Gasboy Atlas 9800 User manual

MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019 Page 1

Introduction

Purpose

This manual provides instructions for installing the Atlas® 9800 Electronics.

Intended Users

This manual is intended for Gasboy®-trained and certified Authorized Service Contractors

(ASCs).

Table of Contents

Topic Page

Introduction 1

Important Safety Information 3

Atlas 9800 Parts 5

Accessing Electronic Components 9

Installing Atlas 9800 Power Supply Assembly (M15579A001) 10

Installing Atlas 9800 CPU Board (M06333KXXXX) 12

Installing Atlas 9800 Pulse-out I/F with EM Totalizer Drive Board (M06587A001) 18

Loading New CPU Software 20

Required Tools

A Phillips® screwdriver is required for installing the Atlas 9800 Electronics.

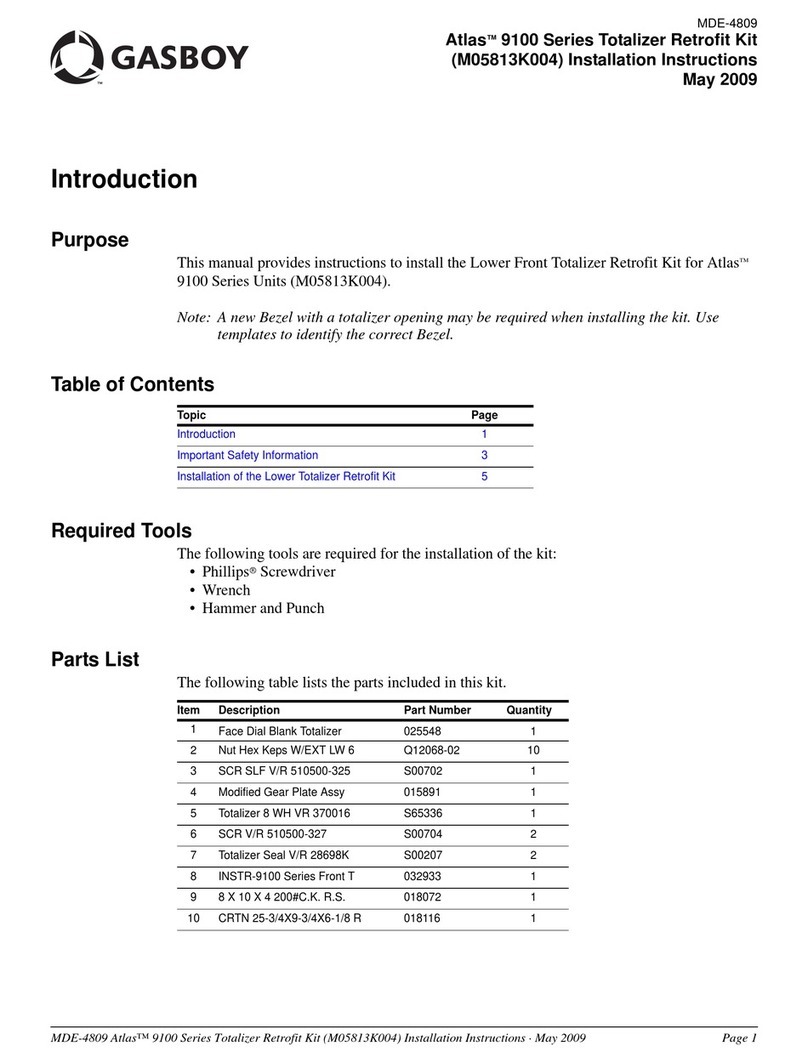

Parts List

The following table lists the parts required for installing the Atlas 9800 Electronics:

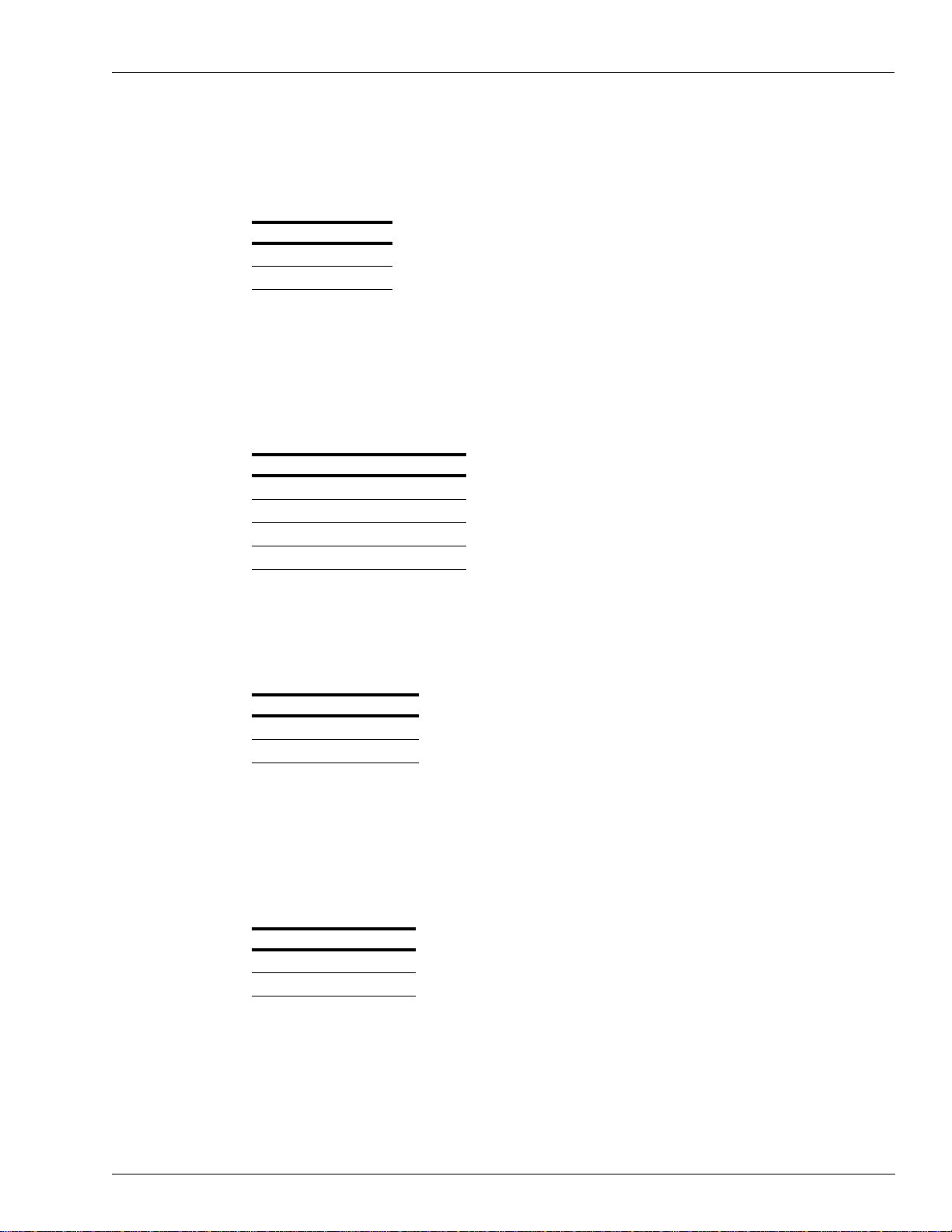

Item # Description Part Number Quantity

1Printed Circuit Assembly (PCA), Central Processing

Unit (CPU) Board

M06333KXXXX 1

2Kit, 115 VAC Power Supply to replace C06397 or

M07588A001

M12421K00X** 1

3Atlas 9800 Power Supply Assembly M15579A001 1

4Kit, 230 VAC Power Supply to replace C06489 or

M07588A003

M12422K00X** 1

MDE-4652F

Atlas® 9800 Electronics Field Installation Instructions

September 2019

Introduction

Page 2 MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019

Related Documents

Document

Number Title GOLDSM Library

MDE-4255 Gasboy Warranty Policy Statement for USA and Canada • Gasboy Policy Documents

• Gasboy Safety and Warranty Docs

MDE-4334 Commercial and Retail Series Atlas Start-up/Service Manual Gasboy Atlas Pumps/Dispensers

MDE-4363 Atlas Fuel Systems Owner’s Manual Gasboy Atlas Pumps/Dispensers

MDE-4998 Main Display Assembly (M12158A004) for Atlas 9800 Gasboy Atlas Pumps/Dispensers

Abbreviations and Acronyms

Term Description

ASC Authorized Service Contractor

ATC Automatic Temperature Control

CFN Cash Flow Network

CPU Central Processing Unit

DEF Diesel Exhaust Fluid

EEPROM Electronically Erasable Programmable Read Only Memory

EM Electro-mechanical

FMS Fuel Management System

GOLD Gilbarco Online Documentation

J-box Junction Box

LED Light Emitting Diode

NEC National Electric Code

NFPA National Fire Protection Association

OSHA Occupational Safety and Hazard Association

PCA Printed Circuit Assembly

PCU Pump Control Unit

STP Submersible Turbine Pump

Warranty

For warranty information, refer to MDE-4255 Gasboy Warranty Policy Statement for USA and

Canada. For any warranty-related queries, contact Gasboy’s Warranty Department at its

Greensboro location.

5PCA, Serial Electronically Erasable Programmable

Read Only Memory (EEPROM)*

M06656K00X 1

• 9800K Software M06656K001

• 9850 Software M06656K002

• 9840K Software M06656K003

• 9800Q Software M06656K004

• 9840Q Software M06656K005

• 9800 ECAL Software M06656K006

*M06656K100 Kit of the latest versions of all these boards is also available.

**X refers to the required number of displays, where X=1 for 1 display, X=2 for 2 displays,

X=3 for 4 displays.

Item # Description Part Number Quantity

MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019 Page 3

Important Safety Information

Important Safety Information

Notes: 1) Save this Important Safety Information section

in a readily accessible location.

2) Although DEF is non-flammable, Diesel is

flammable. Therefore, for DEF cabinets that are

attached to Diesel dispensers, follow all the

notes in this section that pertain to flammable

fuels.

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining, or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock, or

pressure release could occur and cause death or serious injury,

if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain, or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is how

to stop all fuel flow to the pump/dispenser and island. Locate

the switch or circuit breakers that shut off all power to all fueling

equipment, dispensing devices, and Submerged Turbine

Pumps (STPs).

Total Electrical Shut-Off Before Access

Any procedure that requires access to electrical components or

the electronics of the dispenser requires total electrical shut off

of that unit. Understand the function and location of this switch

or circuit breaker before inspecting, installing, maintaining, or

servicing Gilbarco equipment.

Evacuating, Barricading, and Shutting Off

Any procedure that requires access to the pump/dispenser or

STPs requires the following actions:

• An evacuation of all unauthorized persons and vehicles

from the work area

• Use of safety tape, cones, or barricades at the affected

unit(s)

Read the Manual

Read, understand, and follow this manual and any other labels

or related materials supplied with this equipment. If you do not

understand a procedure, call a Gilbarco Authorized Service

Contractor or call the Gilbarco Support Center at

1-800-800-7498. It is imperative to your safety and the safety

of others to understand the procedures before beginning work.

Follow the Regulations

Applicable information is available in National Fire Protection

Association (NFPA) 30A; Code for Motor Fuel Dispensing

Facilities and Repair Garages, NFPA 70; National Electrical

Code (NEC), Occupational Safety and Health Administration

(OSHA) regulations and federal, state, and local codes. All

these regulations must be followed. Failure to install, inspect,

maintain, or service this equipment in accordance with these

codes, regulations, and standards may lead to legal citations

with penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gilbarco replacement parts and retrofit kits

on your pump/dispenser. Using parts other than genuine

Gilbarco replacement parts could create a safety hazard and

violate local regulations.

Federal Communications Commission (FCC) Warning

This equipment has been tested and found to comply with the

limits for a Class A digital device pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is

operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy, and if

not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to

correct the interference at his own expense. Changes or

modifications not expressly approved by the manufacturer could

void the user’s authority to operate this equipment.

Safety Symbols and Warning Words

This section provides important information about warning

symbols and boxes.

Alert Symbol

This safety alert symbol is used in this manual and on

warning labels to alert you to a precaution which must be

followed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible injury

or death.

Signal Words

These signal words used in this manual and on warning labels

tell you the seriousness of particular safety hazards. The

precautions below must be followed to prevent death, injury, or

damage to the equipment:

DANGER: Alerts you to a hazard or unsafe practice

which will result in death or serious injury.

WARNING: Alerts you to a hazard or unsafe practice

that could result in death or serious injury.

CAUTION with Alert symbol: Designates a hazard or

unsafe practice which may result in minor injury.

CAUTION without Alert symbol: Designates a hazard or

unsafe practice which may result in property or

equipment damage.

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled or

leaking fuels cause vapors. Even filling customer tanks will

cause potentially dangerous vapors in the vicinity of the

dispenser or island.

DEF is non-flammable. Therefore, explosion and fire safety

warnings do not apply to DEF lines.

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier’s station

WILL NOT shut off electrical power to the

pump/dispenser. This means that even if you

activate these stops, fuel may continue to flow

uncontrolled.

You must use the TOTAL ELECTRICAL

SHUT-OFF in the case of an emergency and not

the console’s ALL STOP and PUMP STOP or

similar keys.

!

WARNING

!

!

!

!

Important Safety Information

Page 4 MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019

No Open Fire

Open flames from matches, lighters, welding torches or

other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power

tools, burning cigarettes, cigars or pipes can also ignite fuels and

their vapors. Static electricity, including an electrostatic charge on

your body, can cause a spark sufficient to ignite fuel vapors.

Every time you get out of a vehicle, touch the metal of your

vehicle, to discharge any electrostatic charge before you

approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Familiarize

yourself with Cardiopulmonary Resuscitation (CPR) methods, if

you work with or around high voltages. This information is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and caution

them not to activate power while you are working on the

equipment. Use the OSHA Lockout/Tagout procedures. If you

are not familiar with this requirement, refer to this information in

the service manual and OSHA documentation.

Working With Electricity Safely

Ensure that you use safe and established practices in working

with electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Ensure that grounding connections

are properly made. Take care that sealing devices and

compounds are in place. Ensure that you do not pinch wires

when replacing covers. Follow OSHA Lockout/Tagout

requirements. Station employees and service contractors need to

understand and comply with this program completely to ensure

safety while the equipment is down.

Hazardous Materials

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly. Ensure that you

clean hands after handling equipment. Do not place any

equipment in the mouth.

In an Emergency

Inform Emergency Personnel

Compile the following information and inform emergency

personnel:

• Location of accident (for example, address, front/back of

building, and so on)

• Nature of accident (for example, possible heart attack, run

over by car, burns, and so on)

• Age of victim (for example, baby, teenager, middle-age,

elderly)

• Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on)

• Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on).

IMPORTANT: Oxygen may be needed at scene if gasoline has

been ingested or inhaled. Seek medical advice immediately.

Lockout/Tagout

Lockout/Tagout covers servicing and maintenance of machines

and equipment in which the unexpected energization or start-up

of the machine(s) or equipment or release of stored energy could

cause injury to employees or personnel. Lockout/Tagout applies

to all mechanical, hydraulic, chemical, or other energy, but does

not cover electrical hazards. Subpart S of 29 CFR Part 1910 -

Electrical Hazards, 29 CFR Part 1910.333 contains

specific Lockout/Tagout provision for electrical hazards.

The pump/dispenser contains a chemical known to the State

of California to cause cancer.

WARNING

!

The pump/dispenser contains a chemical known to the State

of California to cause birth defects or other reproductive

harm.

WARNING

!

Gilbarco Veeder-Root encourages the recycling of our

products. Some products contain electronics, batteries,

or other materials that may require special

management practices depending on your location.

Please refer to your local, state, or country regulations

for these requirements.

Gasoline/DEF ingested may cause unconsciousness

and burns to internal organs. Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene. Seek medical

advice immediately.

DEF generates ammonia gas at higher temperatures. When

opening enclosed panels, allow the unit to air out to avoid

breathing vapors.

If respiratory difficulties develop, move victim away from source

of exposure and into fresh air. If symptoms persist, seek medical

attention.

WARNING

!

WARNING

!

Gasoline inhaled may cause unconsciousness and

burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline/DEF spilled in eyes may cause burns to eye

tissue.

Irrigate eyes with water for approximately

15 minutes.

Seek medical advice immediately.

WARNING

!

Gasoline/DEF spilled on skin may cause burns.

Wash area thoroughly with clear water.

Seek medical advice immediately.

WARNING

!

DEF is mildly corrosive. Avoid contact with eyes, skin, and

clothing. Ensure that eyewash stations and safety showers are

close to the work location. Seek medical advice/recommended

treatment if DEF spills into eyes.

WARNING

!

MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019 Page 5

Atlas 9800 Parts

Atlas 9800 Parts

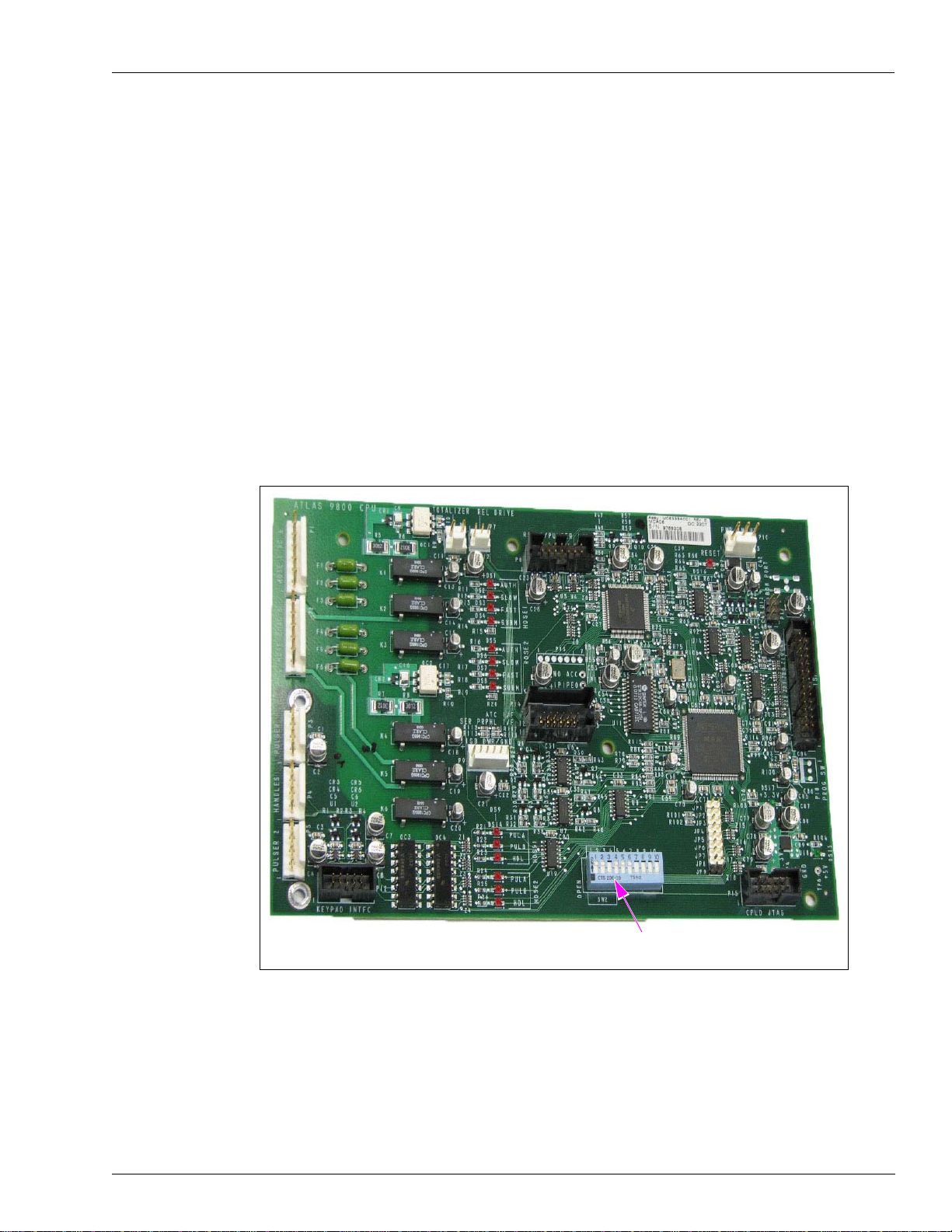

Atlas 9800 CPU Board (M06333KXXXX)

Features of the Atlas 9800 CPU board are as follows:

• Accepts either 115 or 230 VAC on AUTH line inputs.

• Compatible with all RS-485 I/F Boards (C06389, M05248A001, M06725A001).

• Compatible with all Pulse-out I/F Boards (C06425, C06746, M05158A001,

M05158A002, M05158A003, M06587A001).

• Replaces 9800 CPU Boards (C06391, C06392, C06393, C06394, C06500, C06501,

C06502, C06503, M05346A001, M05346A002, M05346A003, M05346A004).

• Requires new Power Supply M15579A001 (refer to “Atlas 9800 Power Supply Assembly

(M15579A001)” on page 6).

• Requires Automatic Temperature Control (ATC) Kit (M08218K001) for models

(9850A/Q, 9850K, 9852A/Q, 9853A/Q, and 9840A/Q) where ATC is present.

Figure 1: Atlas 9800 CPU Board

The ON position (Closed) of the switch is

towards the center of the board.

Atlas 9800 Parts

Page 6 MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019

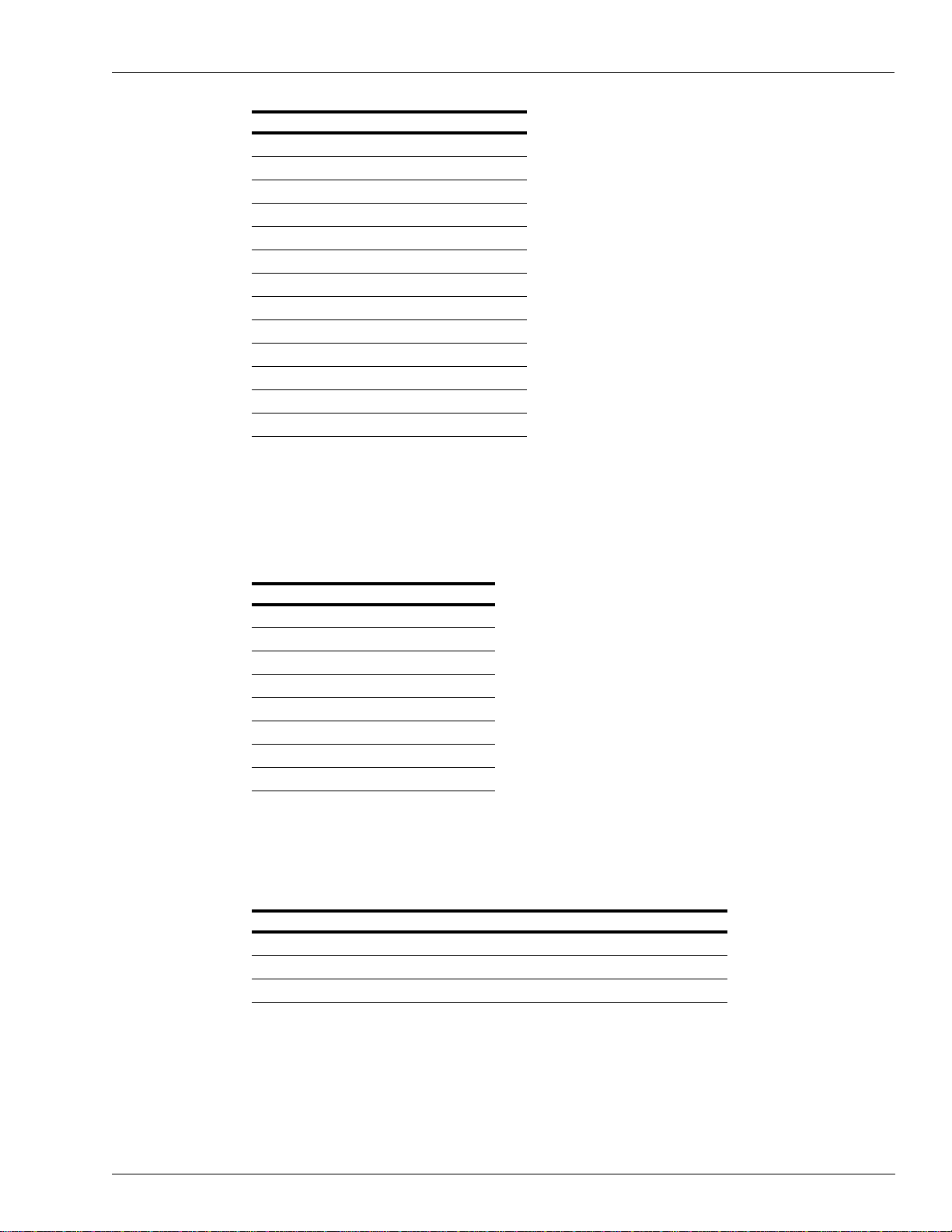

The following table lists the CPU boards with corresponding software type and pump type:

Note: The following software types can be loaded on any one of the CPU boards by using the

appropriate Serial EEPROM Board (M06656K00X).

CPU Boards Software Type Pump Type

M06333K9800K 9800K 9852K, 9853K

M06333K9850 9850 9850A*, 9850Q, 9850K

M06333K9840K 9840K 9840K

M06333K9800AQ 9800Q 9852A/Q, 9853A/Q, 9822A/Q, 9823A/Q/K

M06333K9840AQ 9840Q 9840A, 9840Q

M06333KECAL 9800K 9862KX, 9872KX

*If the serial number is lower than 472238, use the M06333K9800AQ CPU

Board or appropriate EEPROM board.

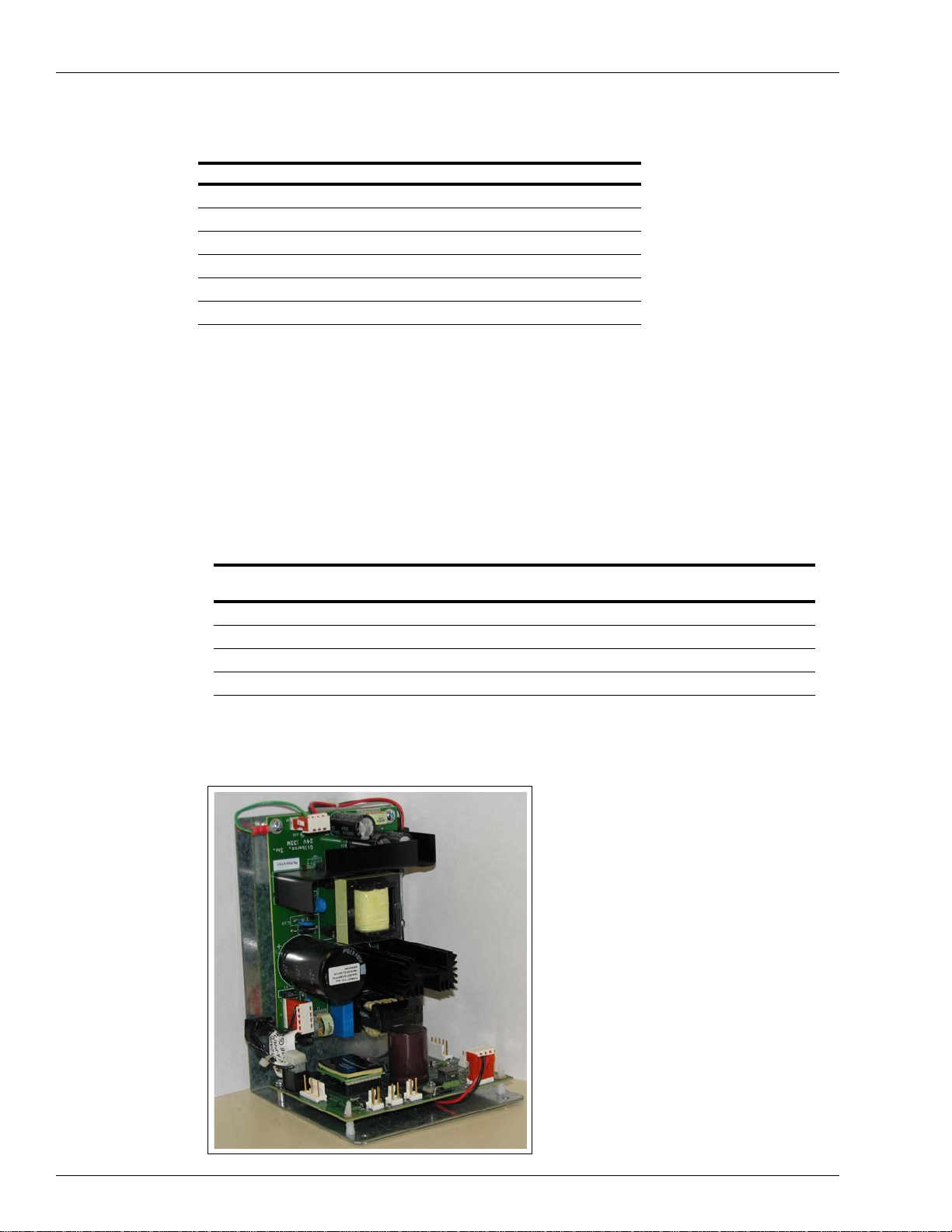

Atlas 9800 Power Supply Assembly (M15579A001)

Features of the Atlas 9800 power supply are as follows:

• Required for M06333 CPU Boards (refer Figure 1 on page 5).

• Compatible with the following 9800 CPU Boards: C06391, C06392, C06393, C06394,

C06500, C06501, C06502, C06503, M05346A001, M05346A002, M05346A003,

M05346A004, and M06333KXXXX.

• Required for Atlas PRIME.

• Replaces current power supplies (9800) as shown in the following table:

Description Old Power Supply Part Number

Replacement Power Supply

Part Number

Kit to replace 115 VAC PS with Battery C06397, M07588A001 M12421K00X*

115 VAC PS without Battery C06396, M07588A002 M15579A001

Kit to replace 230 VAC PS with Battery C06489, M07588A003 M12422K00X*

230 VAC PS without Battery C06488, M07588A004 M15579A001

*X refers to the required number of displays, where X=1 for 1 display, X=2 for 2 displays, X=3 for 4 displays.

Figure 2: Atlas 9800 Power Supply Assembly

MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019 Page 7

Atlas 9800 Parts

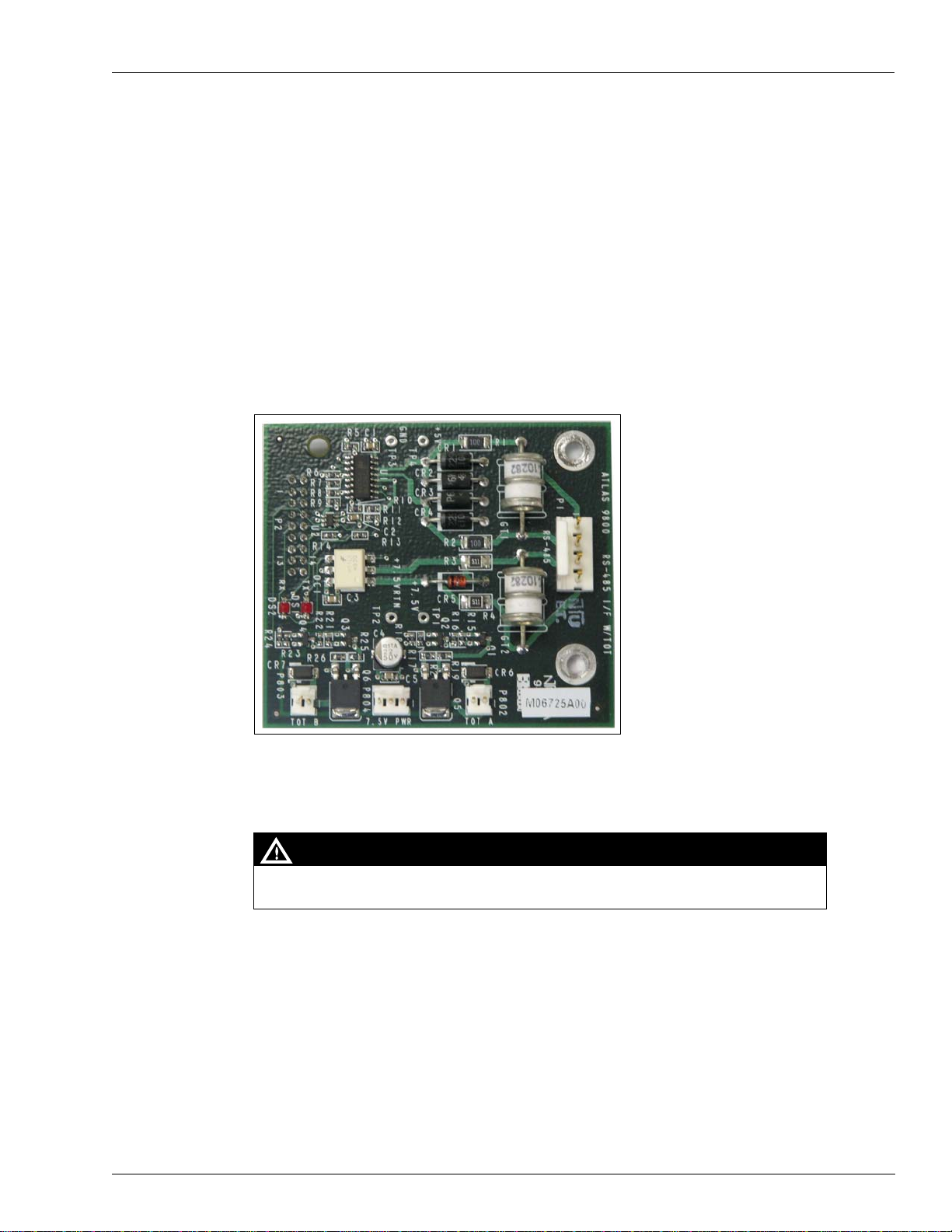

Atlas 9800 Serial EEPROM Board (M06656K00X)

Features of the Atlas 9800 Serial EEPROM board are as follows:

• Used to reprogram the software on the new Atlas 9800 CPU board (refer Figure 1 on

page 5

Serial EEPROM

Board Software Type Pump Type

M06656K001* 9800K 9852K, 9853K

M06656K002* 9850 9850A, 9850Q, 9850K

M06656K003* 9840K 9840K

M06656K004* 9800Q 9852A/Q, 9853A/Q,

9822A/Q, 9823A/Q/K

M06656K005* 9840Q 9840A, 9840Q

M06656K006* 9800K 9862KX, 9872KX

*M06656K100 Kit of the latest versions of all of these

boards is also available.

).

• Provides Light Emitting Diode (LED) indicators to monitor software transfer.

Figure 3: LED Indicators

LEDs for Indication

Atlas 9800 Parts

Page 8 MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019

Atlas 9800 Pulse-out I/F Board with EM Totalizer Drive (M06587A001)

Features of the Atlas 9800 Pulse-out I/F board with Electro-mechanical (EM) Totalizer Drive

are as follows:

• Provides up to two dual channel outputs per hose.

• Compatible with 9800 CPU Boards (C06391, C06392, C06393, C06394, C06500,

C06501, C06502, C06503, M05346A001, M05346A002, M05346A003, M05346A004,

and M06333KXXXX).

• Can be used in place of existing 9800 dual channel Pulse-out I/F Boards (C06746,

M05158A002).

• Can be used in place of existing 9800 dual Pulse-out I/F Boards (C06425, M05158A001).

• Can be used in place of existing 9800 I/F Board (M05158A003).

Figure 4: Atlas 9800 Pulse-out I/F Board with EM Totalizer Drive

MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019 Page 9

Accessing Electronic Components

K-Pump RS-485 with Totalizer (M06725A001)

The features of K-Pump RS-485 with Totalizer board are as follows:

• Allows RS-485 communications between 9800 and a Cash Flow Network (CFN) PLUS

System, TopKAT™ PLUS Electronic System or Atlas PRIME.

• Compatible with 9852K, 9853K, 9850K, 9840K, 9852A/Q, 9853A/Q, 9840A/Q,

9822A/Q, 9823A/Q/K, 9862KX, 9872KX.

• Compatible with 9800 CPU Boards (C06391, C06392, C06393, C06394, C06500,

C06501, C06502, C06503, M05346A001, M05346A002, M05346A003, M05346A004,

M06333KXXXX).

• Can be used in place of previous 9800 RS-485 I/F Board C06389 and M05248A001.

• Required for Atlas PRIME.

Figure 5: K-Pump RS-485 with Totalizer

Accessing Electronic Components

Always remove AC power from the pump/dispenser before servicing the unit. Failure to

turn off the unit before servicing may result in serious injury or death.

WARNING

To access the electronic components, proceed as follows:

1Unlock and remove the front panel on the pump/dispenser.

2Remove the two bolts/screws located over the tabs of the bezel assembly. Lift the bezel

assembly upwards and out to remove.

Note: For A and Q models with front load nozzle, remove the nozzle boot plastic shroud

(two screws) before removing the bezel assembly.

3Loosen the two screws that secure the display panel, remove them if required, and pivot the

display panel down.

Installing Atlas 9800 Power Supply Assembly (M15579A001)

Page 10 MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019

Installing Atlas 9800 Power Supply Assembly

(M15579A001)

If the existing power supply is a working M07588A00X or M15579A001 assembly, proceed

to “Installing Atlas 9800 CPU Board (M06333KXXXX)” on page 12.

To install the Atlas 9800 power supply, proceed as follows:

Always remove AC power from the pump/dispenser before servicing the unit. Failure to

turn off the unit before servicing may result in serious injury or death.

WARNING

1Check the existing power supply. If the existing supply is not a M07588A00X or

M15579A001, or if it is not working, it must be replaced. For the correct replacement part

number, refer to “Atlas 9800 Power Supply Assembly (M15579A001)” on page 6.

2Ensure to disconnect AC power to the pump/dispenser.

3Disconnect the AC power cable from the P3 connector. Disconnect the DC cables from the P2

and P1 connectors.

4Unscrew and remove all the screws that hold the power supply. Retain the screws for installing

the new power supply.

5Remove the power supply. For models with plastic standoffs, after the screws are removed,

carefully unsnap the power supply from the standoffs and remove it. Remove any standoffs

that may have remained on the power supply and place them back into the plate where the

power supply was mounted.(See Figure 6 on page 11)

MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019 Page 11

Installing Atlas 9800 Power Supply Assembly (M15579A001)

Figure 6: Power Supply

M15579A001 Assembly

replaces obsolete single

board power supplies

Obsolete single board power

supply shown for reference

6Install the new power supply on the standoffs. Ensure that the P1 connector is closest to the

CPU board and P3 connector is away from the CPU. If the pump model is 9822 or 9823, the

P1 connector is closest to the pump-handle assembly.

7Reinstall the screws removed in step 4 on page 10. For models with plastic standoffs, carefully

push the power supply onto the plastic standoffs before installing the screws.

8Reconnect the following:

• Cables and AC power to the P3 connector.

• Display backlight to the P2 connector.

• CPU DC to the P1 connector.

Installing Atlas 9800 CPU Board (M06333KXXXX)

Page 12 MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019

Installing Atlas 9800 CPU Board (M06333KXXXX)

To install the Atlas 9800 CPU board, proceed as follows:

Always remove AC power from the pump/dispenser before servicing the unit. Failure to

turn off the unit before servicing may result in serious injury or death.

WARNING

1Check the existing power supply. If the existing supply is not a M07588A00X or

M15579A001 assembly, it must be replaced. For details, refer to “Installing Atlas 9800 Power

Supply Assembly (M15579A001)” on page 10.

2Ensure that the AC power to the pump/dispenser is disconnected. Remove the DC cable from

the P1 connector on the power supply.

3If the pump/dispenser does not have ATC installed, proceed to step 4. If the pump/dispenser

model is one of the following - 9850A/Q, 9850K, 9852A/Q, 9853A/Q, 9840A/Q, the ATC

support bracket (that holds the ATC black box) must be replaced. Use the M08218K001 Kit to

install the new bracket.

4If the pump/dispenser has a RS-485 or pulse-out I/F board, remove the screws that secure the

I/F board and disconnect it from the existing CPU board.

5Disconnect all cables going to the connectors on the CPU board. Ensure that you note the

connectors and cables so that they can be reconnected to the correct connector.

6Unscrew and remove all the screws securing the CPU board. Retain the screws for installing

the new CPU board.

7Remove the CPU board. For models with plastic standoffs, carefully unsnap the CPU board

from the standoffs and remove it. Remove any standoffs that may have remained on the CPU

board and place them back into the plate where the board was mounted.

8The new CPU Board (M06333KXXXX) can be configured for various operating conditions

using the jumpers JP1 to JP9. Check these jumpers and change, if required. Jumper settings

must be changed with the power to the pump/dispenser “Off”. CPU board only reads new

jumper settings during power up.

JP1 - Baud Rate

This jumper selects the baud rate for the RS-485 communications.

Baud Rate JP1

1200 Jumpered

9600 Open

MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019 Page 13

Installing Atlas 9800 CPU Board (M06333KXXXX)

JP2 - Mode

This jumper selects the mode in which the pump/dispenser operates. Set the mode to “Online”

if the pump/dispenser communicates to a controlling system (for example, Gasboy TopKAT

PLUS or CFN PLUS System). Set the mode to “Standalone” for all other configurations [for

example, Gasboy Series 1000 Fuel Management System (FMS) or no controlling system].

Mode JP2

Standalone Jumpered

Online Open

JP3, JP4 - Leak Detect Delay

These jumpers select the delay time used by leak detectors in Submersible Turbine Pump

(STP) applications. The delay time is the period between the activation of the submersible

pump and the activation of the slow flow valve. The delay time must be set according to the

type of leak detector installed on the STP to allow for a normal leak test for each transaction.

The delay time must be set to 0 seconds for suction pumps.

Delay Time JP3 JP4

0 seconds Jumpered Jumpered

4 seconds Jumpered Open

5 seconds Open Jumpered

6 seconds Open Open

JP5 - Hose Pressurization

For US Gallons (always in Hose Pressurization mode), this jumper is ignored. This jumper is

used to determine if hose pressurization is used. If enabled, the slow flow valve is opened

before reset is complete, to allow the hose to be pressurized before fuel dispensing begins.

Pressurization JP5

Enabled Jumpered

Disabled Open

JP6 - Authorization

This jumper allows activation or non-activation of the pump/dispenser from an external source

(for example, an FMS). When jumpered, a 115/230 VAC signal must be present on the Control

Feed/authorization line (refer to the wiring diagram for your model pump/dispenser) for pump

activation to occur (required setting for Gasboy Series 1000). When open, the Control Feed

line signal is ignored (required setting for Standalone mode).

Authorization JP6

Enabled Jumpered

Disabled Open

Note: For JP6 Authorization, in Standalone mode, the authorization signal must be present to

activate the pump.

Installing Atlas 9800 CPU Board (M06333KXXXX)

Page 14 MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019

JP7 - Electronic Totalizers

This jumper must be open for normal operation (electronic totals protected). When jumpered,

this allows the electronic totals to be reset.

Totalizers JP7

Reset Jumpered

Normal Open

JP8 - Pump Disable Detection

This jumper allows the pump/dispenser to detect or ignore a pump disable (RS-485 break

character). When detection is enabled, the pump/dispenser will monitor the RS-485

communications for a pump disable signal. When received, any transaction in progress will be

halted and then completed. This setting must only be used when the pump/dispenser is

communicating to a Gasboy CFN System. This setting must be disabled (jumpered) for all

other configurations (for example, Gasboy TopKAT or Standalone).

Detection JP8

Disabled Jumpered

Enabled Open

JP9

This jumper is spare and not in use.

9CPU Board (M06333KXXXX) can also be configured for various operating conditions using

the switch positions SW2-1 through SW2-10. Check these switches and change, if required.

Switch settings must be changed with the power to the pump/dispenser “Off”. CPU board only

reads new switch settings during power up.

Note: A switch in the closed position indicates that the switch is “On” (towards the center of

the CPU board).

SW2-1 through SW2-4

These four switches serve a dual purpose: as an address setting when communicating through

RS-485 I/F (for example, Gasboy CFN systems), or as a pulser output rate selector when in

Pulse-out I/F configuration (for example, Gasboy Series 1000 FMS).

Address Switches (if JP2 is Open)

A unique address identifier must be set when the pump/dispenser is communicating through

RS-485 I/F. The unique address must correspond to the address of a unique Pump Control Unit

(PCU) configured in a Gasboy CFN or TopKAT system. There are 16 possible address

combinations and up to 16 pumps (single or twin) can be connected through the RS-485 I/F.

Addressing must start at 1 and continue sequentially through 16. The physical wiring order

does not have to correspond with the address order; that is, the first pump/dispenser on the

RS-485 does not have to be address 1.

Address SW2-1 SW2-2 SW2-3 SW2-4

1Closed Closed Closed Closed

2Open Closed Closed Closed

3Closed Open Closed Closed

MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019 Page 15

Installing Atlas 9800 CPU Board (M06333KXXXX)

Pulse Output Rate Switches (if JP2 is Jumpered)

When the pump/dispenser is connected to an external controlling equipment that requires

pulse output signals (for example, Gasboy Series 1000), the pulse signals are sent through the

pulse-out I/F board. Setting Switches SW2-1 through SW2-3 configures the Pulse-out rate

required by the monitoring equipment. Pulse-out rate represents the pulses per unit (gallon,

liter, or imperial gallon).

Pulse Rate SW2-1 SW2-2 SW2-3

1:1 Closed Closed Closed

10:1 Open Closed Closed

100:1 Closed Open Closed

250:1 Open Open Closed

500:1 Closed Closed Open

None Open Closed Open

None Closed Open Open

None Open Open Open

Maximum pulse output rate that can be achieved depends on the model of the pump/dispenser

and the unit of measure. Pulse output rate of 1000:1 is not supported when using the CPU

board.

Note: 9800 refers to models 9852, 9853, 9822, and 9823.

Unit of Measure 9800 Models 9840A/Q Models 9840K Models 9850 Models

US Gallons 500:1 500:1 500:1 100:1

Liters 100:1 100:1 10:1 10:1

Imperial Gallons 500:1 500:1 500:1 100:1

Note: If a valid pulse-out rate is not selected, the CPU will not output pulses.

4Open Open Closed Closed

5Closed Closed Open Closed

6Open Closed Open Closed

7Closed Open Open Closed

8Open Open Open Closed

9Closed Closed Closed Open

10 Open Closed Closed Open

11 Closed Open Closed Open

12 Open Open Closed Open

13 Closed Closed Open Open

14 Open Closed Open Open

15 Closed Open Open Open

16 Open Open Open Open

Address SW2-1 SW2-2 SW2-3 SW2-4

Installing Atlas 9800 CPU Board (M06333KXXXX)

Page 16 MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019

Leading zeros are always suppressed in the tens and hundreds place to the left of the decimal

point. In Standalone mode, positions to the right of the decimal point are displayed based on

the pulse output rate and unit of measure selected.

Pulse Rate Gallons - US or Imperial Liters and/or 9850

1:1 XXX XXXX

10:1 XXX.X XXXX.X

100:1 XXX.XX XXXX.XX

250:1 XXX.XXX XXXX.XX

500:1 XXX.XXX XXXX.XX

Timeout Switch (if JP2 is Jumpered)

When the pump/dispenser is in the Standalone mode, including Pulse-out I/F configurations, it

will turn off an active hose outlet if it does not detect input pulses for 4 minutes and 15

seconds.

Timeout SW2-4

Enabled Closed

Disabled Open

SW2-5 and SW2-6 - Unit of Measure Selection

These two switches set the unit of measure (US gallons, liters, or Imperial gallons) that the

pump/dispenser will use to meter fuel.

Unit of Measure SW2-5 SW2-6

US Gallons Closed Closed

Liters Open Closed

Imperial Gallons Closed Open

NOT USED (default US Gallons) Open Open

SW2-7 - EM Totalizer Enable

This switch is only used on K model pumps/dispensers (excluding the 9850K model). When

closed (“On”), it enables the pump/dispenser to drive electro-mechanical totalizers used on

some K models pump. On A and Q models, this switch must be set to disabled (open).

EM Totalizer SW2-7

Enabled Closed

Disabled Open

SW2-8 - BDM Enable

This switch must be open for normal operation.

SW2-9 - Software Load Enable

This switch must be open for normal operation. When this switch is closed, it enables loading

the new software (refer to “Loading New CPU Software” on page 20).

SW2-10

This switch is not used (or close it to ground input).

MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019 Page 17

Installing Atlas 9800 CPU Board (M06333KXXXX)

10 Set the new CPU board on the standoffs. Reinstall the screws removed in step 6 on page 12.

For models with plastic standoffs, ensure that the metal standoffs are under the mounting holes

located between P2 and P3, and the outside corner next to P5. Carefully push the new CPU

board onto the standoffs before installing the screws.

11 Reconnect all the cables (P1 to P9, and P11), if applicable. Reconnect the DC cable to P1 of

the power supply.

12 Apply power to the pump/dispenser and note the display(s). The first set of numbers displayed

will be the software version (for example, 06013), the second set is the software type (for

example, 9800 1), and the third set is the firmware version (for example, 01008).

Ensure that the displayed software type is correct for the pump/dispenser model that the CPU

is installed in (refer to the following table). If it is, proceed to step 13. If not, proceed to

“Loading New CPU Software” on page 20.

Displayed Software Type Corresponding Pump/Dispenser Model

“9800 1” Corresponds to the 9800Q Software:

9852A/Q, 9853A/Q, 9822A/Q, 9823A/Q/K

“9800 2” Corresponds to the 9800K Software:

9852K, 9853K, 9862KX, 9872KX

“9800 3”* Corresponds to the 9800K Software:

9862KX*, 9872KX*

“9840 1” Corresponds to the 9840Q Software:

9840A, 9840Q

“9840 2” Corresponds to the 9840K Software:

9840K

“9850” Corresponds to all 9850 Software:

9850A, 9850Q, 9850K

*Note: Version 06.0.20 or later.

13 Reassemble the pump/dispenser by proceeding to “Accessing Electronic Components” on

page 9 and follow the steps in reverse order.

Installing Atlas 9800 Pulse-out I/F with EM Totalizer Drive Board (M06587A001)

Page 18 MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019

Installing Atlas 9800 Pulse-out I/F with EM Totalizer Drive

Board (M06587A001)

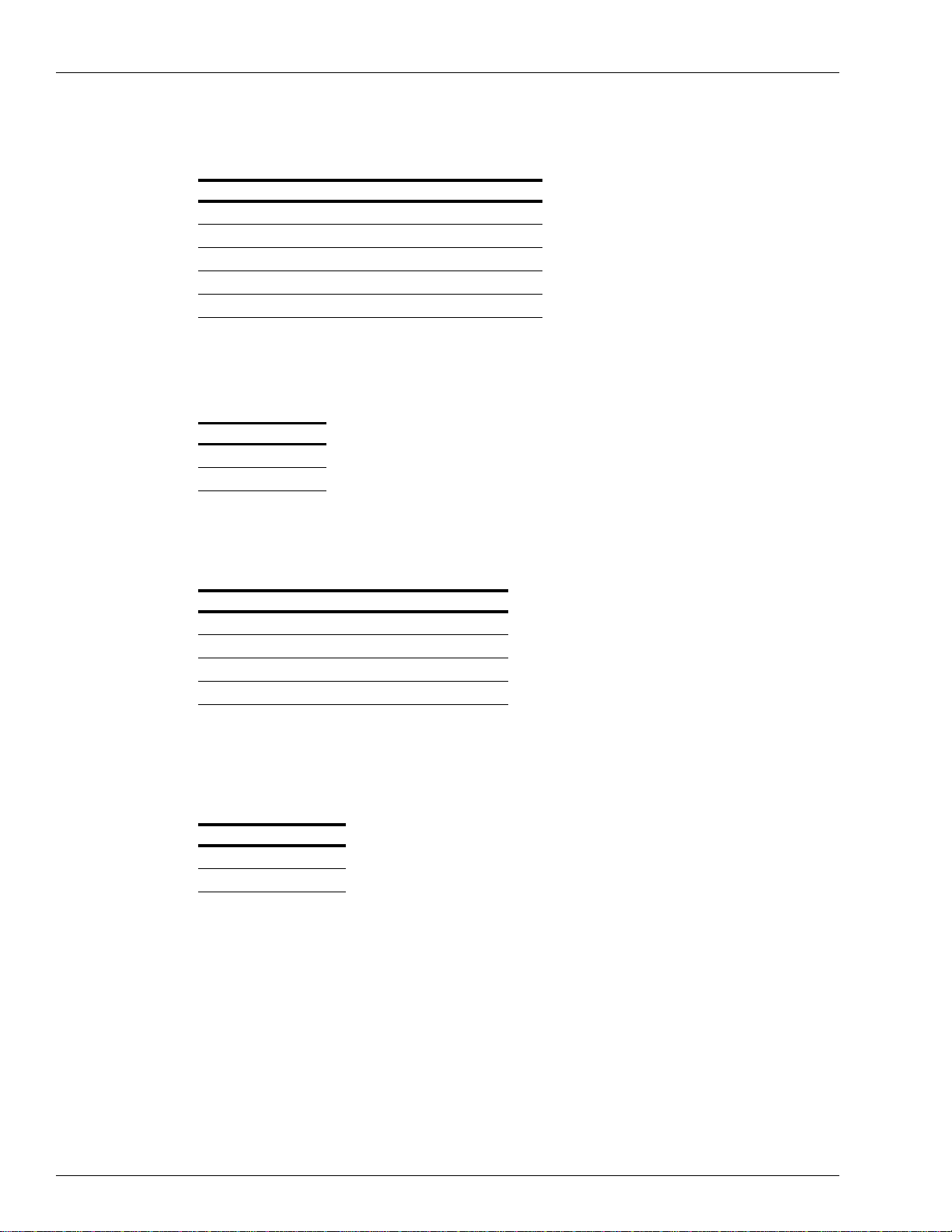

JP1, JP2, and JP3

This board assembly can be configured for use in one of the following pump/dispenser

configurations:

• Dual Channel, Single Hose Pulse-out I/F (refer Figure 7 on page 19)

• Single Channel, Dual/Single Hose Pulse-out I/F (refer Figure 8 on page 19)

• Dual Channel, Dual Hose Pulse-out I/F (refer Figure 9 on page 19)

The following table shows the jumper settings and wires to connect to in the Junction Box (J-

box), based on the configuration.

Check JP1 - JP3 jumpers and change them, if required. The jumper settings must be changed

only when the power to the pump/dispenser is removed, to protect the circuit that they are

connected to.

Default configuration is Single Channel, Dual/Single Hose Pulse-out I/F. When configured for

Dual Channel, Single Hose Pulse-out I/F, or Single Channel, Dual/Single Hose Pulse-out I/F,

the P3 Connector is not connected.

When configured for Dual Channel, Dual Hose Pulse-out I/F, the P3 connector is used.

Jumper Settings

Single Channel, Dual/Single

Hose Pulse-out I/F

(Default Setting)

Dual Channel, Single Hose

Pulse-out I/F

Dual Channel, Dual Hose

Pulse-out I/F

Wire Color JP1 Position 1

JP2 Position 1

JP3 Open

JP1 Position 2

JP2 Position 2

JP3 Open

JP1 Position 2

JP2 Position 2

JP3 Jumpered

Red Pulse out Side 1 Pulse out Side1A Pulse out Side 1A

Green Pulse out Side 2 Pulse out Side1B Pulse out Side 1B

White Common Return Side 1A Return Side 1A Return

Black No Connection Side 1B Return Side 1B Return

Brown No Connection No Connection Pulse out Side 2A

Orange No Connection No Connection Pulse out Side 2B

Yell ow No Connection No Connection Side 2A Return

Gray No Connection No Connection Side 2B Return

JP4 and JP5

When this board is used in a model A or Q pump/dispenser or 9850K, jumpers JP4 and JP5 are

set to the Q/A position. When this board is used for all other K models except 9850K, these

jumpers must be in the K position.

MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019 Page 19

Installing Atlas 9800 Pulse-out I/F with EM Totalizer Drive Board (M06587A001)

Configurations

Figure 7: Dual Channel, Single Hose Pulse-out I/F

Pulse Side 1

Side 1B Output

Side 1A Output

Side 1A Return

Side 1A Return

Figure 8: Single Channel, Dual/Single Hose Pulse-out I/F

Pulse Side 1

Pulse Side 2

Side 1 Output

Side 2 Output

Common Return

Figure 9: Dual Channel, Dual Hose Pulse-out I/F

Pulse Side 1

Side 1A Output

Side 1B Output

Side 1A Return

Side 1B Return

Pulse Side 2

Side 2A Output

Side 2B Output

Side 2A Return

Side 2B Return

Loading New CPU Software

Page 20 MDE-4652F Atlas® 9800 Electronics Field Installation Instructions · September 2019

Loading New CPU Software

CPU board is configured and programmed before shipping from the factory. In the event the

software must be changed, proceed as follows:

Always remove AC power from the pump/dispenser before servicing the unit. Failure to

turn off the unit before servicing may result in serious injury or death.

WARNING

1Disconnect AC power to the pump/dispenser. Remove the DC cable from the P1 connector on

the power supply.

2Set switch SW2-9 to the closed (“ON”) position.

3Select the appropriate Atlas 9800 Serial EEPROM board for the software type you want to

load (refer to “Atlas 9800 Serial EEPROM Board (M06656K00X)” on page 7).

4Ensure that JP1 is not jumpered on the Serial EEPROM board assembly. Carefully insert into

the P14 connector located in the middle of the CPU board.

5Connect the DC cable to the P1 connector on the power supply. Connect AC power to the

pump/dispenser.

6At this point, on the Serial EEPROM board assembly, the green “PWR” and yellow “BUSY”

LEDs will illuminate. A few seconds later, the yellow “BUSY” LED will go off and the green

“OK” LED will illuminate, indicating that the download is successful. Ensure that the green

“OK” LED illuminates before proceeding. If the red “NOT OK” LED illuminates, repeat steps

1 to 6. If the red “NOT OK” LED illuminates after a second attempt, call your service

representative or contact Gasboy Technical Service.

7Disconnect AC power to the pump/dispenser. Remove the DC cable from the P1 connector on

the power supply.

8Set Switch SW2-9 to the open position.

Note: If SW2-9 is left in the closed position, the unit will not display the software version,

software type, and firmware version during power up.

9Carefully remove the Serial EEPROM board assembly from the P14 connector.

10 Connect the DC cable to the P1 connector on the power supply.

11 Connect AC power to the pump/dispenser.

Table of contents

Other Gasboy Dispenser manuals

Popular Dispenser manuals by other brands

Mityvac

Mityvac MV6412 user manual

Atlas Copco

Atlas Copco SDS Product instructions

Franke

Franke SD80 Installation and operating instructions

Vestergaard

Vestergaard LifeStraw manual

Hirschmann

Hirschmann Ceramus HF instruction manual

Tuthill

Tuthill Fill-Rite Owners installation, operation, and safety manual