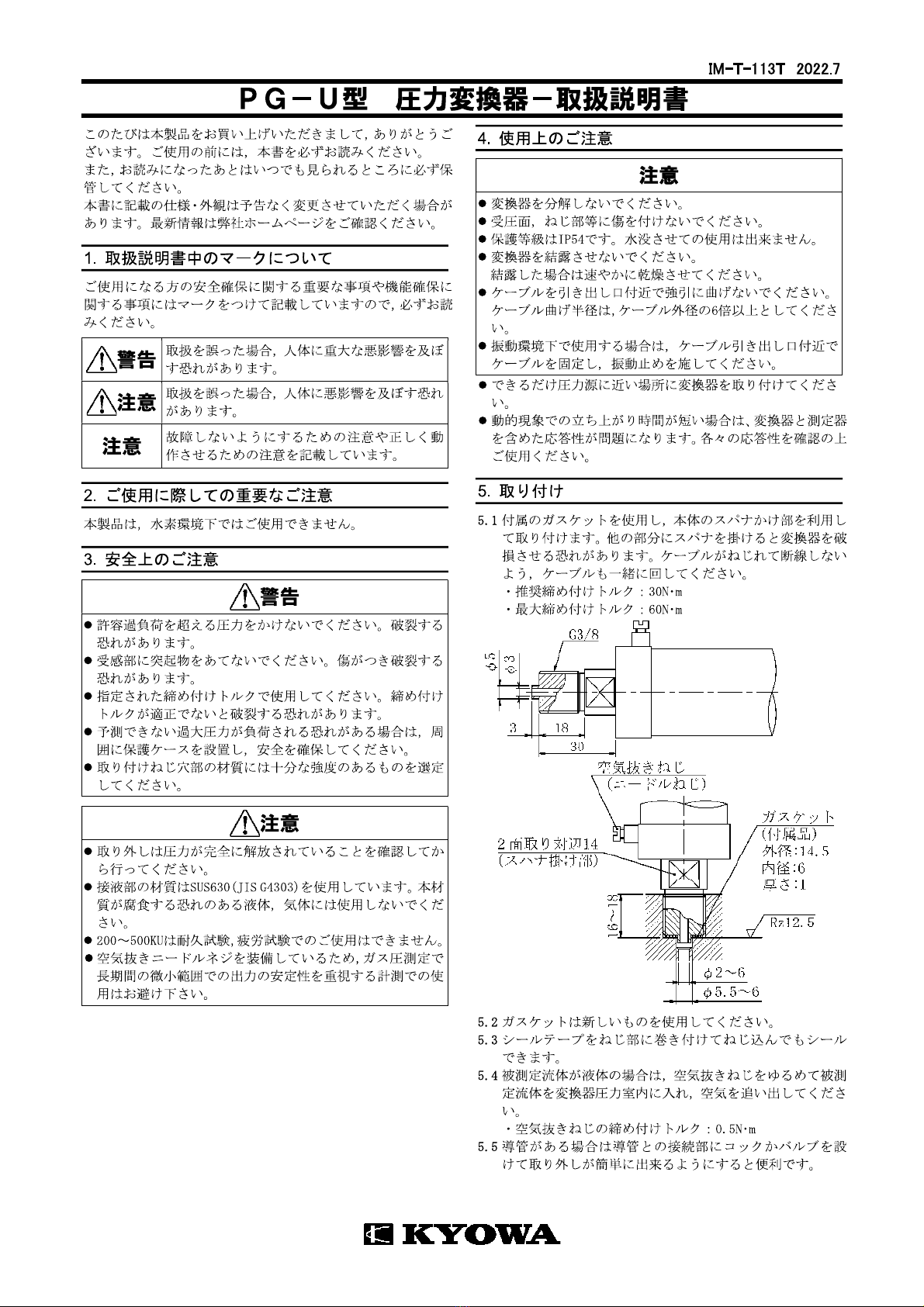

6. Con nectio n

6.1 Connect the transducer to a measuring instrument.

6. 2 When using a measuring instrument other than KYOWA, connector

plug as follows.

When connected the attached cable, shield wire is connected to the

case.

6. 3

Heat run for 5 minutes or longer before starting the measurement.

7. Co n v ers i o n

7. 1 Use the calibration constant described in the test data sheet to

convert a reading into a pressure value.

7 . 2

When a strain amplifier is in use, output reads in ×10-6 equivalent

strain. Find a pressure value corresponding to ×10-6 strain. Then,

obtain a pressure value through multiplication using the following

equation.

Pressure (Pa) = Strain amplifier’s output (×10-6 strain)

x Calibration constant (Pa

/

1×10-6 strain)

7. 3 When using an amplifier of other type or a recorder, first find the exact

bridge exciting voltage applied. Second, find the pressure value that

corresponds to 1(μV) output voltage against 1(V) bridge excitation

voltage. Then, obtain the pressure value through multiplication using

the following equation.

Pressure (Pa) =

Bridge output voltage (μV) ×Calibration constant (Pa

/

1μV/V)

Bridge excitation voltage (V)

Sensitivity Decrease due to Cable Extension

If a strain-gage transducer is connected to a signal conditioner, digital

indicator or strain amplifier via extension cable, we will not ignore the

sensitivity decrease due to the extension cable resistance which lowers

the voltage applied to the transducer.

The rated output with lowered sensitivity is obtained from the following

equation:

Rated output :ε

0

=(

R

)

ε

i

R+(r × L)

R

:

Transducer’s input resistance (Ω)

r

:

Extension cable’s reciprocating resistance (Ω/m)

L

:

Extension cable length (m)

ε

i

:

Rated output written in the Test data sheet

8. Storage and inspection

8. 1 Avoid water, oil, dust, etc. on the connector.

8. 2 Recommend calibrate the product once a year or so. (Contact your

KYOWA representative.)

8. 3 If suspicious outputs have occurred, check the input resistance,

output resistance and insulation resistance. Provided that the

connector operates properly and that the insulation resistance

between the mainframe and conductors is below 100MΩ, the cause

may be failure.

In this case, contact your KYOWA representative.

Ca u tio n

To measure insulation resistance, apply a voltage lower than 50V to

the insulation resistance tester.

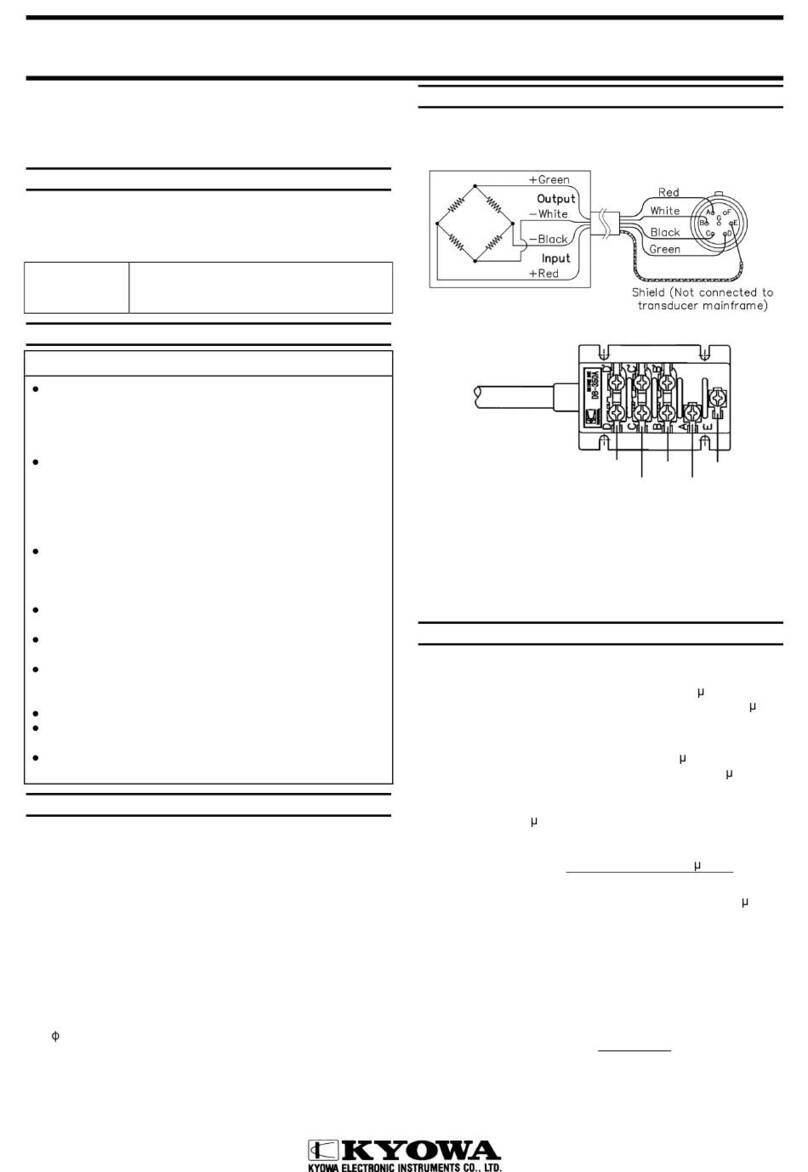

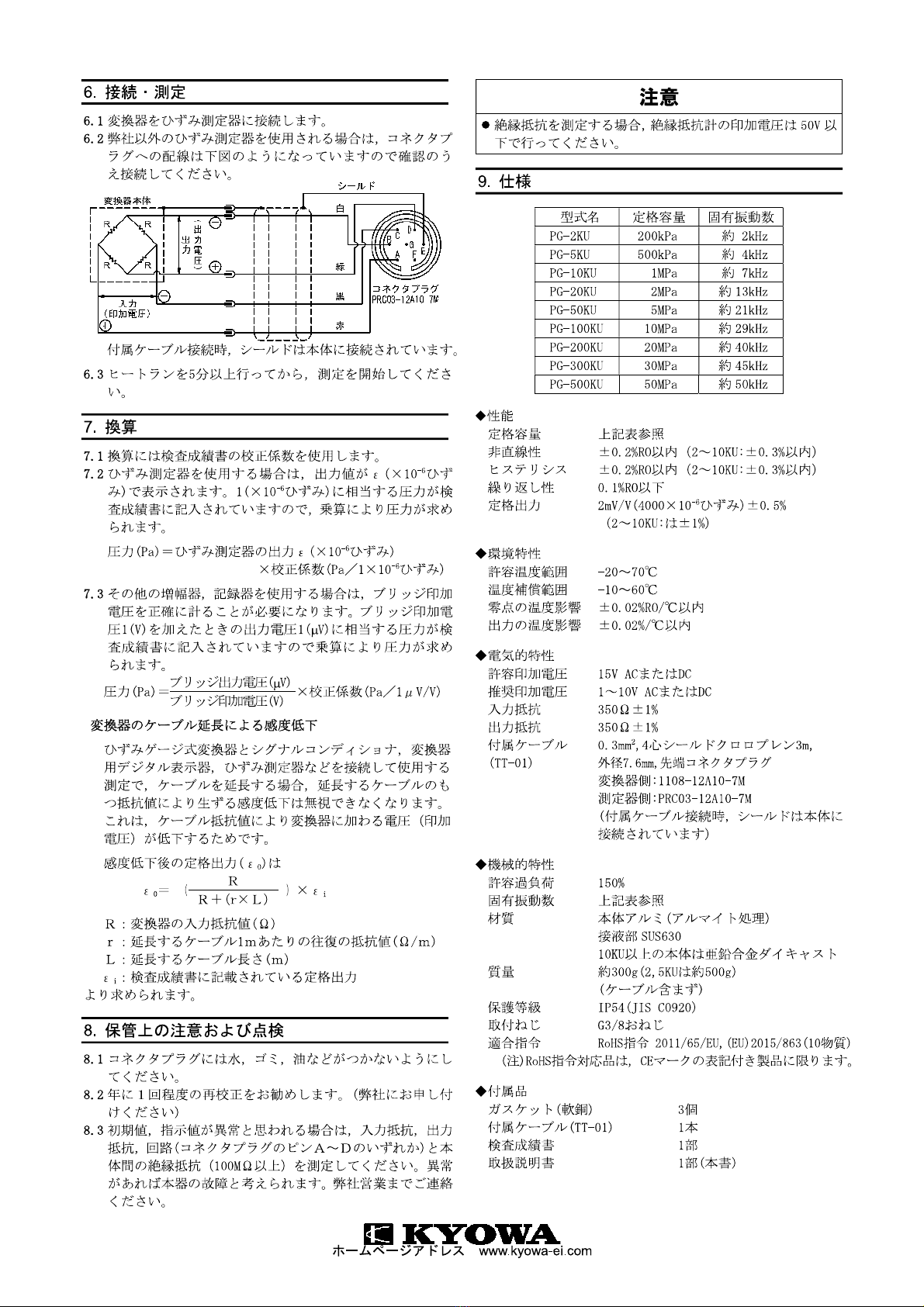

9. Specifications

Models. Rated capacity. Natural frequency.

(Approx.)

PG-2KU 200kPa 2kHz

PG-5KU 500kPa 4kHz

PG-10KU 1MPa 7kHz

PG-20KU 2MPa 13kHz

PG-50KU 5MPa 21kHz

PG-100KU 10MPa 29kHz

PG-200KU 20MPa 40kHz

PG-300KU 30MPa 45kHz

PG-500KU 50MPa 50kHz

◆Performance

Rated Capacity See table above.

Nonlinearity Within ±0.2% RO (2,5,10KU: Within ±0.3% RO)

Hysteresis Within ±0.2% RO (2,5,10KU: Within ±0.3% RO)

Repeatability 0.1% RO or less

Rated Output 2mV/V±0.5% (2,5,10KU: ±1% RO or less)

◆Environmental Characteristics

Safe Temperature -20 to 70

℃

Compensated Temperature -10 to 60

℃

Temperature Effect on Zero W ithin ±0. 02% RO/

℃

Temperature Effect on Output W ithin ±0. 02% /

℃

◆Electrical Characteristics

Safe Excitation 15V AC or DC

Recommended Excitation 1 to 10V AC or DC

Input Resistance 350Ω ± 1%

Output Resistance 350Ω ± 1%

Accessory Cable 4-conductor (0.3mm2) chloroprene

(TT-01) shielded cable, 7.6mm diameter by 3m

long, terminated with a connector plug

Sensor side: 1108-12A10-7M

Measuring instrument side:

PRC03-12A10-7M

(When connected the attached cable,

shield wire is connected to the case.)

◆Mechanical Properties

Safe Overloads 150%

Natural Frequencies See table above.

Material Case: Anode oxidized coated aluminum

Liquid-contacting part: SUS630

For 10KU or more, the case is die case

zinc alloy.

Weight Approx.300g (2,5KU: Approx.500g)

(Excluding Cable)

Mounting Screw G3/8, male

Compliance Directive 2011/65/EU, (EU) 2015/863

(10 restricted substances) (RoHS)

[NOTE]

Products with CE Marking are compliant European RoHS Directive.

◆Accessories

Gasket (Mild copper) 3

Accessory Cable (TT-01) 1

Test Data Sheet 1

Instruction manual 1 (This book)