3

EN

Cautions

Do not use private power generators as a power source

for charging.

Incorrect installation and testing of the GLB Wallbox could

potentially damage either the vehicle’s battery and/or the

GLB Wallbox itself.

Do not operate the GLB Wallbox in temperatures outside

its operating range – see technical specificatrions.

Notes

All installation must be carried out by an authorised

installer and comply with local installation regulations.

If any questions, please contact your local electrical

authority.

Ensure that the GLB Wallbox’s charging cable is

positioned so it will not be stepped on, driven over,

tripped on, or subjected to damage or stress.

Unroll the charging cable to prevent it from overheating.

Do not use cleaning solvents to clean any of the GLB

Wallbox’s components. The outside of the GLB Wallbox,

the charging cable, and the end of the charging cable

should be periodically wiped with a clean, dry cloth to

remove accumulation of dirt and dust.

Be careful not to damage the circuit boards or components

during installation.

Refer to local standards and regulations not to exceed

charging current limitations.

The front cover must always be locked in its upper position

in order to ensure compliance with IP Code IP44.

Avoid to install the GLB Wallbox in direct sunlight to avoid

any heat-problems.

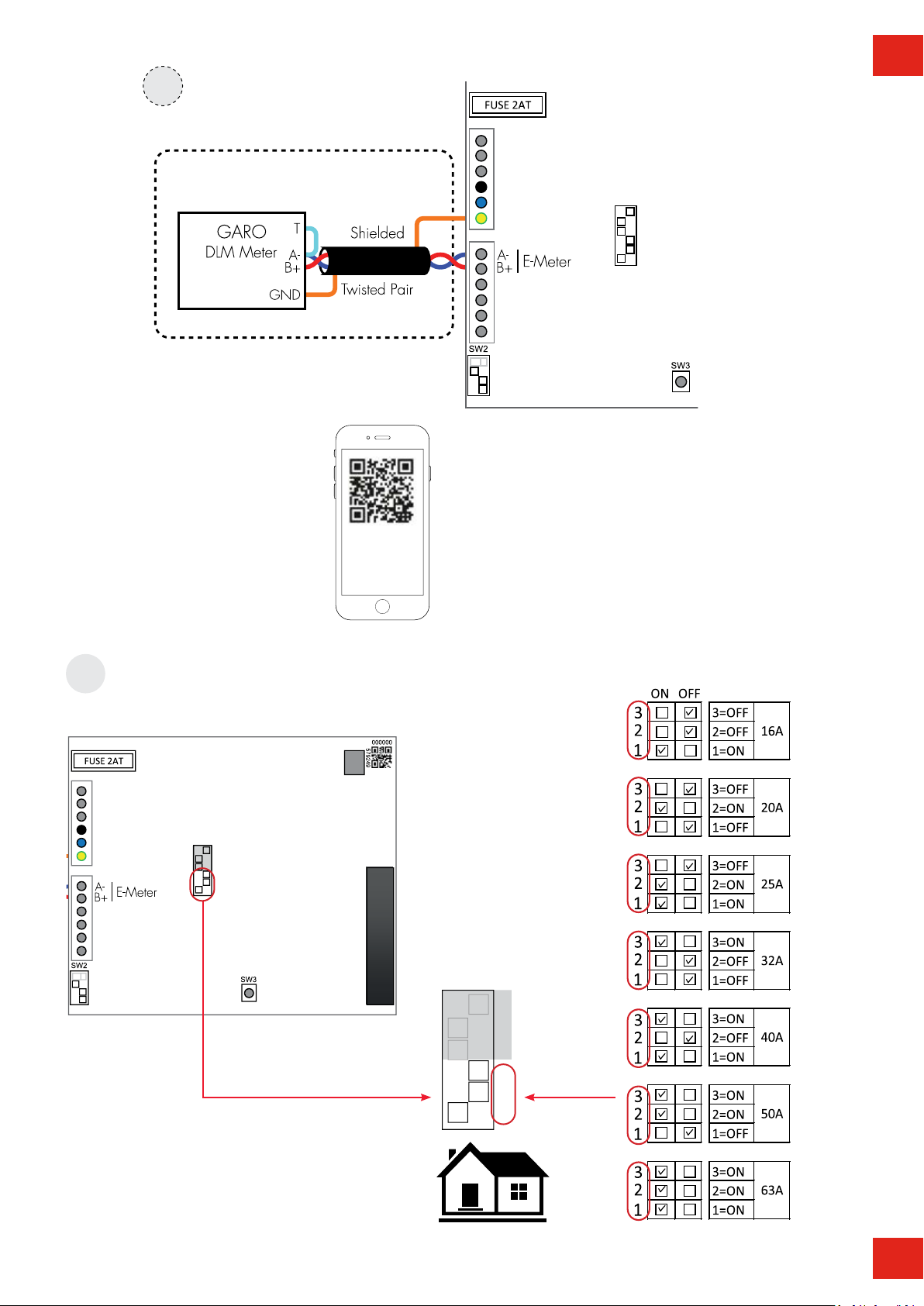

To even out the load, it is important to rotate the phases

when connecting several of GLB Wallboxes to the same

system. Note that 1-phase charging is common in electric

vehicles and L1 in the GLB is used for this purpose.

Ventilation signal from EV is not supported.

Adapters for charging connectors are not allowed to be

used.

Cord extension sets for charging cable is not allowed to

be used.

Dielectric Voltage Withstand Test is not allowed on GLB

Wallbox

This equipment should not be used by anyone (including

children) with reduced physical, sensory or mental

capacity, or anyone lacking in experience or knowledge,

unless they are provided with supervision or prior

instruction in how to use the equipment by the person

responsible for their safety.

The GLB Wallbox range of charging stations is designed

exclusively for charging electric vehicles.

The GLB Wallbox must be grounded according to local

country installation requirements.

Do not install or use the GLB Wallbox near flammable,

explosive, harsh, or combustible materials, chemicals, or

vapors.

Turn off the electrical power at the circuit breaker before

installing, configuring or cleaning of the GLB Wallbox.

Use the GLB Wallbox only within the specified

parameters.

Never spray water or any other liquid directly at the GLB

Wallbox. Never spray any liquid onto the charge handle

or submerge the charge handle in liquid. Store the charge

handle in the dock to prevent unnecessary exposure to

contamination or moisture.

Do not use this equipment if it appears to be damaged or

if the charging cable appears to be damaged.

Do not modify the equipment installation or any part of the

product.

Do not touch the GLB Wallbox’s end terminals with fingers

or any other objects.

Do not insert foreign objects into any part of the GLB

Wallbox.

This document contains general descriptions which are verified to

be accurate at the time of printing. However, because continuous

improvement is a goal at GARO, we reserve the right to make

product and software modifications at any time.

Latest manual can always be found at www.garoemobility.com/

support

Warnings