GasDog GD-600 User manual

www.gasdog.com +86 773-280-9002

GD-600 User Manual

Industrial Fixed Detector

Please read carefully before using

1

Foreword

You are welcome to use the instrument of this product, and hope that this manual will bring

you convenience when you use the instrument. If you find any unclear, wrong or excessively

lengthy place in this manual, please contact the agent or after-sales service department in time.

Before you perform any operation on this instrument, please read this operation manual

carefully, and keep the manual properly so that you can refer to it in time for help in the future.

It is forbidden to disseminate all the contents of this manual without permission;

this manual only provides relevant information.

The company is committed to continuous improvement of product performance, and the

company reserves the right to improve any content in the manual without prior notice.

Please refer to the actual product for the color and style of the product and product.

www.gasdog.com +86 773-280-9002

2

Foreword

1. Instructions before use

2. Attentions

3. Product Description

4. Product features

5. Attachment configuration list

6. Technical Parameters

7. Instrument installation

8. Remote control instruction

9. Function Description

1. Power On/Off

1.1 Power On

1.2 Power Off

2. User Interface

2.1 Detection interface description

2.2 Main menu interface operation

2.3 Calibration

2.3.1 Fresh air/zero calibration

2.3.2 Span Calibration

2.4 Alarm set

2.4.1 High alarm value, low alarm value

2.5 Monitor

2.5.1 Pump On/Off

2.5.2 Address

2.5.3 Current Setting

2.5.4 Relay

2.5.5 Reset

2.5.6 Language Setting

2.6 Info

2.6.1 Monitor Info

2.6.2 Sensor Info

2.6.3 Firmware Upgrade

10. Common faults and solutions

11. Terms of Service

12. National standards for product development, design

and production

14

15

15

15

15

16

16

17

17

17

18

20

20

21

21

21

22

22

23

24

24

24

24

24

25

25

26

---------------------------------------------------

------------------------------------

---------------------------------------------

--------------------------------------

------------------------------------------

----------------------------

------------------------------------

-----------------------------------

------------------------------

----------------------------------

------------------------------------------

----------------------------------------------

----------------------------------------------

------------------------------------------

------------------------

------------------------

-------------------------------------------

--------------------------

-----------------------------------

---------------------------------------------

------------------

------------------------------------------------

-----------------------------------------

----------------------------------------------

---------------------------------------

-------------------------------------------------

-------------------------------------------------

-----------------------------------

---------------------------------------------------

-------------------------------------------

-------------------------------------------

------------------------------------

---------------------------

------------------------------------------

-----------

2

4

4

6

6

6

7

8

Contents

www.gasdog.com +86 773-280-9002

3

1` Please read carefully before using

Anyone who may use, maintain or repair the instrument should read this operating

manual carefully and only follow the operating manual to achieve the design level. Otherwise

the instrument will not work properly and will cause malfunction and damage to the

instrument.

Warning:

●Before using the instrument, please read the product manual carefully.

●It is strictly forbidden to open the cover when the power is on at the scene.

●It is strictly forbidden to replace the sensor with power on.

●The installation, debugging, setting and other operations must be carried out by

professionals.

● Gas calibration inspection should be carried out regularly, and the sensors that have

exceeded the valid period of use and have faults should be replaced in time.

●It is strictly forbidden to input gas with a gas concentration higher than the measuring

range to impact the sensor.

●Prevent the instrument from falling from a high place or subject to severe shocks.

●It is strictly forbidden to expose the instrument to a high-concentration corrosive gas

environment to work for a long time to prevent damage to the sensor.

●It is strictly forbidden to use it under high temperature and high humidity. If the humidity is

high, it must be equipped with a filter dehumidification device.

●Users are not allowed to repair or replace parts without authorization.

●Man-made damage is not covered by the warranty.

●It is not allowed to change the components or structures that affect the explosion-proof

performance at will, so as not to affect the explosion-proof performance.

www.gasdog.com +86 773-280-9002

4

2` Attentions

●Electricity safety: Ensure that the instrument shell is properly grounded.

●For safety reasons, this product can only be operated and maintained by professionals,

and this manual must be fully read and understood before operation and maintenance.

●Because the instrument is a bit heavy, at least two people are required when installing

it, pay attention to it, and carry it carefully. Otherwise, it may cause physical injury.

●When carrying the instrument, please wear gloves, otherwise it may cause

injury.

●During the installation process, be careful not to allow wire heads or other debris to enter

the left channel port of the instrument, otherwise it may cause fire, malfunction, or

malfunction.

Calibration warning:

●The gas detection instrument is a safety and life-saving measuring instrument. In order to

ensure the accuracy of measurement, toxic and catalytic combustible gas sensors should

be calibrated at least once every six months, and infrared sensors should be calibrated

once a year.

●The gas detector needs to be carefully tested or calibrated after an alarm

occurs.

www.gasdog.com +86 773-280-9002

5

3` Product Description

GD700 Industrial Fixed Detector is a fixed pump suction detection instrument used in

complex working environments such as emission gas, oil and gas industry,

pipelines,laboratories, etc. Its built-in brushless pump and suction sampling method make the

detection fast and accurate. It committed to providing users with a reliable, accurate and safe

gas detection program.

4` Product features

2.4-inch high-definition color screen, wide viewing angle, low power

consumption Built-in micro sampling pump

4-20mA current signal, RS485 digital signal, 1 set of relay signal output

Infrared remote control, convenient and quick

Supports multiple gas units switch

5` Attachment configuration list

Standard accessories:

(1) One gas detector

(2) One infrared remote controller

(3) One water and dust filter

(4) One manual

(5) Certificate of conformity, warranty

card (6) Packing box

Optional accessories:

(1) Switching power

supply (2) Alarm light

(3) High temperature

probe (4) Mounting

brackets

(5) Power adapter(24V

DC)(6) Other

www.gasdog.com +86 773-280-9002

6

6` Technical Parameters

Product size: 286*202*96mm (H x W x D)

Product weight: 3.4kg (3.8kg with alarm light)

Sensor: Electrochemical principle, PID principle, infrared principle, catalytic combustion

principle Gas measurement range: To be specified

Resolution: To be specified

Precision: ≤±5%F.S or ≤±10%F.S (depend on sensor type)

Pump flow: 0.6(±0.1)L/Min

Display: 2.4-inch high-definition color display

Display content: gas molecular formula, concentration, unit, pump status, etc.

Alarm: buzzer, alarm status prompt on the display

Power supply: 12~24V DC

Installation method: wall-mounted

Working hours: 24 hours uninterrupted monitoring

Language: Chinese and English

Expansion: PC software

Humidity: 0~95%RH (non-condensing) (optional external filter will be needed if the humidity

is too high)

Temperature: -10℃~ +55℃ (optional sampling probe will be needed if the temperature is

too high) Explosion-proof grade: Ex d IIC T6 Gb

www.gasdog.com +86 773-280-9002

7

7` Instrument installation

Product structure

Wire connection

port

Shell ground

terminal

Screw fixing

hole

Alarm light

(optional)

Gas inlet

Gas chamber

Display

Status indicator

Infrared signal

receiving port

Wire

connection

port

Gas outlet

Screw fixing hole

Water and dust filter

www.gasdog.com +86 773-280-9002

8

* As shown in the figure, the housing grounding

mark " ", the instrument must be

properly grounded to avoid personal safety

accidents or instrument damage caused by

leakage or static electricity.

Installation types

GD700 is a pump suction detector, which can be connected to tube/hose for

detection, and the installation position can be selected flexibly.

Wall-mounted: This installation method is often selected for normal indoor inspection.

According to the nuts and spring washers, and then use 6x30mm nuts and spring washers to

fix the expansion bolts on the wall, as shown.

size of the hole of the detector (above), fix three 6mm expansion bolts on the wall, fix them

with screws,

Note: The installation location must be well

grounded or insulated. Leakage of electricity may

cause the detector to work abnormally.

*Other installation methods such as horizontal pipe,

vertical pipe can be adjusted according to site conditions

286.85

125.00

237.00

180.00

3-φ8.00

96.50

The detector installation avoids the following environmental influences:

●Environment temperature over device working temperature range.

●Environment humidity over device working humidity range.

●Environment pressure over device working pressure range

●High wind speed.

●Mechanical vibration.

●Strong electromagnetic radiation environment.

●high voltage environment.

●Electricity leakage.

Installation size

The upper and lower spacing of the three fixed holes of the instrument and the size of the

device are as shown in the figure below.

The left side is the wiring area, and the right side is the alarm.

www.gasdog.com +86 773-280-9002

9

-10-

Gas outlet

Sampling tube

Sampling side

Sampling tube selection

The sampling tube should be made of materials that have no chemical reaction with the

gas to be detected and no adsorption, and the tube should not exceed 50 meters.

Sampling point selection

The sampling point should be close to the leak source within a distance of 1 m or the

area where workers stay.

To detect toxic gases lighter than the air index, the sampling point should be installed

above the use environment, and the smaller the detection point, the higher.

To detect harmful gases heavier than the air index, the sampling point should be installed

below the operating environment.

Commonly, gas weight is similar to air, their sampling point installation height should be

1.5 meters above the ground .

Filter

www.gasdog.com +86 773-280-9002

10

Warning: The wire connection must be operated by professionals, otherwise it may

cause electric shock or damage the instrument.

*Note: During the wire connection process, it is forbidden to power on.

Cable selection:

1. RS485 transmission cable: Please use shielded twisted pair cable, the theoretical maximum

transmission distance is about 1200m, and the actual transmission distance is less than the

theoretical value. If long-distance transmission is required, signal transmission repeaters can

be used, but no more than 8 repeaters on one wire (repeaters need to be purchased

separately).

2. 4-20mA transmission cable: Please use shielded cable with a core diameter of 0.75mm or

more.

*The transmission distance of 4-20mA is determined by the load resistance. The

maximum load of this

detector is 500Ω (when powered by 24V). The load resistance includes the input resistance of

the control system (controller, PLC, DCS, etc.) and the internal resistance of the cable.Under

the condition that the input resistance of the control system remains unchanged, the

transmission distance is calculated with reference to the following formula:

Reference distance = (500-Rc) ÷ Rm

*Rc-input resistance of control system, Rm-resistivity of transmission cable.

Wire connectioninstructions

In outdoor areas with a lot of dust, rain or water mist, dust-proof, moisture-proof and

rain-proof treatment (such as installing a rain cover) is required, and the wiring is

recommended as shown in the picture below, which can prevent rain from pouring back and

affect the internal circuit board of the instrument.

≥30CM

≤2CM

Cable

www.gasdog.com +86 773-280-9002

11

24V DC

SSR

(AC/DC)

220V/10A

external load

M

+-+-

220V(AC/DC)

Solid State Relays

J1 relay

COM NO

Application example: At the site, the detector detects harmful gas and reaches the alarm

value. The detector screen and indicator lights prompt an alarm, and if an optional alarm light is

installed, there will be an audible and visual alarm. At this time, the normally open end of the

relay closes the circuit, (as shown in the figure below), which can drive the fan for ventilation or

drive the alarm system.

Warning: When the instrument alarms, you must leave the workplace as soon

as possible. Otherwise, serious personal injury or personal injury may be caused.

Please re-calibrate and check the detector afterwards to avoid the expansion of

equipment errors and cause false alarms.

Wiring interface

J1 on left is the relay control interface: COM (common end), NO (normally open end).

J2 terminal on left, the interfaces from top to bottom are: 24V (DC power-positive), GND

(power ground), A (RS485A-positive end), B (RS485B-negative end).

JP5 Alarm light interface

JP2 terminal on right is the 4-20mA

interface

JP3 terminal on right is the

digital probe interface, from top to

bottom are:

GND (power ground), followed

by sensor channels COM4, COM3,

COM2, COM1.

Pump

J1 Relay

Power supply

RS485

Sensor

connection port

Alarm

JP2

JP3

J2

JP6

JP5

JP1

4~20mA

www.gasdog.com +86 773-280-9002

12

Connection diagram of multiple instruments

4-20mA current signal output mode and RS485 digital signal output mode are different in

wiring; the following example power supply connection mode is for reference only, and the

power supply mode can be selected according to the actual situation during installation.

A. 4-20mA current signal output connection mode. (must be grounded together)

GND

A. RS485 digital signal output connection mode 1. (can be independently

grounded)

C. RS485 digital signal output connection mode 2. (can be independently grounded)

Control panel,

DCS or PLC

Channel 2

Channel 1

24V

Channel N

4-20mA

4-20mA

4-20mA

GND

RS485B

RS485A

GND

PC software

RS485-USB

adapter

12N

24V

GND

RS485B

RS485A

GND

24V

GND

12N

12N

Control panel,

DCS or PLC

www.gasdog.com +86 773-280-9002

13

8` Remote controller instruction

Note: When using, please aim at the infrared receiving port above the display screen to

operate. The instrument is equipped with a remote controller with a total of 11 buttons. as

the picture shows.

MENU

PUMP BACK

OK

1. MENU key: enter the menu (in the detection interface).

2. Mute key: Turn off the alarm sound of the instrument (in the detection interface).

3. PUMP key: switch the pump on and off (in the detection interface).

4. BACK key: cancel; return to the previous menu or detection interface,Double-click the

BACK button on the detection interface to switch the unit (only μmol/mol and PPM).

5. OK key: confirm; enter the next level menu.

6. Up key: Move the cursor up.

7. Down key: Move the cursor down.

8. Left key: move the cursor to the left; select the position to modify the data.

9. Right key: move the cursor to the right; choose to modify the data position.

10. Add key: increase the value.

11. Minus key: decrease the value.

Key

MENU

Mute

PUMP

BACK

OK

↑

↓

←

→

+

-

Function

Enter the menu

Turn off the sound

Power on or off the pump

Cancel/Return/Unit Switch

Confirm

Shift Up

Shift Down

Shift left

Shift Up right

Plus

Minus

www.gasdog.com +86 773-280-9002

14

9` Function Description

1 Power On/Off

1.1 Power On

1) In the power-off state, check whether the power cord on the left side of the instrument is

in good condition and has no foreign objects.

2) When connect with the power, the instrument power on.

When the instrument power on, it will initially display "Power On" (if it cannot be displayed

normally, the instrument may be faulty, please contact the agent or after-sales service

department at that time), then enter the self-test, and then enter the instrument preheating

countdown.

After the startup is complete, the reading and various function icons will be displayed on the

screen.

1.2 Power Off

In the normal measurement state or when there is power, just disconnect

the power.

www.gasdog.com +86 773-280-9002

15

2 User Interface

2.1 Detection interface description

The detection interface on the instrument displays the sensor type, indication and other

functional status information.

The top are: self-test status (passed "√", failed "×"), air pump (pump running-blue dynamic;

pump stop-gray), alarm (on-blue; off-gray)

1)

Self-test status: blue √ self-test is successful and the device is normal; gray X means the

device is abnormal in self-test, please contact the manufacturer.

2) Air pump status: blue on, gray off.

3) Sound status(Optional): blue on, gray off. It's the optional function. If detector with alarm

light, then have this function.

4) Gas name: The name of the gas type is in the blue box.

5) Gas unit: Small black characters are gas units.

6) Channel number: Corresponding to output 4-20mA interface CO1, CO2, CO3, CO4 (page

12).

7) Concentration reading: The black characters are the gas concentration readings.

8) Address number: detector address

When the following screen appears, please check the device.

Loss of signal: The detector is not connected or has poor contact. After the reconnection is

correct, the interface still appears, please contact the manufacturer.

www.gasdog.com +86 773-280-9002

16

2.2 Main menu interface operation

In the gas detection interface, short press the "MENU" button, the instrument will enter the

main menu interface immediately; press the "BACK" button in the main menu interface to return

to the gas detection interface.

2.3 Calibration

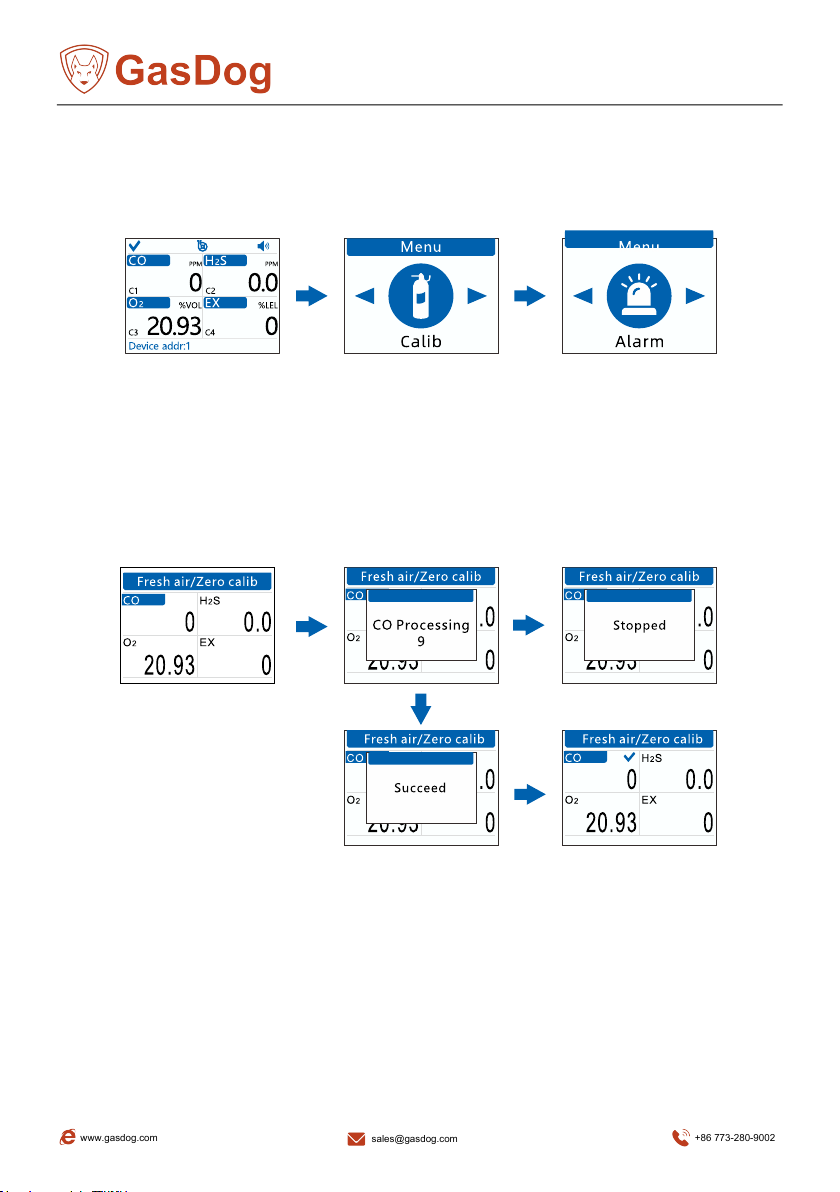

2.3.1 Fresh air/zero

calibration

In the fresh air/zero point calibration interface, press the "←" and "→" keys to select the

sensor to be calibrated, and then press the "OK" key to enter the calibration state, and then

enter the 30-second countdown. During the calibration countdown period, you can press

"BACK" Key to cancel zero calibration..

* In the "fresh air/zero point calibration" interface, you can press the "BACK" key to return to

the previous menu.

Notice:

1. For gases originally existing in the air (such as carbon dioxide, oxygen, nitrogen), the

instrument is calibrated as 450PPM for carbon dioxide; 20.93% VOL for oxygen; 78.1%

VOL for nitrogen.

2. Before do this operation, it is recommended to start up and warm up for 10~20 minutes.

3. When performing this operation, please turn on the instrument and place it in pure air for

3-5 minutes, and wait for the value to stabilize before proceeding, otherwise the displayed

data will be inaccurate.

www.gasdog.com +86 773-280-9002

17

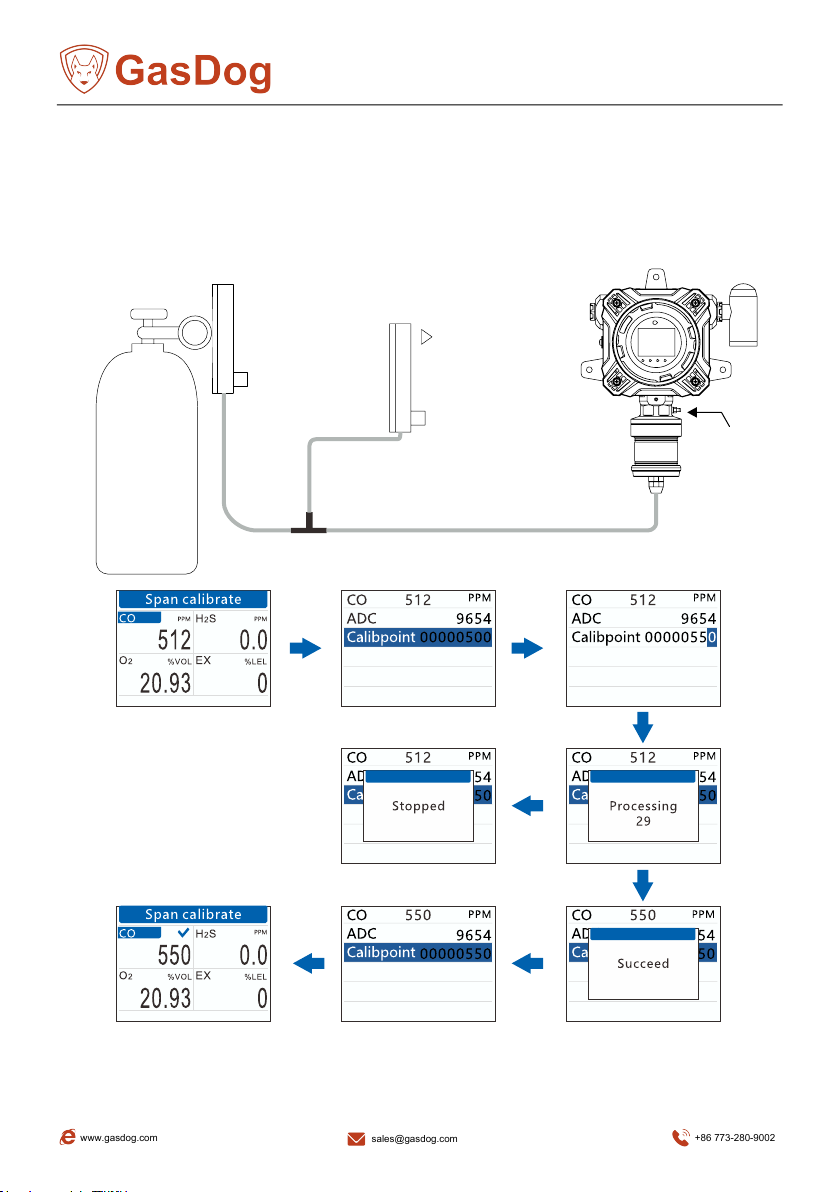

2.3.2 Span Calibration

The pump flow of YT-98H is about 0.6(±0.1)L/min. The instrument must be connected to

the standard gas cylinder through a T-shaped calibration tube (tee joint), and the other end is

connected to the flow meter. During ventilation calibration, ensure that the emptying of the

bypass flow meter is above 100mL/min.

In the span calibration interface, press the "OK" key to enter the span calibration sub-interface.

Calibration

gas

T-tube

PTFE tube

Pressure

reducing

valve

flowmeter

Flowmeter

Emptying

Ensure

normal

exhaust

www.gasdog.com +86 773-280-9002

18

There is an option in the span calibration sub-interface. At the same time, the gas type,

real-time concentration value, unit and ADC value are displayed at the top.

The span calibration process is as follows (the following example assumes that the

calibration gas is 550PPM CO):

After the instrument is turned on and enters the span calibration interface, connect a

calibration gas with a known concentration to the the instrument through a PTFE tube.

According to the actually used calibration gas concentration value (550PPM), use the "↑" and

"↓" keys to move the cursor to select the closest calibration point.

Press the "OK" key to enter the parameter setting mode, use the "←" and "→" keys to move

the cursor to select the pre-modified number, and the "+" and "-" keys to modify the selected

number, and set the value on the right (set fixed value) is modified to be the same as the

calibration gas used.

Open the valve of the calibration gas cylinder, and input the calibration gas into the instrument

at a flow rate of 0.9L/min (ml/min) or more. After the real-time concentration (upper middle)

displayed on the instrument is basically stable (about 1-3 minutes, The stabilization time of

different sensor is different), press the "OK" button, then the instrument enters the 30-second

countdown for calibration, the calibration operation is completed after the screen displays ”

success”.

Notice:

1. During the calibration countdown period, you can press the "BACK" key to terminate

the standard gas calibration.

2. When performing calibration, please confirm that the standard gas pipeline has been

connected. Please perform calibration after the value displayed is stable,

otherwise will cause inaccurate measurement.

3. Setting value: the actual concentration of the calibration gas currently input.

4. When selecting the calibration point, please follow the principle of "zero point <

calibration point≤ range", otherwise the calibration will be failed.

www.gasdog.com +86 773-280-9002

19

2.4 Alarm set

2.4.1 High alarm value, low alarm

value

There are 2 alarm values, high alarm value and low alarm value, take the high reporting limit

as an example. In the alarm setting interface, press the "←" and "→" keys to move the cursor to

select and enter the high alarm limit setting interface.

High alarm value set:

● Press the "OK" key to confirm the input, and then press the "+" and "-" keys to modify

the value.

● Press the "←" and "→" keys to move the cursor.

● After entering the value, press the "OK" key to confirm.

Notice:

1. The high alarm value cannot be lower than the low alarm value.

2. The low alarm value or the high alarm value cannot

be higher than the range.

*Indicator status:

Power: After power on, the green light is on.

Low alarm : no low alarm, light is off; low alarm,

red light is on.

High alarm: no high alarm, light is off; high alarm,

red light is on.

Fault: no fault, no light; self-test fault, orange light

on.

www.gasdog.com +86 773-280-9002

20

Table of contents

Other GasDog Gas Detector manuals