BX444 Gas Detector

Detects Carbon Monoxide,Natural Gas & L.P.G.

230V and 12V DC.

One, two, three or four Zone.

Self Diagnostic

Manual or Automatic Reset

Adjustable Pre-Alarm

Catalytic and Electrochemical Sensors

Audible Alarm

Sensor Fault Alarm

Manual Test Function

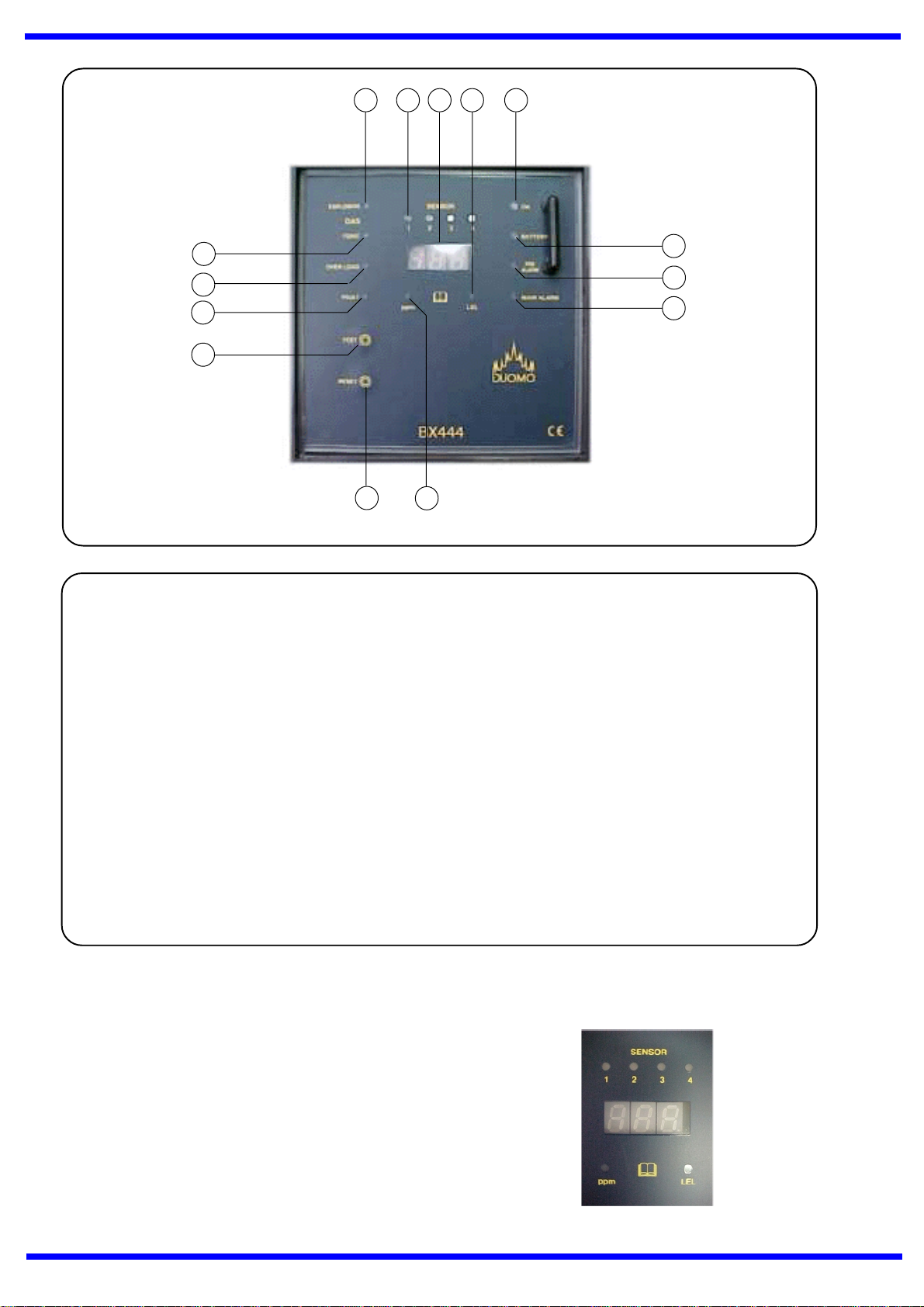

144 x 144 DIN Enclosure

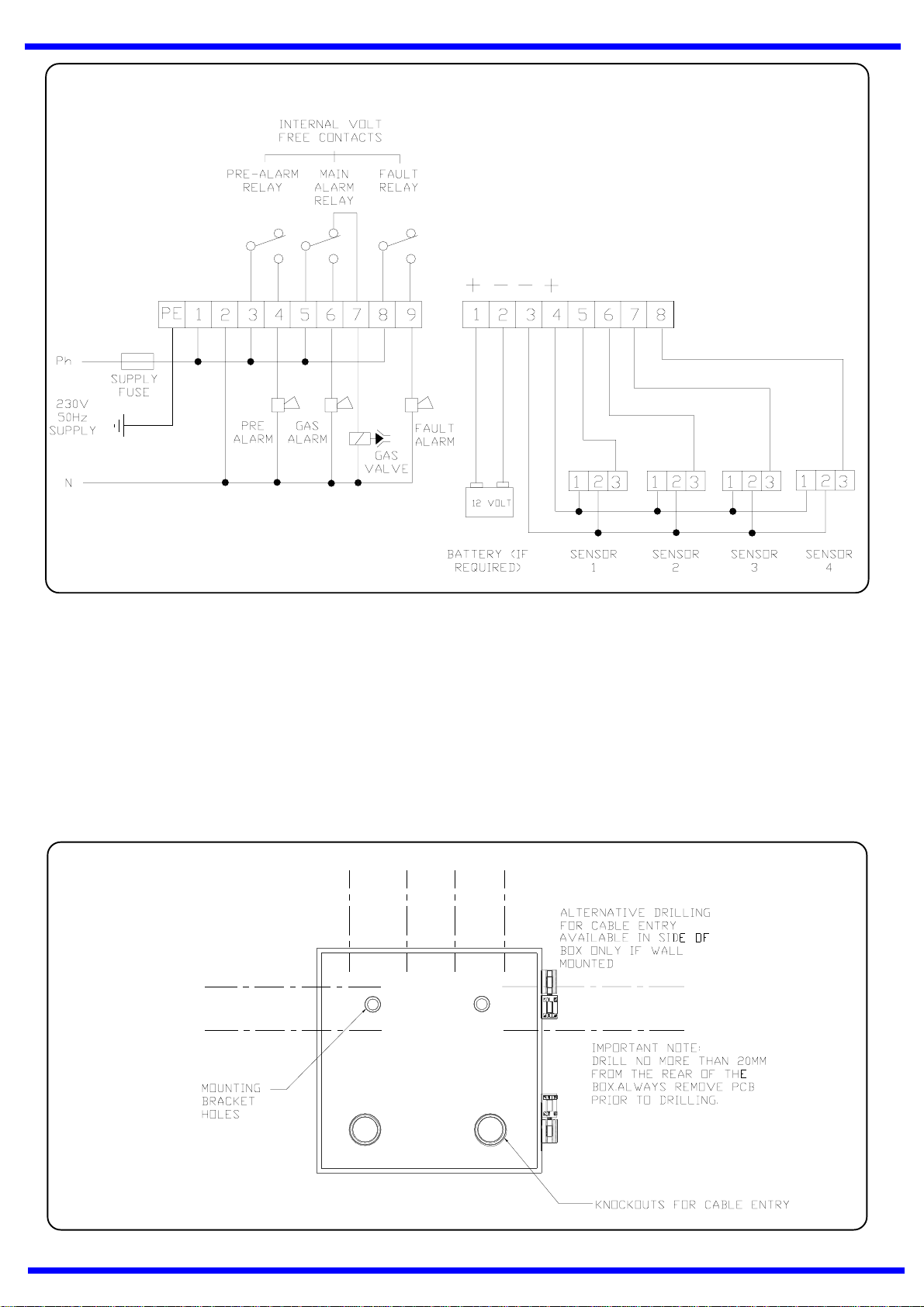

Panel or wall Mounting

1 Year Guarantee

Duomo is recognised within the Gas industry for

providing a comprehensive range of low cost, high

reliability gas detection for many applications. We

have installed and commissioned Natural gas and

carbon monoxide sensors in applications such as

boiler rooms, kitchens, car parks, aircraft hangars,

factories and shopping centres.

Application

The BX444 has been designed to meet all European

Normative proposals for the detection of Natural Gas,

LPGandCarbonMonoxideGasDetectors.TheBX444

is provides protection from gas leakage in areas such

as Boiler Rooms Roof spaces unventilated voids. Car-

bon Monoxide is an invisible, odourless gas which in-

hibits the bodies ability to process Oxygen. The BX444

protects against this in underground or poorly venti-

lated car parks, boiler rooms, vehicle servicing areas

etc. Remote sensors are installed in the areas which

requireconnectedtoremotesensorslocatedinthepro-

tected area. The 144 x 144 enclosure is wall or panel

mounting.

Operation

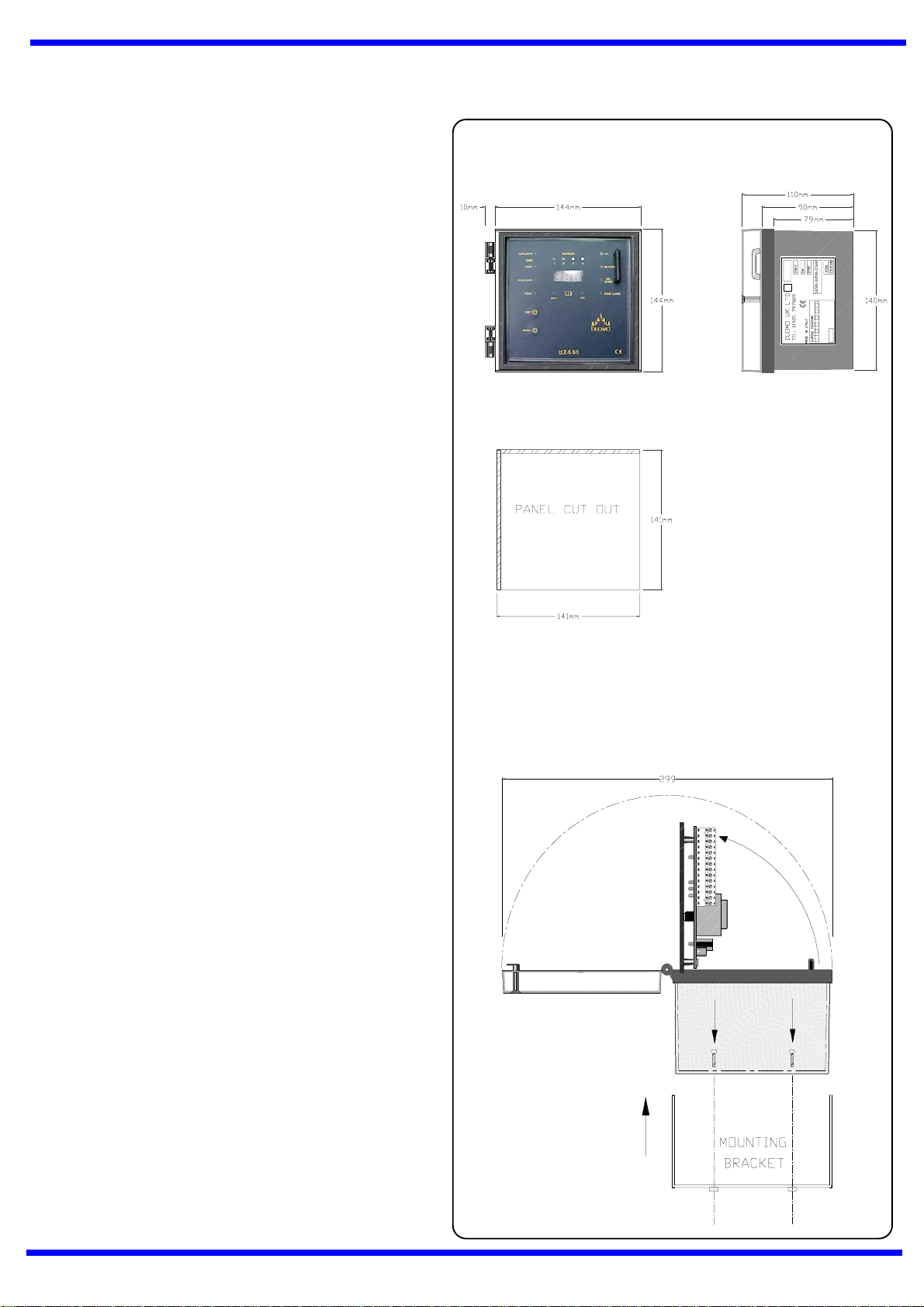

If the remote sensors sense the presence of Gas the

detector operates a pre-alarm relay - used for remote

sirens or extract fans; if the level of gas continues to

rise then the main alarm relay is activated to, either in

the case of explosive gases, break the electrical sup-

plyto the Safety Shut OffValveorforCOsound a Gen-

eral Alarm to allow evacuation of the area.

Features

The Pre-Alarmcanbeadjusted, inthecaseofNatu-

ral Gas or LPG, from 8% to 15% of the Lower Ex-

plosive Level (LEL). For Carbon Monoxide, it can

be adjusted from 120ppm to 250ppm. The Main

Alarm thresholds are not adjustable and are fixed at

20% LEL for explosive gas and 300 ppm for Car-

bon Monoxide. The detectors can be set for either

toxic or explosive Gas. Or both.

It is possible to set one zone for explosive gas such

as Natural Gas or LPG and another for toxic gas for

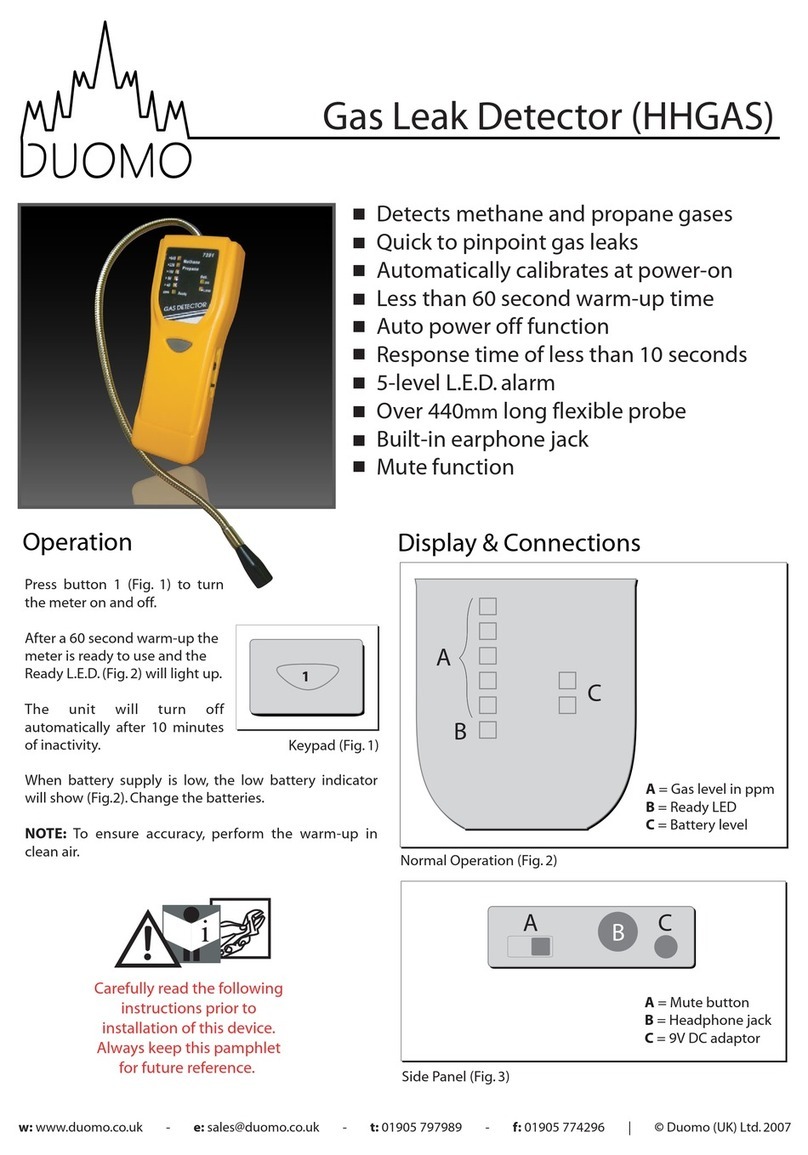

example Carbon Monoxide. An LED display on the

fascia indicates the levels of detected gas in either:-

parts per million (ppm) or percentage of Lower Ex-

plosive Level (%LEL). Lights above the display indi-

cate which sensor the Numeric LED display refers

to. It is possible to use the detector as a one, two,

three or four zone by enabling or disabling each

channel.

A ‘TEST’ button on the facia, when pressed, checks

the complete function of the BX444 and sensors. A

permanent diagnosticcheckismadeofsensorfunc-

tion. If any sensors should become faulty or be con-

nected incorrectly the ‘FAULT’ light will illuminate

and the detector will fail safe.

CAUTION!

Carefully read the following instructions prior to installation of this device. Always

keep this pamphlet for future reference. Ensure that the gas detection system is

wired correctly, the appropriate sensor is installed and used only for the purpose

which it is intended.

BX444 Four Zone

Gas Detector