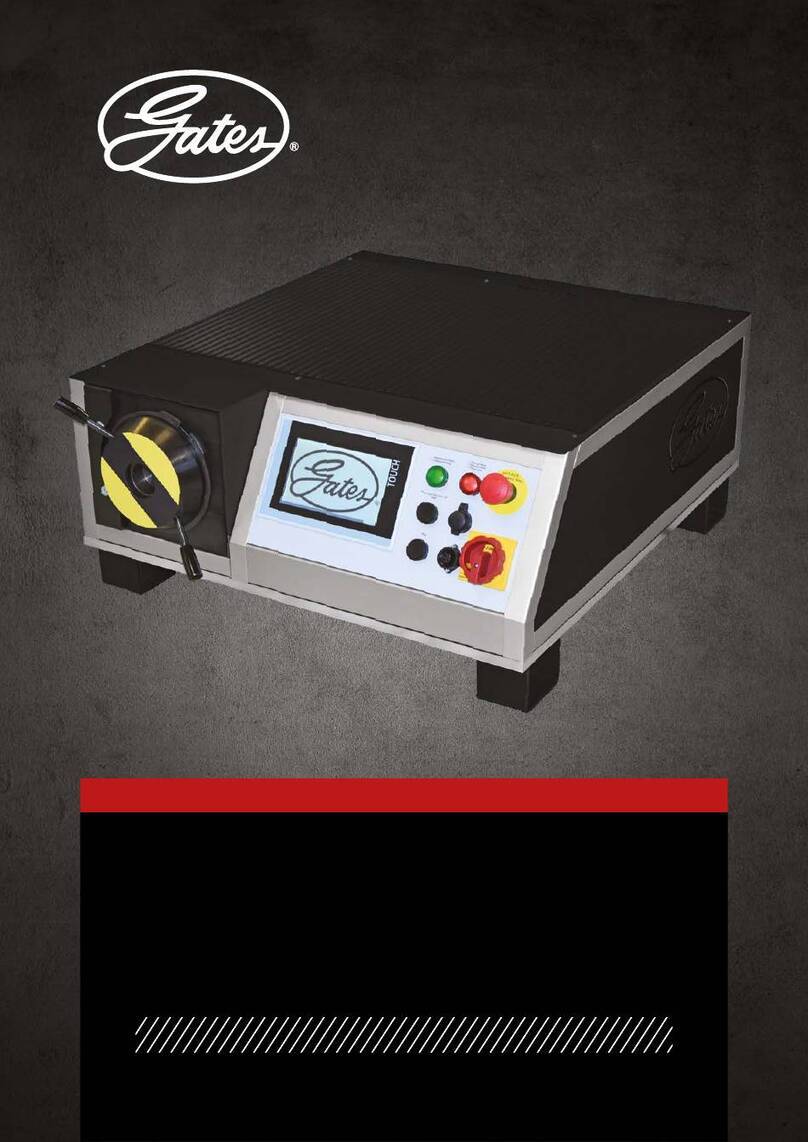

Gates 350C User manual

SONIC TENSION METER

MANUAL · MODEL 350C

WARNINGS 2

SONIC TENSION METER PARTS 2

OPERATING INSTRUCTIONS 3

Taking a Measurement 3

OPERATING INSTRUCTIONS 4

Measurement Range And ON / OFF 4

TIPS ON USING THE SONIC TENSION METER 5

Consistent Readings 5

Minimum Belt Span Length 5

Minimum Belt Tension 5

New Belt Installation 5

Windy Environment 6

SUMMARY OF FEATURES 6

TROUBLESHOOTING 7

WARRANTY 8

TABLE OF CONTENTS

THANK YOU FOR PURCHASING

THE GATES SONIC TENSION METER.

PLEASE READ THIS MANUAL

THOROUGHLY TO FULLY UTILIZE

ALL THE FUNCTIONS OF THIS METER.

350C SONIC TENSION METER GATES

2GATES.COM

TABLE OF CONTENTS

■DO NOT twist the gooseneck

more than 90 degrees.

■DO NOT drop this unit. Impact

of any kind can result in damage.

■DO NOT put water, solvent or any

other liquids on this unit.

■DO NOT leave this unit in a

dusty environment.

MICROPHONE HEAD:

Two small holes on rear side should

be directed towards belt.

FLEXIBLE GOOSENECK:

Enables convenient and effective

positioning of microphone for

measurement.

BACKLIT DISPLAY:

Bright display, suitable for all light

conditions.

BUTTONS

POWER, MEASURE, RANGE:

Simple and intuitive interface.

POWER SUPPLY

2 X AAA BATTERIES

Supplied with silicone case for

comfortable grip.

350C SONIC TENSION METER

WARNINGS ■DO NOT leave this unit where it

will get hot, such as in a car or in

direct sunlight.

■DO NOT use volatile solvents to

clean this unit.

■DO NOT use this in an area

where a spark could cause

an explosion.

■DO NOT pull hard on the cord of

the sensor (microphone) from

either end.

■DO NOT use this unit outside

during a thunderstorm, turn off

power and seek a safe place.

Non-compliance could result in

electric shock from thunderbolt.

■DO NOT bend the flexible arm

sensor (microphone) within 20

mm (3/4 inch) of either end,

because the construction is

tubular, and the flexible arm

sensor should not be bent at

sharp angles.

350C SONIC TENSION METER

GATES

3

GATES.COM WARNINGS & SONIC TENSION METER PARTS

OPERATING INSTRUCTIONS

TAKING A MEASUREMENT

TO TAKE A BELT RESONANT FREQUENCY MEASUREMENT:

1. Press “MEASURE”, to initiate measurement mode on the 350C Sonic Tension Meter.

2. Position microphone head <1cm from the center of the belt span. The small holes in the microphone head should be

directed towards the belt.

3. Tap or pluck the belt in the center of the belt span so that it oscillates up and down relative to its direction of travel.

4. The belt resonant frequency shall appear on the display.

Below diagram shows the user interface elements for taking a measurement.

FREQUENCY READING AREA:

FLASHING BARS = measurement mode

i.e. currently ‘listening’ for belt resonance

SOLID BARS = on standby

VALUE = most recent measured value, Hz.

MEASURE BUTTON:

Press once to start measurement.

The device will continue to listen

for a belt resonance until detected.

To exit measurement mode,

press “MEASURE”.

SIGNAL STRENGTH:

Shows the quality of the received

signal used to identify the belt

resonant frequency. All three bars are

filled when signal quality is highest.

Improve signal quality by following

“Tips on Using the Gates Belt

Frequency Meter”.

350C SONIC TENSION METER GATES

4GATES.COM

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

MEASUREMENT RANGE AND ON/OFF

BELOW DIAGRAM SHOWS THE USER INTERFACE ELEMENTS FOR CHANGING

THE MEASUREMENT RANGE AND SWITCHING THE DEVICE ON/OFF.

CURRENT MEASUREMENT

RANGE:

Range of frequencies within which

the belt resonance is expected.

Frequencies outside this range

will not be reported.

RANGES:

■Low = 10-50 Hz

■Standard = 50-500 Hz

■High = 500-5000 Hz

■Default = “Standard”

POWER BUTTON:

To switch on, press once.

To switch off, press and hold

for 2 seconds.

If inactive for 5 minutes, the device

will switch off automatically.

LOW BATTERY:

A low battery icon will appear when ~1

hour of constant usage remains.

RANGE BUTTON:

Press to cycle through 3 different ranges

(Low, Standard, High).

350C SONIC TENSION METER

GATES

5

GATES.COM OPERATING INSTRUCTIONS

TIPS ON USING THE SONIC

TENSION METER

The Gates Sonic Tension Meter is capable of measuring belt tension with greater accuracy and consistency than traditional methods.

It should not, however, be expected to produce exacting results in every case. While numerous factors can be found to influence

the accuracy of the meter’s output, one must remember that traditional methods of belt tensioning such as force/deflection or belt

elongation are approximate.

The following suggestions are provided to help you achieve a high level of accuracy with the Gates Sonic Tension Meter:

CONSISTENT READINGS

■Take at least three readings to confirm that results are consistent and the meter is not erroneously reading background noise.

MINIMUM BELT SPAN LENGTH

■When measuring the tension in synchronous belts, use spans that are more than 20 times the length of the tooth pitch. Using

spans shorter than this may result in readings that are higher than the actual tension due to belt cross-sectional stiffness.

■When measuring the tension in V-belts, use spans that are more than 30 times the belt top width. Using spans shorter than

this may result in readings that are higher than the actual tension due to belt cross-sectional stiffness.

MINIMUM BELT TENSION

■There are limits as to how low a span tension value the meter can measure depending upon the belt type and cross section.

Minimum recommended installation tension values are available for all belt sections from either drive design manuals or

Gates Product Application Engineering. Attempting to measure belt tensions below these minimum recommended values

should be avoided, as the meter may provide inaccurate results. If the belt span tension is low, and a tension reading cannot

be obtained, try increasing the belt tension and then take another reading.

NEW BELT INSTALLATION

■Before measuring belt installation tension, turn the drive over by hand for several revolutions to fully seat the belt and

equalize tension in all of the belt spans. Factors such as sprocket/shaft eccentricity, belt/sheave groove irregularity, etc.,

can influence belt tension as the sprockets or sheaves rotate. If the measured belt tension changes significantly as the drive

is rotated, and accurate measurements are needed, determine the low and high values and average them together.

350C SONIC TENSION METER GATES

6GATES.COM

TIPS ON USING THE SONIC TENSION METER

WINDY ENVIRONMENT

■Wind can adversely affect the ability of the meter to make a reading by creating excessive background noise.

SUMMARY OF FEATURES

■Model 350C, Product no. 7420-0350

■Max Frequency of 5000 Hz

■Variable Frequency Range Filters

■Auto Shut Off - The meter will automatically shut off after 5 minutes of inactivity. Power can be shut off manually by pressing

and holding the “POWER” button for 1-2 seconds.

■Batteries - 2 each; AAA. The battery compartment can be found on the backside of the meter.

■Supplied with silicon case for comfortable grip

■CE, UKCA

350C SONIC TENSION METER

GATES

7

GATES.COM SUMMARY OF FEATURES

TROUBLESHOOTING

SYMPTOM CAUSE TO CORRECT

METER WON’T

TURN ON

Batteries are dead Replace Batteries

Battery contacts are corroded Clean contacts and replace batteries

Meter has sustained damage

Consider meter repair or replacement

Gates certification / evaluation / repair service

CAN’T OBTAIN A

BELT TENSION

READING

Sensor is too far away from belt surface Move sensor as close as possible without interfering with

vibrating belt span

Belt is too loose to generate frequency signal Tighten belt

Background noise is excessive Temporarily eliminate background noise

Meter is set in the incorrect frequency range

“Standard” frequency range is generally best

"Range" to select the correct frequency

Low (L) = 10 – 50 Hz

Standard = 20 - 500 Hz

High (H) = 500 – 5000 Hz

Belt span frequency is less than 30 Hz Microphone performance is reduced considerably

at frequencies less than 30 Hz

Excessive wind is blowing across Microphone Shield or shelter microphone

Belt span is long and frequency very low

Tighten belt

Check to see if calculated belt frequency is below 30 Hz

Artificially reduce belt span length using a block, etc.

MULTIPLE BELT

TENSION

READINGS ARE

SIGNIFICANTLY

DIFFERENT

Belt tension is near absolute minimum threshold Tighten belt and see if reading variation is reduced

Some tension reading variation is normal

It is normal for the meter to detect slightly different

fundamental span frequencies

Take at least three tension readings and average the results

The drive has been rotated between readings

Belts must fully seat on pulleys / sheaves and equalize for

tension to stabilize

Pulley / shaft eccentricity can change belt tension

significantly; establish minimum / average / maximum

tension level limits and set belt tension accordingly

METER

READINGS

SEEM

INCORRECT

Belt span length may be too short

The minimum span length recommended for synchronous

belts is 20X the belt pitch

The minimum span length recommended for V-type belts

is 30X the belt or rib top width

METER BATTERY

LIFE IS SHORT

Meter usage is heavy Fresh alkaline batteries provide approximately 15 hours of

meter usage

Non-alkaline type batteries are being used Use only alkaline type batteries

350C SONIC TENSION METER GATES

8GATES.COM

TROUBLESHOOTING

WARRANTY

GATES WARRANTS THE METER TO

SUCCESSFULLY OPERATE FOR A

PERIOD OF TWO YEARS FROM THE

DATE OF MANUFACTURE:

■Gates will repair or replace meters, at our discretion,

at no charge within the warranty period.

■Meters damaged by misuses or abuse, at Gates

discretion, are not covered by the warranty.

IN ORDER TO RETURN METERS FOR

WARRANTY REPLACEMENT:

■Contact an authorized Gates distributor for assistance.

■Do not return meters to Gates without prior approval

and an RMA (Return Materials Authorization) in the box.

■Gates takes no responsibility for any meters returned to

the wrong address or without an RMA issued by a Gates

authorized distributor.

■www.gates.com/distributors

350C SONIC TENSION METER

GATES

9

GATES.COM WARRANTY, SERVICE, AND CERTIFICATION

GATES.COM

©GATES 2023

Table of contents

Other Gates Measuring Instrument manuals

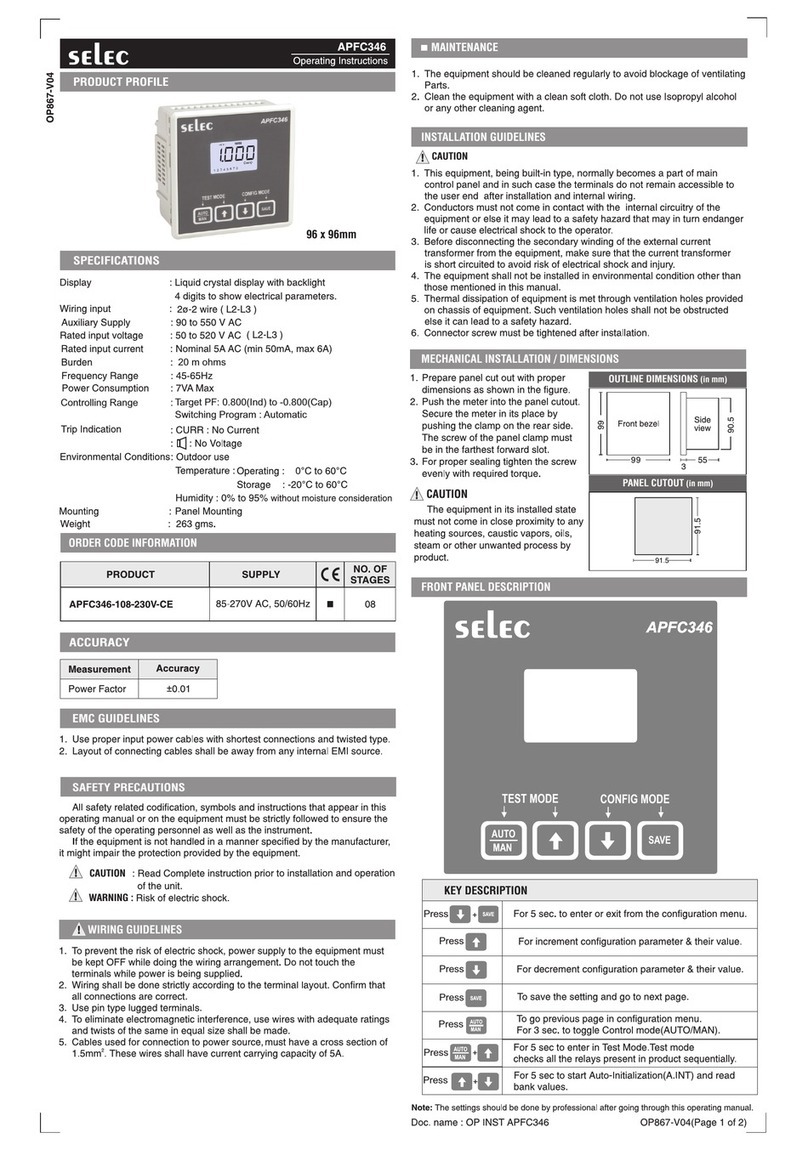

Popular Measuring Instrument manuals by other brands

Prosense

Prosense FMM50-1001 operating instructions

IFM Electronic

IFM Electronic efector 300 SM6100 operating instructions

ANDO ELECTRIC

ANDO ELECTRIC AQ7250 instruction manual

Technomark

Technomark M4 inline Software user's guide

Trace2O

Trace2O METALYSER DELUXE HM2000 instruction manual

Carel

Carel AS Series quick start guide