gazex MDP-1.A/ T User manual

MDP-1.A/T Control Unit User Manual issue 4W32en ©gazex’2016 v1609 Page 1/ 16

Warsaw

Control

Unit

Issue 4W32en

M

MD

DP

P-

-1

1.

.A

A/

/

T

T

[ series W3 ]

BEFORE installation, fully read

the USER MANUAL.

Proceed with installation only after

gaining a full understanding of this

Manual.

For safety reasons during

installation and use of the device, it

is advisable to follow the recommendations and

warnings included in this Manual and marked with the depicted

symbol.

The Manual should be stored for the Gas Detection Systems’

User perusal.

1.

Purpose

p. 2

2.

Technical specifications

4

3.

Description and assembly

4

4.

MDP installation within the system

6

5.

MDP configuration

9

6.

Launching of the MDP in the system

13

6.6

PROBLEM ? Useful information

15

7.

Maintenance/operation

16

8.

Storing the MDP

16

PRODUCER:

©gazex 2016. All rights reserved. No part of these pages, either text or image may be copied or distributed without GAZEX’s permission.

The gazex logo and name as well as dex, ASBIG, “Aktywny System Bezpieczeństwa Instalacji Gazowej” are registered trademarks of the

GAZEX company.

Work and live SAFER with us ! ©gazex

USER MANUAL

MDP-1.A/T Control Unit User Manual issue 4W32en ©gazex’2016 v1609 Page 2/ 16

1. PURPOSE

The MDP-1.A/T digital measurement module is designed for use with one of GAZEX gas detector

types DEX/F, DEX/A or DEX/P (for operation in explosive gas atmospheres of temperature class T4) or

type DG/F, DG/P or DG.EN (for operation outside potentially explosive atmospheres) - see Compatibility

Table 1.2.

The cooperation consists of cyclical measurement and control of detector signals. When the

specified concentration values are exceeded, the optical alarm signaling is activated, the module outputs

are activated and information is transmitted to the monitoring module (e.g. MDD-256/T) or any

visualisation system via the RS-485 industrial standard network in accordance with the MODBUS RTU

protocol (in the MDP-1.A/TM option).

In the further part of this manual, any MDP-1.A/T... module will be referred to as the "MDP" module. -

unless the description is model-specific.

In the later part of this manual, the term "detector" or "DEX" will refer to a DEX/F, DEX/A, DEX/P, DG/F,

DG/P or DG.EN detector of all types of gases, unless a specific type/model is described.

Features and functions realised by the MDP:

it powers and controls one measuring detector of the DEX/P or DG/P type or a double threshold

detector of the DEX/A, DEX/F, DG/F or DG.EN type; it controls the status of the wired connection to

the detector (it provides full detection of fault states);

it assigns - three alarm levels to the measuring detector: A1, A2 and A3, adjustable by the user to any

value within the full measuring range;

- two alarm levels A1 and A2 (according to the detector's factory settings) for the threshold

detector;

allows the calculation of the weighted average (TWA) and the short-time exposure limit STEL for the

toxic gas concentration detectors;

allows you to specify the type of measuring units displayed for the detector: [%] of the measuring

range, [%LEL], [ppm] or [%V/V];

allows five modes of operation: "MEMORY MODE". Indicates that an alarm has occurred after the

alarm has disappeared, "WITH UPHOLDING MODE" - maintains active alarm conditions after the

alarm source disappears, "MODE A3" - turns off the power supply of the detector with the catalytic

sensor, which protects against overload, "NO MEMORY MODE" - automatically resets the states of

inputs and outputs on the front panel after the alarm states disappear, "SERVICE MODE" -

deactivates the module outputs for 1 hour;

"SILENT MODE" - independent from the above - mutes the inner siren;

visually signals the signal value and the alarm and fault states of the detector (LED display) as well as

the states of the control outputs A1, A2, A3 and the detector fault (LED display) with the simultaneous

acoustic signaling (built-in siren);

stores in a non-volatile internal memory the 200 most recent events with the assigned start and end

times and the source of the event;

enables very precise setting of alarm delay times and unchangeability of these parameters in time

thanks to microprocessor control;

12V alarm outputs (one for each threshold A1 and A2) control additional acoustic and optical

signaling devices;

the relay outputs (galvanically separated, one for each A1, A2, A3 and fault) control the fans,

motors, contactors, information boards, or connect to the building/facility automation;

the "FAULT" relay output (galvanically separated from the system) informs about the module's

fault state, damage to the connection line to the detector or power failure;

optionally, the MDP-1.A/TM model with isolated RS-485 (MODBUS RTU) port provides remote

control, identification and diagnostics of the module together with the detectors and cooperation

with the control module or with "intelligent building" control systems;

optional isolated analog output I0=4-20mA (model MDP-1.A/T/420) or U0=2-10V (model MDP-

1.A/T/V10) for inverter control;

the case is suitable for installation on a TS 35mm rail in standard electrical switchboards;

the outputs are compatible with the MD(P)-2(4,8,16)... module outputs;

all electrical terminals are removable (for disconnecting without voltage);

configuration of module settings by means of a keyboard on the front panel.

MDP-1.A/T Control Unit User Manual issue 4W32en ©gazex’2016 v1609 Page 3/ 16

1.1. MDP MATCHING TABLE

M

ODEL

Analog output

4-20mA

Analog output

2-10V

Digital output

RS-485

MDP-1.A/T

(standard)

–

–

–

MDP-1.A/TM

–

–

+

MDP-1.A/T/420

+

–

–

MDP-1.A/T/V10

–

+

–

MDP-1.A/TM/420

+

–

+

MDP-1.A/TM/V10

–

+

+

1.2. COMPATIBILITY TABLE

Detector/version

(series)

Model MDP-1.A/T…

version

W22

W21, U1

operation in explosive gas atmosphere of temperature class T4

DEX/P4… DEX-Pn , DEX-PnE/N, DEX-PnR

+

+

DEX/F4… DEX-nn, DEX-nn/N, DEX-nE/N, DEX-nR

+

+

DEX/A4… DEX-Ann/N

+

–

operation in explosive gas atmosphere of temperature class T6

DEX/P6…

older versions: DEX/P,

DEX/P-C,C2

– –

DEX/F6…

older versions:

DEX/FA…, DEX/F

– –

DEX/A6…

–

–

work outside explosive zones

DG/P DG-PnE/N, DG-PnR

+

+

DG/F

DG-nn, DG-nn/N, DG-nE/N ,DG-nR

+

+

DG.EN DG-nn.EN

+

+

Symbols:

n= gas code number,

+= recommended cooperation (full functionality of the set)

–= cooperation not permitted

MDP-1.A/T Control Unit User Manual issue 4W32en ©gazex’2016 v1609 Page 4/ 16

2. TECHNICAL SPECIFICATIONS

Model

MDP-1.A/TM

Power supply voltage

12V= (permitted range 10,5 ÷ 15V); (limited range 10,5 ÷ 12V in cooperation with DEX in versions

P4-HT…,P4-S-C, F4-HT…, F4-S-C, A4-HT…, A4-S-C)

Power consumption

max 0,2A (without detector or voltage alarm outputs)

for 12V=, max 0,8A (with detector and voltage alarm outputs)

Operating temperature

-10°C to +40°C recommended,

-20°C to +45°C allowed periodically (<2h/24h);

0°C to +40°C limited in cooperation with DEX in versions P4-HT…,P4-S-C, F4-HT…, F4-S-C,

A4-HT…, A4-S-C

Communication with the

detector

DEX/P, DG/P - measurement detector – 3-wire connection, 4-20mA current loop;

DEX/F, DG/F - threshold detector – 4-wire connection, alarm thresholds A1 and A2;

DEX/A – threshold detector – 3-wire connection, 4-20mA current loop;

type selection – from the menu

Measuring precision of the

detector

better than ±3% of the measurement range

Detector power supply

9÷12V=, protected against short-circuiting and over-voltage of 250mA with a resettable fuse,

switching on the detector power supply – with software using the keyboard (available from the

user menu)

Alarm levels for DEX/P

warning - ALARM1 ( A1 ), adjustable*

alarm - ALARM2 ( A2 ) , adjustable *

alarm - ALARM3 (A3 ) , adjustable *

* - the range of alarm threshold regulation depends on the activation of additional MDP functions,

e.g. excess, shortage (see section 5.5.1)

Alarm levels for threshold

detectors

warning - ALARM 1 ( A1 )

alarm/shutting-off - ALARM 2 ( A2 )

Fault levels of the detector's

measuring signal

signal line opening – ( „Er.00” ) for I < 2mA

short-circuit of the signal line – ( „Er.01”) for I >22mA

Optical signaling of the

measurement results

LED display of the current measurement value of the detector signal scaled in selected

measurement units: % range, %LEL, %v/v or ppm

Optical signaling of alarm

states

optical: 7 LEDs; acoustic – inner siren

Fault signaling

yellow LED, messages on graphic display

Acoustic signaling

Inner buzzer

1Hz intermittent signal - A1 alarm signal

5Hz intermittent signal - A2 alarm signal

10Hz intermittent signal - A3 alarm signal

constant signal – fault signal;

(optional: no signaling – "SILENT MODE” set with the keyboard)

Zeroing the module

using the button on the front panel

Event memory

internal, non-volatile, 200 recent alarm or fault states or configuration changes

Signal blockade

warming up of the detector (after power supply is switched on): default: 1 minute,

adjustment: 1÷15 min

Digital output

(optional)

(model MDP-1.A/TM): RS-485, MODBUS RTU protocol, galvanically isolated,

parameters: 9600bps (11-bit frame, parity control: even, 1 stop bit) ;

Analog output

(optional)

current 4-20mA (model MDP-1.A/T/420): active, galvanically isolated, 1mA – fault signaling;

precision ±3% of measured value, ROmax = 300 Ω;

or voltage 2-10V (model MDP-1.A/T/V10): galvanically isolated, 0,5V – fault signaling;

precision ±3% of measured value, R0min = 100 kΩ

Voltage output

12V=, non-stabilised, for states A1 and A2; total load = max 0,2A, for connecting SL-21, SL-32, S-

3x, LD-2 signaling devices

Relay outputs

ALARM 1, ALARM 2, ALARM3, FAULT – relay, type NO and NC, max load:

max 4A (with resistive load) or max 2A (with inductive load- engines) or

max 0,6A (with purely inductive load – fluorescent lamps); max 230V~ or 24V=

Output control

delay of switching on the output: default 10sec., regulation: 3 ÷300 sec.,

delay of switching off the output: default 10 sec., regulation 3 sec. ÷900 sec.;

automatic control (default) – alarm state deleted after the alarm source has disappeared,

or manual – alarm state maintained after the alarm source has disappeared until the user

manually deletes it (by means of the "OK" button on the keyboard)

Electrical terminals

removable, self-springing (screwless), possibility of mounting solid and fine-stranded conductors

(without using clamping ferrulas) with cross-section of 0.2 ÷ 2.5 mm2

(with ferrulas: 0,25 ÷ 1 mm

2

)

Module power supply control

LED, green; also indicates MDP warm-up state

Size, weight

106 x 90 x 65 mm, width x height x depth (width of 6 mod.); ca. 0,2kg

Casing

polystyrene, IP20; for installation in electrical switchboards on a TH35 rail

MDP-1.A/T Control Unit User Manual issue 4W32en ©gazex’2016 v1609 Page 5/ 16

3. DESCRIPTION AND ASSEMBLY

Special functions control lamps

Keyboard

Terminal block of the power supply

Lights for output status

Measurement units (for measuring detectors)

Terminal block of the relay outputs

Pic.3.1 MDP-1.A/T front panel view (rail mounting position)

WIRING DIAGRAM

12VDC

+ S 2 1 M

03 04 05 06 07 08 09 10

Alarm 12V 4-20mA

DETECTOR

27 26 25 24 23 22

com NO NC

ALARM1 ALARM2

MDP-1.A/TM

%LE L

A+ B- GND

11 12 13 14 15

S+ S-

A2 A1 M

21 20 19

ALARM3

18 17 16

AWARIA

RS485

com NO NC com NO NC com NC NO

01 02

+ M

CONTROL

UNIT

ppm

%v/ v

ALARM

A1

ALARM

A2

ALARM

A3

ZASIL ANIE

POWER

SERWIS

SERVICE

SYSTEM

NET

AWAR IA

FAULT

OK

type:

notice

www.gazex.pl

PS

PE

+ - N L

0V

S

+V

DEX/P

M

Siren

Lamp

SL

M

2

+

DEX/F

RS-485

1

DG/F

DG/P

FTP, STP

or

PU

10

MENU

RESET

+ S 2 1 M

03 04 05 06 07 08 09 10

27 26 25 24 23 22

com NO NC

ALARM1 ALARM2

MDP-1.A/TM

%LE L

A+ B- GND

11 12 13 14 15

S+ S-

A2 A1 M

21 20 19

ALARM3

18 17 16

AWARIA

com NO NC com NO NC com NC NO

01 02

+ M

ppm

%v/ v

ALARM

A1

ALARM

A2

ALARM

A3

ZASIL ANIE

POWER

SERWIS

SERVICE

SYSTEM

NET

AWAR IA

FAULT

OK

type:

notice

www.gazex.pl

10

MENU

RESET

DG.EN

DEX/A

Battery 7Ah or 17Ah

230VAC

Detector No.2

Detector No.1

Signaling device

35mm

DIN rail

4x 1

3x 1

3x 0,5

Relay Outputs No.2Relay Outputs No.1

Power supply

2x 2,5

12VDC

Alarm 12V 4-20mA

DETECTOR RS485

with battery back-up

CONTROL

UNIT

MDP-1.A/T Control Unit User Manual issue 4W32en ©gazex’2016 v1609 Page 6/ 16

Table 3.1. Functions performed on outputs:

MODULE

STATUS

[Terminal no.]

RELAY OUTPUTS

12V VOLT. OUTPUTS

FAULT

A1

A2

A3

Pair

COM-NO

[18] [16]

Pair

COM- NC

[18] [17]

Pair

COM-NO

[27] [26]

Pair

COM- NC

[27] [25]

Pair

COM-NO

[24] [23]

Pair

COM- NC

[24] [22]

Pair

COM-NO

[21] [20]

Pair

COM- NC

[21] [19]

A1

[09] [10]

A2

[08] [10]

NORMAL OPEN CLOSED OPEN CLOSED OPEN CLOSED OPEN CLOSED no voltage no voltage

A1 OPEN CLOSED CLOSED OPEN OPEN CLOSED OPEN CLOSED 12V= no voltage

only A2 OPEN CLOSED OPEN CLOSED CLOSED OPEN OPEN CLOSED no voltage 12V=

A1+A2 OPEN CLOSED CLOSED OPEN CLOSED OPEN OPEN CLOSED 12V= 12V=

only A3 OPEN CLOSED OPEN CLOSED OPEN CLOSED CLOSED OPEN no voltage no voltage

A1+A2+A3 OPEN CLOSED CLOSED OPEN CLOSED OPEN CLOSED OPEN 12V= 12V=

FAULT

of MDP pow. sup.

CLOSED OPEN OPEN CLOSED OPEN CLOSED OPEN CLOSED no voltage no voltage

FAULT

DEX CLOSED OPEN XX X. XX. XXX

x – means the last correct state from before the fault;

NORMAL state

only the green light is on;

possible information displayed on the LED screen [ CAL. ] - i.e. exceeded recommended detector

calibration period;

A1 – (ALARM A1)

[ALARM A1] output light is on;

pulsating tone of the inner siren is on;

A2 – (ALARM A2)

red [ALARM A1] and [ALARM A2] alarm outputs lights are on;

only the red [ALARM A2] output light is on (window detector);

pulsating tone of the inner siren is on;

A3 – (ALARM A3) the detector indicates that the A3 concentration threshold has been exceeded,

red [ALARM A1], [ALARM A2] and [ALARM A3] alarm output lights are on;

only the red [ALARM A3] output light is on (window detector or shortage function is active)

pulsating tone of the inner siren is on;

FAULT of the MDP power supply – no power supply or damaged internal systems of the module, all

lights are off;

DEX FAULT –appropriate fault code on the LED screen, yellow FAULT light is on; active relay output

[FAULT];

4. MDP INSTALLATION WITHIN THE SYSTEM

The MDP installation can be started after a period of time suitable for the evening out of temperatures

of the MDP and the ambient air. Especially in winter, at negative temperatures during transport or

storage, wait approx. 20 minutes before removing the MDP from the foil packaging to prevent

condensation on the inner circuits of the device!

4.1 Mount the module in the switchboard box, on a 35mm rail, outside an explosive area, in a place

free from strong electromagnetic interference, vibrations, strokes.

Caution!!!

The setup can be carried out only when the power supply is off!!!

MDP-1.A/T Control Unit User Manual issue 4W32en ©gazex’2016 v1609 Page 7/ 16

4.2 Lead the connection cables "A" from the DEX detector (necessarily of circular cross-section).

The measurement detectors and the DEX/A threshold detector require a 3-wire cable (e.g. of the

YDY 3x1 type) - terminals "+" [03], "S" [04] and "M" [07], other threshold detectors of the 4-wire

cable (e.g. of the YDY 4x1 type) - "+" terminals [03], "2” 05], "1" [06] and "M" [07].

The cross-section of wires of the "A*"

L

L< 150m

L< 300m

cable should be selected as shown here,

depending on the length L of the

connection:

A:

0,5 mm

2

1mm

2

4.2.1 Keep the correct sequence of connection wires to the detector - improper sequence will

cause the alarm status of the module, malfunction of the system or damage to the detector.

4.2.2. The module is delivered with pre-assembled connection terminals on all inputs/outputs. The

terminal blocks can be removed from the connection pins for easy connection/removal. In

accordance with good installation practice, all terminal blocks must be marked (e.g. numbered)

before they can be removed, which makes them easy to reinstall and prevents connection errors.

Solid or fine-stranded conductors (without clamping sleeves) may be used. Mechanical parameters of

power supply connectors and alarm relay outputs (A1, A2, A3, Fault) allow to install cables with

wires of 0,2 ÷2,5 mm2cross-section, for other connectors - of 0,2 ÷1,5 mm2cross-section.

5

4.2.2.A Inserting wires into self-reclosing terminals:

-[1.] remove the wire insulation at the height of 9 mm (as shown on the picture);

- [2.] in case of fine-stranded conductors – slightly twist the wire ends,

-[3.] press the orange blockade button and insert the isolated wire ends into the

opening as far as it will go, [4.] release the button;

- [3.] in case of solid conductors - with pliers or manually insert (push) the isolated

wire ends into the round opening as far as it will go.

A properly inserted cable cannot be removed from the terminal.

The cable can be removed by gently pressing the orange button [2].

4.3. Cable ends must be prepared in a way which prevents the

connectors from having to be wrapped round the module inside the

box after they have been placed in the terminals. Solid or fine-stranded

conductors (with or without clamping sleeves) may be used. The cables

must be laid in such a way that they do not transmit mechanical forces to

the connection terminals.

4.4. Connect external cooperating devices, e.g. automatics control, S-3x external siren, LD-2 warning

lamp (recommended wire cross-section 0.5 mm2), etc. In case of placing the optical and acoustic

signaling devices in the same place it is recommended to use an integrated acoustic-optical

signaling device of SL-32 or SL-21 type. Having separate functions, the siren and the lamps can

be connected to the MDP using a C3 3-wire cable (the recommended wire cross section is 0.5

mm2). The A1, A2, A3 and FAULT relay outputs can be connected to different phases or to low

voltage circuits.

4.5. MDP-1.A/TM version: connect shielded twisted pair FTP or STP 4x2x0.5 cat.5e type cable to the

terminals of digital bus in standard RS485 "A+"-[13], "B-"-[14], "GND"-[15]. The terminals are doubled

for easy connection of the bus cables in the module. The terminals can be removed from the module

pins without disconnecting the bus connections.

A maximum of 224 MDP modules can be connected in one bus loop and the length of the bus must not

exceed 1200m. The transmission port is isolated (1kV) from the MDP internal circuits. The specification

of the communication protocol and the parameters of the port settings are described in a

separate attachment. The configuration settings are described in section 5.5.3.

4.5.1. Prepare the bus cable as described in section 4.4.2, then insert the isolated

wire ends into the corresponding bus terminals.

Caution : incorrect cable polarity may result in an inability to start up the entire network of

digital bus devices.

2.

3.

1.

9 mm

4.

MDP-1.A/T Control Unit User Manual issue 4W32en ©gazex’2016 v1609 Page 8/ 16

Caution : in order to remove the FTP and STP conductor insulation (the cables are actually very thin!),

use only dedicated tools that will not “hurt” the conductors. Using a knife or other sharp tool for this

purpose may result in a local reduction of the cable conductor cross-

section, which when bent or pressed in, breaks the conductor and

causes communication fail of the entire detector bus (which is also

optically difficult to locate quickly)!

4.5.2. Inserting the wire into the removable terminal

designed for connecting FTP single wire

cables (on RS-485 buses):

(1). remove the wire insulation at the height of exactly 6 to 7 mm;

(2). push (insert) the insulated conductor end into the round terminal

hole with pliers as far as it will go; the terminals are closed in pairs

vertically.

A properly inserted cable cannot be removed from the terminal. The

cable can be removed by gently pressing the orange button with a flat screwdriver (according to arrow

[3] and removed according to arrow [4]).

The terminal blocks can be removed from the module's connecting pins without disconnecting the bus

cables.

4.5.3. Each module is equipped with a "TERMINATOR" connector, which enables switching

(jumper in ON position) an R=120Ω resistor terminating the bus in order to eliminate reflections

resulting from the mismatch of bus impedance. By default, the resistor is disconnected (jumper in

OFF position).

CAUTION: Only the resistors in the two extreme modules at the opposite ends of the

bus must be switched on. Leaving more resistors in place increases the load on the bus

and may damage the MDP internal systems responsible for data transmission.

4.6. MDP-1. A/T/420 (or .../V10) version: connect to the "S+" terminals [11]

and "S-" [12] 4-20mA current output or 2-10V voltage output (optional outputs) the

signal cable. The output is isolated (1kV) from MDP internal systems. The maximum

load resistance value for the current output is Ro= 300 Ω.

When a measurement detector is connected, the output value of current Io=4mA or voltage

Uo=1V means zero gas concentration, while Io=20mA or Uo=10V means concentration equal to

the measurement range. Detector fault is signaled by the value of current Io=1mA or voltage

Uo=0.5V. When the DEX/A threshold detector is connected, the output values are in the normal

state respectively: Io=4mA or Uo=1V, in A1 state: Io=8mA or Uo=3.25V, in A2 state: Io=12mA or

Uo=5.5V.

4.7. Connect the "E" cable of the 12V= power supply from the PS... power supply unit (with

battery connected); keep proper polarity (the module is protected against reverse

polarity). Positive terminal "+" [1], negative terminal "M" [2].

MDP-1.A/T Control Unit User Manual issue 4W32en ©gazex’2016 v1609 Page 9/ 16

5. MDP INITIAL CONFIGURATION

CAUTION: all described procedures and LCD display messages refer to the standard version of the

module. Any descriptions of non-standard versions, changes and corrections can be found in the

annex to the operating manual, if provided.

CAUTION: Press the keys gently to avoid damaging the MDP mounting plates and internal

circuits.

5.1 The next stage of the System start-up is to configure the module according to the Customer's individual

needs. It is carried out by means of a keyboard located on the front panel of the module.

5.2 Turn on the module power supply. After the power supply is turned on, an acoustic test of the internal siren

and an optical test of the LED display and signal lights are carried out. The individual lights are cyclically lit

and extinguished. The LED display shows [ tESt ] followed by information about the version of the module

and the date of compilation of the installed software (this information may be required when contacting the

GAZEX service department). During this time, the module settings are initialised.

5.3 After the test phase, the module enters the sensor warm-up mode, signalling on the LED display the time

left until the end of this phase. The green power LED flashes. During this time, the measurement

parameters of the detector are stabilized, which is necessary for its proper functioning. After counting down

the warm-up time, the module will enter the measurement mode by loading the last saved configuration

parameters. The user can change its settings at any time during the warm-up or in the normal operation of

the module by entering the MDP menu.

5.4 In order to make changes in the MDP menu press and hold [ ▲ menu] key for 3 seconds. Correct pressing

of the key will be confirmed by an intermittent acoustic signal and a request to enter the user's password on

the LED screen: [ h.000 ] (factory password is "h.001"). The password is entered by means of the keys [ ▲

] and [ ▼ ], and confirmed by means of the key [ OK ]. Entering an incorrect password will exit the menu

settings and return the detector to the warm-up mode. Repeat the steps described in this section to attempt

to change the module settings again.

Caution!!! The above password is the default one assigned to each MDP copy. In order to prevent

unauthorised access of outside persons to the controller settings, the password must be changed

individually (see section 5.5.5). The new password should be remembered and stored in a safe

place. Losing the password makes it impossible to make MDP configuration changes. Unlocking

the password is possible only by GAZEX (paid service).

5.5 Entering the correct password will be confirmed by an intermittent acoustic signal. The controller enters the

setting mode. At this stage, all control and measurement procedures are suspended until the configuration

of the device is completed. The first item from the user menu is displayed on the LED screen. The below list

shows all available functions:

- [ dEt. ]– detector parameter settings;

- [ out. – module output parameter settings;

- [ nEt ]– RS485 network parameter settings;

- [ tryb ]– module operating mode settings;

- [ hAS. ] – user's password change;

- [ tESt ] – module output test;

- [FAbr. ] – restoring factory settings;

- exiting the menu;

The LED screen displays only one function that is active at the time. In order to change the function to

another one, use the keys [ ▲ ] or [ ▼ ]. Confirm the selection of the function with the [ OK ] key.

To exit the menu, scroll through all available menu functions with [ ▼ ].

Selecting a specific function from the menu makes it necessary to set a number of parameters assigned to

a given function. The return to the main menu takes place after all required parameters have been

confirmed.

Moving in the submenu of the respective function is similar to moving in the main menu: selection of the

parameter by means of the [ ▲ ] and [ ▼ ] buttons, confirmation by means of the [ OK ] button.

The following sections provide a detailed description of the parameters of the individual functions.

5.5.1 [dEt. ]-Detector settings – list of parameters:

a) Turning the detector power supply on or off:

- [ d.On ] – detector is on,

-[d.OFF ] – detector is off (default setting).

When the detector is switched off, the measuring functions of the module are blocked until it is switched

on again.

b) Determination of the type of the detector:

-[ d.P ] – measuring detector of the type DEX/P or DG/P (default setting),

MDP-1.A/T Control Unit User Manual issue 4W32en ©gazex’2016 v1609 Page 10 / 16

-[ d.Fn ]– threshold detector of the type DEX/F or DG/F (if only the A2 state is present, it is interpreted

as a detector failure.),

Threshold detector [d.Fn]

"1" input status

normal

alarm

"2" input status

normal

normal status

alarm A1

Module

outputs

status

alarm fault alarm A1+A2

-[ d.F ]– threshold detector of the type DEX/F or DG/F with independent A1 and A2 thresholds,

Threshold detector [d.F]

"1" input status

normal

alarm

"2" input status

normal

normal status

alarm A1

Module

outputs

status

alarm alarm A2 alarm A1+A2

-[ d.A ]– threshold detector of the type DEX/A.

Depending on the selected detector type, the module launches specific control and measurement

procedures. In the case of the measuring detector and the threshold detector of the type DEX/A, the

concentration value is represented by an analog signal connected to the "S" terminal of the DETECTOR

input. For the other types of threshold detectors, the indication of specific alarm states is dependent on

the values of the digital signals connected to the detector inputs marked "1" and "2". In case of an

incorrect setting, the module will indicate a failure of the detector or alarm conditions.

c) Determination of the warm-up time of the detector each time the module is turned on.

During warm-up, the detector's operating point is stabilised. Any alarms or faults reported by the detector

are ignored by the module. Warm-up time adjustment is available from 60 seconds - [ d.060 ] to 900

seconds - [ d.900 ] in intervals of 60 seconds (default setting 60 seconds - [ d.060 ]).

d) Determination of the detector measuring unit.

The appropriate measuring unit must be read from the Calibration Certificate of the connected measuring

detector. Then the blinking indicator next to the corresponding unit on the MDP front panel to the right

side of the LED display must be set. The selected unit will be displayed together with the concentration

value while the module is in measurement mode. If you do not have a suitable unit, select the option with

three active indicators (default setting). In this case, the unit indicator will not be displayed during

measurements.

e) Determination of the measuring range (for the measuring detector only).

The value of the measuring range must be read from the Calibration Certificate of the connected

measuring detector. The concentration value displayed on the LED screen is scaled from 0 (which

corresponds to the IS=4mA current value) to the measurement range value (which corresponds to the

IS=20mA current value).

f) Determination of the A3 threshold value (for the measuring detector only).

Adjustable value in the range of 2 ÷ 100% of the measuring range value (default setting is A3 = 50).

g) Determination of the alarm threshold activation mode (for the measuring detector only).

-[ d. A12 ] –thresholds of momentary values (default setting),

-[ d. ndS ]– time-averaged thresholds.

When [ d.A12 ] is selected, the alarms are triggered if the momentary value of the detector signal

exceeds the set thresholds of A1 and A2 that can be adjusted in the full measuring range.

The [ d.ndS ] option assigns time averaging to alarm thresholds. The A1 threshold corresponds to the

TWA (time-weighted average) value, the A2 threshold corresponds to the STEL (short-term exposure

limits) value, calculated according to Regulation of the Minister of Labour and Social Policy ( Rozp.

Ministra Pracy i Polityki Społecznej) from 6.06.2014, Journal of Laws of the Republic of Poland (Dziennik

Ustaw) 2014, position 817.

The relevant values of the TWA and STEL concentrations should be read from the above mentioned

Regulation and entered in the settings of the threshold values A1 and A2.

At the A3 threshold, time averaging is disabled. The alarm is activated if the momentary gas

concentration exceeds the A3 value.

h) Determination of the direction of activation of the alarm thresholds (for the measuring detector only):

-[ d. ┌┘ ] – excess (default setting),

-[ d. └┐ ]– shortage.

The [ d. ┌┘ ] excess option activates the alarm thresholds when the detector signal value exceeds the

value of the set alarm thresholds A1 and A2, where A1 <= A2. The [ d. └┐ ]shortage option activates the

thresholds after the detector signal drops below the set alarm thresholds A1 and A2, where A1 <= A2.

The A3 alarm is only activated if the gas concentration value exceeds the A3 value (excess only).

MDP-1.A/T Control Unit User Manual issue 4W32en ©gazex’2016 v1609 Page 11 / 16

i) Determination of the A2 threshold value ( for measuring detector only).

The value is adjustable from 2% of the measuring range value to threshold value A3 (default setting is A2

= 30).

j) Determination of the A1 threshold value (for the measuring detector only).

Adjustable value in the range from 2% of the measuring range value to the A3 threshold value (default

setting is A1 = 10).

5.5.2 [ out. ] - Outputs settings – list of parameters:

a) Determination of the delay of switching on the outputs.

-[ ┌┘003 ] ÷ [ ┌┘300 ]

It is the time (standard = 10 sec.) from the moment when the MDP records the alarm status at the

detector input until the moment when the MDP activates the appropriate outputs depending on where the

alarm has occurred. This delay can be set in range: 3,300 seconds: 3 ÷300 seconds.

b) Determination of the delay of switching off the outputs.

-[ └┐003 ] ÷ [ └┐900 ]

It is the time (standard = 10 sec.) from the moment the alarm disappears to the moment the outputs are

switched off. This delay can be set in range: 3 ÷900 sec. (option not available when the mode with alarm

retention at the outputs is active).

5.5.3 [ nEt. ] - Setting the RS485 network parameters.

a) Setting the slave address.

-A.000 – zero address – means that the communication is off (default setting);

-A.001 ÷ A.224 – correct slave address, the communication is on.

The unique slave address identifies the MDP module in the RS485 industrial network and allows the

module to be polled by a supervisory device, e.g. MDD-256/T. The communication protocol is in

accordance with the MODBUS RTU standard. The protocol specification is a separate annex to this User

Manual.

After confirming the non-zero address, the MDP automatically starts communication, i.e. sends answers to

correct queries from the supervisory module. The green NET light blinks to confirm that the query frame

has been correctly received and sent by the MDP.

5.5.4 [ trYb ] - Settings of module operation modes.

-[ t.b12 ] – normal mode with alarm memory (default, factory setting),

-[ t.A12 ]– mode with alarm maintenance,

-[ t.A3 ] – A3 alarm maintenance mode with turning off the detector power supply,

-[ t. n ] – auto-zeroing mode without alarm memory,

-[ t.SEr. ] – service mode with 1-hour long blockade of the module outputs.

MDP-1.A/T Control Unit User Manual issue 4W32en ©gazex’2016 v1609 Page 12 / 16

The operating mode determines the specific control functionality of the module. Depending on the set

mode, the module leaves information on the front panel about alarm states that have ended (alarm

memory), or clears messages (no alarm memory). Additionally, activation of the module outputs can be

carried out for the duration of the alarm or until manual reset by the user (maintenance of the alarms).

Details are provided in the table below.

Operating

mode

Active alarm Finished alarm

Optical

signalling of

the output

status

Inner acoustic

signal

Alarm

outputs

status

Optical

signa

lling of the

output status

Inner acoustic

signal

Alarm outputs

status

t.b12 Continuous

Pulsating

cycle depends on

alarm level

Active Pulsating Pulsating

1s/4s Inactive

t.A12 Continuous

Pulsating

cycle depends on

alarm level

Active Continuous

Pulsating

cycle depends on

alarm level

Active

t.A3 Continuous Pulsating

cycle depends on

alarm level Active

Pulsating

(after exceeding A3

threshold -

continuous)

Pulsating

cycle depends on

alarm level

Inactive

(after exceeding A3

threshold - active)

t. n Continuous

Pulsating

cycle depends on

alarm level

Active None None Inactive

t.SEr. Continuous

Pulsating

cycle depends on

alarm level

Inactive Pulsating Pulsating

1s/3s Inactive

Normal mode with alarm memory – activates alarm and fault signaling both during the event and after it

has ended. The pulsating signal is maintained after the alarm has disappeared until the user consciously

clears the MDP. Alarm outputs are activated only for the duration of the alarm, while maintaining the

delays of switching on and off the outputs. This mode can be activated indefinitely.

Mode with alarm maintenance – causes the alarm outputs to be activated both for the duration of the

alarm and for this state to be maintained after the end of the event which caused the alarm. The output will

be disabled ONLY after external user intervention (resetting the module with "OK" button). This mode can

be activated indefinitely.

A3 alarm maintenance mode with turning off the detector power supply – is dedicated only for

cooperation between MDP and a measuring detector equipped with a catalytic sensor. This mode retains

normal mode functionality with alarm memory for concentrations below A3 threshold value. If the A3

threshold value is exceeded, the alarm maintenance at the module outputs is activated and the detector

power supply is switched off to prevent the catalytic sensor from being overloaded. The detector power

supply is switched on again and the alarms are switched off ONLY after external user intervention

(resetting the module with the "OK" button). This mode can be activated indefinitely. This mode is only

active if you specify the measurement units as %LEL in the detector menu at the same time.

Auto-zeroing mode without alarm memory – automatically resets the module after an alarm has been

triggered, no user intervention is required. There is no information on the front panel about an alarm that

has ended. The acoustic signals are also switched off. This mode can be activated indefinitely.

Recommended especially for ventilation control systems.

Service mode – allows the module outputs to be blocked for 60 minutes. Recommended for

maintenance of gas detection system. In this mode, the measurement activities of the module are kept, i.e.

the module controls the status of the connected detectors, displays information about alarms and faults on

the front panel, but does not activate the outputs. The mode can be switched off at any time before the

time has fully passed from the user menu or by temporarily turning off the power supply to the module.

Activation of the service mode is signalled by switching on the SERVICE light.

5.5.5 [ hAS. ] – User password change.

-[ h.001 ] – default user password (default setting);

-[ h.000 ] ÷ [ h.999 ]– password regulation range.

Caution!!! In order to prevent unauthorised access of outside persons to the controller settings, the

password must be changed individually. The new password should be remembered and stored in a

safe place. Losing the password makes it impossible to make configuration changes to the module.

Unlocking the password is possible only by GAZEX (paid service).

5.5.6 [ tESt ] – MDP outputs test.

MDP-1.A/T Control Unit User Manual issue 4W32en ©gazex’2016 v1609 Page 13 / 16

Module outputs test - enables verification of the correctness of switching on all outputs without the need to

generate alarms at the module inputs.

Outputs are switched on sequentially for time = 10 sec. The currently enabled outputs are signaled on the

front panel by an appropriate LED. After testing all outputs, MDP automatically returns to the user menu.

The outputs are switched on in the following order ("+" means active output):

Time [s]

Relay output

A1

Relay output

A2

Relay ou

tput

A3

Relay output

FAULT

Current

output A1

Current

output A2

Output

4-20mA

[mA]

0 – 10

4

10 – 20

+

+

8

20 – 30

+

+

12

30 – 40

+

20

40 – 50

+

1

50 – 60

4

60 – 70

+

+

8

70 – 80

+

+

+

+

12

80 – 90

+

+

+

+

+

20

4

5.5.7 [ FAbr. ] – Restoring MDP factory settings.

This option restores the standard MDP configuration settings (specified in sections 5.5.1 to 5.5.5) by

clearing the previously made changes. This option is especially recommended in situations when not

knowing the previous settings may unexpectedly start MDP control procedures unsuitable for the desired

configuration.

6. LAUNCHING OF THE MDP IN THE SYSTEM

6.1 After the configuration settings have been exited (or the configuration stage has been omitted by the user), the

MDP switches to the sensor warm-up mode, signalling this by a flashing green power light and counting down

the remaining time on the LED screen.

During warm-up, the time of which is defined in the user's menu, the detector's operating point is stabilized,

which is necessary for its proper operation. In this phase, all alarms and faults of the detector are blocked.

6.2 After the warm-up the MDP switches to the normal operation mode. On the front panel are signaled in real

time: detector status, output status, correctness of power supply and RS485 communication as well as

possible activation of special MDP functions.

a) The LED segment display is assigned to indicate the current status of the detector connected to the MDP.

With the measuring detector connected, the current gas concentration value calibrated within the set

measuring range is displayed on the screen, as well as the fault conditions. With a connected threshold

detector, symbols indicating the respective alarm and fault conditions are displayed on the LED display.

The delay in signalling the detector status is constant and is about 5 seconds. This delay is due to the time

taken for the detector output signals to be processed by the module's input systems.

The following are possible alarm state symbols for the threshold detector and emergency state symbols:

-alarm states (ONLY for the threshold detector),

[n ]– normal state;

[d.OFF ]– detector is off;

[A1 ] – level 1 alarm in progress;

[A2 ] – level 2 alarm in progress;

[b 1 ] – there was a level 1 alarm;

[b 2 ] – there was a level 2 alarm;

-fault states or special information,

[CAL. ] – information that the detector needs to be re-calibrated;

[Er.00 ]– detector line opening, insufficient Izas detector current <10mA, signal line fault (interruption,

short circuit),

[Er.01 ] – short-circuit of the detector power supply line or short-circuit of the detector's internal

circuits;

[Er.02 ] – detector fault reported by the detector;

[Er.03 ] – internal Vdd voltage outside the range of 4.8V ÷ 5.2V;

[Er.04 ] – external supply voltage of 12V outside the range of 10.5V ÷ 15V.

b) Red LEDs indicate the status of alarm outputs, yellow LED - the status of fault outputs:

-continuous light - alarm output active

-Pulsating light - the output was active, currently inactive,

-off - the output was and is inactive.

c) Green NET light signals RS485 communication status:

MDP-1.A/T Control Unit User Manual issue 4W32en ©gazex’2016 v1609 Page 14 / 16

-light pulsating in time intervals according to the frequency of polling - correct communication;

-off - communication off, MDP did not receive the correct enquiry frame;

d) The green SERVICE light indicates that the special functions are activated:

-continuous light - the service mode is on;

-pulsating light - silent mode is on;

-off - no active output or acoustic signalling blockades.

e) Green POWER light indicates MDP power supply status:

-continuous light - power supply parameters within the norm;

-pulsating light - power supply parameters outside the permissible range;

-off - the module is switched off.

f) The internal siren signals the MDP alarm and fault states acoustically:

-continuous sound - any fault state;

-pulsating sound in cycle (0.1 sec on/0.1 sec off) - active alarm A3;

-pulsating sound in cycle (0.2s/0.2s) - active alarm A2;

-pulsating sound in cycle (0.5s/0.5s) - active alarm A1;

-pulsating sound in cycle (1s/3s) - alarm or fault state is over;

-no sound - normal state.

6.3 Once the detector has been properly installed and warmed up, no acoustic or optical signals should be

generated and the detector should be marked on the LED screen with an 'n'. (threshold detector) or a value

compatible with the 'zero level' should be displayed (measuring detector).

If other signs are visible on the LED screen, the yellow or red lights are on, and an acoustic signal is heard,

the detector has not been installed correctly. Check the connections of the detector and correct the faults.

The detector input circuits are equipped with a self-return fuse that limits the detector power supply current. In

case of short circuit of the detector's power supply wires, overloading of the power supply line or incorrect

polarity of the "+" and "M" wires, the power supply is automatically cut off from the detector (the state is

indicated on the LED screen by the "Er.01" symbol and a continuous acoustic signal). After removing a short

circuit or overload, the MDP resumes the power supply to the given track only after manual resetting of the

MDP. Overloading or short circuit of one of the voltage outputs "12V AC OUTLET" during the active state A1

or A2 causes automatic switching off of the self-return fuse. Once the overload or short-circuit is removed, the

internal fuse automatically resumes normal operation within seconds.

6.4 The MDP module operation is done by means of a keyboard located on the front panel. During normal

operation, additional functions are permanently assigned to the keys. Pressing and holding for approx. 3

seconds causes, respectively:

•[ OK ] key – resetting the module, i.e. restoring the initial settings of MDP registers, as in the state after

turning on the power supply. Resetting deletes the signalling memory of discontinued alarm or

emergency states.

•[ ▼] key – switching the internal siren on and off. Switching off the siren (activating the "silent mode") is

indicated by an intermittent acoustic signal and a pulsating green SERVICE light. This option is especially

recommended when the controller is installed inside control cabinets and only functions as a ventilation

controller, without the need to generate acoustic signals. Silent mode allows you to mute the internal

siren for an indefinite period of time.

•[ ▲] – key – entering the user menu. Holding down this key at any time during MDP operation interrupts

the measurement and control processes, and enables the user to make the required changes to the

module settings.

6.5 The final stage of the system operation check is to check the measurement accuracy of the MDP controller and

the generation of all alarm conditions for the connected detector, and to check the performance of external

devices.

CONDITIONS REQUIRED FOR SYSTEM CONTROL:

-The MDP is in the normal mode (after a warming up), the light [POWER] is on, the concentration value

displayed on the LED screen is in accordance with the 'zero level' specified in the user's manual of the

respective measuring detector or the threshold detector marked with the 'n' symbol .

-The DEX/DG detector does not generate alarm signals (the output current value is in accordance with

the "zero level" specified in the detector's user's manual).

-To obtain the measurement accuracy of the system as specified in the measuring system manual, the

additional conditions specified in the manual for each DG/P detector must be fulfilled during the

inspection of the detectors.

6.5.1 Generate the detector alarm conditions with a test gas of known concentration value according to the

instructions in the detector's user manual. After the gas has been fed to the threshold detector, the

indication on the LED screen shall change to "A1" or "A2", which is sufficient to confirm that the

detector-module set interacts correctly. In the case of a measuring detector, check that the displayed

measured gas concentration value matches the test gas concentration (the measurement accuracy of

MDP-1.A/T Control Unit User Manual issue 4W32en ©gazex’2016 v1609 Page 15 / 16

the controller, the detector and the accuracy of the test mixture must be taken into account when

making the comparison).

If the alarm signals A1 and A2 of the threshold detector, or the measurement signal of the measurement

detector (greater than A1 and A2) lasts for at least the time corresponding to the delay in switching on

the outputs, an alarm signal will be generated at the corresponding alarm outputs (in normal mode),

the red "ALARM1" and "ALARM2" lights shall be on and the modulated acoustic signal will be

activated.

6.5.2 After the test gas has been removed, the gas concentration in the detector decreases, which results in

a change on the LED screen of the detector status to " b 2" and/or " b 1" or a decrease of the displayed

concentration value depending on the completed alarm status. The control outputs return to their

normal state (red LEDs are pulsating), while the acoustic signal changes to intermittent in a 1s/3s cycle.

The alarm information remains on the LED screen (for the threshold detector) until the user consciously

deletes it. The concentration values of the measurement detectors displayed on the measurement

screen will aim to reach 0.

6.5.3 Control procedure 6.5.1 should be supplemented by an outputs test carried out by software on the user

menu level described in section 5.5.6.

Results of the control or the launch should be entered into Periodic Control Protocol.

If the test result is positive, the Gas Detection System may be considered as operational.

PROBLEM?

Before you call the system Producer, check and compare the effect you observed with the below table

6.6 TABLE for exceptional states of the module after switching on the power:

EFFECT

WHY

WHAT TO DO

After warming up, the detector's alarm

messages appear on the LED screen

for several/a few tens of seconds,

after which the alarms disappear.

If the DEX is stored for a long time

or if the ambient temperature is low,

the warm-up period was shorter

than the intended 1 minute (for low-

calibration detectors).

Press the [OK] button for a short

time while the lamps are pulsating (it

should bring the module back to its

normal state);

enter the menu and extend the

warm-up time of the detector.

Er.01 message on LED screen,

continuous acoustic signal, fault light

on.

Overloading or short-circuit of the

detector power supply.

Remove the cause of a short circuit

or line overload;

switch off the MD power supply for 5

seconds.

The alarm device(s) connected to the

NAP.12V outputs is (are) not working

in A2 or A1 state.

Short-circuit in the connection line;

or a defective signaling device (self-

returning fuses have activated);

or the service mode is on.

Switch off the MDP power supply.

Remove the short circuit from the

cable or repair the signaling device.

Turn on the power supply; trigger

"TEST" of the outputs from the

menu, check the signaling devices.

All lights are off.

No power supply.

Turn on the power supply.

Version MDP-1.A/TM: no

communication with the module via

the RS485 bus.

Incorrect configuration of

transmission parameters,

transmission off - slave address

A.000, defective transmission

cables.

Check communication parameters,

set the correct slave address from

the menu, repair transmission

cables, check that the terminating

resistor is connected correctly.

Analog output current efficiency too

low (during test sequence).

Load resistance too high, which

causes the output transistor to

saturate at higher current values.

Shorten connections, reduce

resistance of the receiver.

If you notice effects other then the above mentioned contact an Authorised Service or the Producer.

MDP-1.A/T Control Unit User Manual issue 4W32en ©gazex’2016 v1609 Page 16 / 16

7. MAINTENANCE / OPERATION

The MDP module and the DEX detectors are electronic devices without moving parts. They are based on

semiconductor components that have a long service life. Therefore, maintenance is limited to the System Periodic

Inspection.

7.1. System Periodic Inspection:

dust the perforated MDP cover;

inform all system users about the planned inspection;

system test according to section 6.5. of the Manual.

RECOMMENDED FREQUENCY OF THE PERIODIC INSPECTION OF THE MDP

AT LEAST EVERY 3MONTHS;IT IS ENOUGH TO TEST THE SYSTEM’S

ELECTRIC AND MEASUREMENT PROPERTIES.

The System Periodic Inspection should also be carried out EVERY TIME the system has worked in

extraordinary conditions, i.e.:

–extreme conditions, e.g. high gas concentration, high or very low temperature, high periodic dustiness or an

increase in humidity,

–presence of high concentrations of other gases not expected to be present in the monitored room,

–long-term operation with an alarm on,

–after a power outage longer than 1 hour,

–in the event of over-voltage or major disturbances to the electrical system,

–after carrying out any maintenance or installation work likely to affect the operation of the system or its

configuration, etc.

7.2. Avoid using mobile phones, radios or other sources of strong electromagnetic field in the immediate vicinity of

MDP during operation, as their use may cause the controller to malfunction and false alarms.

7.2.1 When operating the MDP, avoid temperatures below the recommended limits (section 2).

CAUTION! IMPORTANT!!

7.3. All:

-results of each system inspection according to section 6.5. of this manual,

-situations in which the A2 or A3 alarm has been generated, together with actions taken by operators,

-situations when the module is switched off for a period longer than 3 months,

-unusual signs of system operation which have been observed

MUST be put down in the enclosed Periodic Inspection Protocol under loss of warranty for the elements of the

system penalty and exemption from any liability of the Producer due to System use.

7.4. After 10 years from the MDP production date, it is essential to replace the internal lithium battery with a new

one. It is a paid service carried out by the Producer.

7.5. CAUTION: any attempt to interfere with MDP's internal circuits shall render the guarantee null and void.

7.6. According to the Law from 11 September 2015 on electrical and electronic waste, a

used module cannot be placed together with other household waste. It must be

handed over to a specialist collection point. This is why it is marked with a special

symbol:

Correct disposal protects against the negative impact of waste on human health and

the environment.

CAUTION:

In view of the continuous process of product improvement and the desire to provide as complete and detailed

information as possible on these products, as well as to provide the knowledge necessary for the proper operation

of the products, based on the experience of our Customers to date, GAZEX reserves the right to make minor

changes to the technical specifications of the products supplied and not included in this User Manual, and to

change its content. Therefore, please verify and confirm the validity of your version of the User Manual with the

Producer (please specify the type and series of devices used and the issue number of the manual - from the footer

of the document).

8. STORING THE MDP

It is recommended to store the MDP in dry rooms whose temperature is within the +5°C to 40°C

range. For short time periods (<2h/8h) it is allowed to store it in an environment whose

temperatures range from -10 °C to 45°C.

Internal memory battery life (with no power supply) - 5 years from the production date. After

this period, the battery should be replaced with a new one - only by the Producer.

Table of contents

Other gazex Control Unit manuals

Popular Control Unit manuals by other brands

SSV Embedded Systems

SSV Embedded Systems System-on-Module eSOM/2586 Hardware reference

Beckhoff

Beckhoff EP3204 Documentation

Quantum Rehab

Quantum Rehab DX Basic operation instructions

GEM

GEM 655 Installation, operating and maintenance instructions

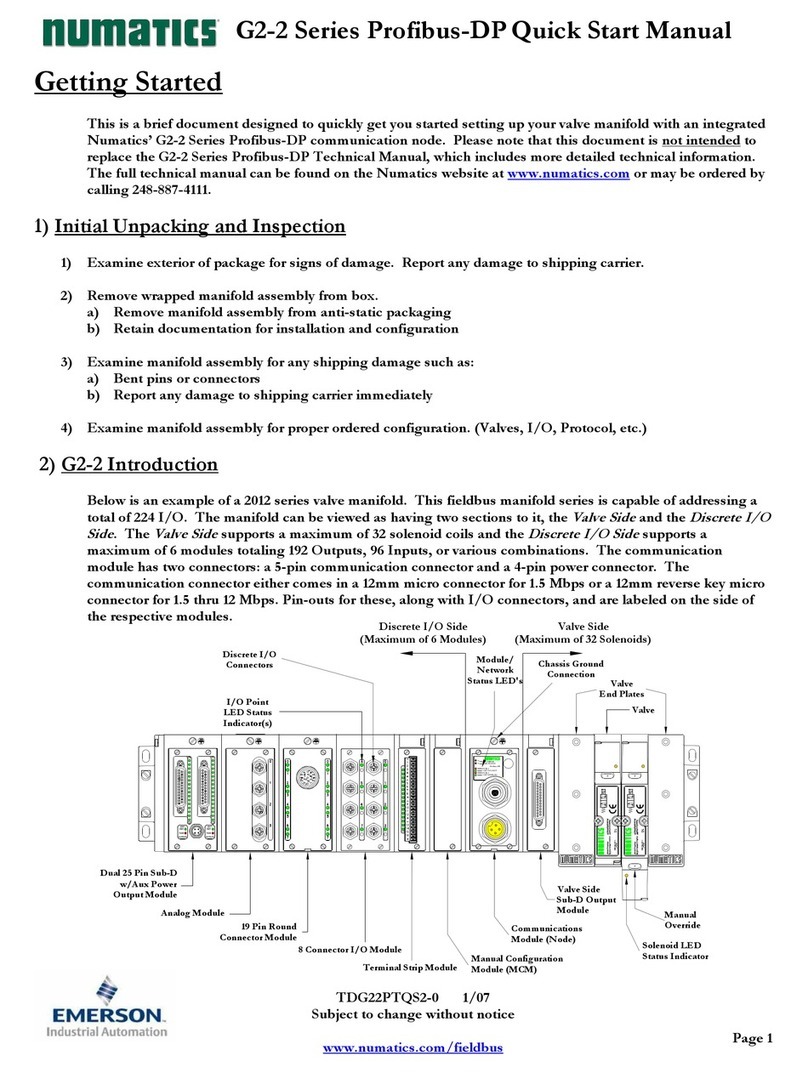

Numatics

Numatics G2-2 Series Quick start manual

Renesas

Renesas RYZ014A quick start guide

Beninca

Beninca CP.J3M quick start guide

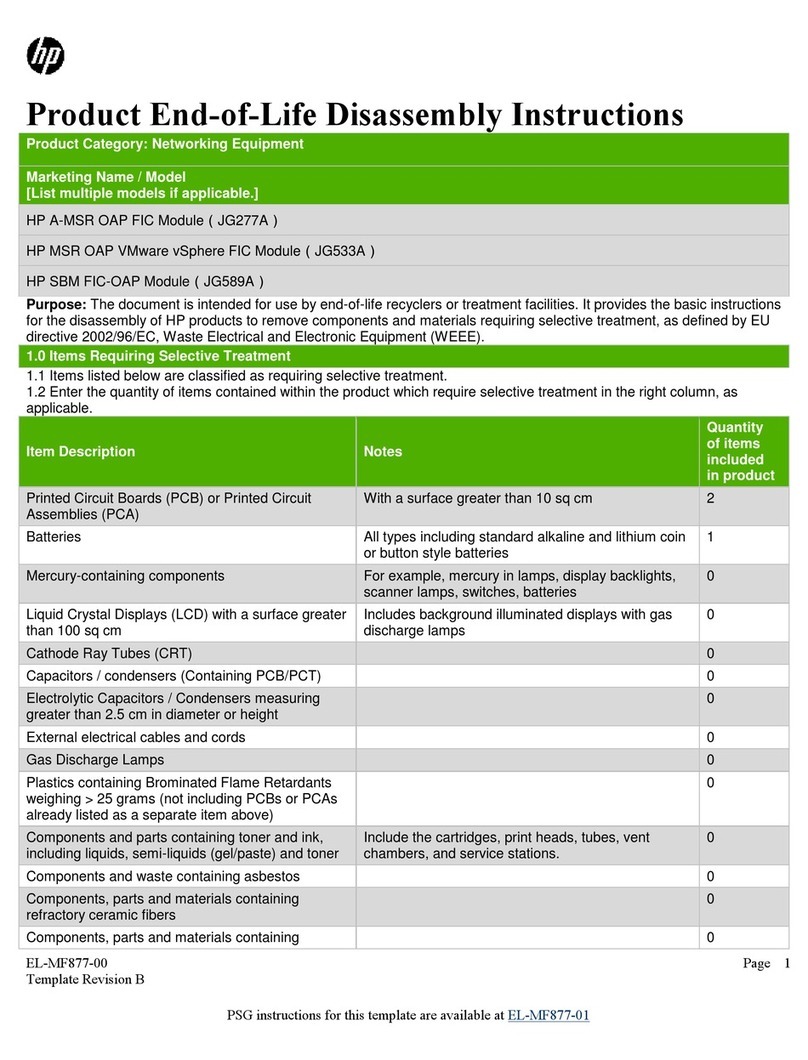

HP

HP JG589A Product End-of-Life Disassembly Instructions

Beninca

Beninca BRAIN 24 operating instructions

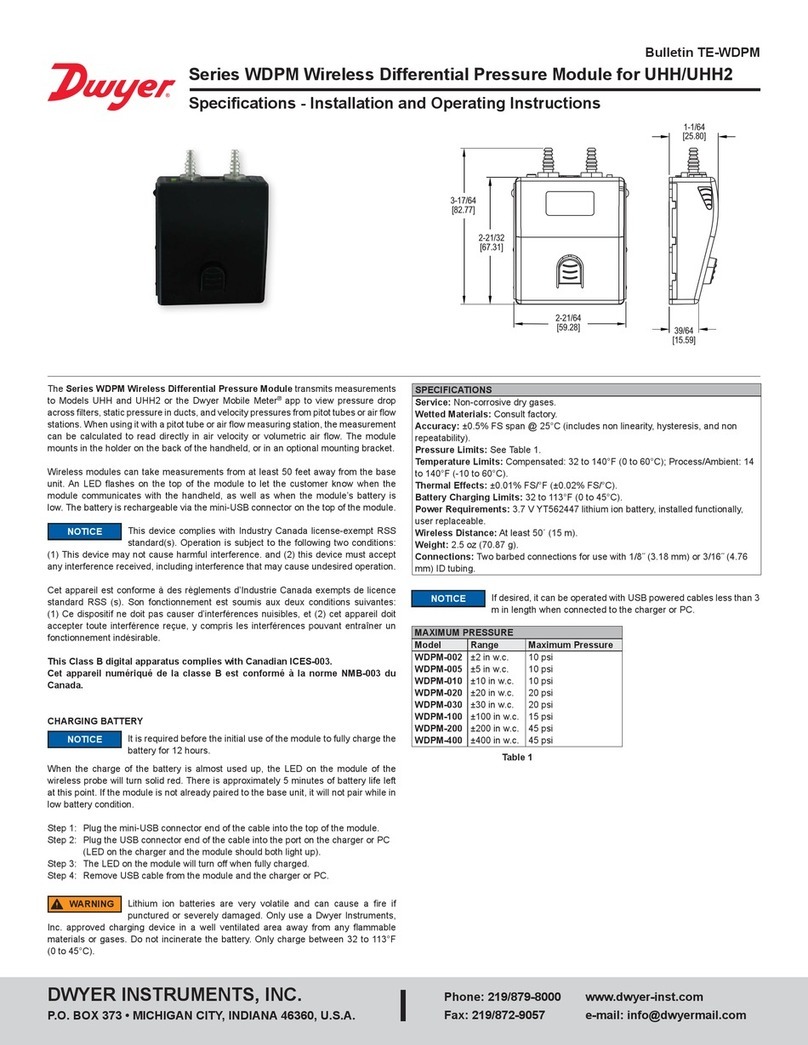

Dwyer Instruments

Dwyer Instruments WDPM Series Specifications-installation and operating instructions

ABB

ABB ACH550 series installation manual

SCHNERZINGER

SCHNERZINGER GIGA GUARD manual