GasDog GD300 Series User manual

Online Fixed Gas

Detector

GD300:XX

Instruction Manual

Notice to Reader

Please read this instruction manual before using the detector

1

1 Read before operation

1)All operators who operate and test the instruments must read the instruction manual carefully

before operation. The instruments can only work properly when they are operated in accordance with

the company's instructions for use.

2) The use of the instruments must be operated in accordance with the procedures determined in the

manual.

3) The maintenance of the instrument and the replacement of parts are handled by our company or

local maintenance stations.

4. If the user does not follow the above instructions to repair or replace parts without authorization, the

operator is responsible for the reliability of the instrument, and our company is no

longer responsible for the warranty.

5) The instrument should be calibrated at least once a year (it is recommended to calibrate every 3-6

months); the explosion-proof disc of the sensor should be cleaned regularly (purging with low-pressure

compressed air) according to the applicable scene, otherwise dust and impurities will block the protective

hole, which will affect the detection sensitivity.

6) The use of the instruments should also comply with the laws and regulations of relevant domestic

departments and the management of instruments in the factory.

Warranty

The instruments produced by our company have a 12-month warranty period and lifetime

maintenance. The warranty period starts from the date of delivery. During use, the user should follow

the instructions. The damage to the instrument due to improper use by the user or poor working

environment is not covered by the warranty. The user should keep the factory certificate properly, and

the warranty period is subject to the date on the certificate. Please pay attention to attach the factory

certificate when returning for repair.

2

Contents

------------------------------------------------------ 3

---------------------------------------------------------- 5

----------------------------------------------------------- 5

----------------------------------------------------------- 8

----------------------------------------------------------- 11

-----------------------------------------------14

------------------------------------------------16

----------------------------------------------------16

-------------------------------------------------------------------------17

1 Read before operation

2 Structure diagram

3 Installation method

4 Wiring Instructions

5 Calibration method

6 Remote controller operation

7 Common faults and repairs

8 Instrument configuration

9 Appendix

3

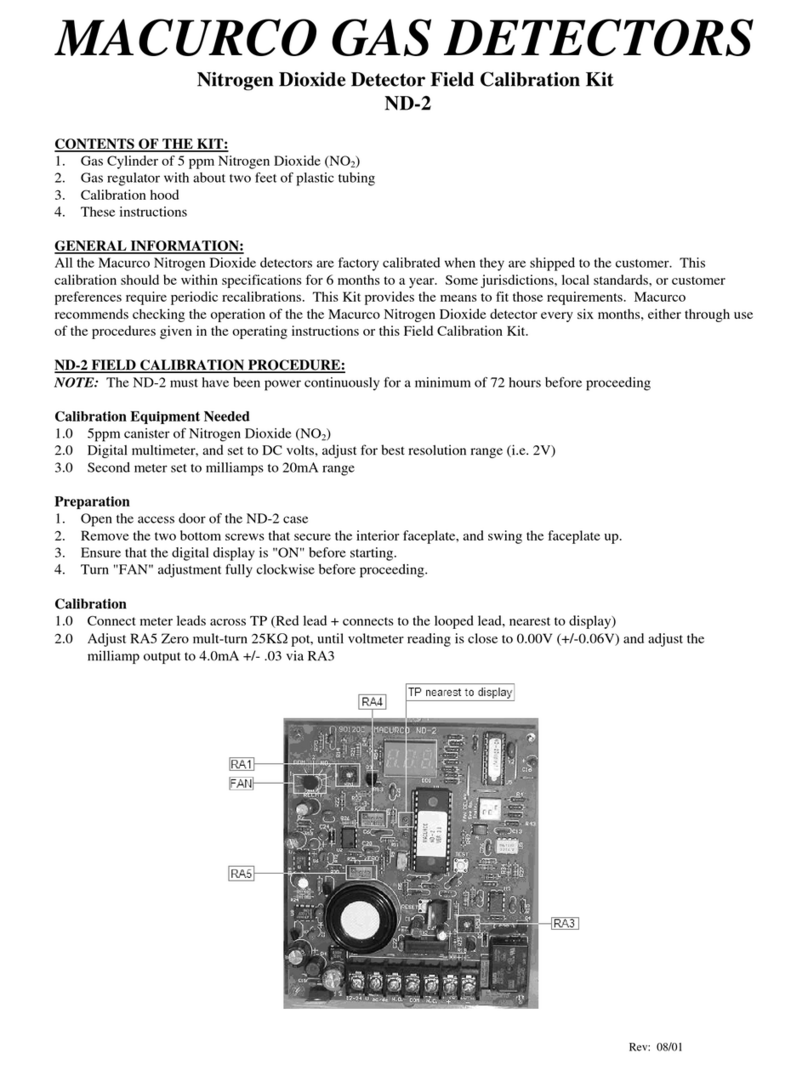

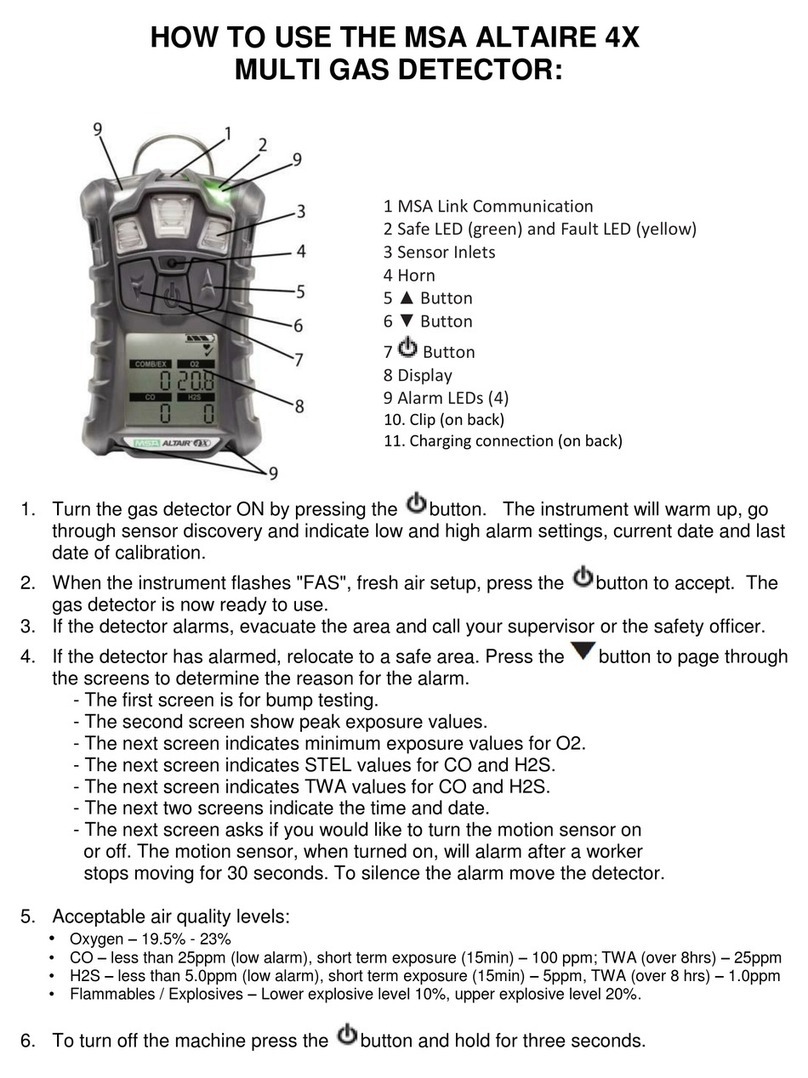

2 Structure diagram

1,Power supply and Signal line entrance and exit

2,Circuit board

3,Terminals

4,Sound and light alarm interface

5,Sensor head

6,Sensor head interface

7,Connect the claw socket to the mainboard

3 Installation method

Select the installation location

The installation position is very important to achieve the best detection effect.

When determining the location, it is necessary to comprehensively consider the following factors:

such as the density of the gas leak point, the specific gravity of the gas to be measured, the influence of

the surrounding buildings, the age of the production equipment, the wind direction and the weather

conditions all year round, etc. The location of doors and windows should also be considered indoors.

The following suggestions are for users' reference:

A. Appropriate distance should be maintained between the instrument and the possible leakage point of

the gas to be tested. If it is too close, the reaction speed will be very fast, but if the leakage is frequent, it will

cause too many alarms, or the long-term alarm state will make people paralyzed; if it is too far, the reaction

speed will be too slow, or even no response.

B. The instrument should be installed in the downwind direction of the leakage point.

C. When installing indoors, if the leakage source is outdoors, the instrument should be installed at

the air inlet.

D. The installation height should be determined according to the specific gravity of the measured gas and

air.

E. The number of instruments should be selected according to the possible leakage points of the gas to

be measured, the frequency of personnel appearance and the residence time, so as to achieve the best

detection effect.

F. If the equipment is outdated, it can be considered to increase the measured points.

G. The instrument should be prevented from being radiated by a high temperature heat source. Too

high or too low temperature will affect the use effect and lifetime of the sensors.

≥30CM

≤2CM

Cable

Figure H

IR ALAH

8.8.8.8

H. The instrument should be protected

from damp and rainwater inflow, which will

affect the internal circuit board.

The wiring recommendations are shown

in the diagram below.

Ground

connection port

5

6

123

4

7

4

四、技术性能及参数

1、技术性能

检测误差:≤±5%FS或±10%(视具体气体类型而定)

工作温度:-20~50℃

工作湿度:0~95%RH

传感器工作原理:氧气及有毒气体为电化学式,可燃性气体为催化燃烧

式。

传感器寿命:视具体检测环境而定

2、其它技术参数

检测方式:扩散式

工作方式:固定式二十四小时连续工作

工作电压:12~24V,DC

功 率:<4W

输出信号:三线制4~20mA标准信号、RS485信号

继 电 器:标配一个(可选配扩展一个),

用户自行外接其他负载需增加单独固态继电器进行隔离

外型结构:压铸铝壳体

外型尺寸:206X179X90mm(无安装支架)、

206X179X110mm(带支架)

重 量:无安装支架~1.2kg,带支架~1.6kg

连接距离:<1000m

防护等级:IP65

管道螺纹尺寸:M45XP2.0

安装方式:壁挂式、管道式

防爆形式:隔爆型

防爆等级:Ex d IIC T6 Gb

进 线 口:六角型锁紧螺母

Select the installation type

1) Wall-mounted type: This type of installation is usually selected for normal indoor inspection.

According to the size of the outer hole of the mounting bracket (optional), fix two or four 6mm expansion

bolts on the wall, and fix the bracket and the detector with screws, nuts, spring washers and flat washers.

Then use 6x30mm nuts and spring washers to fix the expansion bolts on the wall, see the picture

below.

Note: The installation location must be well grounded or insulated. Leakage of electricity may cause the

detector to work abnormally.

2)

Pipe-mounted type: The installation thread size of the instrument is M45*P2.0. During the

installation process, hold the detector with both hands so that the sensor is parallel to the installation

thread, align the screw mouth, rotate the detector clockwise, and then install the detector on the target

position. In order to prevent air leakage at the threaded interface, suitable raw tape can be wrapped

around the threads on the sensor head before installation.

Note: The pipe-mounted type requires that the inside of the pipeline is normal temperature and

pressure (temperature -20~50℃, pressure 0.1mPa) and humidity ≤95%RH. If the above conditions are

not met and this installation method is required, please contact the manufacturer for a solution.

5

Instrument Dimensions and Mounting Hole Map

●Apperance and installation hole map

118.00

φ8.00

140.00

φ8.00 φ8.00

102.30

206.00

89.00

●Apperance and installation hole map of gas detector with alarm light

φ8.00

179.00

102.00

φ8.00φ8.00

118.00

206.00

89.00

6

4 Wiring Instructions

4.1, Cable requirements:

Power lines and 4-20mA signal lines need to use shielded cables, and RS485 lines are recommended to

use twisted pairs. When using RS485 communication to connect with the controller (Under normal

conditions) , the RS485 signal transmission distance of our detector can reach more than 1000 meters.

When the signal interference is large or the transmission distance is longer, it is recommended to add an

RS485 repeater, a 120Ω/0.5W matching resistor should be connected in parallel between the A and B lines

of the farthest detector.

The power supply voltage of this series of detectors is 12~24VDC. Due to the voltage drop caused by the

impedance of the cable itself, it should be ensured that the minimum supply voltage of all detectors is

12VDC.

When the detector is powered by the controller, the power supply voltage of the controller of our

company is 24VDC. To ensure that the minimum input voltage of the detector is 12VDC, the circuit

voltage drop must be less than or equal to 12VDC, as shown in the figure below.

Maximum Loop Impedance: Rloop = (VController – VDetector(min)) / IDetector Calculated

according to the above formula.

The maximum current of combustible gas detector is 250mA, and the maximum loop resistance is

48Ω;

The maximum current of the toxic gas detector is 100mA, and the maximum loop resistance is 120Ω.

The cable cross-sectional area and the farthest transmission distance are shown in the table below

(when connected to our controller). Make sure that the actual installed cable length is shorter than the

calculated maximum cable transmission distance.

4-20mA

Maximum Loop Resistance

V Controller=24VDC V Controller=12VDC Gas detector

Controller

0VDC 0VDC

1

2

33

2

1

RL

Cross-sectional area of cable core (mm) 0.75 1.00 1.50 2.50

Resistance (ohm/km copper wire) 24.7 18.5 12.3 7.4

The longest cable distance (m)

(loop length/2)

Combustible gas 1000 1250 2000 3200

Toxic gas 2400 3200 5000 8000

Note: The above transmission distance is calculated based on the cable core with a resistivity of

1.85×10ˉ Ω·mm. If a cable of the same wire diameter with a smaller resistivity than this is used, the

transmission distance can be longer; if a cable of the same wire diameter with a higher resistivity than this is

used, the transmission distance will be shortened. The loop length indicates the total length of the positive

and negative wires of the power supply, and the actual length of the cable is equal to half of the loop length.

7

Refer to the following formula for the maximum number of detectors allowed on a single cable: N=Im/

lc=((U-12)/R)/Ic=((U-12)/(ρ×L/S))/Ic

N: Maximum number of detectors

Im: the maximum current passing through the wire(A)

Ic: the average current of a single detector at the lowest starting voltage(A)

U: controller output voltage (our controller is 24V)

R: internal resistance on the cable(Ω)

ρ: core resistivity (copper: 1.85×10ˉ Ω·mm)

L: cable length (the total length of the positive and negative lines of the power supply, if the length

of a single line is 100m, the total length of the two lines is 200m)

S: core cross-sectional area(mm)

When the detector uses our controller to supply power, taking the material as copper (the resistivity is

1.85×10ˉ Ω·mm) as an example, the maximum number of detectors allowed for a single cable can refer to

the following table:

When the detector is not powered by the controller (that is, powered by an independent power supply),

the 4-20mA transmission distance is determined by the load resistance, which includes the output resistance

of the control system (controller, DCS or PLC) and the internal resistance of the cable.

Cable distance (m) 100 200 500 1000

The maximum allowable number of

detectors when using 0.75mm wire

diameter

Toxic gas(100mA@12V) 24 12 4 2

Combustible gas(250mA@12V) 10 5 2 1

The maximum allowable number of

detectors when using 1.0mm wire

diameter

Toxic gas (100mA@12V) 32 16 6 3

Combustible gas (250mA@12V) 12 6 2 1

The maximum allowable number of

detectors when using 1.5mm wire

diameter

Toxic gas (100mA@12V) 48 24 8 4

Combustible gas (250mA@12V) 20 10 4 2

The maximum allowable number of

detectors when using 2.5mm wire

diameter

Toxic gas (100mA@12V) 80 40 15 7

Combustible gas (250mA@12V) 30 15 6 3

The maximum transmission distance refers to the following formula:

L=(R-Rc)/(ρ/S)

L: Maximum transmission distance(m)

R: Maximum load resistance(Ω) (500Ω when powered by 24V, including control system input

resistance and cable internal resistance)

Rc: input resistance of the control system (the input resistance of our controller is 50Ω) ρ:

core resistivity (copper: 1.85×10ˉ Ω·mm)

S: core cross-sectional area(mm)

8

4.2 Wiring Instructions

1: Cable requirements: use shielded cables, the wire diameter is about 0.75mm, and the copper wires at

the wiring must be tightened without burrs;

2: Different instruments, the wiring methods are different:

A. For instruments with lead wires, the following are the meanings of each connection wire (for

reference only):

Red wire: Power positive input (12 to 24V)

Black wire: power ground wire

Yellow wire: 4~20mA output or RS485A

Green wire: RS485B

B. For instruments without lead wires, the user needs to open the instrument shell and connect wires to

the inside terminals. The following figure is the description of each terminal:

Warning: The wiring work must be performed by professionals, otherwise it may cause electric

shock or damage to the instrument.

J1

24V

GND

4-20mA

GND

RS485A

RS485B

Power

Signal output

Low Alarm

Relay High Alarm

Relay

J2

Motherboard connector JP1

J3

Alarm

Digital probe port

Digital probe portDigital probe port

S1

Note: Do not connect wires with power on at any time.

NO:Normally open

COM:Common

24V:24+,positive

GND:24-,negative

4~20mA:4~20mA analog

signal

Wiring diagram

(Optional)

COM

NO

COM

NO

* High alarm relay (Optional) .

9

5 Calibration method

In order to ensure the measurement accuracy, the instrument should be calibrated regularly and

strictly recorded during use.

Calibration equipments:

One bottle of calibration gas with known concentration (Note: The instrument defaults to full scale. In

principle, the selected calibration gas concentration should be greater than 50% of the range and less than

the range.);

Pressure reducing valve;

flow meter 0~1000ml/min;

PTFE tube;

Calibration cap, etc.

Note: When the instrument leaves the factory, the alarm settings of the detector and the panel are

adjusted to the factory default values, and the user can adjust it through the remote controller according to

the situation.

Zero calibration

Make sure the instrument is in clean air environmrnt (do not do this in a non-clean air environment).

Note: After the zero point calibration, the instrument reading will automatically return to zero

(oxygen 20.93% VOL, nitrogen 78.1% VOL, carbon dioxide 450ppm).

Power on when ready.

External load application (low alarm for reference)

24V DC

SSR

(AC/DC)

220V/10A

External load

M

+-+-

220V

(AC/DC)

Low Alarm

Relay High Alarm

Relay

J2

COM

NO

Solid state relay

*High alarm relay (Optional) .

10

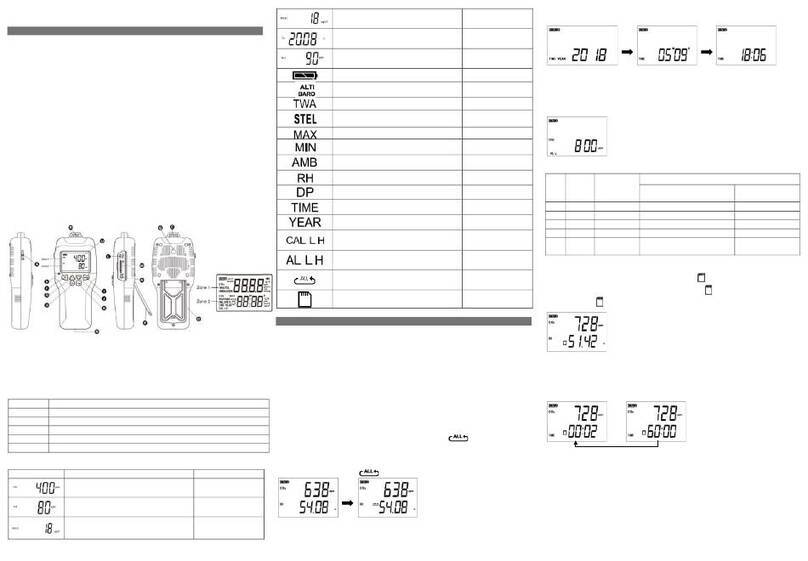

The zero calibration steps are as follows:

1: Press the "MENU" key on the remote controller, then

instrument displays F-01.

2: Press "+" key or "-" key to adjust to F-04.

3: Press the "OK" key to display the current gas concentration

reading. Wait until the instrument value is stabilize, press the "OK" key

again, then detector reading will display "PASS", indicating that the

calibration is successful.

IR ALAH

IR ALAH

IR ALAH

4: If the zero calibration is successful, it will automatically return to

the detection interface.

IR ALAH

Span calibration

Connect the calibration gas cylinder of known concentration to the calibration cap (Optional) of the

instrument(as shown in the figure below) through PTFE pipe.

This operation is mainly divided into two steps: [Set Calibration Point] and [Span Calibration].

Note: After the calibration, please remove the calibration cap. Do not install the calibration cap

on the detector during testing.

PRV

PTFE PIPE

Empty

Gas

detector

Standard gas

Flowmeter

Calibration

cap

11

●Set the calibration point

Make sure the detector is connected correctly, power on until the

output of the detector is stable.

1. Press the "MENU" key on the remote controller, the detectorr

displays F-01.

2. Press the "+" key or the "-" key to adjust to F-07.

3.

Press the "OK" key to enter the gas concentration value display interface. The value can be

modified by the "+" and "-" keys to make the value consistent with the calibration gas concentration .

Press the "OK" key to display "PASS" briefly.

IR ALAH

IR ALAH

IR ALAH IR ALAH

IR ALAH

IR ALAH

2.

Press the "+" key to display F-08,

●Span calibration

1.

Press the "BACK" key to exit, the detector will display F-07.

IR ALAH

3.

Press the "OK" key again to enter the function interface. After adjusting the "0" displayed on the

interface to “1 " by the "+" key, press the "OK" key again to display the current detection reading.

IR ALAH

12

4.

At this time, pass in the calibration gas at 300±20ml/min. When

the value of the instrument is stable, press the "OK" key. The instrument

will be automatically calibrated and display "PASS" for a short time. At

this time, the measured concentration value is consistent with the value

set in "F-07" (concentration value of calibration gas). IR ALAH

Note: Pass the calibration gas into the detector. After the output is

stable, adjust and correct the display value of the detector to be the

same as the calibration gas value, and then cut off the gas. Observe

whether it can return to the zero point (in a pure air environment) or

the starting point, and then repeat it again, and the calibration can be IR ALAH

completed with a small difference between the two values (within the

basic error range). If there is a big difference, repeat the above method to calibrate until the calibration

specification is met (the detector is usually adjusted to "20.93% VOL" for oxygen in the air environment, and

the detector is usually adjusted to "78.10% VOL" for nitrogen in the air environment).

Remote controller key function

OK

BACK

MENU RESET

6 Remote controller operation

1: Press the MENU key once to enter the F-01 address code setting menu, press the "OK" key to enter

the modification, press the "+" and "-" keys to modify the instrument address code, and press the "OK" key to

save after the modification is completed. Press the "BACK" key to cancel.

2: Press the "+" key to enter F-02 to enter the low alarm point setting menu, and press the "OK" key to

enter the modification. Press the "+" or "-" key to modify the low alarm value of the instrument. After the

modification is completed, press the "OK" key to save, and press the "BACK" key to cancel.

3: Continue to press the "+" key to enter F-03 to enter the high alarm point setting menu, and press the

"OK" key to enter the modification. Press the "+" and "-" keys to modify the high alarm value of the

instrument. After the modification is completed, press the "OK" key to save, and press the "BACK" key to

cancel.

4: In the parameter setting state, if the remote controller is not operated for 10 seconds, the

instrument will automatically return to the gas detection state, and the parameters being modified

(without pressing the "OK" key to confirm the operation) will not be saved in the EEPROM. The

parameters used are still the previous values when restarted again.

Key Function

MENU Enter the parameter setting state from the

detection state

RESET Cancel the alarm state

+ Displayed parameter increase 1

- Displayed parameter minus 1

OK Confirm the operation

BACK Cancel operation/return

13

F-0X function table

Note: F-06 and below operations do not need to be operated under normal circumstances, and only

professionals can operate when necessary. F-11 to F-19 are reserved functions, please consult the

manufacturer for details.

F-01 address settings RS485 communication address modification

F-02 low alarm value setting The setting value cannot exceed the high alarm value

F-03 High alarm value setting

F-04 Zero calibration

The setting value cannot be lower than the low alarm value

Calibration after stable reading in clean environment

F-05 4MA current trimming

C-04, 4mA output (modifiable)

C-08, 8mA output (cannot be modified)

C-12, 12mA output (cannot be modified)

C-16, 16mA output (cannot be modified)

C-20, 20mA output (modifiable)

F-06 ADC value Cannot be modified

F-07 Set calibration point Span calibration concentration value

F-08 Span calibration Change 0 to 1, press the OK key, the real-time concentration value will

be displayed, and then press the OK key to calibrate as the value set in

F-07

F-09 Production date cannot be modified

F-10 Communication

protocol

0:Standard version

1:Non-standard version (old protocol)

14

7 Common faults and repairs

Trouble

phenomenon Reasons Solution

Detector has no

output

Reconnect correctly

Detector

reading is low

Detector

reading is high

Detector

reading is not

stable

Wrong wire connection

Circuit failure

Calibration expired Detector

range is set too high Sensor

failure

Calibration expired Detector

range is set too low Sensor

failure

Not enough warm-up time

Sensor failure

Circuit failure

Send back for repair

recalibrate

Reset the detector range

Replace the sensor

recalibrate

Reset the detector range

Replace the sensor

Power on and waiting

Replace the sensor

Send back for repair

Display“----” The detector signal wire is disconnected Plug the signal wire tightly

8 Instrument configuration

1, Gas detector 1 piece

2, Instruction Manual 1 piece

3, Product certificate 1 piece

4, Remote controller 1 piece

5, Label 1 piece 1 piece

6, packing box 1 piece

15

9 Appendix

Connection diagram of multiple instruments

According to the signal type of the user's implementation site, 4-20mA current signal output and

RS485 digital signal output can be selected respectively

These two signal output modes are also different when wiring

A. 4-20mA current signal output connection mode. (must be grounded together)

B. RS485 digital signal output connection mode 1. (can be independently grounded)

Control panel

DCS or PLC

24V,DC

GND

GND

12N

4-20mA

IN

Ch-1

Ch-2

Ch-N

Control panel

DCS or PLC

RS485B

RS485A

GND

24V,DC

GND

12N

16

C. RS485 digital signal output connection mode 2. (can be independently grounded)

RS485B

RS485A

GND

PC

software

RS485

to USB

12N

24V,DC

GND

17

This manual suits for next models

1

Table of contents

Other GasDog Gas Detector manuals

Popular Gas Detector manuals by other brands

Honeywell

Honeywell Searchline Excel Open-Path Technical handbook

Alecto

Alecto COA-26 manual

isweek

isweek CP01 Operation manual

New Cosmos Electric

New Cosmos Electric KD-12 instruction manual

Coster

Coster RFG 361 quick start guide

Critical Environment Technologies

Critical Environment Technologies CGAS-AP installation manual