Gates 508C User manual

UK

F

D

E

NL

I

PL

RU

CZ

1

• Gates Sonic tension meter manual

• Manuel d’utilisation pour

le tensiomètre Sonic Gates

• Handbuch für Gates Sonic

Vorspannungsprüfer

• Manual para el tensiómetro

Sonic de Gates

• Gebruiksaanwijzing Gates’

Sonic spanningsmeter

• Manuale d’uso per

il tensiometro Sonic

Gates

• Instrukcja obsługi

akustycznego miernika

naprężenia Sonic 508C

firmy Gates

• Руководство по

работе со звуковым

измерителем

натяжения ремней

Sonic 508C

компании Gates

• Příručka pro

Sonic měřič

napnutí

společnosti

Gates

508C

2

UK

F

I

E

NL

D

PL

R

TJ

Gates Sonic tension meter

manual

Contents Page

1. Important warnings .....................................2

2. Components of the 508C meter..................3

3. Operating procedure for the 508C meter ...4

4. Sonic tension meter operating theory ........7

5. Belt installation tension...............................8

6. Tips on using the Sonic tension meter .......8

7.

Meter recalibration for non-standard belts

..10

8. Summary of features .................................10

9. Optional accessories..................................10

10. Warranty and service .................................11

11. Belt unit weight calculation .......................11

Thank you for purchasing the Gates Sonic

tension meter. Please read this manual

thoroughly to fully utilise all the meter’s

functions.

1. Important warnings!

>Do not drop this unit. Impact of any kind

can result in damage.

>Do not disassemble the unit.

>Do not put the unit in a place where fire or

explosion is possible.

>Do not put water, solvent or any other

liquids on this unit.

>Do not leave this unit in a dusty

environment.

>Do not leave this unit where it will get hot,

such as in a car or in direct sunlight.

>Do not use volatile solvents to clean this

unit.

>Do not use this in an area where a spark

could cause an explosion.

>Do not bend the flexible arm sensor

(microphone) within 20 mm (3/4 inch)

of either end. Its construction is tubular,

and it should not be bent at sharp angles.

3

UK

F

I

E

NL

D

PL

R

TJ

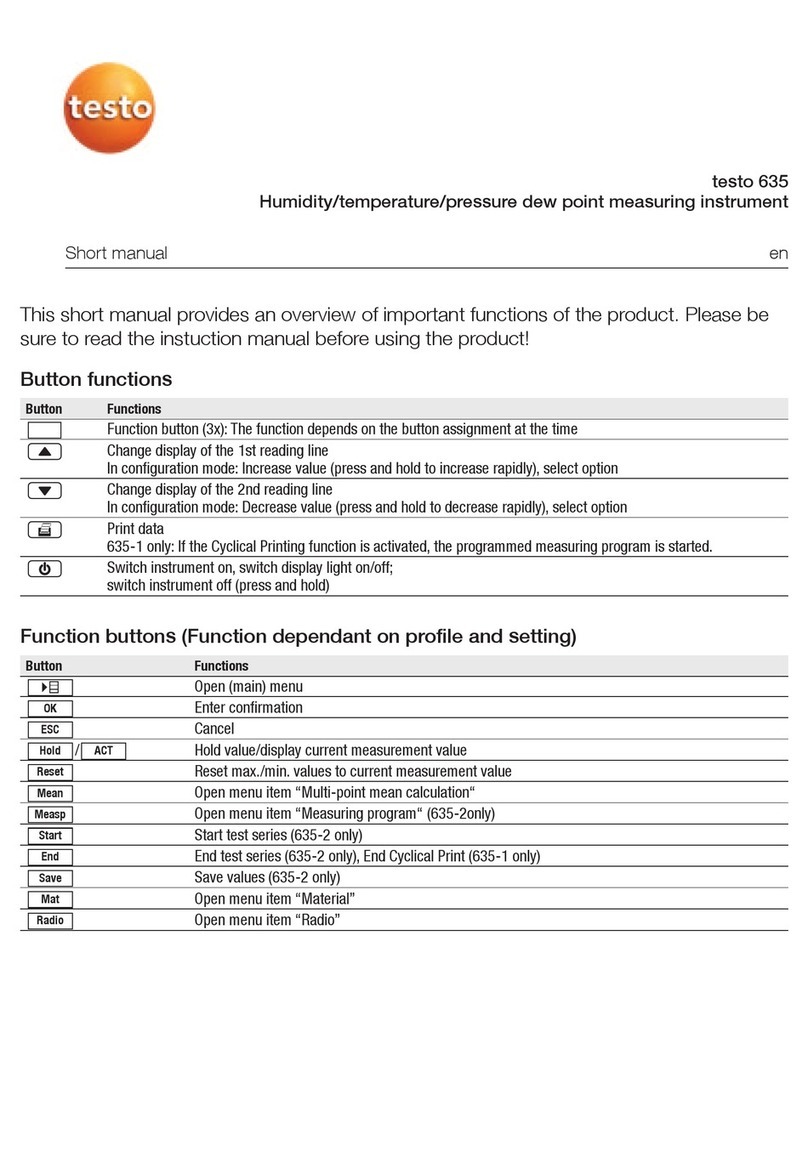

2. Components

of the 508C meter

1 - Flexible sensor

2 - Sensor connector

3 - Power switch

4 - Belt unit weight key

5 - Belt width key

6 - Up button

7 - Down button

8 - Frequency range button

9 - LCD screen with backlight

10 - Measure key

11 - Belt span length key

12 - Frequency/tension display key

13 - Data selection key

14 – Batteries

2

1

3 10

9

4 11

5

6

7 12

8 13

14

4

UK

F

I

E

NL

D

PL

R

TJ

3. Operating procedure for

the 508C meter

The Sonic tension meter enables non-contact,

simple and accurate measurement of

installation tension by analysing sonic wave

action, which is related to the belt

characteristics. The sonic wave is generated

by vibrating the belt span of the stationary belt,

and it is captured by the sensor and processed

to give belt tension which is displayed digitally.

Attaching sensor

Each of the male and female connectors has

a notch on the surface. Align the notches and

push the connectors together. To disconnect,

hold the collar towards the sensor and pull out.

Turn on the power

1 “MASS”

2 “WIDTH”

3 “SPAN”

4 Storage Register Number

5 Frequency Setting

6 Battery Level Meter

Press the “Power” key and the LCD screen

displays the current input data storage register

number. To change, refer to “Input data storage

and retrieval”.

The LCD screen is back lit for use in low light

conditions. The screen and back light remain

on for up to five minutes of inactivity, and then

the unit automatically turns off. The opening

screen displays the contents of the data storage

register that was last being used when the

Sonic tension meter was turned off. Values for

(1) “MASS” (Belt Mass Constant), (2) “WIDTH”

(Belt Width), and (3) “SPAN” (Belt Span Length)

are all displayed simultaneously.

Important Note: Reasonable (non-zero)

belt constant values must be used in the

storage registers in order to receive belt

tension readings. The unit will display span

frequency values regardless of the belt

constants entered, but will display “Error”

and the red light will remain on if the

calculated belt tension value is beyond

the display range of the screen.

Enter belt unit mass

M = .g/m

(Grams per metre length – enter factors page

11-12-13-14).

Capacity available for input is from 000.1 to

999.9 g/m. Press the “Mass” key and enter

numbers on the keypad. Make sure the decimal

is placed correctly in the display panel. If your

entry is incorrect press “Mass” again, and

the cursor returns to the original position.

SNo. 01

M 999.9 g/m

W 999.9 mm/R

S 9999 mm

1

2

3

5

6

4

5

UK

F

I

E

NL

D

PL

R

TJ

Enter width or number of ribs/strands

W = .mm/#R

Capacity available for input is from 000.1 to

999.9 mm or number of ribs or strands.

For a synchronous belt, enter the width in

millimetres. For an Industrial V-belt, enter

the number of belts being measured.

For a Micro-V®belt, enter the number of ribs.

For a Polyflex®JB®or PowerBand®belt, enter

the number of strands. Enter the number of

ribs/strands only for the belt being tested.

When using the Sonic Tension Meter on

drives with multiple single or PowerBand®

or Polyflex®JB®belts, be sure to use

the appropriate mass constant and enter

the correct number of belt strands being

measured. There is no need to multiply the

mass constant by the number of ribs/strands,

as the Sonic Tension Meter will calculate

the correct total belt mass.

Example:

For a V-belt drive using four individual SPB belts

enter “1” for the belt width (“Width” key).

The Sonic Tension Meter will display the static

belt tension per individual belt. When measuring

the belt tension in the V-belt drive, make sure

the V-belts do not interfere with each other

while vibrating.

If the same drive used a 4-strand SPB

PowerBand®belt instead of single belts enter

“4” for the belt width (“Width” key). The total

belt tension for all four belts is measured as

the entire belt vibrates. The Sonic Tension Meter

will display the total static belt tension for the

PowerBand®belt (for all strands within belt).

Enter the span length

S = mm

Capacity available for input is from 0001 to

9999 mm.

The span length represents

the distance between the contact points on

adjacent pulleys/sheaves. This distance may

be measured directly, or it may be calculated

from the formula below. Calculating the span

length gives the best results.

Span length (mm) = CD2- (D - d)2

4

Where:

CD = centre distance (mm)

D = large pulley diameter (mm)

d = small pulley diameter (mm)

Input data storage and retrieval

Weight, width and span values can be stored

for up to 40 different drive systems. Press the

“Select” key to toggle through the 40 storage

registers or press a number between 0 and 39,

then enter values for the belt constants.

After this is completed, the belt values can

be recalled for a drive by simply pressing

the “Select” key and the number that

corresponds to the storage register.

6

UK

F

I

E

NL

D

PL

R

TJ

Measurement

Press the “Measure” key and the green LED

will begin flashing. It will flash until a signal

is received by the sensor. Tap the belt span

to make the belt span vibrate. Hold the sensor

approximately 1 cm (0.4 inch) from the belt

or closer as long as the belt does not hit

the sensor. The green light will turn off after

a signal is received and remain off for about

1.5 seconds during processing. The measured

belt tension is then displayed, the meter beeps

three times and the green LED turns back on

and remains on until another signal is received.

If the belt tension or frequency cannot

be measured, the red LED will turn on.

Tension display

T = . kg or lb or N

The units of measured force can be switched

between kilograms, pounds and Newtons.

This can be accomplished as follows:

When the power is switched off, press the “0”

and “9” and “Power” key down at the same

time. Units can then be changed by pressing

the “Select” key until the desired unit appears.

Press the “Power” key again to return the meter

to its normal operating mode.

Frequency display

F = . Hz

Press the Hz key to view the frequency

measurement.

When the Hz key is pressed again,

the measured tension is re-displayed.

If the Hz key is pressed a third time, a double

indication is given in Newton and Hz.

Measurement errors

If the belt tension or frequency cannot be

measured the red LED will turn on. If an error

has been made in the measurement, “ERROR”

will be displayed. Continue to retry the

measurement until tension is displayed.

It is not necessary to press the “Measure” key

again. If the memory is not used, the tension

meter switches to “ERROR” after three

measurements. Switch the meter off and

on again to continue measuring.

If the double display is used (Newton – Hz), then

the unit for which a value cannot be displayed,

will be indicated with a dotted line.

Frequency range

A frequency filtering feature is available to focus

the meter frequency measurement response

to a narrower range. This can be useful in

improving the response of the meter, and

in filtering out potentially interfering

background noise.

The standard selected frequency range is

between 10–600 Hz. The frequency range can

be changed. Hold down the “0-RANGE” button

one second or longer. The frequency ranges

STANDARD (10-600 Hz) or HIGH (500-5000 Hz)

7

UK

F

I

E

NL

D

PL

R

TJ

will be displayed. Choose a range with

the “UP” or “DOWN” button, and determine

with “MEASURE”.

Note: the letter in the upper left hand corner

of the LCD display indicates the frequency

range setting pointer (5) on page 4: H - High,

S - Standard.

Background noise

The microphone gain level is set automatically

when the unit is turned on, based upon

environmental background noise.

Note: if maximum microphone sensitivity is desired,

turn the meter on without the microphone attached

and wait for the meter to power up. Then connect

the microphone so tension measurements can

be taken.

Battery Gauge

A battery graphic is located in the upper-right

hand corner of the LCD screen. This gauge

provides an estimate of the remaining

battery power.

A dark filled graphic indicates a full charge.

When the battery level becomes critically low,

the meter indicator as well as a “Low Batt”

message both blink.

4. Sonic tension meter

operating theory

When an impulse is applied to a belt span,

it first oscillates in all modes of vibration,

but the higher frequency modes decay faster

than the fundamental mode. This leaves

a continuous sinusoidal wave that is related

to a specific belt tension. See diagram below.

Using a microcomputer, a data processing

method to capture a belt’s natural oscillation

frequency was developed. Using this method,

the wave form frequency can be determined

easily.

The new system uses special sensors to detect

belt oscillation wave forms. Data from these

sensors is sent to the microcomputer inside

the Sonic tension meter for processing

and conversion into the natural frequency.

To calculate belt tension, the Sonic tension

meter system uses the “transverse vibration

of strings theory”. To operate the meter,

the unit weight, span length and width of

the belt must be entered.

Changes in sound pressure

Time (millisecond)

Oscillation damping in a synchronous belt

3MGT - PowerGrip®GT3

9 mm width belt

2

0

-2080

8

UK

F

I

E

NL

D

PL

R

TJ

Formula: T = 4 x S2x M x W x f2x 10-9

Where:

T = belt span tension (Newton)

S = length of the span to be measured (mm)

M = belt unit weight (g/m/mm)

W = belt width (mm) or number of belt strands

f = natural frequency of the belt (Hz)

Unlike a string, belts have cross-sectional

rigidity. Therefore, tension values measured

by the meter may be higher than the actual

belt tension, depending on the operating

conditions under which the effects of rigidity

arise. When the actual belt tension must be

more precisely measured, a simple calibration

test may be necessary. This calibration

procedure is discussed in the section on

“Meter recalibration for non-standard belts”.

5. Belt installation tension

Proper belt installation tension is essential

in V-belt, Micro-V®and synchronous drives

for optimum performance and reliability.

The correct installation tension for a belt,

or set of belts, depends upon the drive

geometry and load conditions and must be

calculated. Procedures for calculating belt

tension are included in the appropriate drive

design manual or software. To determine

the belt tension recommended for specific

drive applications, either refer to the

appropriate drive design software

DesignFlex®Pro™(available for download on

www.gates.com/

europe), or contact Gates

Application Engineering.

The following catalogues may be helpful:

›Poly Chain®GT2 belt drive design manual

(E2/20109)

›V-belt drive design manual (E2/20070)

›Synchronous belt drive design manual

(E2/20099)

›Long Length drive design manual (E2/20065)

6. Tips on using the

Sonic tension meter

Gates’ Sonic tension meter is capable of

measuring belt tension with greater accuracy

and consistency than traditional methods.

It should not, however, be expected to produce

exact results in every case. Numerous factors

can influence the accuracy of the meter’s

output, one must remember that traditional

methods of belt tensioning such as force/

deflection or belt elongation are approximate.

The following suggestions are provided to help

you achieve a high level of accuracy with Gates

Sonic tension meter.

›After you have entered the correct numbers

into the meter, take at least three readings

to confirm that results are consistent and

that the meter is not erroneously reading

background noise.

›When measuring the tension in synchronous

belts, use spans that are more than 20 times

longer than the tooth pitch. Using spans

9

UK

F

I

E

NL

D

PL

R

TJ

shorter than this may result in readings that

are higher than the actual tension due to belt

cross-sectional stiffness.

›When measuring the tension in V-belts,

use spans that are more than 30 times

the belt top width. Using spans shorter than

this may result in readings that are higher

than the actual tension due to belt

crosssectional stiffness.

›There are limits as to how low a span tension

value can be measured depending upon

the belt type and cross-section. Minimum

recommended installation tension values

are available for all belt sections from either

drive design software, drive design manuals

or Gates Application Engineering.

Measuring tensions below these minimum

recommended values should be avoided,

as the meter may display “ERROR”/

“Error-Re-measure” or provide inaccurate

results.

›When measuring belt installation tension,

turn the drive over by hand for several

revolutions to fully seat the belt and equalise

tension in all of the spans before making any

measurements. Factors such as pulley/shaft

eccentricity, belt/sheave groove variation, etc.,

can influence belt tension as the pulley or

sheaves rotate. If the measured belt tension

changes significantly as the drive is rotated,

and accurate measurements are needed,

determine the low and high values and

average them together. When the tension of

2 spans differs more than 30% approx., adjust

them almost equally and measure again.

›Wind can adversely affect the ability of

the meter to make a reading by creating

excessive background noise. If measuring

in a windy location, shield the sensor from

the wind or use a microphone windscreen.

›An optional inductive sensor should be

utilised in noisy or windy environments for

optimal results. The inductive sensor uses

a magnetic field rather than sound waves.

A simple way to use this sensor is with

a magnet taped to the backside of the belt.

Small “rare earth” magnets, which are

included in the inductive sensor package

provide excellent results with minimal

influence on the belt span frequency due

to the added weight.

›If a specific process is used to set belt tension

in a particular application, and the meter

is used only to monitor the resulting belt

tensions, the frequency mode can be used

rather than displaying an absolute tension

value. Belt span frequencies for minimum

and maximum tension conditions can be

measured so assemblers/technicians can

use the meter to verify that belt installation

tension is within an acceptable range.

These frequency values can also be found by

using the DesignFlex®Pro™belt drive design

software (available for download on

www.gates.com/europe)

›Tension measurements made on belts at very

low tensions may yield greater variability and

a greater probability for errors. If a tension

reading cannot be obtained, the belt may

be too loose to generate a clear harmonic

frequency signal. If this is the case, the belt

may need to be tightened in order to obtain

a tension reading.

10

UK

F

I

E

NL

D

PL

R

TJ

7. Meter recalibration for

non-standard belts

Measuring the tension of special belts with

extra thick backings, alternate materials, etc.,

may yield less than accurate results using unit

weights for standard belts. In these cases,

a simple calibration process may be used.

The belting can be placed on a fixture with

a known span length under various known

tensions (hanging weights can be used).

By taking frequency measurements at various

tensions, span frequency vs. tension data can

be collected. These data can then be used in

a graphical format or in equation form to

convert measured span vibration frequencies

to accurate belt tensions. Data of this type is

specific to each application and cannot be

applied to drives with different span lengths.

Because the resulting data may not be linear,

it is best to measure the tension of non-

standard belts in terms of frequency rather

than deriving a new belt unit weight to measure

in terms of absolute tension.

8. Summary of features

›H 160 mm x D 26 mm x W 59 mm

›Batteries: 2 x AAA

›Suitable for multi-ribbed belts, V-belts and

synchronous belts

›Measurement range: 10 Hz to 5,000 Hz

›Measured accuracy: ± 1%

›LCD screen backlight

›Double display possible (Newton and/or Hz)

›Flexible sensor (Product No. 7420-00204)

›Cord sensor and inductive sensor available

on request

›Stores weight, width and span constants for

up to 40 different drive systems

›Auto gain adjustement function cancels out

background noise automatically

›Shuts off automatically after five minutes of

inactivity, making it an energy-saving device

›CE approved

›RoHS compatible: the device complies with

the European Directive (2002/95/EC) on

the restriction of the use of certain hazardous

substances in electrical and electronic

equipment.

9. Optional accessories

›Cord sensor - Product No. 7420-00206.

Cord sensor is recommended for measuring

tensions a distance from the Sonic tension

meter (+/- 1 meter cord length).

›Inductive sensor (Magnets included) -

Product No. 7420-00212. Comes as cord

sensor type. Recommended for noisy or

windy environments, for measuring steel

reinforced belts and low frequency

measurements (+/- 1 meter cord length).

11

UK

F

I

E

NL

D

PL

R

TJ

10. Warranty and service

Thank you for using Gates Sonic tension meter.

Gates warrants the meter to successfully

operate for a period of one year (or six months

for the sensors) from the date of purchase

and will repair any defects for which Gates is

responsible without charge within this period.

For certification needs contact your sales

representative.

11. Belt unit weight calculation

Unit conversion formulas

lbfx 4.4482 = N

lbfx 0.4536 = kgf

N x 0.1020 = kgf

N x 0.2248 = lbf

kgfx 2.2046 = lbf

kgfx 9.8067 = N

lbf= pounds force

N = Newton

Kgf= kilograms force

inches x 25.4000 = mm

mm x 0.0394 = inches

mm = millimetres

Note: Unit weights are for standard stock belts only.

Non-standard belt constructions may yield

inaccurate results and may require special unit

weights or special calibration procedures.

Synchronous belts

Poly Chain®GT Carbon™ (g/m)

5MGT 3.0

8MGT 4.7

14MGT 7.9

Poly Chain®GT2 (g/m)

8MGT 4.7

14MGT 7.9

PowerGrip®GTX (g/m)

8MX 5.8

14MX 9.7

PowerGrip®GT3 (g/m)

2MGT 1.4

3MGT 2.8

5MGT 4.1

8MGT 5.8

14MGT 9.7

PowerGrip®HTD®(g/m)

3M 2.4

5M 3.9

8M 6.2

14M 9.9

20M 12.8

PowerGrip®(g/m)

MXL (0.080”) 1.3

XL (0.200”) 2.4

L (0.375”) 3.2

H (0.500”) 3.9

XH (0.875”) 11.3

XXH (1.250”) 15.0

12

UK

F

I

E

NL

D

PL

R

TJ

Twin Power®(g/m)

PowerGrip®GT2

8MGT 8.2

14MGT 12.7

PowerGrip®HTD®

5M 4.6

PowerGrip®

XL 1.9

L 3.2

H 4.6

Long Length (g/m)

Poly Chain®GT Carbon™

5MGT 3.0

8MGT 4.7

14MGT 7.9

PowerGrip®GT Steel Glass fibre

3MR - 2.29

5MR 4.48 3.76

8MR 7.40 5.40

PowerGrip®HTD®Steel Glass fibre

3M - 2.29

5M 4.48 3.76

8M 6.52 5.40

14M 13.20 9.60

PowerGrip®Steel Glass fibre

XL - 2.32

L - 3.16

H 5.15 5.76

Synchro-Power®Steel Aramid

T5 2.2 2.0

T10 4.4 3.6

T10HF 4.7 -

T20 7.5 5.9

AT5 3.3 2.7

AT10 5.7 4.2

AT10 Niro 5.7 -

AT10 HF 5.5 -

AT20 9.7 7.3

ATL5 2.8 -

ATL10 6.7 -

ATL10HF 7.2 -

ATL20 10.7 -

HTD5 4.4 2.9

HTD8 6.9 4.7

HTDL8 7.9 4.5

HTD14 10.8 8.4

HTDL14 12.2 -

HPL14RSL 14.0 -

STD5 3.9 2.9

STD8 5.1 4.3

XL 2.1 1.9

L 3.5 3.0

H 3.9 3.2

XH 10.5 9.1

Synchro-Power®

T2.5 1.4

T5 2.2

T10 4.4

AT5 3.3

AT10 5.7

DL-T5 2.3

DL-T10 4.5

13

UK

F

I

E

NL

D

PL

R

TJ

V-belts

Predator®(g/m)

AP 109

BP 212

CP 315

SPBP 190

SPCP 354

8VP 513

Quad-Power®III (g/m)

XPZ 51.5

XPA 80.2

XPB 127

XPC 245

Super HC®MN (g/m)

SPZ-MN 72.2

SPA-MN 116

SPB-MN 186

SPC-MN 340

Super HC®(g/m)

SPZ 72

SPA 116

SPB 186

SPC 339

8V 510

Hi-Power®(g/m)

Z 60.5

A 110

B 193

C 316

D 605

Delta Classic™(g/m)

Z 53

A 95

B 169

C 262

D 552

Delta Narrow™(g/m)

SPZ 62.5

SPA 98

SPB 171

SPC 310

PowerBand®(g/m/rib)

Predator®PowerBand®

SPBP 266

SPCP 378

9JP 93

15JP 246

8VP 528

Quad-Power®PowerBand®

3VX 70.4

5VX 185

XPZ 92

XPA 145

XPB 228

Super HC®PowerBand®

SPB 244

SPC 378

9J/3V 96

15J/5V 241

25J/8V 579

14

UK

F

I

E

NL

D

PL

R

TJ

Hi-Power®PowerBand®

B 200

C 343

D 665

Polyflex®JB®(g/m/rib)

3M-JB 5.3

5M-JB 11.4

7M-JB 29.6

11M-JB 64.2

Polyflex®(g/m)

3M 3.5

5M 9.6

7M 26

11M 55

Micro-V®(g/m/rib)

PJ 10

PK 14

PL 36

PM 95

Note: For a single V-belt, enter 1 rib/strand with

“per belt” unit weight. When measuring a multiple

rib/strand belt, enter the number of ribs or strands

with “per rib/strand” unit weight.

15

30

D

Handbuch für Gates Sonic

Vorspannungsprüfer

Inhalt Seite

1. Wichtige Warnung......................................30

2. Teile des Vorspannungsprüfers -

Modell 508C................................................31

3. Bedienung des Vorspannungsprüfers -

Modell 508C................................................32

4. Funktionsprinzip des Gates Sonic

Vorspannungsprüfers ................................36

5.

Montagespannungswert für Antriebsriemen

..37

6. Hinweise zum Gebrauch des Gates Sonic

Vorspannungsprüfers ................................37

7.

Kalibrierung des Vorspannungsprüfers

für Nicht-Standardriemen

..........................38

8. Übersicht der Eigenschaften.....................39

9. Zubehör.......................................................39

10. Garantie und Kundendienst.......................40

11. Berechnung der Einheitsgewichte ............40

Vielen Dank für den Erwerb des Gates

Sonic Vorspannungsprüfers. Bitte lesen

Sie dieses Handbuch genau durch, um

alle Funktionen des Gerätes vollständig

nutzen zu können.

1. Wichtige Warnung!

>Lassen Sie dieses Gerät nicht fallen.

Erschütterungen jeder Art können

Schäden verursachen.

>Nehmen Sie das Gerät nicht auseinander.

>Verwenden Sie das Gerät nicht in

explosionsgefährdeten Bereichen oder

in der Nähe von Zündquellen.

>Das Gerät sollte nicht mit Wasser,

Lösungsmitteln oder anderen

Flüssigkeiten in Berührung kommen.

>Schützen Sie das Gerät vor Staub.

>Bewahren Sie das Gerät nicht in heißer

Umgebung wie z.B. in einem Auto auf

und setzen Sie es nicht direktem

Sonnenlicht aus.

>Benutzen Sie zur Reinigung dieses Gerätes

keine aggressiven Lösungsmittel.

>Nicht in Bereichen benutzen, in denen

Funken eine Explosion auslösen könnten.

>Der Biegeradius des flexiblen Sensors

(Mikrofon) sollte 20 mm nicht unterschreiten,

um ein Knicken zu verhindern. Der Sensor

darf nicht über scharfe Kanten gebogen

werden.

31

D

2. Teile des

Vorspannungsprüfers -

Modell 508C

1 - Flexibler Sensor

2 - Sensorverbindungsstück

3 - Ein/Aus Schalter

4 - Eingabetaste Einheitsgewicht

des Antriebsriemens

5 - Eingabetaste Riemenbreite

6 - Aufwärtstaste

7 - Abwärtstaste

8 - Frequenzbereichstaste

9 - LCD-Hintergrundbeleuchtung

10 - Auslösetaste zur Messung

11 - Eingabetaste Trumlänge

des Antriebsriemens

12 - Anzeigetaste Frequenz – Spannung

13 - Dateneingabetastatur

14 – Batteriefach

2

1

3 10

9

4 11

5

6

7 12

8 13

14

32

D

3. Bedienung des

Vorspannungsprüfers -

Modell 508C

Der Sonic Vorspannungsprüfer ermöglicht eine

berührungslose, einfache und genaue Messung

der Montagespannung, welche in direktem

Zusammenhang mit den Eigenschaften des

Riemens steht. Dies geschieht durch Analyse

der Schallwelle. Die Schallwelle wird erzeugt,

indem der Riementrum bei stillstehendem

Riemen in Schwingung versetzt wird. Sie wird

von einem Sensor erfasst und verarbeitet,

um eine Riemenspannung anzugeben,

die digital angezeigt wird.

Anbringen des Sensors

Der Stecker als auch die Buchse sind mit einer

Kerbe versehen. Richten Sie die Kerben aus und

drücken Sie die Stecker zusammen. Zur Trennung

halten Sie den Stellring in die Richtung des

Sensors und ziehen diesen heraus.

Einschalten des Gerätes

1 “MASS”

2 “WIDTH”

3 “SPAN”

4 Speicher Nr.

5 Frequenzbereich

6 Batteriestand

Drücken Sie die Taste “Power”. Auf der LCD-

Anzeige erscheint die Registernummer der

zuletzt gespeicherten Daten. Die Änderung

des Registers ist dem Abschnitt “Speichern

und Wiederauffinden der Daten” zu entnehmen.

Die LCD-Anzeige ist hintergrundbeleuchtet

und kann damit auch in Umgebungen mit

geringem Lichteinfall benutzt werden. Anzeige

und Hintergrundbeleuchtung bleiben ohne

Benutzeraktivität fünf Minuten lang eingeschaltet.

Danach schaltet sich das Gerät automatisch

ab. Nach dem Einschalten zeigt die Anzeige den

Inhalt des vor dem Abschalten des Sonic zuletzt

benutzten Datenspeicherregisters. Die Werte

für (1) “MASS” (Riemenmassekonstante),

(2) “WIDTH” (Riemenbreite) und (3) “SPAN”

(Riementrumlänge) werden alle gleichzeitig

angezeigt.

Wichtiger Hinweis:

Um Riemenspannungsmesswerte zu

erhalten, müssen in

den Speicherregistern

sinnvolle Werte ungleich

Null für die

Riemenkonstanten verwendet werden.

Das Gerät zeigt, ungeachtet der eingegebenen

Riemenkonstanten, Werte für die Trumfrequenz

an. Die Anzeige “ERROR” erscheint und die

rote LED bleibt eingeschaltet, wenn der

berechnete Riemenspannungswert außerhalb

des Anzeigebereichs des Bildschirms liegt.

SNo. 01

M 999.9 g/m

W 999.9 mm/R

S 9999 mm

1

2

3

5

6

4

33

D

Geben Sie die Masse des Antriebsriemens ein

M = .g/m

(Gramm pro Meter Riemenlänge -geben Sie

die Faktoren ein, wie auf den Seiten 40-41-42-43

angegeben).

Der Eingabebereich liegt zwischen 000,1 und

999,9 g/m. Drücken Sie die Taste “Mass”

(Masse) und geben Sie die Zahlen mittels

Tastaturfeld ein. Vergewissern Sie sich, dass

die Dezimalzahlen im Anzeigefeld korrekt

eingegeben wurden. Wenn Ihre Eingabe falsch

ist, dann drücken Sie erneut auf die Taste

“Mass” (Masse). Der Cursor kehrt in seine

Ausgangsstellung zurück.

Geben Sie die Breite oder die Anzahl

der Rippen ein

W = .mm/#R

Sie können eine Breite zwischen 000,1 und

999,9 mm oder die Anzahl der Rippen eingeben.

Die Breite eines Zahnriemens muss in

Millimetern angegeben werden. Für einen

Industriekeilriemen geben Sie die Anzahl der

zu messenden Riemen ein. Bei einem

Micro-V®-Keilrippenriemen geben Sie die Anzahl

der Rippen ein. Bei einem Polyflex

®

JB

®

-Riemen

oder einem PowerBand®-Riemen geben Sie die

Anzahl der Stränge ein. Geben Sie nur die Anzahl

der Rippen ein, die gemessen werden sollen.

Wenn Sie den Gates Sonic Vorspannungsprüfer

in Antrieben mit mehreren einzelnen PowerBand

®

-

oder Polyflex®JB®-Riemen verwenden, achten

Sie darauf, die passende Massekonstante zu

verwenden und geben Sie die richtige Anzahl

der zu messenden Stränge ein. Es ist nicht

erforderlich, die Massekonstante mit der

Anzahl der Stränge zu multiplizieren, weil

der Sonic Vorspannungsprüfer die korrekte

Gesamtriemenmasse berechnet.

Beispiel:

Für einen Keilriemenantrieb mit vier einzelnen

SPB-Riemen, geben Sie als Riemenbreite “1”

ein (Taste “Width” (Breite)). Der Sonic

Vorspannungsprüfer zeigt die statische

Riemenspannung pro Riemen an. Beim Messen

der Riemenspannung im Keilriemenantrieb,

achten Sie darauf, dass sich die Keilriemen

beim Vibrieren nicht gegenseitig beeinflussen.

Wenn derselbe Antrieb einen viersträngigen

SPB-PowerBand®-Riemen anstelle der

Einzelriemen verwendet, geben Sie als

Riemenbreite (Taste “Width”) “4” ein. Es wird

die Gesamtriemenspannung für alle vier Riemen

gemessen, da der gesamte Riemen vibriert.

Der Sonic Vorspannungsprüfer zeigt die statische

Gesamtspannung des PowerBand®-Riemens

an (für alle Stränge in dem Riemen).

Geben Sie die Trumlänge ein

S = mm

Der für die Eingabe vorhandene Bereich liegt

zwischen 0001 und 9999 mm. Die Trumlänge

stellt den Abstand zwischen den Kontaktstellen

auf den Zahnscheiben/Riemenscheiben dar.

Dieser Abstand kann direkt gemessen, oder aus

der unten aufgeführten Formel errechnet

34

D

werden. Die Berechnung der Trumlänge führt

zu den genauesten Resultaten.

S (mm) = CD2- (D - d)2

4

Wobei gilt:

S = Trumlänge (mm)

CD = Achsabstand (mm)

D =

Wirkdurchmesser der großen Riemenscheibe (mm)

d =

Wirkdurchmesser der kleinen Riemenscheibe (mm)

Speichern und Wiederauffinden

der Daten

Das Gewicht, die Breite und die Trumlänge

von bis zu 40 verschiedenen Antriebssystemen

können gespeichert werden. Drücken Sie auf

die Taste “Select”, um der Reihe nach durch

die 40 Speicherregister zu schalten oder geben

Sie eine Nummer zwischen 0 und 39 ein. Geben

Sie dann die Werte für die Riemenkonstanten

ein. Danach lassen sich die Riemenwerte eines

Antriebs leicht wiederfinden, indem Sie auf

die Taste “Select” drücken und die richtige

Registernummer eingeben.

Messung

Drücken Sie die Taste “Measure” und die grüne

LED beginnt zu blinken. Sie wird weiter blinken

bis der Sensor ein Signal erhält. Tippen Sie den

Riementrum an, um den Riemen zum Schwingen

zu bringen. Halten Sie den Sensor ungefähr 1 cm

(0,4 Zoll) vom Riemen entfernt. Sie können den

Sensor auch näher an den Riemen halten, aber

stellen Sie sicher, dass er den Riemen nicht

berührt. Nachdem der Sensor ein Signal erhalten

hat, erlischt die LED für etwa 1,5 Sekunden.

Dies ist normal und durch die Datenverarbeitung

bedingt. Die gemessene Spannung wird angezeigt,

der Vorspannungsprüfer gibt ein akustisches

Signal ab und die grüne LED geht wieder an.

Sie bleibt an bis der Sensor andere Signale

erhält. Kann die Riemenspannung oder die

Frequenz nicht gemessen werden, dann wird

sich die rote Anzeige einschalten.

Spannungsanzeige

T = . kg oder lb oder N

Die Spannung kann in Kilogramm, Pfund oder

Newton wiedergegeben werden. Sie wählen die

benötigte Einheit der Kraft auf folgende Weise:

Wenn der Strom ausgeschaltet ist, drücken

Sie gleichzeitig die Tasten “0”, “9” und “Power”.

Sie können die Einheiten ändern, indem Sie

die Taste “Select” drücken, bis die benötigte

Einheit erscheint. Drücken Sie erneut die Taste

“Power” und der Vorspannungsprüfer kehrt

zur üblichen Betriebsart zurück.

Frequenzanzeige

F = . Hz

Drücken Sie die Taste “Hz”, um die gemessene

Frequenz anzuzeigen.

Bei erneutem Drücken der Taste “Hz” wird

wieder die Spannung angezeigt.

Other manuals for 508C

3

Table of contents

Languages:

Other Gates Measuring Instrument manuals