8

6.0 Functional Check and Safety

Inspection

To assure optimum performance, dependability, and

safety, the following should be performed every twelve

months or as specified in the facility’s preventive

maintenance program.

Equipment or tools required

oAny Gaymar D25340 series Blood/Fluid

Warming Set

oTemperature measurement device:

• Gaymar D25340 Blood/Fluid Warming

Set; and

• Temperature sensor (Gaymar catalog

FWT1) and an ohmmeter (accuracy,

1.5% of reading; maximum excitation

current of 100uA) and the resistance

temperature chart. See figure 10 (p. 12).

or

• Any Gaymar D25000 series

Blood/Fluid Warming Set; and

• Waterproof temperature sensor/

meter with an accuracy of ± 0.3%

across the range of 30°C to 60°C

and a thermal time constant of 2

seconds or faster.

oFlow measurement device (Gaymar

catalog FWT2 flowmeter):

• Fluid source with calibrated flow

meter and a minimum accuracy of

± 12 ml/minute

or

• Fluid source with adjustable flow

control, Use a stop watch and

graduated cylinder to adjust flow

rate.

oCurrent Leakage/Ground resistance tester

oAC multimeter

6.1 Physical Inspection

Check that the following items are in good condition

and secure.

oLabels, if peeling or missing

oScrews in cover

oBubble trap receiver

oPower cord

oIV pole clamp

6.2 Output Fluid Temperature

Verification

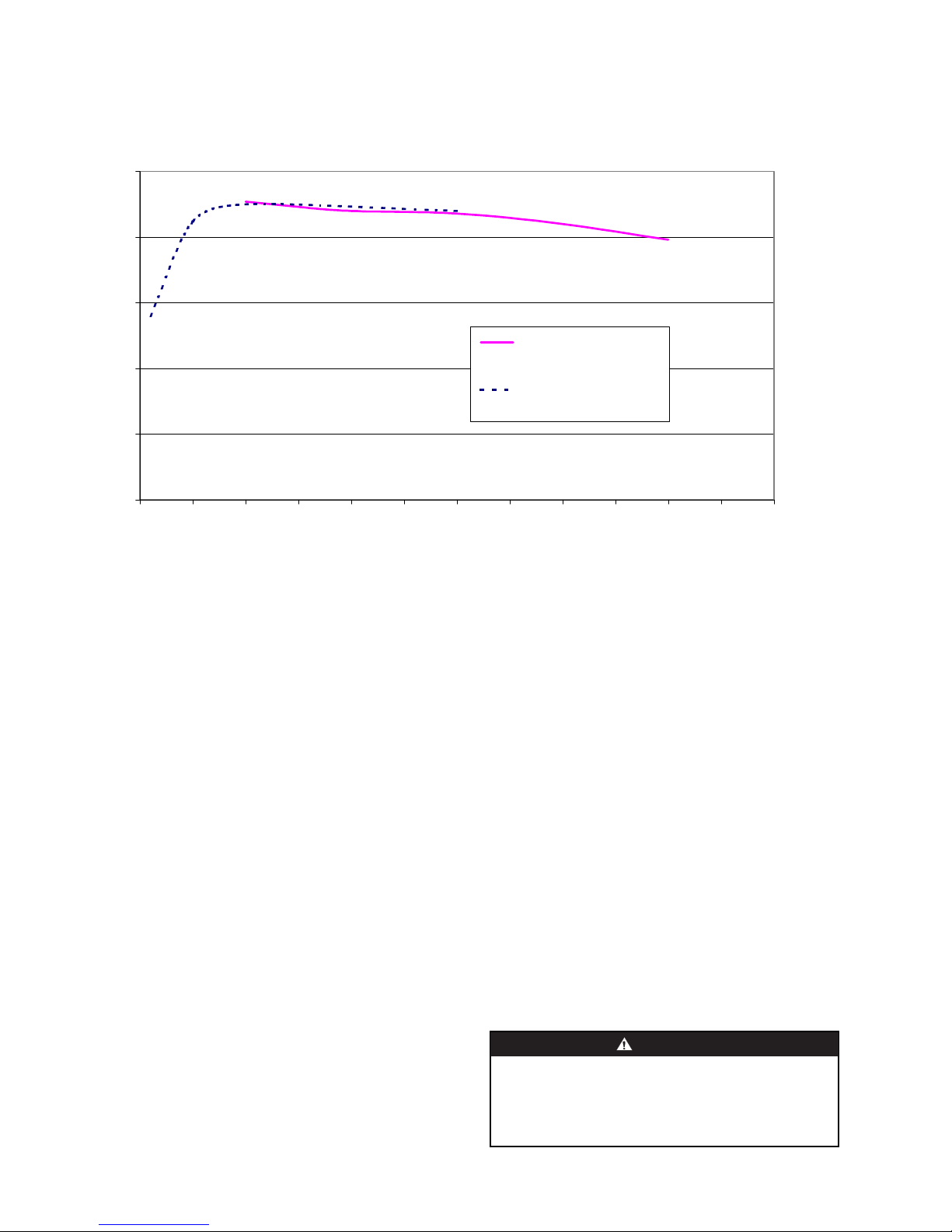

The FW600 Series Blood/Fluid Warmer is factory

calibrated at a flow rate of 100 ml/min with a set point

of 43.0°C.

To verify the output fluid temperature is correct:

1. The ambient room temperature must be between

20°C to 24°C.

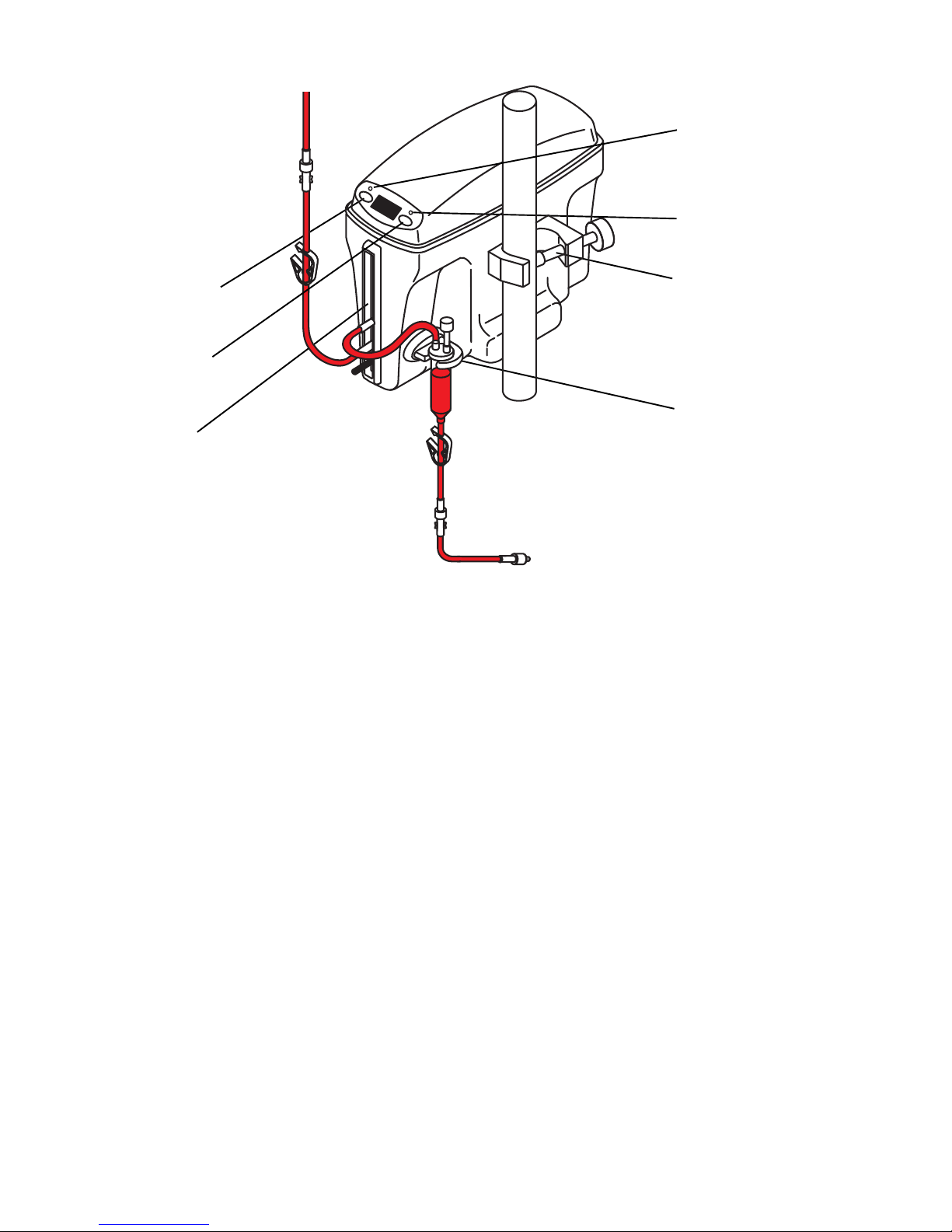

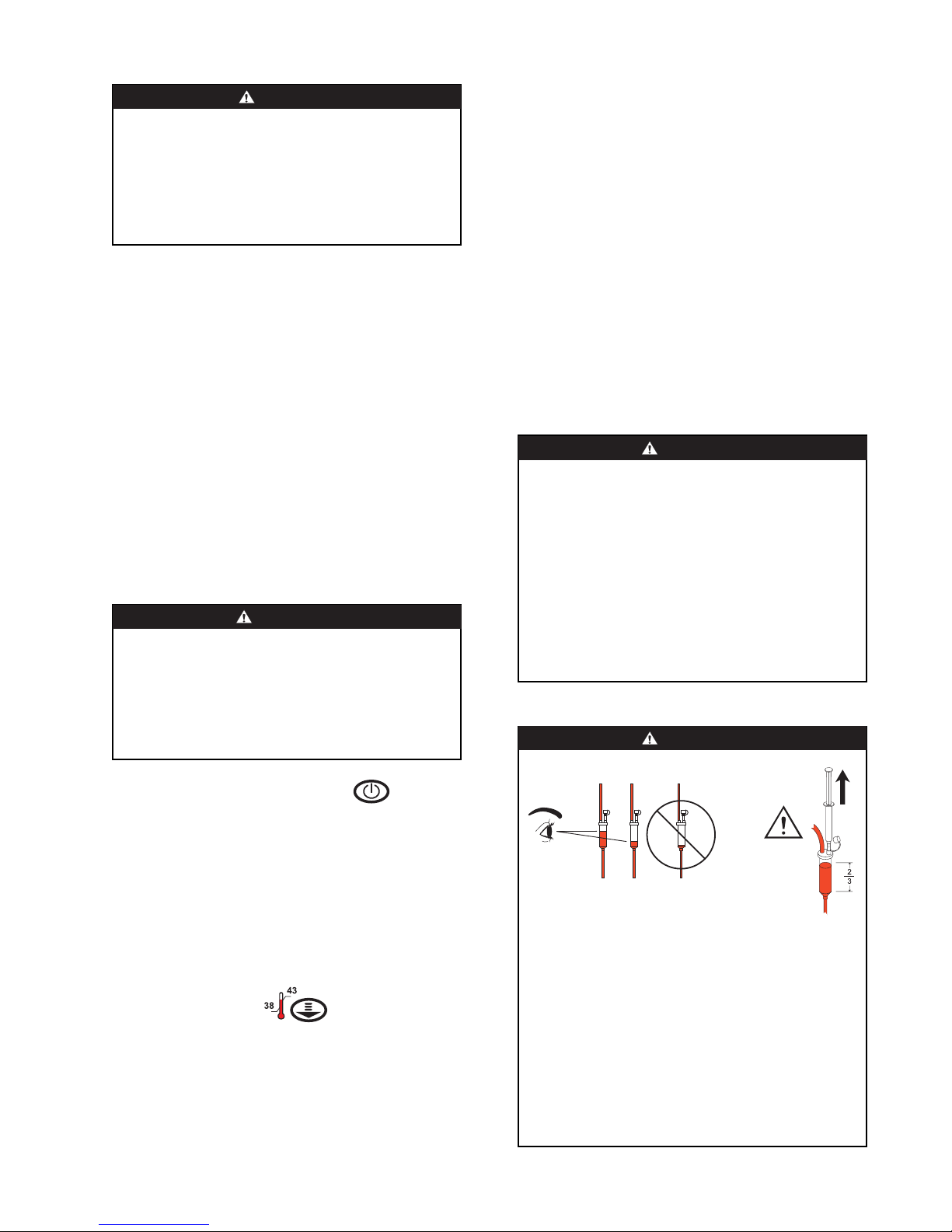

2. Connect the test setup (see figure 7). Attach the

Gaymar FWT1 temperature sensor to the output

of the bubble trap.

Alternate method: Put a hole in the top of the

bubble trap and insert a temperature

measurement device through this hole. Make

certain sensor is completely submerged in

fluid then seal the hole in the bubble trap.

3. Connect the FWT2 flowmeter or flow

measurement/control device to the output of the

FWT1 temperature sensor.

Alternate method: If using the sensor in the bubble

trap method, connect the FWT2 flowmeter or

flow measurement/control device directly to the

output of the bubble trap.

4. Flow room temperature water through the

warmer at 100 ml/min (cc/min). Verify that the

bubble trap is maintained 1/2 to 2/3 full.

5. Turn the warmer on. Adjust the SETPOINT to

43.0°C. Allow it to run for 10 minutes.

6. Verify that the output water temperature is

43.0°C ± 1.1°C. If using the FWT1 temperature

sensor and an ohmmeter, verify that the resistance

is within 1019—1112 ohms.

If temperature or resistance values are not

met, check setup and repeat test. If still not

within range, contact your dealer for service.

This device is factory calibrated and cannot be

field adjusted.

6.3 Overtemp Protection Verification

Proper operation of the overtemp protection system is

verified each time the unit is switched from STANDBY

to RUN mode. Therefore, periodic testing of this

system is not necessary. However, the following

procedure may be used to force an OVERTEMP

condition in order to observe that the overtemp

protection system works:

ENGLISH