•Stopwatch

•Adhesive Tape

•TestTool*(P/N08606000),or two 16 gauge

insulated Test Jumpers

* TheTestToolisavailablefromGaymar.

This tool was designed to allow for more

convenient testing of the thermostats

and eliminate the need to install jumpers.

Contact Gaymar's Technical Service

Department for more information.

•INSPECTION FORM (table 2, pp. 16-18)

Procedures

Perform the following procedures carefully,

paying particular attention to test setups.

Anydeviationfromthesetups,procedures,

or test equipment may result in incorrect or

misleading results.

7.1 Enclosure

Examine the overall condition of the Power Unit

exterior:

1. Unplugthepowerunit.

2. Examine the enclosure, checking for cracks.

3. Check that exterior screws are tight.

4. Check that labelling and markings are legible.

5. Clean accumulated dirt from the air vents

with a vacuum cleaner.

6. Check hose assembly for holes and broken

fittings. Replace if necessary.

7.2 Plug, Line Cord

Examine the plug, line cord:

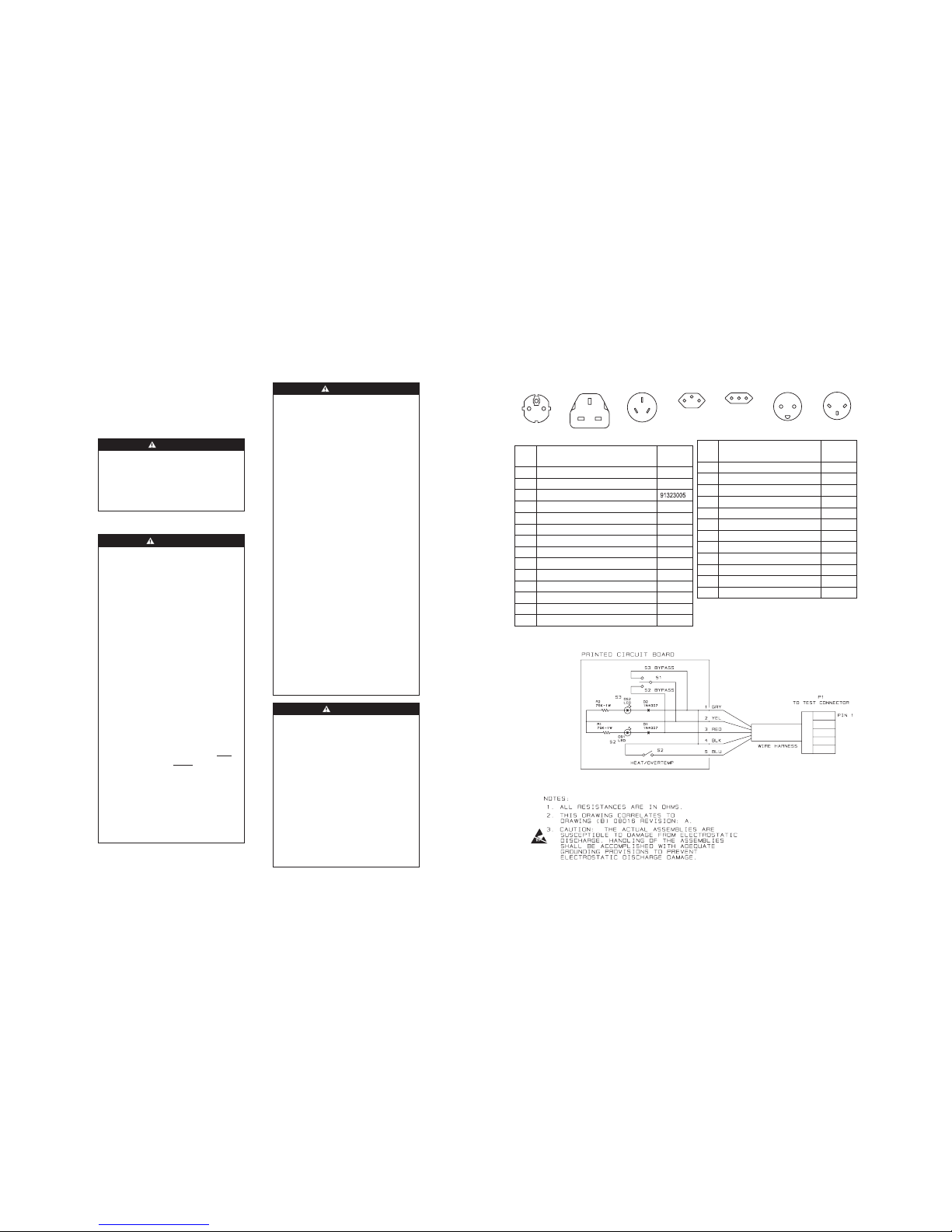

1. Examine the attachment plug on the line cord

to be sure it is in good condition.

2. Examine the line cord along its entire

length for physical damage, such as cuts

or cracked insulation. Check the quality of

the strain relief. Replace, rather than repair,

damaged line cords.

7.0 FunctionalCheckandSafety

Inspection

To assure optimum performance, dependability

and safety, perform FUNCTIONAL CHECK AND

SAFETY INSPECTION as follows:

•Afterrepair,andevery12monthsthereafter

— the FUNCTIONAL CHECK AND SAFETY

INSPECTION consists of all procedures

(sections 7.1 through 7.9).

If your facility's procedures call for more

frequent functional test and safety inspections,

note this fact on the INSPECTION FORM.

Inspection Form

An INSPECTION FORM (table 2, pp. 16-18) is

provided at the end of this section to facilitate and

document the inspection process.

Test Equipment

The following test equipment (or equivalent)

is required in order to perform the preventive

maintenance procedures:

•Digital air thermistor thermometer

(YSI 400 series)

Range: 50°F to 160°F (10°C to 71°C)

System accuracy: ±1°F (±0.6°C)

•Temperaturesensor

(P/N 77948-000)

NOTE:

1. Include the accuracy of the measuring

equipment when making judgments

about observed temperature readings.

2. Test Conditions: 230 VAC ± 2 ,

70°F-75°F (21°C-24°C) ambient.

(With heater on, may require the use of a

variable transformer.)

•#2 Phillips screwdriver

•Current Leakage / Ground Resistance Tester

•Quilt (See page 10, Figure 6B)

Section7-FunctionalCheckandSafetyInspection

8

the HEPA filter.

4. Remove the ten screws securing the filter

inlet plate.

5. Remove the screw and lock washer

securing the ground wire to the backing

plate. Remove the two screws securing the

terminal block.

6. Carefully lift the filter inlet plate, exposing the

blower wheel.

7. Remove the blower wheel using 1/8" hex

wrench through hole in one blade of blower

wheel.

8. Remove the two #6 screws holding the

heater to the motor bracket.

9. Disconnect the short wire from the heater to

the motor.

10. Remove the red heater wire from terminal

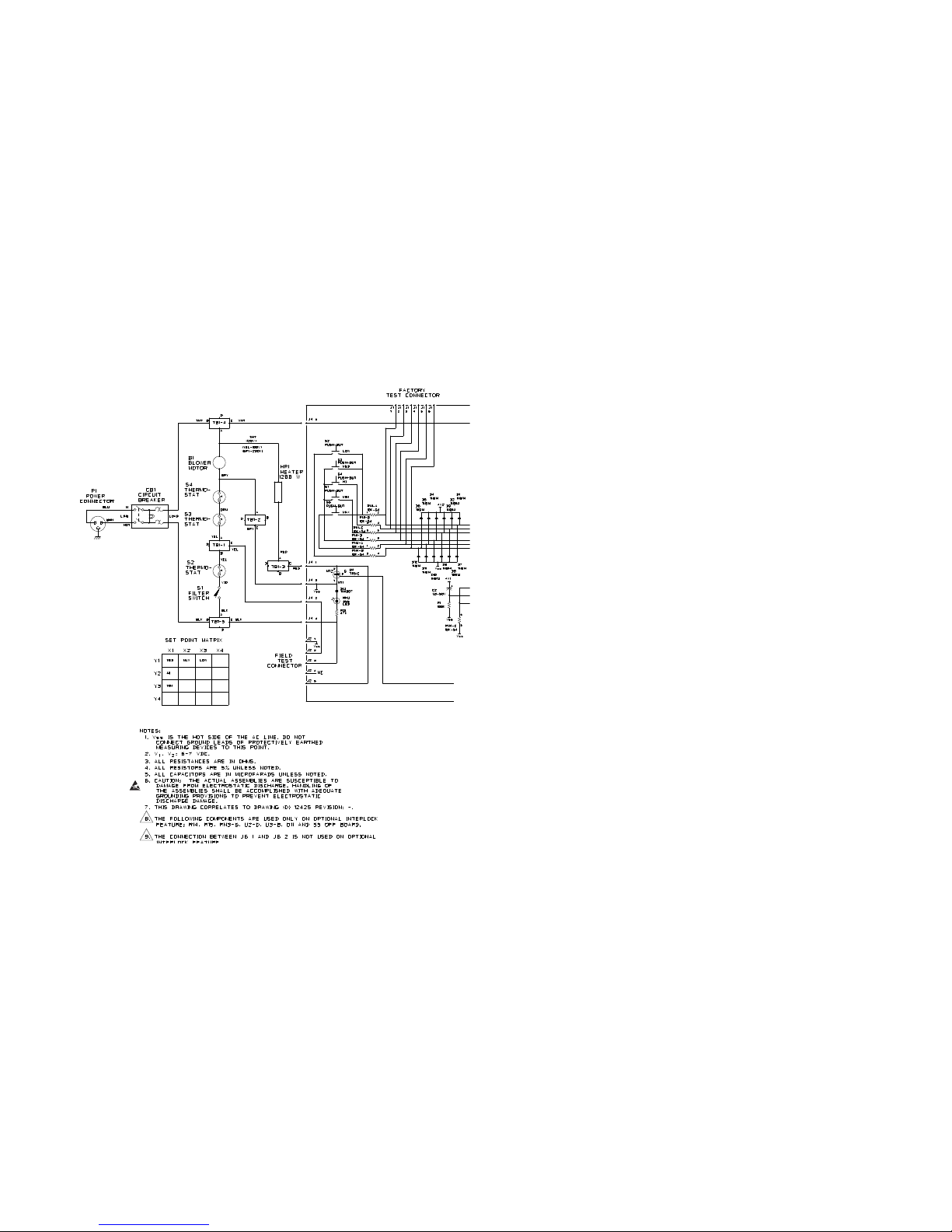

block location TB1-3 (see figure 11).

Remove cable ties.

11. Remove the heater.

12. Install the replacement heater.

13. Reroute the red wire through the 4-hole

grommet.

14. Reconnect both wires. Refer to TB1

designators in the schematic (figure 13) and

terminal block wiring designators in figure

11. Install cable ties.

15. Reinstall the blower wheel, making sure

there is 0.10" (2.5 mm) clearance between

the wheel and the blower inlet ring (see

fig. 9). NOTE: the hex screw must be

aligned with the flat on the motor shaft.

16. Place the filter inlet plate back on top of the

scroll. Secure the ten screws.

17. Replace the terminal block. Reconnect the

ground wire to the backing plate; make sure

the lock washer is reinstalled.

18. Replace the HEPA filter. Secure it with the

filter retainer and nut.

19. Perform the FUNCTIONAL CHECK AND

SAFETY INSPECTION (section 7, pp. 8-15).

10.0 Repair Procedures

Use only Gaymar replacement parts as

identified in the parts lists (pp. 24-27).

Useofsubstitutepartscouldresultin

power unit malfunction or patient injury.

To identify replacement parts, refer to figures

9-11 (pp. 24-27). To order replacement parts,

contact Gaymar's Export Department:

Export Telephone: (716) 662-8636

Fax: (716) 662-0730

10.1 Replacing the Patient Limit

Thermostat(s) (S2 & S3)

To replace either thermostat (item 18, fig. 11):

1. UnplugthePowerUnit.

2. Remove the six screws securing the

enclosure. Open the enclosure.

3. Carefully unplug the terminals from the

thermostat.

4. Remove the two #4 nuts from the

thermostat.

5. Replace the thermostat. Reinstall the nuts.

6. Carefully replace the terminals.

7. Perform the FUNCTIONAL CHECK AND

SAFETY INSPECTION (section 7, pp. 8-15).

10.2 Replacing the Heater

To replace the heater (item 3, fig. 9):

1. UnplugthePowerUnit.

2. Remove the six screws securing the

enclosure. Open the enclosure.

3. Remove the filter retainer and nut. Remove

Section 10 - Repair Procedures