If you choose to ride under conditions of poor visibility,

check and be sure you comply with all local laws about

night riding, and take the following strongly recommended

additional precautions:

• Purchase and install battery or generator powered

head and tail lights which meet all regulatory

requirements for where you live and provide adequate

visibility.

• Wear light colored, reective clothing and accessories,

such as a reective vest, reective arm and leg bands,

reective stripes on your helmet, ashing lights attached

to your body and/or your bicycle ... any reective device

or light source that moves will help you get the attention

of approaching motorists, pedestrians and other trac.

• Make sure your clothing or anything you may be

carrying on the bicycle does not obstruct a reector or

light.

• Make sure that your bicycle is equipped with correctly

positioned and securely mounted reectors.

While riding at dawn, at dusk or at night:

• Ride slowly.

• Avoid dark areas and areas of heavy or fast-moving

trac.

• Avoid road hazards.

• If possible, ride on familiar routes.

If riding in trac:

• Be predictable. Ride so that drivers can see you and

predict your movements.

• Be alert. Ride defensively and expect the unexpected.

• If you plan to ride in trac oen, ask your dealer

about trac safety classes or a good book on bicycle

trac safety.

F. Extreme, stunt or competition riding

Whether you call it Aggro, Hucking, Freeride, North

Shore, Downhill, Jumping, Stunt Riding, Racing or

something else: if you engage in this sort of extreme,

aggressive riding you will get hurt, and you voluntarily

assume a greatly increased risk of injury or death.

Not all bicycles are designed for these types of riding,

and those that are may not be suitable for all types of

aggressive riding. Check with your dealer or the bicycle’s

manufacturer about the suitability of your bicycle before

engaging in extreme riding.

When riding fast down hill, you can reach speeds

achieved by motorcycles, and therefore face similar

hazards and risks. Have your bicycle and equipment

carelly inspected by a qualied mechanic and be sure

it is in perfect condition. Consult with expert riders,

area site personnel and race ocials on conditions and

equipment advisable at the site where you plan to ride.

Wear appropriate safety gear, including an approved ll

face helmet, ll nger gloves, and body armor. Ultimately,

it is your responsibility to have proper equipment and to

be familiar with course conditions.

WARNING: Although many catalogs, advertisements

and articles about bicycling depict riders engaged

in extreme riding, this activity is extremely

dangerous, increases your risk of injury or death, and

increases the severity of any injury. Remember that the

action depicted is being performed by professionals with

many years of training and experience. Know your limits

and always wear a helmet and other appropriate safety

gear. Even with state-of-the-art protective safety gear, you

could be seriously injured or killed when jumping, stunt

riding, riding downhill at speed or in competition.

WARNING: Bicycles and bicycle parts have

limitations with regard to strength and integrity,

and this type of riding can exceed those limitations

or dramatically reduce the length of their safe use.

We recommend against this type of riding because of

the increased risks; but if you choose to take the risk, at

least:

• Take lessons om a competent instructor rst

• Start with easy learning exercises and slowly develop

your skills before trying more dicult or dangerous riding

• Use only designated areas for stunts, jumping, racing

or fast downhill riding

• Wear a ll face helmet, safety pads and other safety

gear

• Understand and recognize that the stresses imposed

on your bike by this kind of activity may break or damage

parts of the bicycle and void the warranty

• Take your bicycle to your dealer if anything breaks

or bends. Do not ride your bicycle when any part is

damaged.

If you ride downhill at speed, do stunt riding or ride in

competition, know the limits of your skill and experience.

Ultimately, avoiding injury is your responsibility.

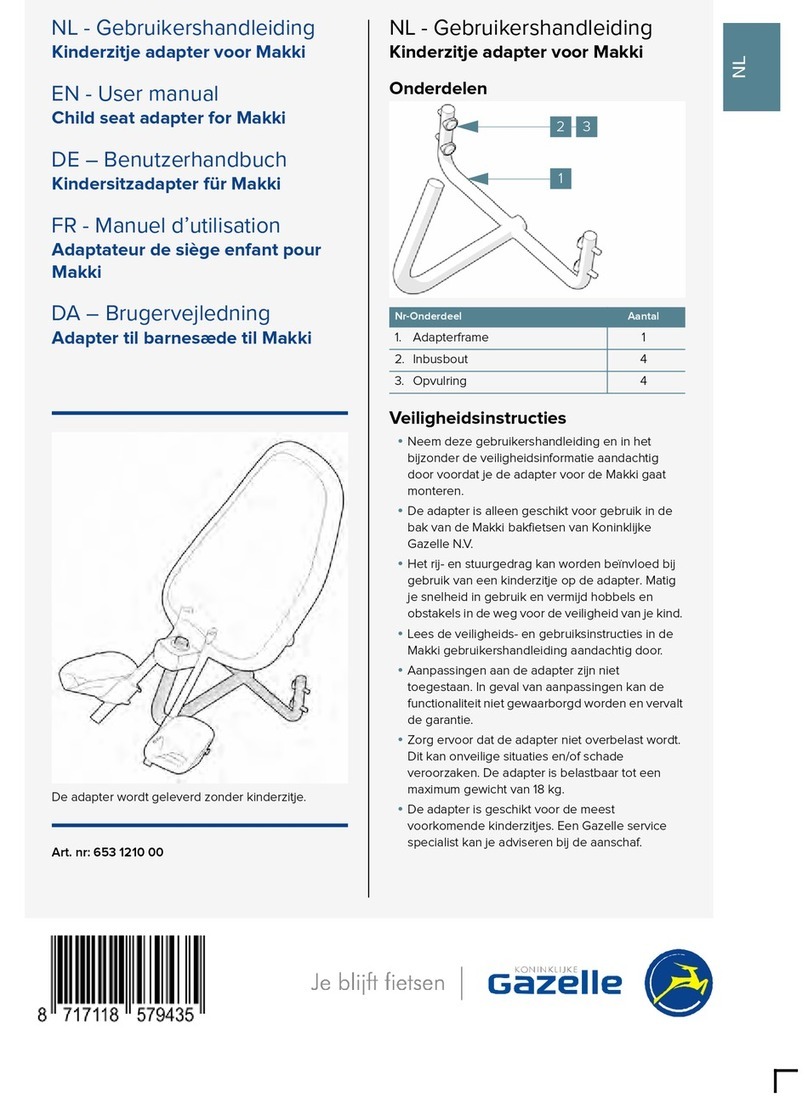

G. Changing Components or Adding Accessories

There are many components and accessories available

to enhance the comfort, performance and appearance of

your bicycle. However, if you change components or add

accessories, you do so at your own risk. The bicycle’s

manufacturer may not have tested that component or

accessory for compatibility, reliability or safety on your

bicycle. Before installing any component or accessory,

including but not limited to a dierent size tire, a lighting

system, a luggage rack, a child seat, a trailer, etc., make

sure that it is compatible with your bicycle by checking

with your dealer. Be sure to read, understand and follow

the instructions that accompany the products you

purchase for your bicycle. See also Appendix A, p. 24 and

B, p. 28.