GB Evolution F1 Pocket Bike Instruction manual

I

MANUAL INSTRUCTION

Air

cooledengine

1

.-:3

-

.

;&$

r-

i*

...

..

-

-1.

.; .

l..

'C

Pocketbike

www.gbevolution.it

SERVICE

MANUAL

FOR

USE

AND

PflAINTENANCE AND

SPARE

PARTS

LIST

For your own

safety

and

lhe

safoty

01

01-ers

Follow

these

rccornmendat~ons

in

order

to

use

vour I~II~IISIKEs;:fely gild correctl?

.

Read

tbc Ins!ructions

CAREFULLY

.

failure

to

co

so

n?aY

blnce

yourself and ithers

In

extreme

and

or

ultimate

DANGER

.

I:

you do rot understand

th;

Instructions and Data tlien. you are not to

aCPmp:

to operate this Mlnibike under

any

circumstances

.

It

may

be

used

for

si;ow

purposes only!

CONTENTS

PAGE

..........................................................................................................

INTRODUCTION

2

TECHNICAL DATA

......................................................................................................

2

.....................................................

UNPACKING AND SETTING UP BEFORERlGlNG

3

.......................................................................................................................

SAFETY

3

BEFORE STARTING

...................................................................................................

3

.

................................................................................

STARTING THE ENGINE

-

FIG

2

4

.

...........................................................................................

.

CARBURETOR FIG

3

4

RIDING

.......................................................................................................................

4

PERIODIC

MAINTENANCE

.........................................................................................

5

CHAIN SETTINGAt:D MAINTENAFICE

................................................................

5

CENTRIFUGAL CLUTCH REPAlR

0%

REPLACEMENT

......................................

'

.

5

.

.

....................................................................................

BRAKES ADJUSTING FIG

4

t

FRONT BRAKES PADS REPLACEMENT

.

FIG

.

7

..................................................

6

REAR BRAKES PADS REPLACEMENT

.

FIG

.

7

......................................................

6

REMOVE AND REFIT THE FRONT WHEEL-

FIG

.

6

............................

1

..................

7

REMOVE AND RFFlT THE REAR WHEEL

.

FIG

.

5

...................................................

7

REPLACEhlENT

OF

SPROCKET

-

FIG

.

9

..................................................................

7

MINIBIKE

..........................................................................................................

8-3

PARTS LIST

......

L

..............................................................................

10,

11

ENGINE

.........................................................................

12

CLUTCH COMPLETE- FIG

.

6

.............................................................................

13

FRONT AND

REAR

BRAKES .FIG

.

7

.................................................................

14

REPLACEMENT OFTIRE

-

FIG

.

6

15

..............................................................................

REMOVE AND REFIT AIR FILTER

..................................................................................

15

CLUTCH ADJUSTMENT

-

FIG

.

8

.............................

...........

.................................

15

MAINTENANCE OF COOLING SYSTEhl

...........................................................

16

TOXQUE SETTINGS

..................................................................................................

7

STORAGE PROCEEDURES

................................................................................

18

www.gbevolution.it

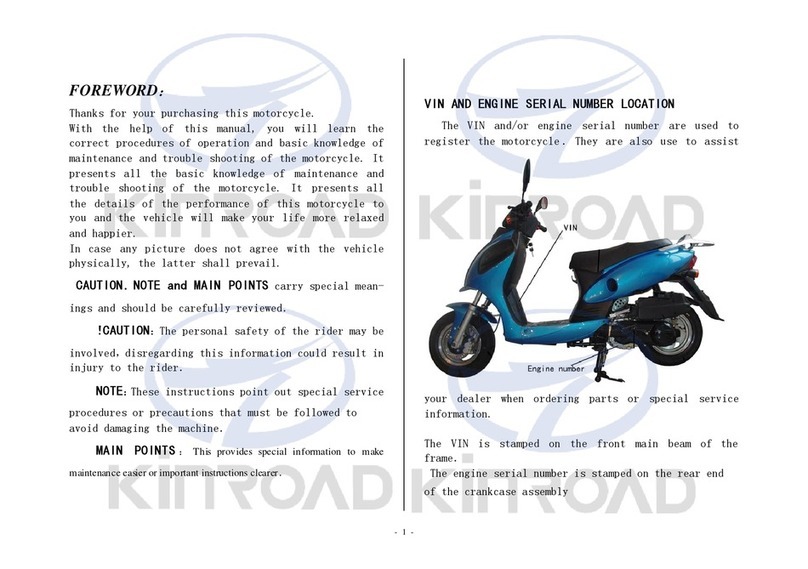

Tlie fdinih~keis designecl and built

for

use on

a

pavcc! cl00

).LI

circuil

track

The

trark

s!lollld'ile clcat, arid v~itnoutobstacles of anv b..ntl. Qualifirtl

adi~its2nd yot!n!)c: j~ersonscilrl drive the rliiriil~ike.Cliiidren c,?;, drive

the

min:blke only under the supervision

of

a respcrisible adu!t person. T!ie

niini!)ikc

is

corlstruc!ed especially for racing cornpctiii~tiscri sr?eciil[rnci:~?

tracits.

Thc ~iiinlbike

uses

a singie-cylinder t\.:o-stroke, Gasoline co~r;b~~sti:nencine.

andhas an air fiiter arid erhat~stsilencer. Transfer of po:':er to the rear v:tie~.l

is

through a drive chain. The the

overall

rtrive ratio to the rear v:ilee! can tle

changer!

b:!

the repiacenlen! of c!lain sprockets. The front a?(] :car vdieel

IS

equipped with disk Drakzs. The rear brake is con!ro!lecl '::it11 t!le left lever 2nd

the front brake

is

control!ed with tb- rlght lever on the hanilleb,7rs.

BASIC TECHNICAL

DATA

ENGINE:

-

TWO-STROKE

NUPABER OF CYLINDERS

...................................................................

7

.........

CYLINDER CAPACITY

......................+..........

39,0

CC

................

ENGINE COOLING SYSTErL

...

.......

LIQUID COOLED

POWER OUTPUT

.................

....

...................

4.5

kW

at

11

530

rpm

-

..

TORQUE ................................................

4

Ntn

ar

1:

5'20

r?rn

CARBURETOR

....................................

-:

......

PHVA

17,s

DELL' ORTO

............

FUELADMlSlON REEDVALVE DIRECT TO CRAI'IXCfiSE

..........

IGNlTIOFJ

..

..........

..

................................

COP7ACT-LESS

.............................................................

SPARK PLUG

NGK

BSES

STARTING

..........................................

HAND

PULLTYPE, MAFJUAL

FRAME:

BRAKES:

.-

-

WHEELS:

TIRE:

-

W:

...

CLUTCH

.............................................

CENTRIFUGAL AUTOMATIC

.................

ENHANCEDTRELLIS SUPPORTING STRUCTURES

MADEOF LIGHT ALLOYS

...

FRONT

WHEEL DISC ERAKE- DISC DIAMETER 162rnn)

(

63")

........

REAR

WHEEL

DISCBRAKE-DISC DlAhlETER 119mm

(

4,7")

FRONT

......................................

OFLIF,!T ALLOY

2,l

"X

6,6"-

99

...................................

REAR OF

LIGH?

ALLOY 2,I"x 6.5"-

130

.

FRONT

.........................................................................

SIZE

90165

5;s"

...........................................................

REAR 110153 -6,5",

90!65

-6,s"

......

..MIXTURE

OF

PETROL

92

OR

HIGHER

OCTANE

+2

STROhE

SYNTHETICOIL

........................................

hllXlNG ,RATIO(after break inperiocl)

50: 1

.......................................

TANK CAPACITY

1.7

Litre

(

0,44

US

gal.

1

UNLOADEDWEIGHT:

................................................................

25

kg

(

55

lb.

)

CARRYING CAPACITY:

................................-......................... 110

kg

(

242

lb.

)

BASIC DIMENSIONS:

LENGTH

...................................................................

1

100

mm

(

41"

WIDTH

...........................................................................

560

mm

122

"

)

......................................................................

HEIGHT 550

mm

(

21.6"

)

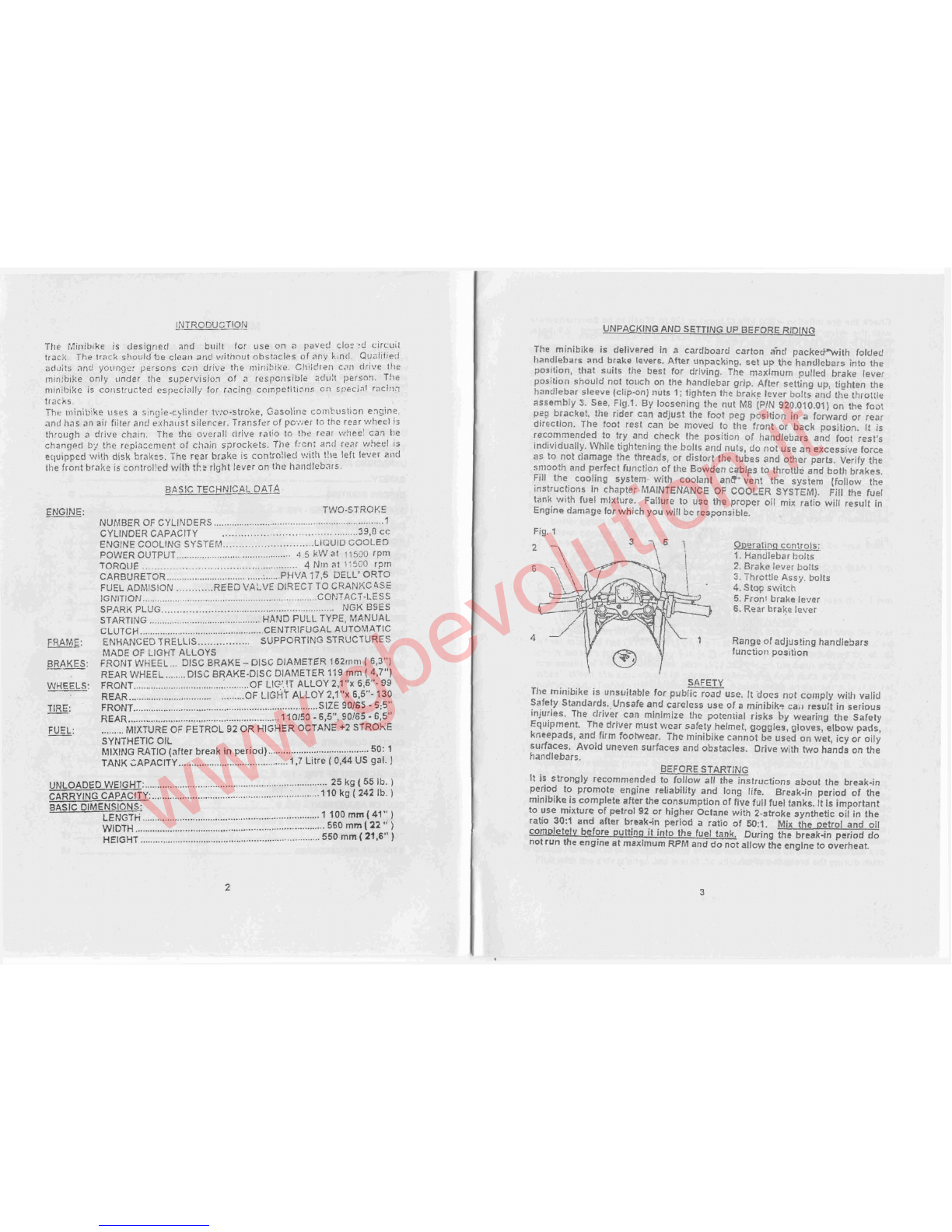

UNPACKINGAND SETTING UP BEFORERIDING

The minibike

is

delivered in

a

cardboard carton

&cl

packedwith folded

handlebars

and

brake levers. After

unpacking,

set

up

the handlebars into the

position, that suits the best for drlving. The maximum pulled brake lever

position should not touch on the handlebar grip. After setting

up,

tighten the

handlebar sleeve (clip-on) nuts

1;

tighten the

bra~e

lever bolts and the throttle

assembly

S.

See. Fig.1.

By

loosening the nut

M8

(PIN 920.010.01) on

the

foot

peo

bracke!. the rider can adjust the foot peg position in a forward or rear

direction. The foot rest can be moved to

the

front or back position. It is

recommended to try and check the position of handlebars and fwt rest's

individually.Whlle tightening the bolts arldnuts, do not use anexcessive force

as to not damage the threads, or distort the tubes and other parts. Verify the

sniooth and perfect function of the Eowden cables to throttle and botli brakes.

Fill the cooling system with coolant anpvent the system [follow the

instructions In chapter MAINTENANCE

OF

COOLER

SYSTEM), Fill the fuel

tank with

fuel

mlxture. Failure to usc the proper oil mix ratio will result in

Enginedamage for which youwi!l be responsible.

Fig.

1

3

75

1

Oweranqconlrofs:

1.

Handlebar bolts

2.

Brakelever bolts

3.

Throttle Assy. bolts

4.Stopswitch

5.

Front brake lever

6.

Rear brake lever

4

-/

1

Rangeof adjus!ing handlebars

functiori position

SAFETY

The minibike is unsuitable for public road use.

It

goes not cornply wilt1 valid

Safety Standards.,Unsafe and careless use of a minibik.? ca,t resuit in serious

injuries. The driver can minimize the potential risks

by

wearing the Safely

Equipment. The driver must wear safety helmet, goggles, gloves, elbow

pads,

kneepads, and firm footwear. The minibike cannot be used on wet, icy or oily

surfaces. Avoid uneven surfaces and obstacles. Drivewith two hands on the

handlebars. BEFORESTARTING

It

is strongly recommended to follow all the instructions about the break-in

period to promote engine reliability and long life. Break-in period

of

the

minibikeiscomplete after

the

consumption of five fullfuel tanks. ItIs important

to use mixture of petrol

92

or higher Octane with 2-stroke synthetic oil in the

ratio

30:l

and after break-in period

a

ratio of

50:l.

Mix the petrol and oil

com~letelvbefore puttinn it into the fuel tank. During the break-in period do

notrunthe engine

at

maximum

RPM

anddonotallow the englne to overheat.

www.gbevolution.it

Check the tire inflation

-

200 kPa (2 bars) or (28 to 30psij to becomlnensilrale

with the driver's weigh!. The Tyre pressure shoi~lclnever exceed

2.5

bars,

(38psi)ineither the front or rearwheel.

IPAPORTANT NOTICE: Ifthe coolant level rises in the balance tank, switch off

the engine immediately! Check thedrive ofthe coolant pump andsealing of the

cooling system. After these steps, execute the ventilation of the Rad~ator.The

raised level ofcoolant is an indicator of

a

overheated engine, which can result

inseizing the piston inthe cylinder.

STARTING THE ENGINE

Engine starting shoulc be done onlyonthe stand -Fig.

2.

Fillthe fuel tank and

close itwith the filler cap. Open the Gas petcock. Set the petrol supply cock.

Set the choke lever

i

gjl)

position

"C",

Fig. 3. Without turning the accelerating

handle, pill1 gently twlce the starting wire and by next guick puli start the

engine. It is not allowed to pull the starting wire up to full winding off. The

choke lever will turn back to the position

"A"

autornaticaly

by

t~~rningthe

accelerating lever alter a short engine run .Let the engine run about

1

min.

Ltavethe minibike on the stand with running englne and if necessary adjust

the revolutions so the rear wheel is not tt~rning. For adjtlstrnent tlse the

adjustment screwNo.on the carburetor Fig.

3.

Fig.

3

l.

Air filter

2. Carburetor body

3. Idlespeed adjusting screw

4.

Float chamber

A

-Cock positionfor riding

C

-

Cock position for cold starting

RlDlNG

Remove the minibike from the stand to sit on the seat. When seated, then

slowly rotate the throttle grip to start riding. Before braking, rotate the Throttle

grip to the off or idle position and lightly depress the rear brake lever with left

hand and then the front brake lever with right hand. Beware to not skid the

wheels. The minibike engine is switched off

by

pushing the red button (Engine

stop switch) on the handlebars. It is necessary to check the tightness of bolts

and nuts, especially of the englne, and the brake settings after the first rideand

often during the break inperiod.

PERIODIC MAINTENANCE

Periodic maintenance is the best way to help the machine perform well, give

'longevity and provide safety and low cost operation. In addition, you will be

spared from many worries frorn self caused problems, resulting-from poor

malntinenceor nomalntinence.

A

-

Before everv ride:

1.

Check the Cables andefficiency of brakes.

2.

Check the lubrication and chain tension settings. The chain free playshor~ld

be(5 mm) (.200in) After every ride clean the minibike carefully and keep it

clean. Donot useaggressive cleaningdetergents.

3.

After l-hour of use, wash the air filter in air drying spirits and lubricate it

with special oilfor air filters.

4.

After

1-

hour of use, check the state of the clutch pads. Review the clutch

adluslnlent.

B.

&er everv 6 hoursofridlng:

Check the tightness ofall bolts and nuts. Tiuhtenwith a uroperlv adiusted

torque wrench only! Fortorque settinqssee tables on paqe

17.

5.

Wash tlie air filter in gas and lubricate itwith special nit for an air filters

to

better catchthe dust.

6.

Clean carefully the carburetor float chamber.

7.

Check the brake pads, the thickness of brnke lining cannot be less than

1

mm (.039 inj. Review the basic braheadjustment.

8.

Check the state of the clutch pads ;!he thickness cann~tbe$s than

1

Inn,

(.039in). Review the clutchadjustmknl.

C

-

Everv time after 10 hours of rlding:

9.

Check the state of the clutch pads -the thickness cannot be less than

1

mm

(.039in). CHAIN SEnlNQ

AND

MAINTENANCE

To set the chain tenslon, looserl the Nu! (920.011.01) of ?heaxe1 thru the rear

wheel and

the

nui(914.021.01) of the rear Caliper anchor plate. The required

rhaln tension (chain free play

)

is (6 mm] (.2OOin) and is performed by equal

movement of the Axel adjustor plate (920.009.01) on the both sides of the rear

wheel. When the ad,ustment is correct, tighten the Axel nuts and the Caliper

holding nut. Tlghten the adjustor platenuts both sides an extra nip, just to set

then1 firmly. It is important to lubricate the chaln regularly, to avoid excess

wear and prolong effective lifetime. The lubrication is Importantafter every ride

on

a

wet surface. It is recomlnended to

lubricate

the minibike with sp9cial

chain spray. If chain replacement is necessary, check both chain Sprockets

and Ifthere isa needtochange them do ittogether with thechain.

CENTRIFUGAL

CLUTCH

PARTS. REPLACEMENT

Remove the chain guard by loosing two bolts M6 (916.020.01), Fig.

5.

Loosen

the chainand remove it from the sprocket. Next, loosen three bolts holding the

alumlnum clutch housing. Remove it together with steel clutch basket, and

dismantle

it

Loosen the bolt lrom the carrier and remove

the

clutch from the

engine. Loosen and remove the adjustable bolts and springs. Then dismantle

the safety rings from pins. When all this is done, replace with new clutch

slipper shoes and springs (if required), at this time. During the reassembly

process follow these steps:

l.

put the plate with the springs on the slipper

shoes. 2. Putthe plateagainst the carrierand mount itonthe fixed plns.

Fititwith the safetyringsand install the adjustablebolts.

www.gbevolution.it

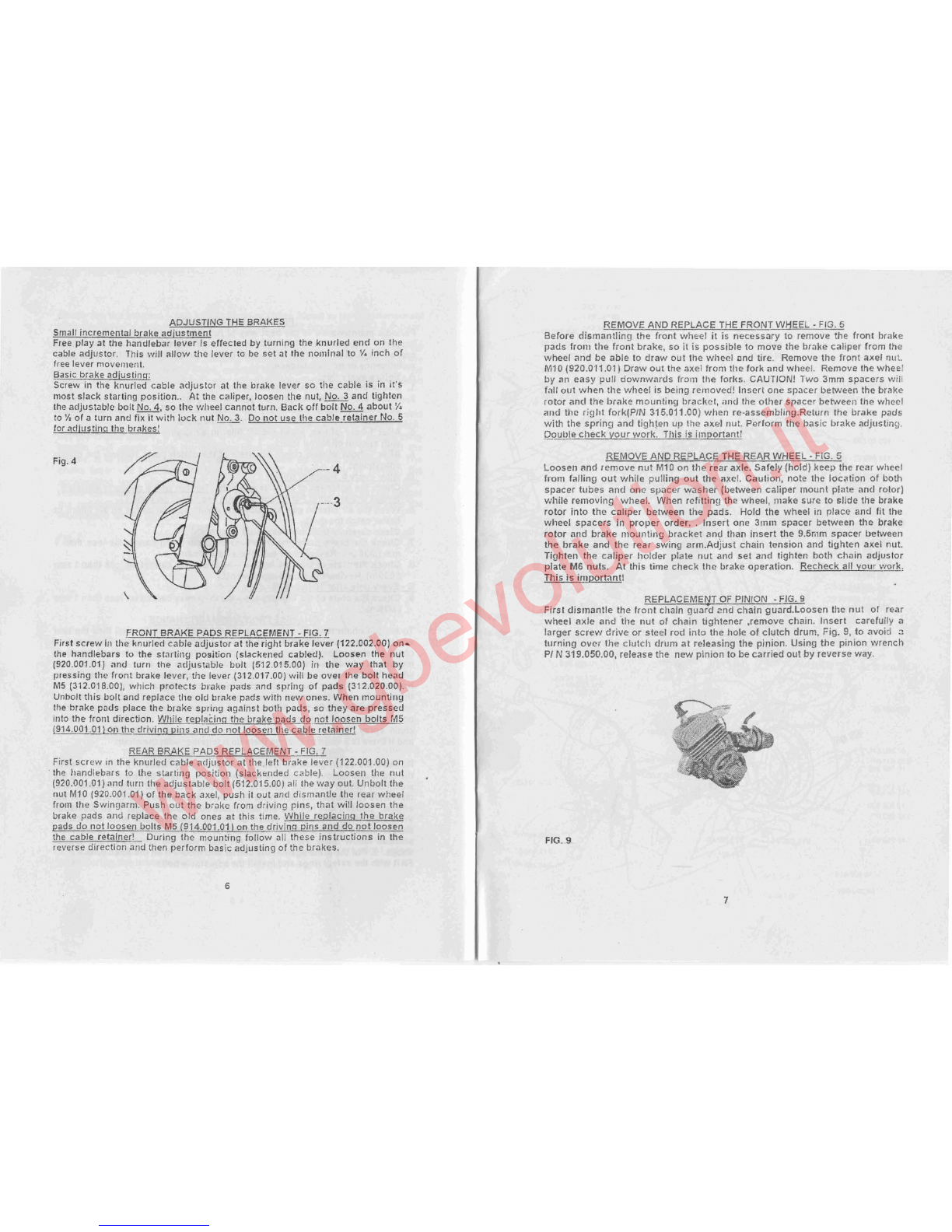

ADJUSTING

THE

BRAKE-?

Small incrementalbrake adiustment

Free play at the handlebar lever is effected by turning the knurled end on the

cable adjustor. This will allow the lever to be set at the notriinal to

%

inch of

free lever movertierit.

Basic brake adiustinq:

Screw in the knurled cable adjuslor at the brake lever so tlie cable is in it's

nlost slack starting position.. At the caliper, loosen the nut,

No.

and tighten

the atljustable bolt=, so the wlteel cannot turn. Back off bolt

No.

about

%

to

X

of a turn and fix itwith locknut

Nu.

Do not use the cable retainer

No.

5

for aclil~stinc~the brakes!

Fig.

4

FRONT BRAKE PADSREPLACEMENT

-

Fs.1

First screw

it1

the knurled cable adiustor at the riaht brakelever (122.002.001 on-

the handlebars to the starling (slackened cabled). ioosen the 'nut

(920.001.01) and turrr the adj~cstablebolt (512.015.00) in the way that by

pressing the front brake lever, the lever (312.017.00) will be over the bolt head

M5

(312.018.00), which protects bt-akepads and spring of pads (312.020.00).

Unbolt tliis bolt and replace the old brake pac!s wilt) nev~ones. When ~nounti~ig

the brake pads place the brake spriny against both pads, so they are pressed

into the front direction. While replaiinq the brake pad~d_o~notloosen bolts

M5

~914.001.011ontke drivinq pins and do not loosen t1:e cable retainer!

REAR

BRAKE

PADS

REPLACEMENT -FIG.

7

First screw in the knurled cable arliustor a1 the left brake lever (122.001.00) on

the handlebars to the starting po;ition (slackended cable). ~oosenthe'nut

,

(920.001.01) ancl turn the adjustable bolt (512.015.00) ali the way out. Unbolt the

nut M10 (920.001.01) of the back axel, push it out and disrnantle the rear wheel

frorn the Swingarm. Push out the brakc from driving pins, that will loosen the

brake pads and replace the old ones at this time. While replacinq the brake

pads do not loosen bolts M5 (914.001.01

)

onthe drivinq pins and do not loosen

the cable retainer! During the niounting follow all these instructions in the

reverse direction and then perform basic adjusting of the brakes.

REMOVE

AND REPLACE THE FRONT WHEEL

-

FIG. 5

Before dismanlling the front wheel it is necessary to remove the front hrake

pads fron~the front brake, so it ispossible to move the brake caliper from the

wheel and be able to draw out the v~hceland tire. Remove the front axe1 nu:.

M10 (920.011.07

)

Drawout the axe1 front the fork and wheel. Remove

the

whee!

by an easy pull downwards frorn the forlts. CAUTION! Two 3mm spacers Wili

fallout when the wheel isbeingremoved! Insert one spacer between the brake

rotor ancl the brake mounting braclcct, ;~ndthe other spacer belween the wheel

a~idthc rigltt fork(P1N

315.011.00~

when re-assemb1ing.Return the brake pads

with the spring and tighten up the axe1nut. Perform the basic brakeadjusting.

Double

check your work. Tf~isis ilnportantl

..-p

REMOVEAND REPLACE THE

REAR

WHEEL

-FIG.

S

Loosen and removenut M10 on the rear axle. Safelv (hold)keep the rear wheel

.,

.

frorn falling out while pulling out the nxc!. Caut~on,note the iocation

of

both

spacer tubes ancl onc spacer washer (between caliper lnount plate ancl rotor)

while removing wheel. When refttting the wheel, ntake sure to slide the brake

rotor into the caliper between the pads. Hold the wheel in olacc and fit the

wheel spacers in proper order.

.

Insert one 31ntn spacer between the brake

rotor and brake mounting bracket an? than insert the

9.5fiirn

spacer betrveen

the brake and the rear swing arm.Adjust chain tension and tighten axe1 nut.

Tighten the caliper liolcler plate nut and set and tighten both chain adjustor

plate

M6

nuts. At this time check the brake operation. Recheck all vour

vg&,

This isintportnntl

REPLACEMENT

OF

PINION

-

F=

First distnantle the front chain g~ra?d2nd chain guard.Loosen the nut of rear

wheel axle and tlie nut of cllain tightener .remove chain. Insert carefullv

a

larger screw drive or steel rod into the hole of clutch drum, Fig.

9,

to avoici

2

turning over the clutch drum at releasing the pinion. Using the pinion wrench

PIN

319.050.00, release the newpinion to becarriedout byreverse way.

FIG.

9

www.gbevolution.it

Other GB Evolution Scooter manuals