INFORMATION

Warnings

About this manual

GARO TWIN+ assortment is a range of EVSE stations for Mode-3

AC charging.

Below are some example of standard features:

• Double outlets or cables for Mode-3 EV charging.

• Up to 2x22kW simultaneous charging from one EVSE

depending on model.

• RCCB and DC-fault monitoring for each side.

• Double mains terminals for easy forwarding of mains cable to

next TWIN+.

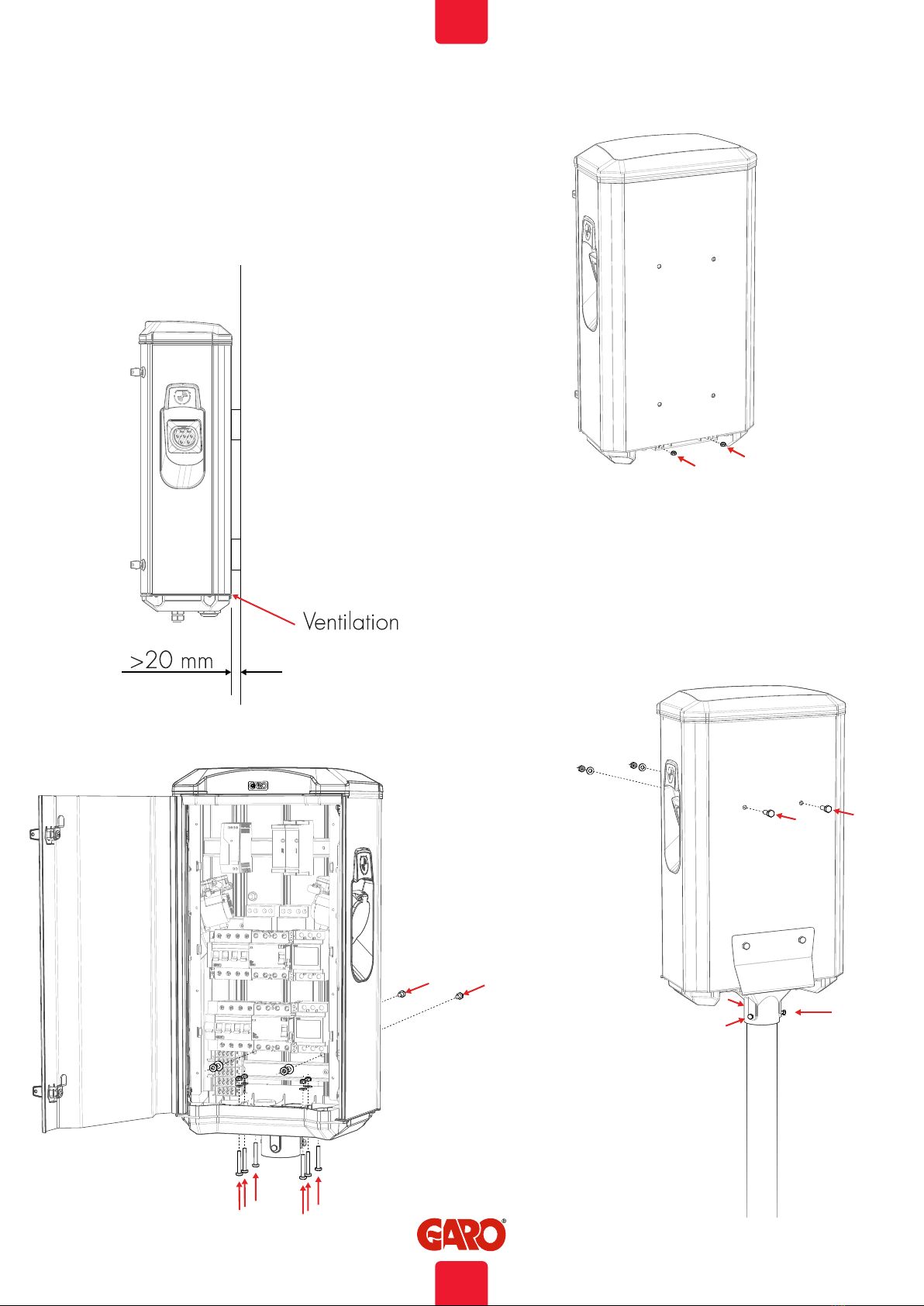

• Suitable for installation on wall or pole.

• LED status indication.

• Upgradeable firmware

• Energy meters for each side

• OCPP via Wifi or LAN

• RFID readers

TWIN+ supports following features

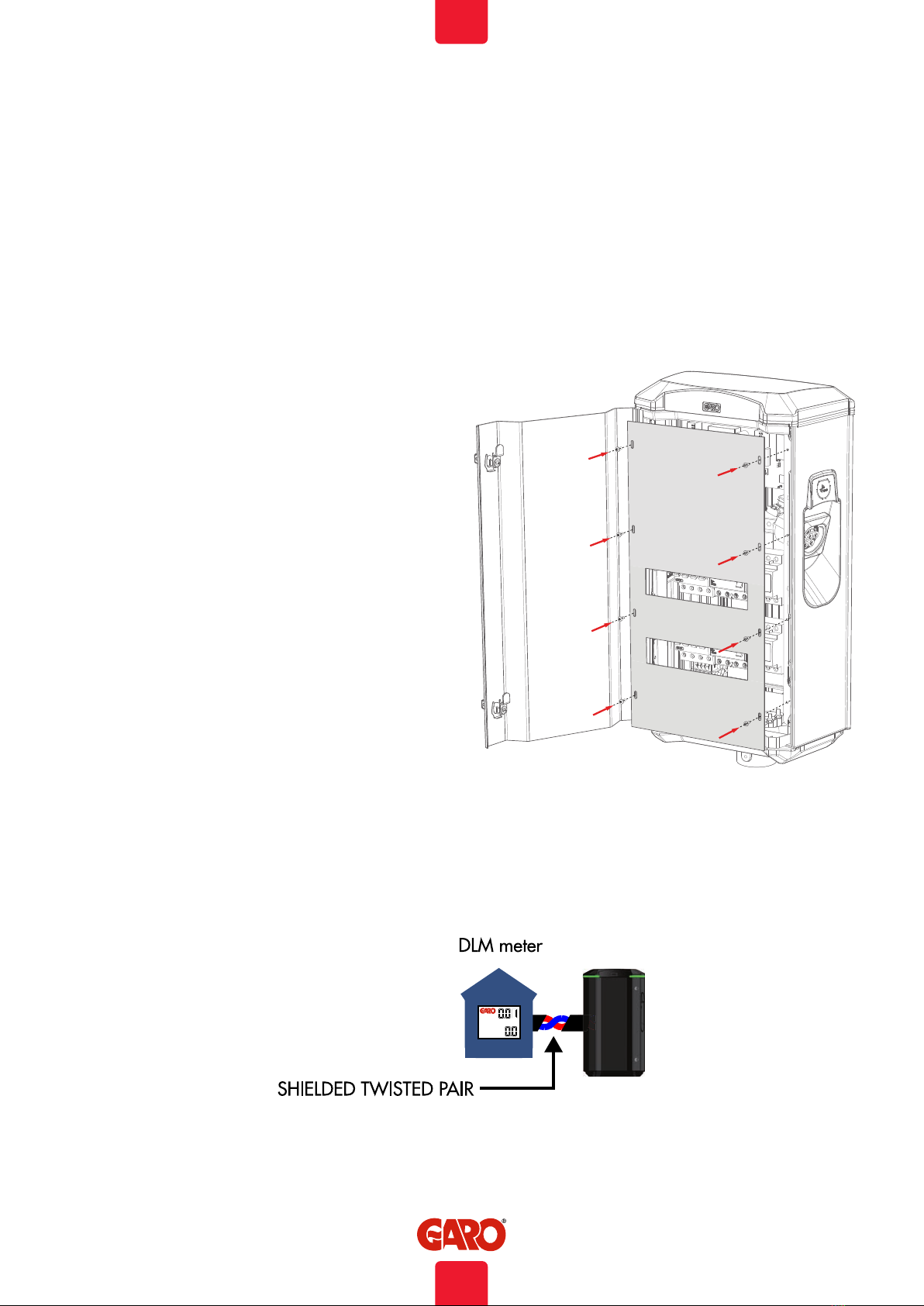

External DLM energy meter

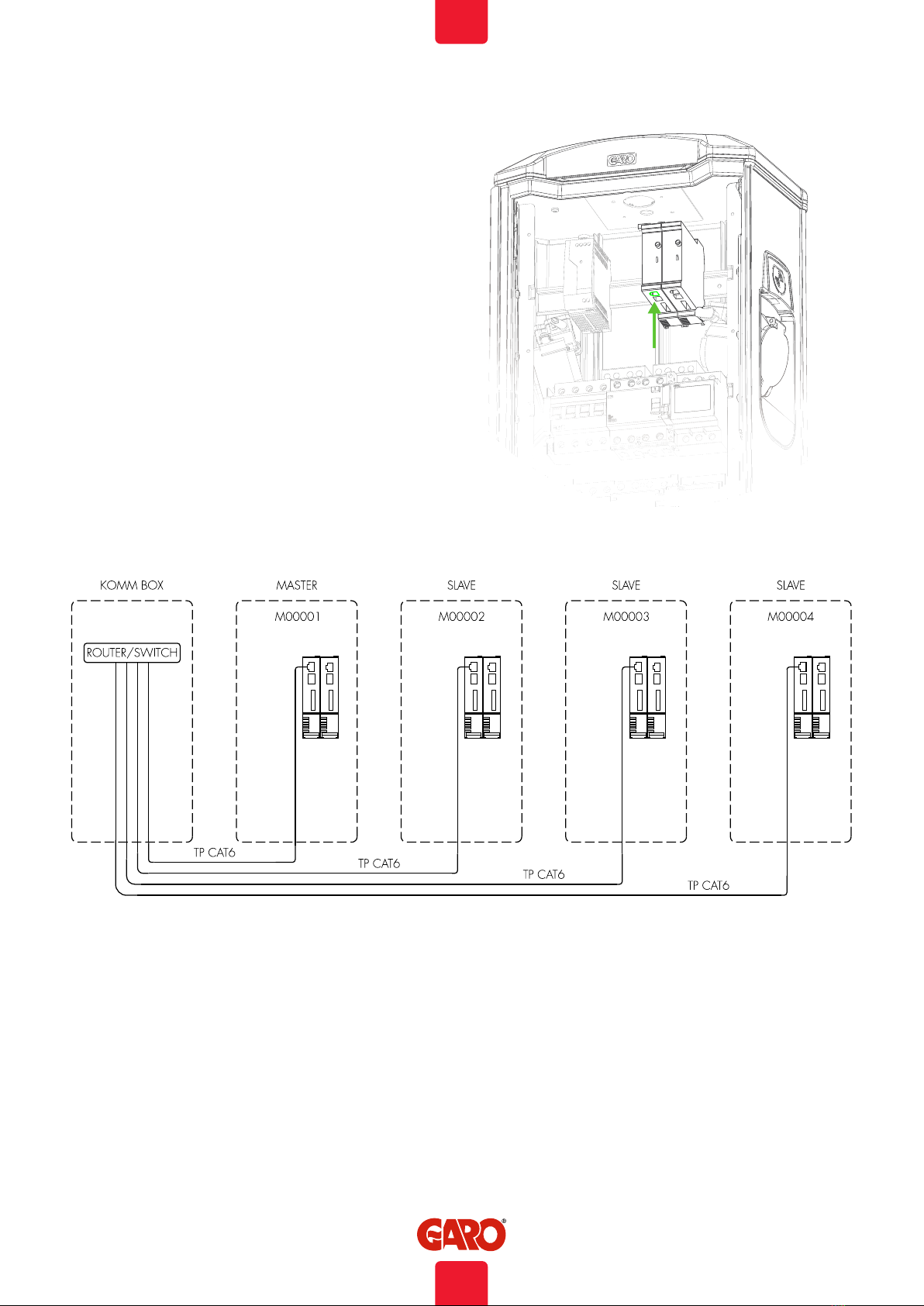

Cluster installation of multiple TWIN+ via Ethernet

Cluster installation of multiple TWIN+, LS4 and GLB+ via Ethernet

Dielectric Voltage Withstand Test is not allowed on

TWIN+

This equipment should not be used by anyone (including

children) with reduced physical, sensory or mental

capacity, or anyone lacking in experience or knowledge,

unless they are provided with supervision or prior

instruction in how to use the equipment by the person

responsible for their safety.

TWIN+ is designed exclusively for charging electric

vehicles.

TWIN+ must be grounded according to local country

installation requirements.

Do not install or use the TWIN+ near flammable,

explosive, harsh, or combustible materials, chemicals, or

vapors.

Turn off the electrical power at the circuit breaker before

installing, configuring, cleaning or maintenance.

Use TWIN+ only within the specified parameters.

Never spray water or any other liquid directly at TWIN+.

Never spray any liquid onto the charge handle or

submerge the charge handle in liquid. Store the charge

handle in the dock to prevent unnecessary exposure to

contamination or moisture.

Do not use this equipment if it appears to be damaged or

if the charging cable appears to be damaged.

Do not modify the equipment installation or any part of the

product.

Do not touch the terminals with fingers or any other

objects.

Do not insert foreign objects into any part of TWIN+

INFORMATION

This document contains general descriptions which are verified to

be accurate at the time of printing. However, because continuous

improvement is a goal at GARO, we reserve the right to make

product and software modifications at any time. This range

is subject to continual product development. Errors, typo and

omissions excepted. Latest manual can always be found at

www.garoemobility.com/support

For full user manual: www.garoemobility.com/support

3

EN