GasDog GD200 User manual

Product overview

GD200 series gas detector is a kind of fast response and

high accuracy gas measurement device. With internal

sam-pling pump, fast sampling speed and high flow rate,

ensuring the response time of the detector. Unique design,

small size and easy to carry with. Special high intensity

engineering plastics housing, suitable for different kinds of

situation and environment. We dedicate to provide you the

most reliable, accurate and the safest solution of gas

detection.

GD200

Portable Gas Detector

GD200

gas detectors are imported

with world top imported

sensors

1

Employing original imported first-class brand sensor.

(optional) High speed data transmission by USB, which can download

and print data.

LCD dot matrix display, the gas type, unit, concentration,

local time can be showed on the screen.

Support Chinese and English operation, easy to shift.

The gas concentration unit PPM and mg/m3 can be shifted quickly.

Built-in micro sampling pump, 10 grades of suction are available.

Explosion-proof certification, explosion-proof grade: II 2G Ex ia IIC T4

Ga IP66.

Monitor the specified gas concentration in environment and enclosed

space and alarm.

With Self-calibration and zero calibration functions, makes the detection

more accurate and reliable.

One press to restore factory setting, free from the bother of mis-operation With

temperature and pressure compensation, this is able to realize gas

concentration compensation under conditions of different temperatures or

pressures.

Two-stage alarm with sound and light, alarm point is settable.

Rechargeable lithium polymer battery of large capacity.

Employing pumping sampling method and the pumping suction is adjustable.

Special engineering plastics housing of high intensity, anti-skipping,

water-proof, dust-proof, explosion-proof. Elegant

and exquisite aluminum alloy suitcase

GD200 portable gas

detector

Product advantages

Functions

Product Advantages

Specialized in Gas Detection

For 16 Years

2

Standard

Accessories

Instruction

Aluminum suitcase

GD200

Pumping Gas Detector

GD200

Aluminum suitcase

A charging adapter

Instruction

Qualification certificate

A charging adapter

Accessories & Configuration List

Application

Petrochemical & Chemcial Industry Municipal Engineering & Utilities Agricultral & Environmental Protection

Electronic Food & Pharmaceutical Industry Other Industries

3

Detected gas measure range Optional ranges

Normal gas types and paramaters (Other gases are not listed can be customized)

Resolution Response time

GD200

Gas Detected

Detection principle

Sampling Method

Measure Range

Resolution

Precision

Signal Output (optional function)

Response Time

Repeatability

Zero shift

Operating language

Temperature

Explosion-Proof

Alarm mode

Dimensions

Recovery Time

Linearity error

Display

Gas unit

Humidity

Degree of protection

Operating time

Weight

O2, N2, CO2, EX, VOC, PH3, etc. According to customers' requirements.

Flammable gas(EX)

Oxygen(O2)

Carbon monoxide(CO)

Hydrogen sulfide(H2S)

Ammonia(NH3)

Chlorine(CL2)

Hydrogen Chloride(HCL)

Nitric oxide(NO)

Nitrogen dioxide(NO2)

formaldehyde(CH2O)

Ozone(O3)

Carbon dioxide(CO2)

0-100%LEL

0-30%VOL

0-1000ppm

0-100ppm

0-100ppm

0-10ppm

0-20ppm

0-100ppm

0-20ppm

0-10ppm

0-10ppm

0-2000ppm

0-100%VOL

0-25%VOL

0-2000ppm

0-1000ppm

0-200ppm

0-100ppm

0-100ppm

0-250ppm

0-100ppm

0-50ppm

0-100ppm

0-100%VOL

0.1%LEL/0.1%VOL

0.01%VOL/0.1%VOL

0.1ppm/1ppm

0.01ppm/0.1ppm

0.01ppm/0.1ppm

0.01ppm/0.1ppm

0.01ppm/0.1ppm

0.01ppm/0.1ppm

0.01ppm/0.1ppm

0.01ppm/0.1ppm

0.01ppm/0.1ppm

1ppm/0.01%VOL

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

Electrochemistry, infrared ray, catalytic combustion, PID photo

ionization (according to the target gas and sensor).

Pumping suction, flow rate can up to 1L/min, ten grades of pumping suction for selection.

The range is optional, according to the target gas and the sensor.

According to sensor and measure range

According to sensor.

High-speed data transmission by USB, available for data downloading and printing

≤10S

≤±1%

≤±1%(F.S/year)

English

-20℃~50℃

II 2G Ex ia IIC T4 Ga IP66.

Sound, light, vibration

205*75*32mm

≤10S

≤±1%

LCD dot matrix display

Units are switchable

0-90%RH

IP66

100h(pump off), 12 hours(pump on)

300g

Technical Specification

4

GD200

Used in laboratory,

pharmac eutical factory,etc

GD200

Applied in warehouse,workshops,etc

GD200

Used in Large oil refinery

and metallurgi cal plant,etc

GD200

Applied in Repair shops ,

mines, sewers,etc

Project Cases

More Application

Furniture, Floor, Wallpaper, Coating, Gardening, Interior Decoration and Renovation, Dyestuff,

Papermaking, Pharmacy, Health Care, Foodstuff, Antiseptic.

Disinfection, Chemical Fertilizer, Resin, Adhesive, Pesticide, Raw Material, Sample,

Technological Process,

Livestock Farm, Refuse Processing Plant, Perm Place.

Bio-pharmaceutical Plant, Green Household, Livestock Breeding, Green House Cultivating,

Warehouse Logistics, Brewing And Fermentation, Agricultural Production.

5

User Manual-GD200

Thanks for purchasing our product. Please read the user manual carefully before using.

Keys Operation:

Turn on/off: long press for 3s to turn on/off the device, short press to confirm or save data.

Menu: in detection mode, press this button to enter into parameter setting mode, and in parameter setting

mode, press this button to move the cursor.

Plus: in parameter setting mode, short press it to select items upward or add value. Long press for 3 seconds

to turn on/off alarm function quickly.

Minus: in parameter setting mode, short press it to select items downward or decrease value. Long press

for 3 seconds to turn on/off air pump quickly.

Exit: in parameter setting mode, short press it to go back to previous menu. Long press to shift the gas

concentration unit quickly.

(Note: The long press function only work in detection mode. When you change or reset any data, please remember to

click

“ON/OFF” button to confirm and save the settings. Remember to turn on the pump when start the detection. Please

turn off the pump when there is no need to detect, which will be helpful for the service life of the pump)

Power On / Off

Put the detector in clean air, and press the “ON/OFF” for three seconds, the detector will be turned on and the pump

will start to work. The screen displays the following interface successively: Brand and Logo, main parameter

interface, initialing countdown. The countdown would be 60 or 120 seconds, which is to make sure that the sensors are

fully activated. After countdown, the device enter normal detection interface.

Take the detector out of the detected environment and wait for the data to get down to zero, then press the “ON/

OFF” to turn off the detector

Zero Calibration

Zero calibration must be done in clean air. Better to do once after alarming happens.

Press ”MENU” to enter parameter setting mode, select the "calibrate zero", and press “ON/OFF” to enter the mode.

Observe the value of “real time concentration”. If the reading is not zero and the drifting is too big when the reading is

stable, then it is necessary to conduct zero point calibration.

Press “ON/OFF”, the real-time concentration will go back to zero, and press ”ESC” to go back to detection mode,

gas concentration values also back to zero.

Note: Zero calibration of oxygen detector, nitrogen detector and carbon dioxide detector (target gases are

component of the air) can not be done in the air. Only the target point calibration (value of target point

concentration is the standard concentration values in the clean air) can be done.

6

Process of Over-range incorrect operation

Users should avoid using gases which exceed the measure range to impact the sensor, because it will affect the

lifespan and sensitivity of the sensor, even, "poison" the sensor. If there is any over-range incorrect operation makes

the detector displaying an concentration at a large reading, the remedy is to take the device out of the environment

immediately and put it in clean air for over half an hour, and then observe the reading, if it keeps going down, then wait

until the reading back to zero before powering it off, and do the zero point calibration next time before using it. If the

reading maintained at full scale, user should send the device back to manufacturer or agent for repair or replacing the

sensor.

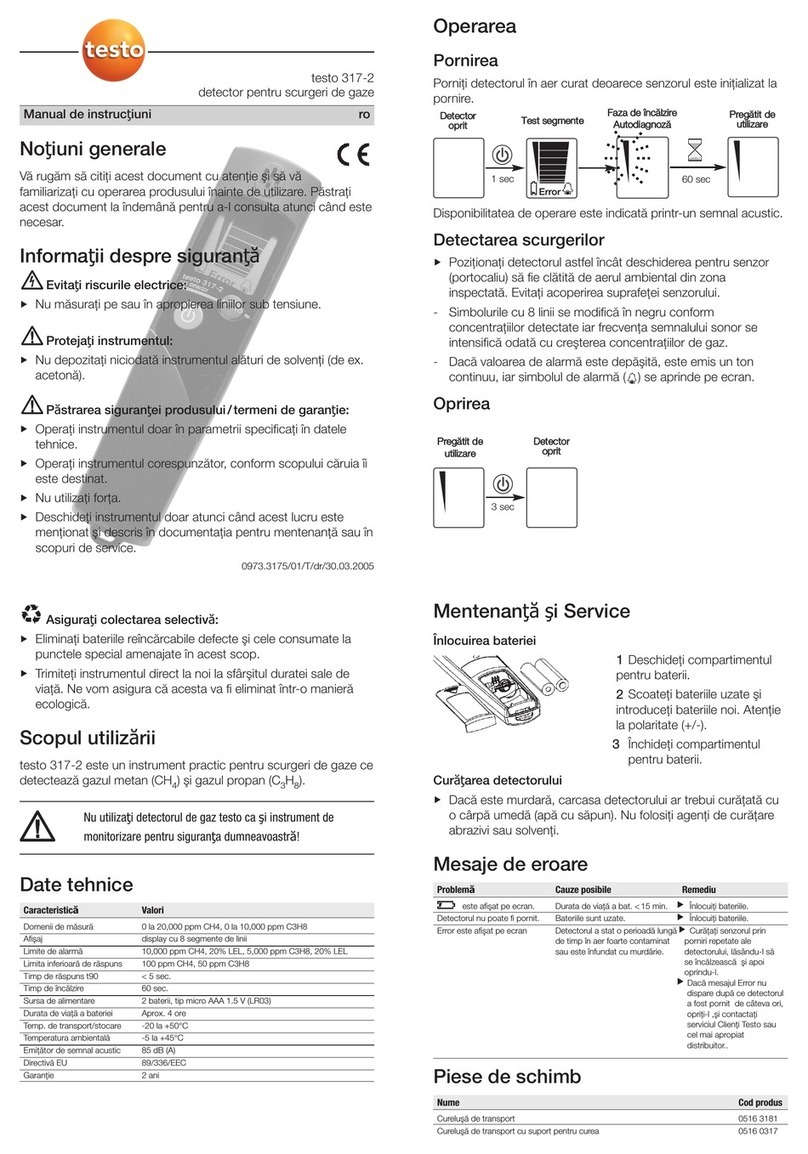

①

— Air Inlet

②— Air Outlet

③— air chamber of sensor

④— LCD

⑤— PLUS

⑥— MINUS

⑦— MENU

⑧— ESC

⑨— ON/OFF

-----------------------------------------------------------------------------------------------------------------------------

Note

*If detector is used for the gas cylinder detection, considering the high pressure in the cylinder, please use a

pressure regulator, and keep it as the below data:

Flow rate: 800mL~1L/minute

Pressure: 0.1MPa or 1Bar

*Please put the detector in clean air for about 5 minutes and waiting for the data falling down to normal before

turning it off after measurement.

7

Operation Interface

When the detector is turned on completely, the device will enter the detecting interface. The gas type will be showed on

the top left, and the time and battery power will be at the right. In the middle, there is the real- time concentration. If the

detector is with data storage function, there will be the storage status at the top of the concentration: ON or OFF, and

the total storage number. There will be BEEP-ON at the bottom left, which means the alarm is on. The PUMP-ON at

the bottom right, which means the pump is working.

Alarm Status

When the detected gas concentration is higher than the low alarm value, the alarm sound will be on, yellow light will

be flickered.

When the detected gas concentration is high than the high alarm value, the alarm sound will be on, red light will be

flickered.

Alarm Setting

Press “Menu”, choose the “Alarm point set”, and start to set the alarm value.

There are LOW POINT and HIGH POINT for set, press “MENU” to move the cursor to the value you want to set, and

press the “PLUS” or “MINUS” to change the value. After the setting is done, press “ON/OFF” button to save the settings.

Low Battery Alarm

When the battery is low, there will be sound, light low battery alarm. There will be sound and light every 5 seconds to

remind the user to charge the device in time. When the battery is used up, the device will be turned off automatically.

Restore Setting

When all the settings are wrong, or users operate the detector in a wrong way, you can restore the detector to factory

settings. But if the detector works normally, please don’t operate this setting. In order to avoid wrong setting, password

is needed. If you want to restore the detector to factory setting, please contact the supplier.

Storage set

In the storage setting, you can set the storage status and the interval. Every time you turn on the detector, the storage

status defaults OFF, so you need to set the storage status if you want to record the data.

Press MENU, choose the “Storage set”, move the cursor by pressing MENU at the “ENABLE”, press MINUS to change

NO to YES.

The storage interval can be 5 seconds, 10 seconds, 15 seconds, etc. The highest interval is 1 hour.

8

View history data

Press the MENU, choose “view history data”. Then at the top is the record total number, and the reminder

“PLEASE SELECT”. Now, if you press MINUS, then the record data will be from the first record to the second in turn. If

the record number is above 10, and you want to check the specific number, you press the MENU again, then you can

input the exact number and check that record(press the MENU to move the cursor, and press the MINUS and PLUS to

change the number), press ON/OFF to confirm and then you will see the detailed record.

In the detailed record interface, at the top are the record total number and current number. In the middle are the date

and time, and the concentration is at the bottom.

Erase history data

To make sure the detector work perfectly and you can check the history data quickly, we suggest you to erase the

history data regularly. Press MENU, choose the “Erase ex_flash”, password is needed (the password is 9999), then

press ON/OFF, it shows that “erasing”, and when finished, it will turn back to the detecting interface.

Target Point Calibration

Note: Calibration needs to be done by professionals and with necessary accessories and standard gas.

Prepare the standard gas before starting the target point calibration. In detection mode, press ”MENU”, select “calibrate

span”, press ON/OFF button to enter. Then you will need to enter password. (If you need password, please contact the

manufacturer to get it)

After entering the password successfully, press ON/OFF to enter the target point calibration interface, as shown in the

picture. The interface will display “concentration”, “set value. The concentration is the result got from the calculation of

several internal calibration parameters. The process of calibration is the process to recalculate the internal parameters

of the device. The set value is the value need to be entered manually; it should be the concentration of the standard

gas to be calibrated. Select the parameter under the current interface, modify its value with “PLUS” and “MINUS”

button.

The calibration process is as below:

1. Connect the detector with standard gas cylinder by hose.

2. Enter the target point calibration interface, set the “SET value” as the standard gas

concentration.

3. Release the standard gas to the detector in a flow rate of 500mL/min. The value of

“concentration” will become larger gradually, and become stable after 30seconds.

4. When the value of “concentration” is stable, press the “ON/OFF” button, the value of

“concentration” will be same with or almost same with the “Set value”. The calibration

is finished.

5. Cut off the standard gas supply. Press “ESC” to go back to detection interface.

9

Table of contents

Other GasDog Gas Detector manuals