GAS ESD5550 Series User manual

ENGINE

GOVERNING

ESD5550/5570 Series

SYSTEM

Speed Control Unit

Installation

Adjustments

The speed control unit is rugged enough to be placed in a

control cabinet or engine mounted enclosure with other

dedicated control equipment. If water, mist, or condensation

may come in contact with the controller, it should be mount-ed

vertically. This will allow the fluid to drain away from the speed

control unit. Extreme heat should be avoided.

An overspeed shutdown device, independent of the gover-

nor system, should be provided to prevent loss of engine

control, which may cause personal injury or equipment dam-

age. Do not rely exclusively on the governor system electric

actuator to prevent overspeed. A secondary shutoff device,

such as a fuel solenoid, must be used.

Wiring

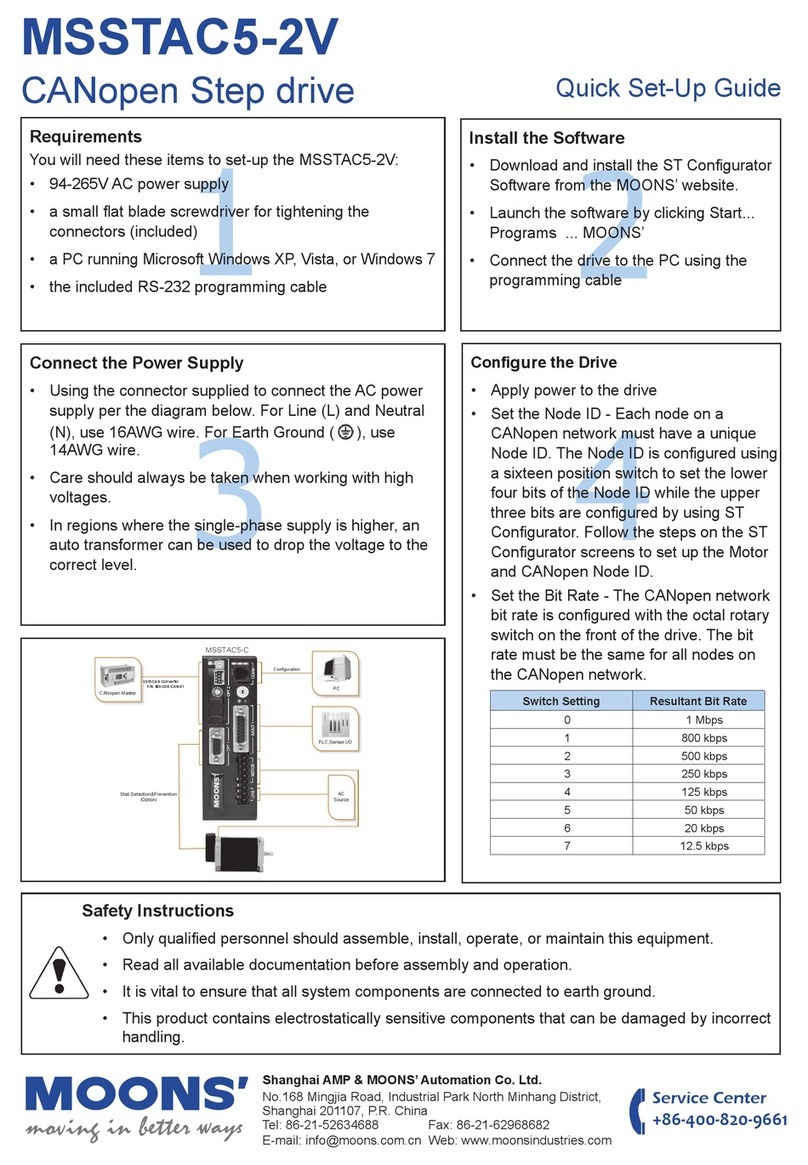

Basic electrical connections are illustrated in Diagram 2 (for

the ESD5550, ESD5555 and the ESD5570) and Diagram 3

(for the ESD5556 only). Actuator and battery connections to

Terminals A, B, E, and F should be #16 AWG (1.3 mm2) or

larger. Long cables require an increased wire size to mini-

mize voltage drops. The battery positive (+) input, Terminal

F, should be fused for 15 amps as illustrated.

Magnetic speed sensor wires connected to Terminals C and D

MUST BE TWISTED AND/OR SHIELDED for their entire

length. The speed sensor cable shield should ideally be con-

nected as shown in Diagram 2 or 3. The shield should be

insulated to insure no other part of the shield comes in con-tact

with engine ground, otherwise stray speed signals may be

introduced into the speed control unit. With the engine stopped,

adjust the gap between the magnetic speed sensor and the ring

gear teeth. The gap should not be any smaller than 0.020 in.

(0.45 mm). Usually, backing out the speed sensor 3/4 turn after

touching the ring gear teeth will achieve a satisfactory air gap.

The magnetic speed sensor voltage should be at least 1 VAC

RMS during cranking.

Before Starting Engine

Before starting the engine, check and/or adjust the POTs/

switches to the following settings. See Table 1 for the fac-

tory presets.

Start Engine

The speed control unit governed speed setting is factory set

at approximately engine idle speed. (1000 Hz., speed sen-

sor signal) Crank the engine with DC power applied to the

governor system. The governor system should control the

engine at a low idle speed. If the engine is unstable after

starting, turn the GAIN and STABILITY adjustments CCW

until the engine is stable.

Adjusting Crank Termination (ESD5556 only)

To protect the engine from harm the CRANK TERMINATION

adjustment is factory set at full CCW [Lowest Setting]. To adjust

CRANK TERMINATION speed setting, rotate the CRANK

adjustment to full CW. Crank the engine and simul-taneously

turn the CRANK adjustment slowly CCW until the proper crank

termination speed is reached. In operation, when the cranking

termination set point is reached, the green CRANK LED will

illuminate. (Cranking has terminated).

The ESD5556 is set for manual reset. To reinstate engine

cranking, battery power must be removed and then reap-

plied which will recycle the control.

Adjusting Overspeed

When the engine is running at the desired speed, push and

hold the TEST button. Rotate the OVERSPEED adjustment

CCW until the red OVERSPEED LED lights and the relay

energizes. Current to the actuator will be removed and the

Table 1 factory presets

Adjustment / Switch

Potentiometer/Switch

Setting

Applicable Units

SPEED

25 turn

1470 Hz ± 50 Hz w/ min. trim

all

GAIN

270° turn

50%

all

STABILITY

270° turn

50%

all

DROOP

270° turn

0% (CCW)

all

IDLE

270° turn

1075± 75 Hz

all

STARTING FUEL RAMP

270° turn

100% (CW) Maximum Fuel

all

SPEED RAMP

270° turn

0% (CCW) Fastest

all

OVERSPEED

25° turn

100% (CW) Highest

all

CRANK TERMINATION

25° turn

0% (CCW) Lowest

ESD5556 only

SWI Lead Circuit

switch

ON

all

SW2 Soft Coupling

switch

OFF

all

engine will shut off.

Release the TEST button. After the engine stops, press the

RESET button or remove battery power. Restart the engine

and it will return to the original speed setting. The overspeed

function is now set to approximately 10% above the request-

ed speed.

If a different value of overspeed setting is required, raise the

engine speed to the desired overspeed value, i.e. 115%. Ro-

tate the OVERSPEED adjustment CCW until the red OVER-

SPEED LED lights and the relay energizes.

⚠WARNING

Always use the relay contacts provided to shut down the

system by a means other than the governor or actuator. It

is recom-mended that an overspeed protection sys-tem be

routinely tested and verified during the scheduled service

of equipment.

Governor Speed Setting

The governed speed set point is increased by a CW rotation

of the SPEED adjustment control. Remote speed adjust-

ment can be obtained with an optional 5K Speed Trim Con-

trol. (See Diagram 1.)

Governor Performance

Once the engine is at operating speed and at no load, the

following governor performance adjustment can be made.

A. Rotate the GAIN adjustment CW until instability devel-

ops. Gradually move the adjustment CCW until stability

returns. Move the adjustment one division further CCW

to insure stable performance.

B. Rotate the STABILITY adjustment clockwise until insta-

bility develops. Gradually move the adjustment coun-

terclockwise until stability returns. Move the adjustment

one division further to insure stable performance (270°

pot).

C. GAIN and STABILITY adjustments may require minor

changes after engine load is applied. Normally, ad-

justments made at no load achieve satisfactory perfor-

mance. A strip chart recorder can be used to further

optimize the adjustments.

If instability cannot be corrected or further performance

improvements are required, refer below to the SYSTEM

TROUBLESHOOTING section.

Starting Fuel Adjustment

The engine’s exhaust smoke at start-up can be minimized

by completing the following adjustments:

A. Place the engine in idle by connecting Terminals M & G.

B. Adjust the IDLE speed for as low a speed setting as the

application allows.

C. Adjust the STARTING FUEL CCW until the engine speed

begins to fall. Increase the STARTING FUEL slightly so

that the idle speed is returned to the desired level.

D. Stop the engine.

One of two methods of operation for the ESD5550/5570

may now selected. (See Table 2.)

Table 2 Starting Method

Method 1

Method 2

Start the engine and accelerate

Start the engine and control

directly to the operating speed

at an idle speed for a period of

(Gen Sets, etc.).

time prior to accelerating to the

operating speed. This method

separates the starting process

so that each may be optimized

for the lowest smoke emissions.

Remove the connection between

Replace the connection be-

Terminals M & G. Start the en-

OR

tween Terminals M & G with a

gine and adjust the SPEED

switch, usually an oil pressure

RAMPING for the least smoke

switch. Start the engine. If the

on acceleration from idle to rated

starting smoke is excessive,

speed. If the starting smoke is

the STARTING FUEL may need

excessive, the STARTING FUEL

to be adjusted slightly CCW. If

may need to be adjusted slightly

the starting time is too long, the

CCW. If the starting time is too

STARTING FUEL may need to

long, the STARTING FUEL may

be adjusted slightly CW.

need to be adjusted slightly CW.

When the switch opens, adjust

the SPEED RAMPING for the

least amount of smoke when

accelerating from idle speed to

rated speed.

Idle Speed Setting

If the IDLE speed setting was not adjusted as detailed in

‘Starting Fuel Adjustment’ section, then place the optional

external selector switch in the IDLE position. A CW adjust-

ment to the IDLE adjustment control will increase the idle

speed set point. When the engine is at idle speed, the speed

control unit applies droop to the governor system to insure

stable operation.

Speed Droop Operation

Droop is typically used for the paralleling of engine driven

generators.

Place the optional external selector switch in the DROOP po-

sition. DROOP is increased by CW rotation of the DROOP

adjustment control. When in droop operation, the engine

speed will decrease as engine load increases. The percent-

age of droop is based on the actuator current change from

engine no load to full load. A wide range droop is available

with the internal control. Droop level requirements above

10% are unusual.

If droop levels experienced are higher or lower then these

required, contact GAC for assistance.

After the droop level has been adjusted, the rated engine

speed setting may need to be reset. Check the engines

speed and adjust that speed setting accordingly.

2

Accessory Input

The AUXiliary Terminal N accepts input signals from load

sharing units, auto synchronizers, and other governor sys-

tem accessories. It is recommended that this connection

from accessories be shielded as it is a sensitive input ter-

minal.

If the auto synchronizer is used alone, not in conjunction with

a load sharing module, a 3Ωresister should be connected

between Terminals N and P. This is required to match the

voltage levels between the speed control unit and the syn-

chronizer.

When an accessory is connected to Terminal N, the speed

will decrease and the speed adjustment must be reset.

When operating in the upper end of the control unit frequen-

cy range, a jumper wire or frequency trim control may be

required between Terminals G & J. This increases the fre-

quency range of the speed control to over 7000 Hz.

Accessory Supply

The +10 VDC regulated supply, Terminal P, can be utilized

to provide power to GAC governor system accessories. Up

to 20 mA of current can be drawn from this supply. Ground

reference is Terminal G. Caution: a short circuit on Terminal

P could damage the speed control unit.

Table 3 Variable speed range Potentiometer

Speed Range

Potentiometer

900 Hz

1K

2,400 Hz

5K

3,000 Hz

10K

3,500 Hz

25K

3,700 Hz

50K

Wide Range Remote Variable Speed Operation

Simple and effective remote variable speed can be obtained

with the ESD5550/5570 Series control unit using an external

potentiometer.

A single remote speed adjustment potentiometer can be used

to adjust the engine speed continuously over a specific speed

range. Select the desired speed range and corre-sponding

potentiometer value. (Refer to Table 3.) If the exact range

cannot be found, select the next higher range poten-tiometer.

An additional fixed resistor may be placed across the

potentiometer to obtain the exact desired range. Con-nect the

speed range potentiometer as shown in Diagram 1.

To maintain engine stability at the minimum speed setting, a

small amount of droop can be added turn the DROOP

adjustment CW. At the maximum speed setting the gover-

nor performance will be near isochronous, regardless of the

droop adjustment setting.

Contact GAC for assistance if difficulty is experienced in ob-

taining the desired variable speed governing performance.

Diagram 1 Variable Speed Pot

*

cw

*Select Proper Potentiometer Value from Table 3.

SYSTEM TROUBLESHOOTING

SYSTEM INOPERATIVE

If the engine governing system does not function, the fault may be determined by performing the voltage tests described in Steps 1, 2, 3 and 4. [+] and [-] refer to

meter polarity. Should normal values be indicated as a result of following the troubleshooting steps, the fault may be with actuator or the wiring to

the actuator. See the actual publication for testing details.

Steps

Terminals

Normal Reading

Probable Cause of Abnormal Reading

1

F(+) & E(-)

Battery Supply Voltage 12 or

1.

DC battery power not connected. Check for blown fuse.

24 VDC

2.

Low battery voltage.

3.

Wiring error.

2

C & D

1.0 VAC RMS min., while

1.

Gap between speed sensor and gear teeth too great. Check gap.

cranking.

2.

Improper or defective wiring to the speed sensor. Resitance between Terminals C & D

should be should be 30 to 1200 Ω.

3

P(+) & G(-)

10 VDC, Internal Supply.

1.

Short on Terminal P. (This will cause a defective unit.)

2.

Defective Speed Control.

4

F(+) & A(-)

1.0 - 2.0 VDC while cranking.

1. Speed Adjustment set too low.

2. Short/open in actuator wiring.

3. Defective speed control.

4. Defective actuator. See Actuator Troubleshooting.

3

UNSATISFACTORY PERFORMANCE

If the engine governing system functions poorly, preform the following test.

Symptom

Test

Probable Fault

Engine overspeeds.

1. Do not crank. Apply DC power to

1. Actuator goes to full fuel. Then, disconnect speed sensor at Terminals C & D. If the actuator is still at full fuel - the

the governor system.

speed control is defective. If the actuator is still at minimum fuel fuel position - erroneous spped signal. Check speed

sensor data.

2. Manually hold the engine at the

1. If the voltage speed reading is 1.0 to 2.0 VDC; a.) SPEED adjustment is set above desired speed. b.) Defective

desired running speed. Measure the

speed control unit.

DC voltage between Terminals A (-) &

2. If the voltage reading is above 2.0 VDC; a.) Actuator or linkage binding.

F(+) on the speed control unit.

3. If the voltage reading is below 1.0 VDC; a.) Defective speed control unit.

4. Gain set too low.

Actuator does not energize fully.

1. Measure the voltage at battery while

1. If the voltage is less than 7VDC for a 12VDC system or less than 14VDC for a 24VDC system, replace the battery if

cranking.

it is weak or undersized.

2. Momentarily connect Terminal A &

1. Actuator or battery wiring in error.

F. The actuator should move to full

2. Actuator or linkage bringing.

throttle position.

3. Defective actuator. See actuator troubleshooting.

4. Fuse opens. Check for short in actuator or actuator wiring harness.

Engine remains below desired

1. Measure the actuator output.

1. If voltage measurement is within approx. 2 volts of the battery supply voltage, then fuel control restricted from reach-

governed speed.

Terminal a & B, while running under

ing full fuel position. Possible due to interference from the mechnical governor, carburetor spring or linkage alignment.

governor control.

2. Speed setting too low.

Insufficient Magnetic Speed Signal

A strong magnetic speed sensor signal will eliminate the

possibility of missed or extra pulses. The speed control unit

will govern well with 0.5 volts RMS speed sensor signal. A

speed sensor signal of 3 volts RMS or greater at governed

speed is recommended. Measurement of the signal is made

at Terminals C and D.

The amplitude of the speed sensor signal can be raised by

reducing the gap between the speed sensor tip and the

engine ring gear. The gap should not be any smaller than

0.020 in (0.45 mm). When the engine is stopped, back the

speed sensor out by 3/4 turn after touching the ring gear

tooth to achieve a satisfactory air gap.

Electromagnetic Compatibility (EMC)

EMI SUSCEPTIBILITY - The governor system can be ad-

versely affected by large interfering signals that are conduct-

ed through the cabling or through direct radiation into the

control circuits.

All GAC speed control sensors contain filters and shielding

designed to protect the unit’s sensitive circuits from mod-

erate external interfering sources. Although it is difficult to

predict levels of interference, applications that include mag-

netos, solid sate ignition systems, radio transmitters, voltage

regulators or battery chargers should be considered suspect

as possible interfering sources.

If it is suspected that external fields, either those that are

radiated or conducted, are or will affect the governor sys-

tems operation, it is recommended to use shielded cable for

all external connections. Be sure that only one end of the

shields, including the speed sensor shield, is connected to a

single point on the case of the speed control unit. Mount the

speed control to a grounded metal back plate or place it in a

sealed metal box.

Radiation is when the interfering signal is radiated directly

through space to the governing system. To isolate the gover-

nor system electronics from this type of interference source, a

metal shield or a solid metal container is usually effective.

Conduction is when the interfering signal is conducted

through the interconnecting wiring to the governor system

electronics. Shielded cables and installing filters are com-

mon remedies.

In severe high-energy interference locations such as when

the governor system is directly in the field of a powerful

transmitting source, the shielding may require to be a spe-

cial EMI class shielding. For these conditions, contact GAC

application engineering for specific recommendations.

Instability

Instability in a closed loop speed control system can be

categorized into two general types. PERIODIC appears to

be sinusoidal and at a regular rate. NON-PERIODIC is a

random wandering or an occasional deviation from a steady

state band for no apparent reason.

Switch C1 controls the “Lead Circuit” found in the

ESD5550/5556/5570. The normal position is “ON.” Move the

switch to the “OFF” position if there is fast instability in the

system.

Switch C2 controls an additional circuit added in the

ESD5550/5570 that is designed to eliminate fast erratic gov-

ernor behavior, caused by very soft or worn couplings in the

drive train between the engine and generator. The normal

position is “OFF.” Move to the “ON” position if fast erratic en-

gine behavior due to a soft coupling is experienced.

The PERIODIC type can be further classified as fast or slow

instability. Fast instability is a 3 Hz. or faster irregularity of the

speed and is usually a jitter. Slow periodic instability is below 3

Hz., can be very slow, and is sometimes violent.

If fast instability occurs, this is typically the governor respond-

ing to engine firings. Raising the engine speed increases the

frequency of instability and vice versa. In this case, plac-ing

switch C1 in the “OFF” position will reduce the speed control

unit’s sensitivity to high frequency signals. Readjust the GAIN

and STABILITY 1or optimum control. Should in-stability still be

present, the removal of E1 to E2 jumper may help stabilize the

engine. Post locations are illustrated in

4

Diagram 1. Again, readjust the GAIN and STABILITY for

optimum control. Interference from powerful electrical sig-

nals can also be the cause. Turn off the battery chargers or

other electrical equipment to see if the system instability

disappears.

Slow instability can have many causes. Adjustment of the

GAIN and STABILITY usually cures most situations by

matching the speed control unit dynamics. If this is unsuc-

cessful, the dead time compensation can be modified. Add

a capacitor from posts E2 to E3 (negative on E2). Post loca-

tions are illustrated in Diagram 1. Start with 10 mfds, and

increase until instability is eliminated. The control system

can also be optimized for best performance by following this

procedure.

If slow instability is unaffected by this procedure, evaluate

the fuel system and engine performance. Check the fuel

system linkage for binding, high friction, or poor linkage. Be

sure to check linkage during engine operation. Also look at

the engine fuel system. Irregularities with carburetion or fuel

injection systems can change engine power with a constant

throttle setting. This can result in speed deviations beyond

the control of the governor system. Adding a small amount

of droop (Jumper K-L) can help stabilize the system for trou-

bleshooting.

NON-PERIODIC instability should respond to the GAIN con-

trol. If increasing the gain reduces the instability, then the

problem is probably with the engine. Higher gain allows the

governor to respond faster and correct for disturbance. Look for

engine misfirings, an erratic fuel system, or load changes on the

engine generator set voltage regulator. If the throttle is slightly

erratic, but performance is fast, move switch C1 to the “OFF”

position. This will tend to steady the system.

If unsuccessful in solving instability, contact GAC for assis-

tance.

Specifications

PERFORMANCE

Isochronous Operation/Steady State Stability ...................±0.25% or better

Speed Range/Governor……………………………....1K-7.5K Hz continuous

Speed Drift with Temperature................................................

±1% Maximum

Idle Adjust CW...................................................................

60% of set speed

Idle Adjust CCW.............................................................

Less than 1200 Hz.

Crank Termination Adjustment Range.....................................

300-2200 Hz.

Droop Range....................................................................

1 - 5% regulation*

Droop Adj. Max. (K-L Jumpered) ..........

400 Hz., ± 75 Hz. per 1.0 A change

Droop Adj. Min. (K-L Jumpered)................

15 Hz., ± 6 Hz. per 1.0 A change

Speed Trim Range ........................................................................

± 200 Hz.

Remote Variable Speed Range .................

500 - 7.5 Hz. or any part thereof

Speed Switch Adjustment Range........................................

1000-10000 Hz.

Terminal Sensitivity

J ...............................

100 Hz., ± 15 Hz / Volt @ 5.0 K Impedance

L ................................

735 Hz., ± 60 Hz / Volt @ 65 K Impedance

N.............................

148 Hz., ± 10 Hz / Volt @ 1 Meg Impedance

P.....................................................

10 VDC Supply @ 20 ma Max

Speed Switch Adjustment Range........................................

1000-10000 Hz.

INPUT POWER

Supply...........................................................

12 or 24 VDC Battery Systems

(Transient and Reverse Voltage Protected)**

Polarity......................................................

Negative Ground (Case Isolated)

Power Consumption........................

50 mA continuous plus actuator current

Actuator Current Range @ 77°F (25°C) - (Inductive Load)............................

..................................................

Min. 2.5Amps.. Max. 10Amps continuous***

Speed Sensor Signal.......................................................

0.5-120 Volts RMS

Speed Switch Relay Contacts (N.O. and N.C.)

...............................10 Amps

ENVIRONMENTAL

Ambient Operating Temperature Range.......-40° to +180°F (-40° to +85°C)

Relative Humidity .........................................................................

up to 95%

All Surface Finishes.........................

Fungus Proof and Corrosion Resistant

RoHS Regulation...........................................................................

Compliant

RELIABILITY

Vibration...........................................................................

1G @ 20 -100 Hz.

Testing .................................................................

100% Functionally Tested

PHYSICAL

Dimensions .........................................................

See Outline (DIAGRAM 1)

Weight ...........................................................................

1.8 lbs. (820 grams)

Mounting---------------------------------------------

Any Position, Vertical Preferred

COMPLIANCE / STANDARDS

Agency…...........................................................................CE Requirements

*Droop is based on a speed sensor frequency of 4000 Hz. and an actuator current change of 1 amp from no

load to full load. Applications with higher speed sensor signals will experience less percent-age of droop.

Applications with more actuator currant change will experience higher percentages of droop. See droop

description for specific details on operation of droop ranges.When used with the ADC100 actuator the droop

percentage will he less due to the actuators low current consumption.

**Protected against reverse voltage by a series diode. A I5 amp fuse must be installed in the posi-

tive battery lead.

***Protected against short circuit to actuator (shuts off current to actuator), unit automatically turns

back on when short is removed.

5

Diagram 2 System Wiring and Outline (for ESD5550, Esd5555 and Esd5570 only)

6.00

(152)

Ø0.27(7)

5.25

(133)

O.S.

TEST

1 OFF

ON 2

LEAD

SOFT

OVERSPEED

CIRCUIT

COUPLING

ON

OFF

MERICA

1 2 3

RESET TEST

OVERSPEED

SPEED CONTROL UNIT

MODEL: ESD55xx

SPEED

S/N :

GAIN

MADE IN AGAWAM, MA U.S.A.

6.50 6.00

STABILITY

OVER

(165) (152)

STARTING

SPEED

SPEED

FUEL

RAMPING

DEAD TIME

DROOP

COMPENSATION

ENGINE SPEED CONTROL

JUMPER

COMPONENT. WHEN INSTALLING

OR SERVICING, REFER TO

PRODUCT PUBLICATION

PICK-UP

-

+

IDLE

10V

ACTUATOR

BATTERY

AUX OUTPUT

A B C D E F G H J K L M N P

OPTIONAL ACTUATOR

CABLE SHIELDING TO

MEET CE DIRECTIVE

*

ACTUATOR

MAGNETIC

CW

PICK-UP

_

SPEED TRIM

+

CONTROL - 5K

S1

BATTERY

FUSE

15A MAX

ACCESSORY POWER

SUPPLY

ACCESSORY INPUT

ADD JUMPER FOR 12V

BATTERY OR ACTUATOR

CURRENTS ABOVE 5A

GROUND REFERENCE

CLOSE FOR DROOP

CLOSE FOR IDLE

*SEE SPECIFIC ACTUATOR PUBLICATION FOR PROPER WIRING OF

ACTUATOR BASED ON BATTERY VOLTAGE

6

Diagram 3 System Wiring and Outline (for Esd5556 only)

6.00

(152)

Ø0.27(7)

5.25

(133)

CRANK

O.S.

OVERSPEED

TEST

O.S.

1

2 3 4 5 6

RESET

1

LEAD

SOFT

OFF

ON 2

CIRCUIT

COUPLING

ON

OFF

SPEED CONTROL UNIT

CRANK

MODEL:

ESD5556

SPEED

S/N :

GAIN

MADE IN AGAWAM, MA U.S.A.

6.50

6.00

STABILITY

OVER

SPEED

(165) (152)

STARTING

SPEED

FUEL

RAMPING

ENGINE SPEED CONTROL

DROOP

COMPONENT. WHEN INSTALLING

OR SERVICING, REFER TO

PRODUCT PUBLICATION

PICK-UP

-

+

IDLE

10V

ACTUATOR

BATTERY

AUX OUTPUT

A B C D E F G H J K L M N P

DEAD TIME

COMPENSATION

JUMPER

OPTIONAL ACTUATOR

CABLE SHIELDING TO

MEET CE DIRECTIVE

*

ACTUATOR

MAGNETIC

CW

PICK-UP

_

SPEED TRIM

+

CONTROL - 5K

BATTERY

FUSE

15A MAX

ACCESSORY POWER

SUPPLY

ACCESSORY INPUT

ADD JUMPER FOR 12V

BATTERY OR ACTUATOR

CURRENTS ABOVE 5A

GROUND REFERENCE

CLOSE FOR DROOP

CLOSE FOR IDLE

*SEE SPECIFIC ACTUATOR PUBLICATION FOR PROPER WIRING

OF ACTUATOR BASED ON BATTERY VOLTAGE

7

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

Harman

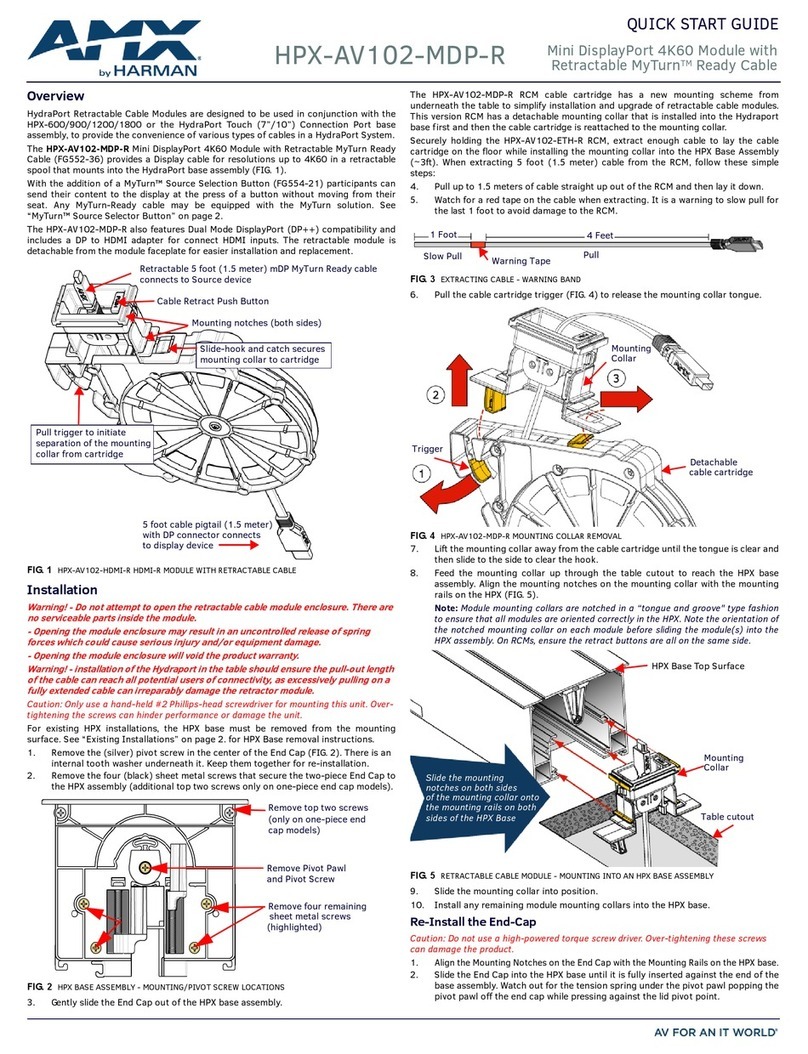

Harman AMX HPX-AV102-MDP-R quick start guide

National Instruments

National Instruments NI 9214 Operating instructions and specifications

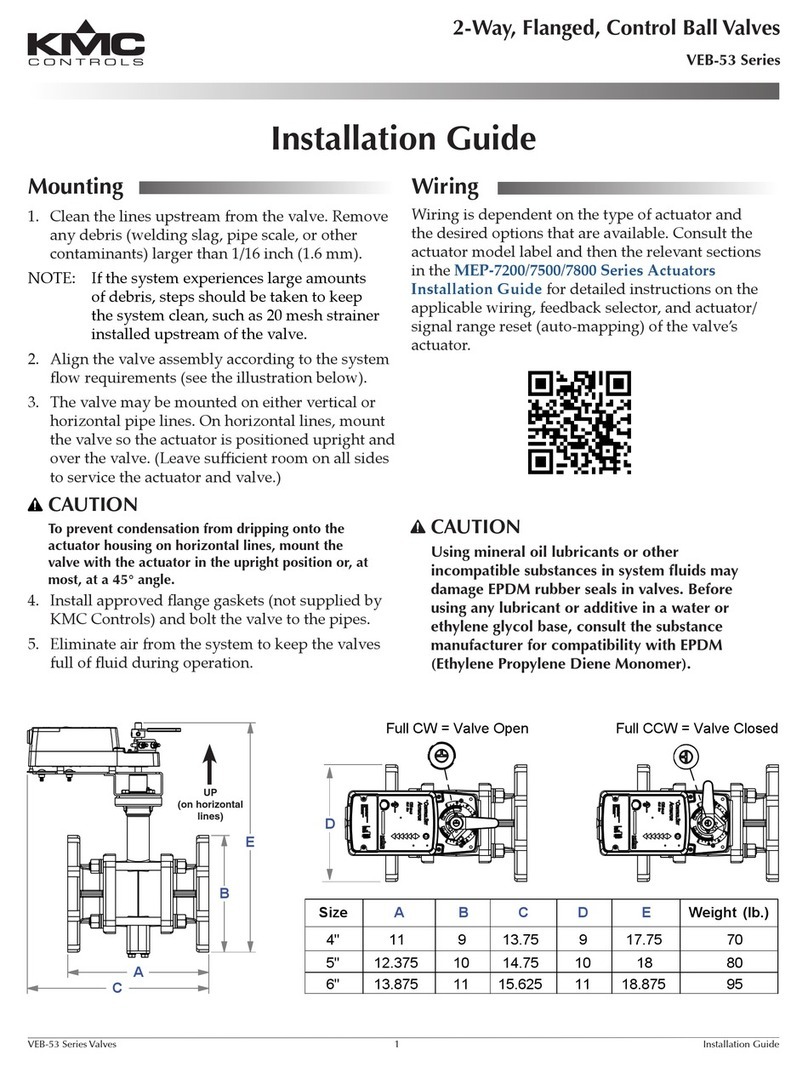

KMC Controls

KMC Controls VEB-53 Series installation guide

artisan

artisan ITC8 Series Operation manual

Epson

Epson RX8804CE Applications manual

Dover

Dover PSG BLACKMER AIR VALVE Installation, operation and maintenance instructions