GBD TOP EVO TOP 291E Guide

TOP EVO

TOP 291E(R)(/S)

TOP 391E(R)(/S)

TOP 441E(R)(/S)

UK

Linear hydraulic operator

INSTRUCTIONS FOR INSTALLATION

2TOP EVO 3

TOP EVO

% Fu

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

30

40

50

60

70

80

90

100

TOP 391E - TOP 441E(R)(/S)

Time (h)

% Fu

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

20

30

40

50

60

70

80

90

TOP291E(R)(/S)

Time (h)

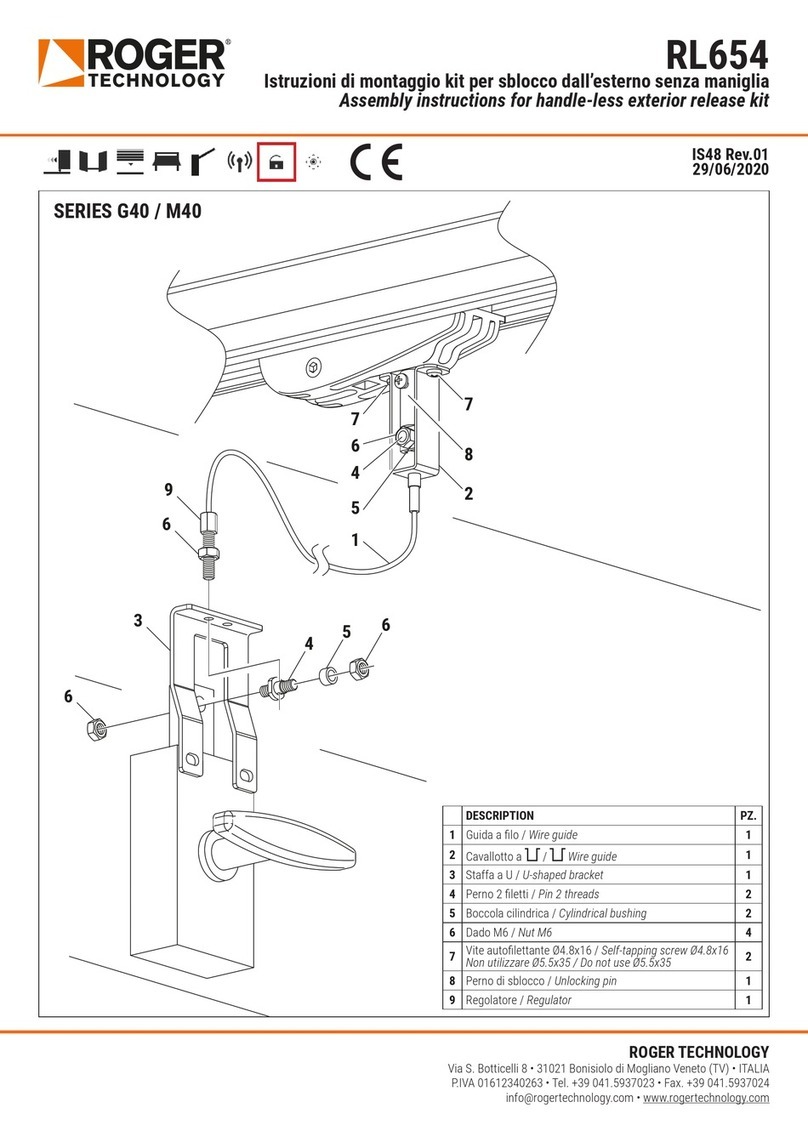

9

2

5

3

4

7

1

8

8

11 11

11

10

4

6

5

1

2a 2b

Elettroserratura

Electric lock

Serrure électrique

Electro cerradura

=

Limite BAC

BAC Limit

Limite BAC

Límite BAC

TOP291E(R)(/S)

TOP391E(R)(/S)

TOP441E(R)(/S)

Peso anta / Leaf weight (Kg) / Poids de la porte / Peso de la hoja (Kg)

Lunghezza anta / Leaf lenght (m)

Longueur de la porte / Longitud de la hoja (m)

291E(R)(/S) 391E(R)(/S) 441E(R)(/S)

100 200 300 400 500 6000

1

2

3

4

5

6

TOP391E TOP391ER - TOP391ER/S

TOP291E TOP291ER - TOP291ER/S

TOP441E

TOP441ER - TOP441ER/S

825

1250

65x65

1265

810

90x90

680

945

65x65

960

670

90x90

65x65

895

630

80x80

910

620

2c

3

TECHNICAL DRAWINGS

2TOP EVO 3

TOP EVO

% Fu

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

30

40

50

60

70

80

90

100

TOP 391E - TOP 441E(R)(/S)

Tempo / Time / Temps / Tiempo (h)

% Fu

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

20

30

40

50

60

70

80

90

TOP291E(R)(/S)

Tempo / Time / Temps / Tiempo (h)

9

2

5

3

4

7

1

8

8

11 11

11

10

4

6

5

1

2a 2b

Electric lock

=BAC Limit

TOP291E(R)(/S)

TOP391E(R)(/S)

TOP441E(R)(/S)

Leaf weight (Kg)

Leaf lenght (m)

291E(R)(/S) 391E(R)(/S) 441E(R)(/S)

100 200 300 400 500 6000

1

2

3

4

5

6

TOP391E TOP391ER - TOP391ER/S

TOP291E TOP291ER - TOP291ER/S

TOP441E

TOP441ER - TOP441ER/S

825

1250

65x65

1265

810

90x90

680

945

65x65

960

670

90x90

65x65

895

630

80x80

910

620

2c

3

DISEGNI TECNICI • TECHNICAL DRAWINGS • DESSINS TECHNIQUES • DISEÑOS TÉCNICOS

β

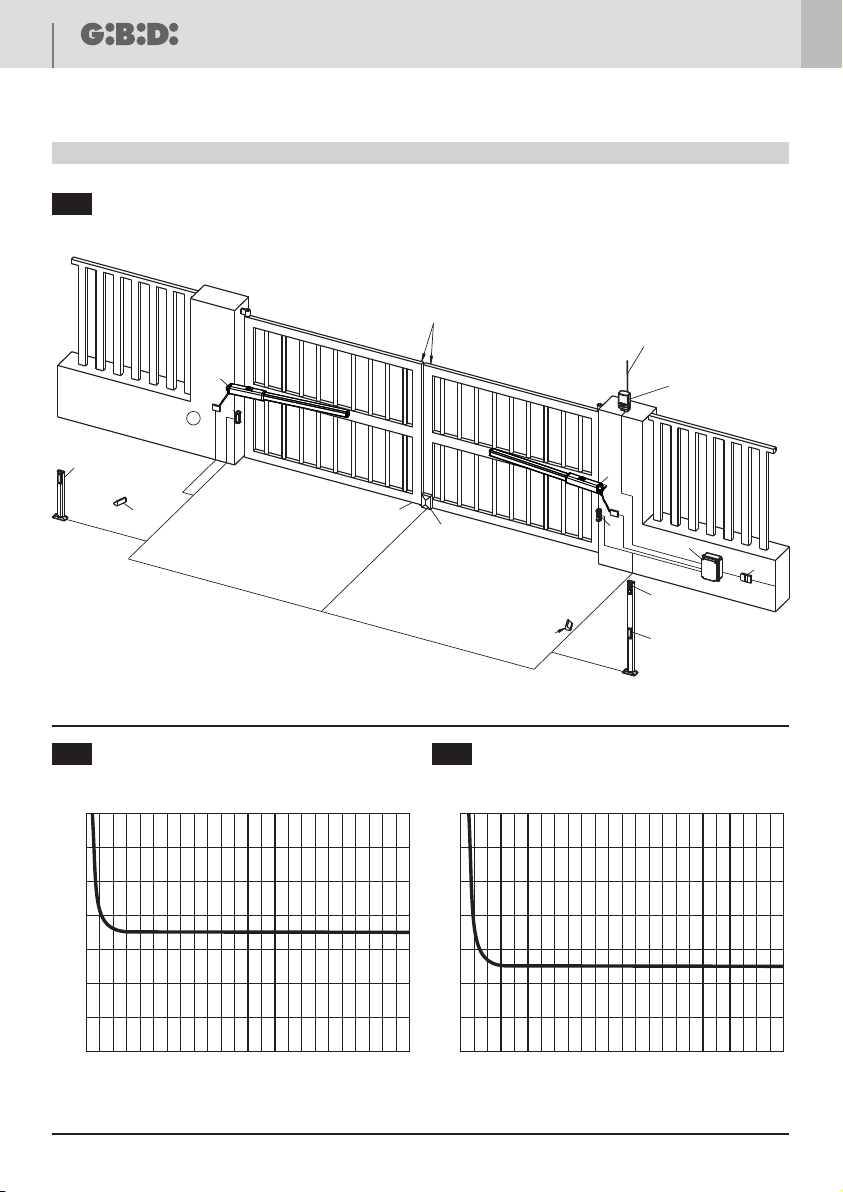

A B C D Cu

TOP 291E

TOP 291ER-ER/S

TOP 291ER-ER/S

TOP 291E

90° 130 130 900 100 260

110° 110 120 900 95 265

90° 125 125 885 95 250

105° 110 110 885 95 245

TOP 391E 90° 130 130 950 100 260

110° 110 120 950 95 260

TOP 391E

TOP 391ER-ER/S 90° 125 125 940 100 250

F

>80

>100

E

>55

>65

TOP 391ER-ER/S 105° 110 115 940 95 250

205 1243

TOP 441E 90° 205 125 410

TOP 441E 110° 175 175 1243 120 410

TOP 441ER-ER/S 90° 200 200 1243 120 400

TOP 441ER-ER/S 110° 175 175 1243 120 400

β

B

A

D

E

F

C

Cu

4

4TOP EVO 5

TOP EVO

100/120

B

A

100/150

150150

B

A

20 mm

5 6

7

β

A B C D Cu

TOP 291E

TOP 291ER-ER/S

TOP 291ER-ER/S

TOP 291E

90° 130 130 900 100 260

110° 110 120 900 95 265

90° 125 125 885 95 250

105° 110 110 885 95 245

TOP 391E 90° 130 130 950 100 260

110° 110 120 950 95 260

TOP 391E

TOP 391ER-ER/S 90° 125 125 940 100 250

F

>80

>100

E

>55

>65

TOP 391ER-ER/S 105° 110 115 940 95 250

205 1243

TOP 441E 90° 205 125 410

TOP 441E 110° 175 175 1243 120 410

TOP 441ER-ER/S 90° 200 200 1243 120 400

TOP 441ER-ER/S 110° 175 175 1243 120 400

β

B

A

D

E

F

C

Cu

4

4TOP EVO 5

TOP EVO

100/120

B

A

100/150

150150

B

A

20 mm

5 6

7

M

OPENING

COM

CLOSING

YELLOW-GREEN

BLACK

GREY

BROWN

BROWN

GREY

BLACK

YELLOW-GREEN

8

9

6TOP EVO 7

TOP EVO

1

2

3

5

2

34

10

11

M

APERTURA / ABERTURAOPENING / OUVERTURE /

COM

CHIUSURA / CLOSING / FERMETURE / CIERRE

GIALLO-VERDE / YELLOW-GREEN / JAUNE-VERT / AMARILLO-VERDE

NERO/ BLACK / NOIR / NEGRO

GRIGIO / GREY / GRAY / GRIS

MARRONE / BROWN / BRUN / MARRÓN

MARRONE / BROWN / BRUNE / MARRÓN

GRIGIO / GREY / GRIS / GRIS

NERO/ BLACK / NOIR / NEGRO

GIALLO-VERDE / YELLOW-GREEN

JAUNE-VERT / AMARILLO-VERDE

8

9

6TOP EVO 7

TOP EVO

1

2

3

5

2

34

10

11

1

PRESSURE ADJUST

OPEN CLOSE

+

-

+

-

2

34

1

3

3

4

12

13

8TOP EVO 9

TOP EVO

3

4

5

6

2

1

5

3

4

7

7

4

3

15

2

6

14a

14b

1

PRESSURE ADJUST

REGOLAZIONE PRESSIONE

OPEN

APRE CLOSE

CHIUDE

+

-

+

-

2

34

1

3

3

4

12

13

8TOP EVO 9

TOP EVO

3

4

5

6

2

1

5

3

4

7

7

4

3

15

2

6

14a

14b

UK

22 TOP EVO 23

TOP EVO

UK

INTRODUCTION

INSTALLATION WARNINGS

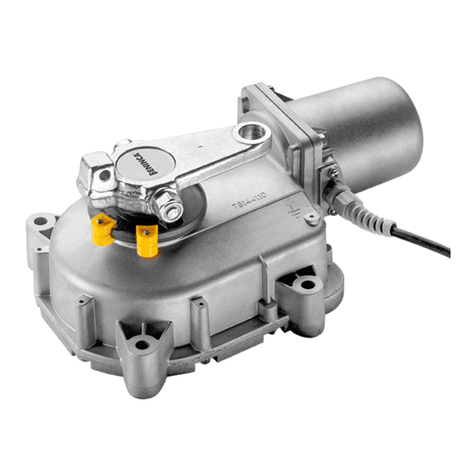

TOP EVO operator allows the automation of swinging gates.

The automation is composed by an operator with arm, that transmits the movement to the leaf, and by a built-in

hydraulic control unit.

TOP EVO operators are interchangeable with previous TOP versions, see chapter 8.

• Before proceeding with the installation, it is necessary to fit a magneto-thermal differential switch with a max.

capacity of 10A upstream of the system. The switch must guarantee an omnipolar separation of the contacts,

with an opening distance of at least 3mm.

• Keep all the materials contained in the packaging away from children since they pose a potential risk.

• The manufacturer declines all responsibility for improper functioning of the automated device, if the original

components and accessories suitable for the specific application are not used.

• After installation, always carefully check the proper functioning of the system and devices used.

• This instruction manual addresses professionals qualified to install “powered equipment” and therefore requires

a good technical knowledge and installation in compliance with the regulations in force.

• Maintenance must be carried out by qualified personnel.

• Before carrying out any cleaning or maintenance operation, disconnect the control unit from the main line.

• This product has been designed and constructed exclusively for the use indicated in this documentation. Any

other use may cause damage to the product and be a source of danger.

• Verify the end purpose of the product and take all the necessary safety precautions.

• The use of the products for purposes different from the intended use has not been tested by the manufacturer

and is therefore on full responsibility of the installer.

• Mark the automated device with visible warning plates.

• Warn the user that children or animals must not play or stand near the gate.

• Appropiately protect the dangerous points (for example, using a sensitive edge).

• Check the proper installation of the earthing system: connect all the metal parts of doors, gates, etc. and all the

system components to an earth terminal.

• Exclusively use original spare parts for any maintenance or repair operation.

• Do not modify any components of the automated device unless expressly authorised by GI.BI.DI.

• Use suitable cable clamps to ensure that the wiring is properly connected mechanically and such that an IP 65

protection degree is maintained.

WARNINGS:

This product has been tested by GI.BI.DI. for full compliance with the requirements of the directives in force.

GI.BI.DI. S.r.l. reserves the right to change the technical data without prior notice in relation to product

development.

READ CAREFULLY THESE INSTRUCTIONS BEFORE PROCEEDING WITH INSTALLATION.

Thank you for choosing GI.BI.DI.

DISPOSAL: GI.BI.DI. advises recycling the plastic components and to dispose of them at special

authorised centres for electronic components thus protecting the environment from polluting

substances.

UK

22 TOP EVO 23

TOP EVO

UK

INTRODUCTION

INSTALLATION WARNINGS

TOP EVO operator allows the automation of swinging gates.

The automation is composed by an operator with arm, that transmits the movement to the leaf, and by a built-in

hydraulic control unit.

TOP EVO operators are interchangeable with previous TOP versions, see chapter 8.

• Before proceeding with the installation, it is necessary to fit a magneto-thermal differential switch with a max.

capacity of 10A upstream of the system. The switch must guarantee an omnipolar separation of the contacts,

with an opening distance of at least 3mm.

• Keep all the materials contained in the packaging away from children since they pose a potential risk.

• The manufacturer declines all responsibility for improper functioning of the automated device, if the original

components and accessories suitable for the specific application are not used.

• After installation, always carefully check the proper functioning of the system and devices used.

• This instruction manual addresses professionals qualified to install “powered equipment” and therefore requires

a good technical knowledge and installation in compliance with the regulations in force.

• Maintenance must be carried out by qualified personnel.

• Before carrying out any cleaning or maintenance operation, disconnect the control unit from the main line.

• This product has been designed and constructed exclusively for the use indicated in this documentation. Any

other use may cause damage to the product and be a source of danger.

• Verify the end purpose of the product and take all the necessary safety precautions.

• The use of the products for purposes different from the intended use has not been tested by the manufacturer

and is therefore on full responsibility of the installer.

• Mark the automated device with visible warning plates.

• Warn the user that children or animals must not play or stand near the gate.

• Appropiately protect the dangerous points (for example, using a sensitive edge).

• Check the proper installation of the earthing system: connect all the metal parts of doors, gates, etc. and all the

system components to an earth terminal.

• Exclusively use original spare parts for any maintenance or repair operation.

• Do not modify any components of the automated device unless expressly authorised by GI.BI.DI.

• Use suitable cable clamps to ensure that the wiring is properly connected mechanically and such that an IP 65

protection degree is maintained.

WARNINGS:

This product has been tested by GI.BI.DI. for full compliance with the requirements of the directives in force.

GI.BI.DI. S.r.l. reserves the right to change the technical data without prior notice in relation to product

development.

READ CAREFULLY THESE INSTRUCTIONS BEFORE PROCEEDING WITH INSTALLATION.

Thank you for choosing GI.BI.DI.

DISPOSAL: GI.BI.DI. advises recycling the plastic components and to dispose of them at special

authorised centres for electronic components thus protecting the environment from polluting

substances.

UK

24 TOP EVO 25

TOP EVO

UK

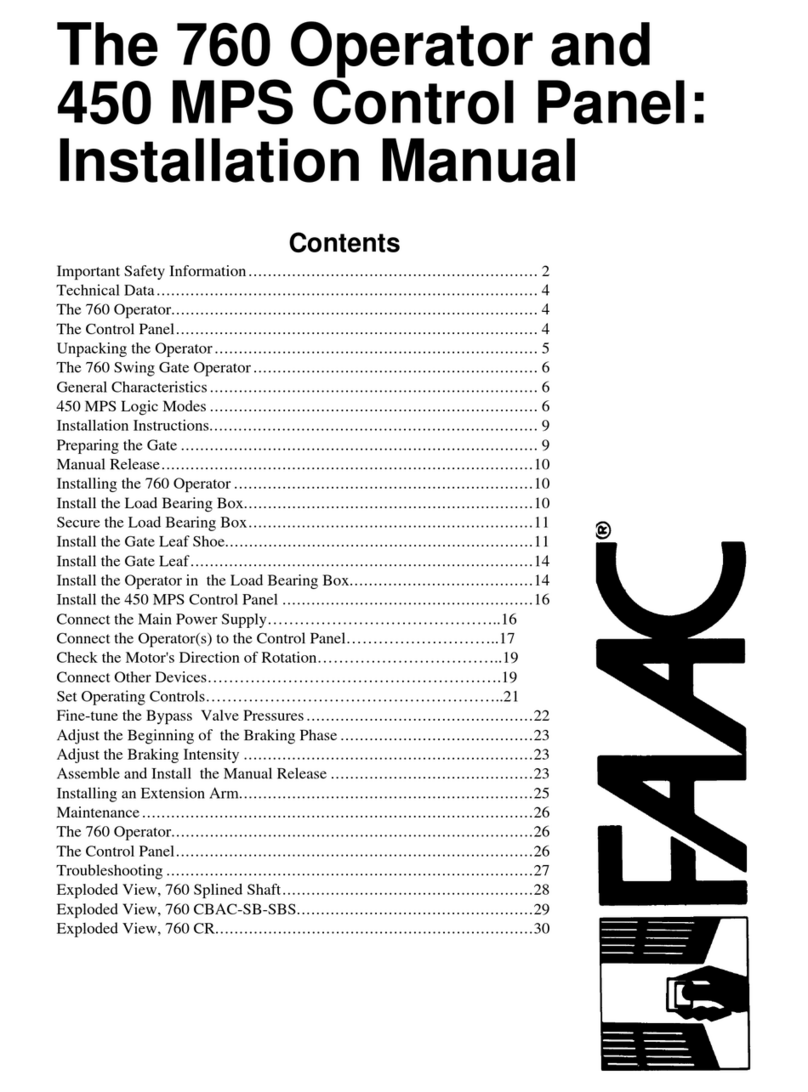

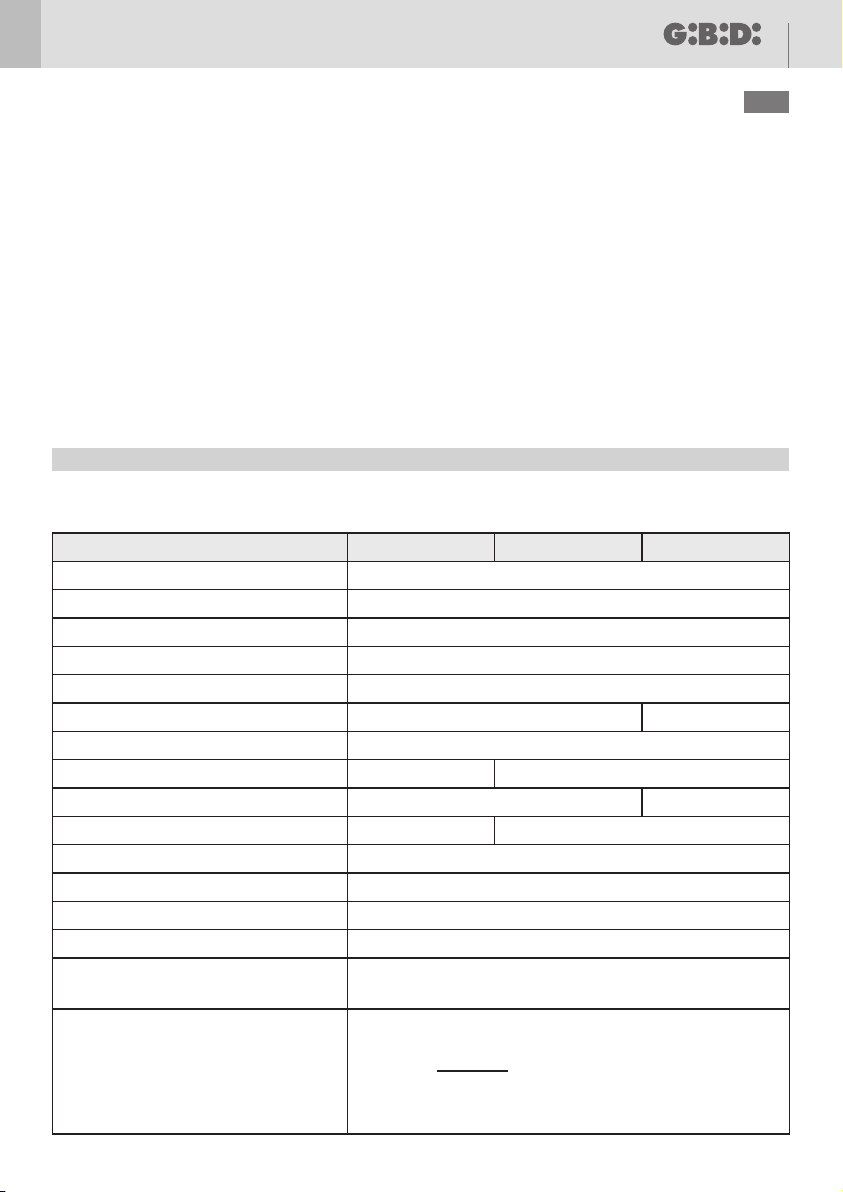

2 TECHNICAL DATA

TOP 291E - 291ER - 291ER/S

-

To lay the cables use appropiate cable ducts.

It is good practice to separate the power cables from the accessory connection cables and it is therefore

advisable la to use at least two tubes to run the cables through.

WARNING:

It is important to fit an omnipolar magnetothermal /difeerential switch with a min. contact opening of 3 mm on the

power line upstream of the control unit.

OPERATOR

Operating frequency (%Fu) at 20°C

Electric motor

Capacitor

Maximum thrust

Hydraulic slowdown

Rod maximum stroke

Operating temperature

Leaf maximum lenght

Hydraulic lock granted for leaf

maximum lenght

Power absorbed

Protection degree

Thrust adjustment

Rod speed

Hydraulic oil

Thermal protection

Formula to calculate the operation

frequency

TOP 291E TOP 291ER

[ ]

55% 2a

230 Vac 1450 rpm

max 170 W

10 μF

IP65

hydraulic

GBD PH-03

[ ]

3.5 m 2c

2.0 m

100°C

from -20°C to +60°C

2000 N

20 mm/s

yes

265 mm

3000 N

10 mm/s

no

290 mm

TOP 291ER/S

A = Opening time

C = Closing time

P = Overall pause time

A+C+P = Time between two

openings

%Fu = x 100

A + C

A + C + P

WARNINGS FOR THE USER

In the event of an operating fault or failure, cut the power upstream of the control unit and call Technical Service.

Periodically check the good functioning of the safety devices.

Any repair must be carried out by specialised personnel using original and certified materials.

The product must not be used by children and persons with reduces physical, sensorial or mental capacities, or

without experience and knowledge.

Do no access the control unit for adjustments and/or maintenances.

WARNING: IMPORTANT SAFETY INSTRUCTIONS

It is important to follow this instruction to safeguard persons.

Keep this instruction manual.

1 - ELECTRICAL CONNECTIONS

[ ]

Set up the electric system as shown in fig. 1 referring to the electric system regulations and other

national regulations in force. Keeps the mains power connection clearly separated from

service connections (photocells, sensitive edge, control units etc.).

The main components of the automated device are:

ÀFlashing light: 0.75 mm² 2-core (2x0,75) cable.

ÁAntenna: screened coaxial cable.

ÂKey selector: 0,5 mm² 3-core (3x0,5) cable.

ÃPhotocell receiver: 0,5 mm² 4-core (4x0,5) cable.

ÄPhotocell transmitter: 0,5 mm² 2-core (2x0,5) cable.

ÅOmnipolar magnetothermal differential switch with min. contact opening of 3 mm.

220-230Vac 50-60Hz power line to the device: 1,5 mm² min. 3-core (3x1,5) cable (adhere to the regulations

in force).

ÆCase for electronic control unit: 3x1,5 mm² cable.

Ç230Vac operator:

Power supply: 1,5 mm² 4-core cable:

Grey = motor common; Brown = opening; Black = closing; Yellow/green = earth

È8K2 sensitive edge: 0,5 mm² 2-core (2x0,5) cable.

Electronic lock: 1,5 mm² 2-core (2x1,5) cable.

Mechanical stops in opening and closing.

0

UK

24 TOP EVO 25

TOP EVO

UK

2 TECHNICAL DATA

TOP 291E - 291ER - 291ER/S

-

To lay the cables use appropiate cable ducts.

It is good practice to separate the power cables from the accessory connection cables and it is therefore

advisable la to use at least two tubes to run the cables through.

WARNING:

It is important to fit an omnipolar magnetothermal /difeerential switch with a min. contact opening of 3 mm on the

power line upstream of the control unit.

OPERATOR

Operating frequency (%Fu) at 20°C

Electric motor

Capacitor

Maximum thrust

Hydraulic slowdown

Rod maximum stroke

Operating temperature

Leaf maximum lenght

Hydraulic lock granted for leaf

maximum lenght

Power absorbed

Protection degree

Thrust adjustment

Rod speed

Hydraulic oil

Thermal protection

Formula to calculate the operation

frequency

TOP 291E TOP 291ER

[ ]

55% 2a

230 Vac 1450 rpm

max 170 W

10 μF

IP65

hydraulic

GBD PH-03

[ ]

3.5 m 2c

2.0 m

100°C

from -20°C to +60°C

2000 N

20 mm/s

yes

265 mm

3000 N

10 mm/s

no

290 mm

TOP 291ER/S

A = Opening time

C = Closing time

P = Overall pause time

A+C+P = Time between two

openings

%Fu = x 100

A + C

A + C + P

WARNINGS FOR THE USER

In the event of an operating fault or failure, cut the power upstream of the control unit and call Technical Service.

Periodically check the good functioning of the safety devices.

Any repair must be carried out by specialised personnel using original and certified materials.

The product must not be used by children and persons with reduces physical, sensorial or mental capacities, or

without experience and knowledge.

Do no access the control unit for adjustments and/or maintenances.

WARNING: IMPORTANT SAFETY INSTRUCTIONS

It is important to follow this instruction to safeguard persons.

Keep this instruction manual.

1 - ELECTRICAL CONNECTIONS

[ ]

Set up the electric system as shown in fig. 1 referring to the electric system regulations and other

national regulations in force. Keeps the mains power connection clearly separated from

service connections (photocells, sensitive edge, control units etc.).

The main components of the automated device are:

ÀFlashing light: 0.75 mm² 2-core (2x0,75) cable.

ÁAntenna: screened coaxial cable.

ÂKey selector: 0,5 mm² 3-core (3x0,5) cable.

ÃPhotocell receiver: 0,5 mm² 4-core (4x0,5) cable.

ÄPhotocell transmitter: 0,5 mm² 2-core (2x0,5) cable.

ÅOmnipolar magnetothermal differential switch with min. contact opening of 3 mm.

220-230Vac 50-60Hz power line to the device: 1,5 mm² min. 3-core (3x1,5) cable (adhere to the regulations

in force).

ÆCase for electronic control unit: 3x1,5 mm² cable.

Ç230Vac operator:

Power supply: 1,5 mm² 4-core cable:

Grey = motor common; Brown = opening; Black = closing; Yellow/green = earth

È8K2 sensitive edge: 0,5 mm² 2-core (2x0,5) cable.

Electronic lock: 1,5 mm² 2-core (2x1,5) cable.

Mechanical stops in opening and closing.

0

UK

26 TOP EVO 27

TOP EVO

UK

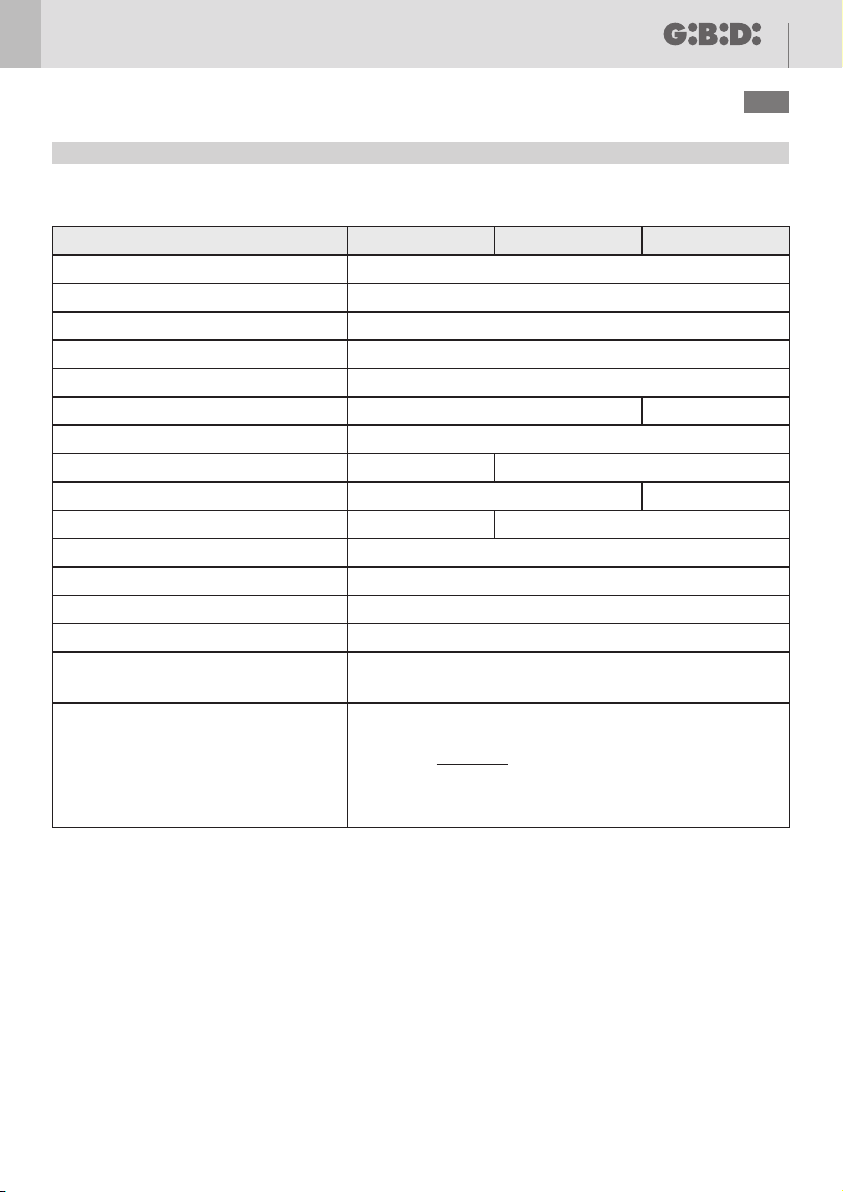

OPERATOR

Operating frequency (%Fu) at 20°C

Electric motor

Capacitor

Maximum thrust

Hydraulic slowdown

Rod maximum stroke

Operating temperature

Leaf maximum lenght

Hydraulic lock granted for leaf

maximum lenght

Power absorbed

Protection degree

Thrust adjustment

Rod speed

Hydraulic oil

Thermal protection

Formula to calculate the operation

frequency

TOP 391E TOP 391ER

[ ]

55% 2a

230 Vac 1450 rpm

max 190 W

10 μF

IP65

hydraulic

GBD PH-03

[ ]

4.5 m 2c

2.0 m

100°C

from -20°C to +60°C

3000 N

20 mm/s

yes

265 mm

4500 N

10 mm/s

no

290 mm

TOP 391ER/S

A = Opening time

C = Closing time

P = Overall pause time

A+C+P = Time between two

openings

%Fu = x 100

A + C

A + C + P

OPERATOR

Operating frequency (%Fu) at 20°C

Electric motor

Capacitor

Maximum thrust

Hydraulic slowdown

Rod maximum stroke

Operating temperature

Leaf maximum lenght

Hydraulic lock granted for leaf

maximum lenght

Power absorbed

Protection degree

Thrust adjustment

Rod speed

Hydraulic oil

Thermal protection

Formula to calculate the operation

frequency

TOP 441E TOP 441ER

[ ]

55% 2a

230 Vac 1450 rpm

max 190 W

10 μF

IP65

hydraulic

GBD PH-03

[ ]

6 m 2c

2.0 m

100°C

from -20°C to +60°C

3000 N

20 mm/s

yes

425 mm

4500 N

10 mm/s

no

440 mm

TOP 441ER/S

A = Opening time

C = Closing time

P = Overall pause time

A+C+P = Time between two

openings

%Fu = x 100

A + C

A + C + P

2

TOP 441E - 441ER - 441ER/S

- TECHNICAL DATA

2

TOP 391E - 391ER - 391ER/S

- TECHNICAL DATA

UK

26 TOP EVO 27

TOP EVO

UK

OPERATOR

Operating frequency (%Fu) at 20°C

Electric motor

Capacitor

Maximum thrust

Hydraulic slowdown

Rod maximum stroke

Operating temperature

Leaf maximum lenght

Hydraulic lock granted for leaf

maximum lenght

Power absorbed

Protection degree

Thrust adjustment

Rod speed

Hydraulic oil

Thermal protection

Formula to calculate the operation

frequency

TOP 391E TOP 391ER

[ ]

55% 2a

230 Vac 1450 rpm

max 190 W

10 μF

IP65

hydraulic

GBD PH-03

[ ]

4.5 m 2c

2.0 m

100°C

from -20°C to +60°C

3000 N

20 mm/s

yes

265 mm

4500 N

10 mm/s

no

290 mm

TOP 391ER/S

A = Opening time

C = Closing time

P = Overall pause time

A+C+P = Time between two

openings

%Fu = x 100

A + C

A + C + P

OPERATOR

Operating frequency (%Fu) at 20°C

Electric motor

Capacitor

Maximum thrust

Hydraulic slowdown

Rod maximum stroke

Operating temperature

Leaf maximum lenght

Hydraulic lock granted for leaf

maximum lenght

Power absorbed

Protection degree

Thrust adjustment

Rod speed

Hydraulic oil

Thermal protection

Formula to calculate the operation

frequency

TOP 441E TOP 441ER

[ ]

55% 2a

230 Vac 1450 rpm

max 190 W

10 μF

IP65

hydraulic

GBD PH-03

[ ]

6 m 2c

2.0 m

100°C

from -20°C to +60°C

3000 N

20 mm/s

yes

425 mm

4500 N

10 mm/s

no

440 mm

TOP 441ER/S

A = Opening time

C = Closing time

P = Overall pause time

A+C+P = Time between two

openings

%Fu = x 100

A + C

A + C + P

2

TOP 441E - 441ER - 441ER/S

- TECHNICAL DATA

2

TOP 391E - 391ER - 391ER/S

- TECHNICAL DATA

UK

28 TOP EVO 29

TOP EVO

UK

5 - DIMENSIONS

[3]

Refer to figure .

6 PRELIMINARY WARNINGS -

• Check that the gate structure is adapted for installing the operator.

• Check that the fixed and mobile parts of the gate are structurally intact and appropriate or whether require

reinforcement work.

• Check that the parts subject to friction, especially the top hinge, does not require any setup.

• In the working area of the operator there must no obstacles of any kind.

• Check the existence of an efficient earth.

• The installation should be done far away from any road, so as not to pose a threat to circulation.

• It is useful to signal the automatic entrance with easily visible warning plates (inside and outside) and, if

necessary, that warn pedestrians they are not allowed to pass through.

• If the installation presents some unsafety details, stop the work and contact your dealer.

• Check that the gate structure is strong enough. In any case the operator must push the leaf at a reinforced

point.

• Check that the leaves can be moved manually without effort throughout the stroke.

• Check that the mechanical stops, both in opening and closing, are correctly installed.

• If the automatic system is not a completely new installation, check the wear of all components and repare or

replace the defective or worn parts.

• The reliability and safety of the automatic device are directly affected by the condition of gate structure.

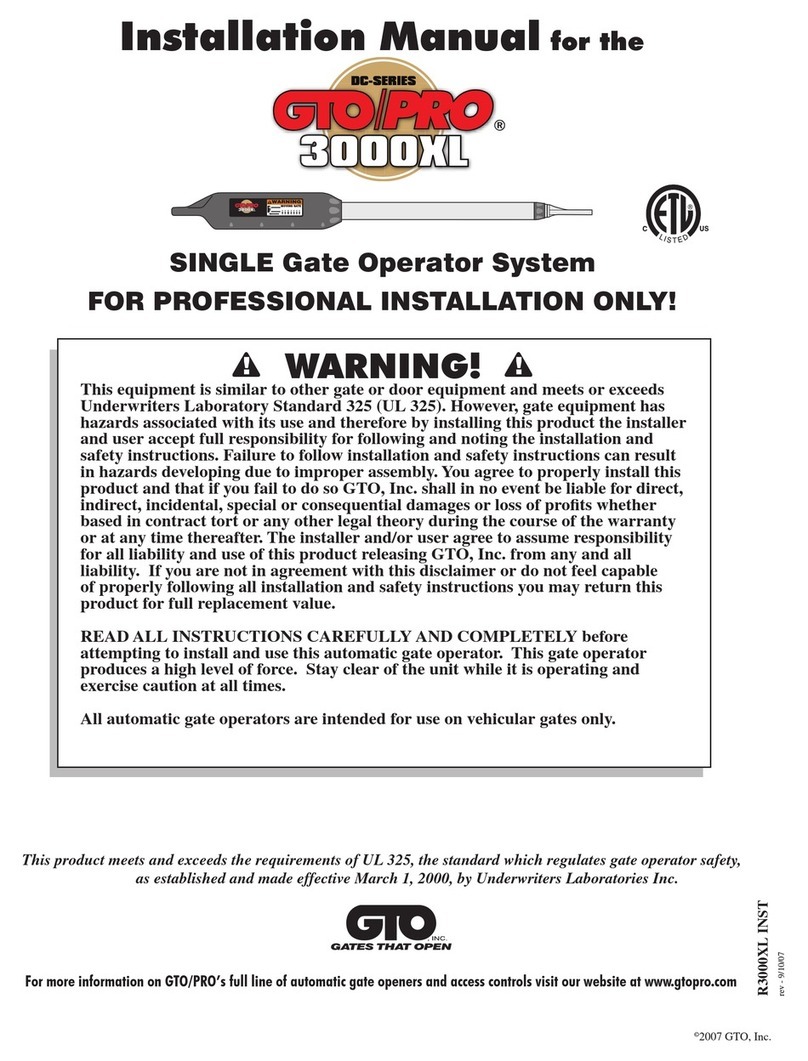

3 - MAXIMUM OPERATING CURVE

4 - APPLICATION DIAGRAM

[ ] [ ]

The operating time based on the desired operating frequency can be derived from the graphs 2a and 2b .

[ ]

The maximum leaf lenght related to the weight can be derived from the graph 2c .

7 END STOPS OF THE LEAVES ON THE GROUND -

For the correct operation of the actuator, use the end stops both in opening and closing.

The end stops of the leaves must prevent the actuator rod from arriving to the limit switch and must be

positioned so as to keep a stroke room of the rod of about 5-10 cm, in order to avoid any possible operation

anomaly.

Moreover it is recommended to use some amortised / rubber limit switch stops, in order to attenuate shock.

8 MOUNTING DIMENSIONS -

If it is not possible to maintain the dimensions in table [4], consider the following to calculate the measurements:

• For b = 90° ® A + B = Cu

• For b > 90° ® A + B < Cu (b max 110°)

• Quota A must always be bigger than quota D.

•The difference between A and B must not exceed 50 mm. Larger differences cause an uncostant

movement of the leaf (the tractive/thrust force and the movement speed vary during the manoeuvre).

• If the leaf is very thick, with consequent difficulty in respecting the dimension F, it is possible to increase the

dimension D and dimensions A and B must also be increased by the same amount, maintaining anyway

the rules indicated above.

9 HYDRAULIC SLOWDOWNS -

TOP291ER(/S), TOP391ER(/S), TOP441ER(/S) operators are equipped with hydraulic slowdowns.

The hydraulic slowdown occurs during the last 45mm of rod stroke, both in opening and closing.

WARNING:

ŸThe intensity of the slowdown is predetermined at the factory and cannot be modified, but some little

[ ].

adjustments are still possible, properly acting on the thrust adjustment valves À and Á 13

ŸIt is of fundamental importance to comply with the installation quotas and take into consideration what said

above to make use of the hydraulic slowdowns.

ŸThe effectiveness of the hydraulic slowdown is affected by the ambient temperature, at low temperature

UK

28 TOP EVO 29

TOP EVO

UK

5 - DIMENSIONS

[3]

Refer to figure .

6 PRELIMINARY WARNINGS -

• Check that the gate structure is adapted for installing the operator.

• Check that the fixed and mobile parts of the gate are structurally intact and appropriate or whether require

reinforcement work.

• Check that the parts subject to friction, especially the top hinge, does not require any setup.

• In the working area of the operator there must no obstacles of any kind.

• Check the existence of an efficient earth.

• The installation should be done far away from any road, so as not to pose a threat to circulation.

• It is useful to signal the automatic entrance with easily visible warning plates (inside and outside) and, if

necessary, that warn pedestrians they are not allowed to pass through.

• If the installation presents some unsafety details, stop the work and contact your dealer.

• Check that the gate structure is strong enough. In any case the operator must push the leaf at a reinforced

point.

• Check that the leaves can be moved manually without effort throughout the stroke.

• Check that the mechanical stops, both in opening and closing, are correctly installed.

• If the automatic system is not a completely new installation, check the wear of all components and repare or

replace the defective or worn parts.

• The reliability and safety of the automatic device are directly affected by the condition of gate structure.

3 - MAXIMUM OPERATING CURVE

4 - APPLICATION DIAGRAM

[ ] [ ]

The operating time based on the desired operating frequency can be derived from the graphs 2a and 2b .

[ ]

The maximum leaf lenght related to the weight can be derived from the graph 2c .

7 END STOPS OF THE LEAVES ON THE GROUND -

For the correct operation of the actuator, use the end stops both in opening and closing.

The end stops of the leaves must prevent the actuator rod from arriving to the limit switch and must be

positioned so as to keep a stroke room of the rod of about 5-10 cm, in order to avoid any possible operation

anomaly.

Moreover it is recommended to use some amortised / rubber limit switch stops, in order to attenuate shock.

8 MOUNTING DIMENSIONS -

If it is not possible to maintain the dimensions in table [4], consider the following to calculate the measurements:

• For b = 90° ® A + B = Cu

• For b > 90° ® A + B < Cu (b max 110°)

• Quota A must always be bigger than quota D.

•The difference between A and B must not exceed 50 mm. Larger differences cause an uncostant

movement of the leaf (the tractive/thrust force and the movement speed vary during the manoeuvre).

• If the leaf is very thick, with consequent difficulty in respecting the dimension F, it is possible to increase the

dimension D and dimensions A and B must also be increased by the same amount, maintaining anyway

the rules indicated above.

9 HYDRAULIC SLOWDOWNS -

TOP291ER(/S), TOP391ER(/S), TOP441ER(/S) operators are equipped with hydraulic slowdowns.

The hydraulic slowdown occurs during the last 45mm of rod stroke, both in opening and closing.

WARNING:

ŸThe intensity of the slowdown is predetermined at the factory and cannot be modified, but some little

[ ].

adjustments are still possible, properly acting on the thrust adjustment valves À and Á 13

ŸIt is of fundamental importance to comply with the installation quotas and take into consideration what said

above to make use of the hydraulic slowdowns.

ŸThe effectiveness of the hydraulic slowdown is affected by the ambient temperature, at low temperature

UK

30 TOP EVO 31

TOP EVO

UK

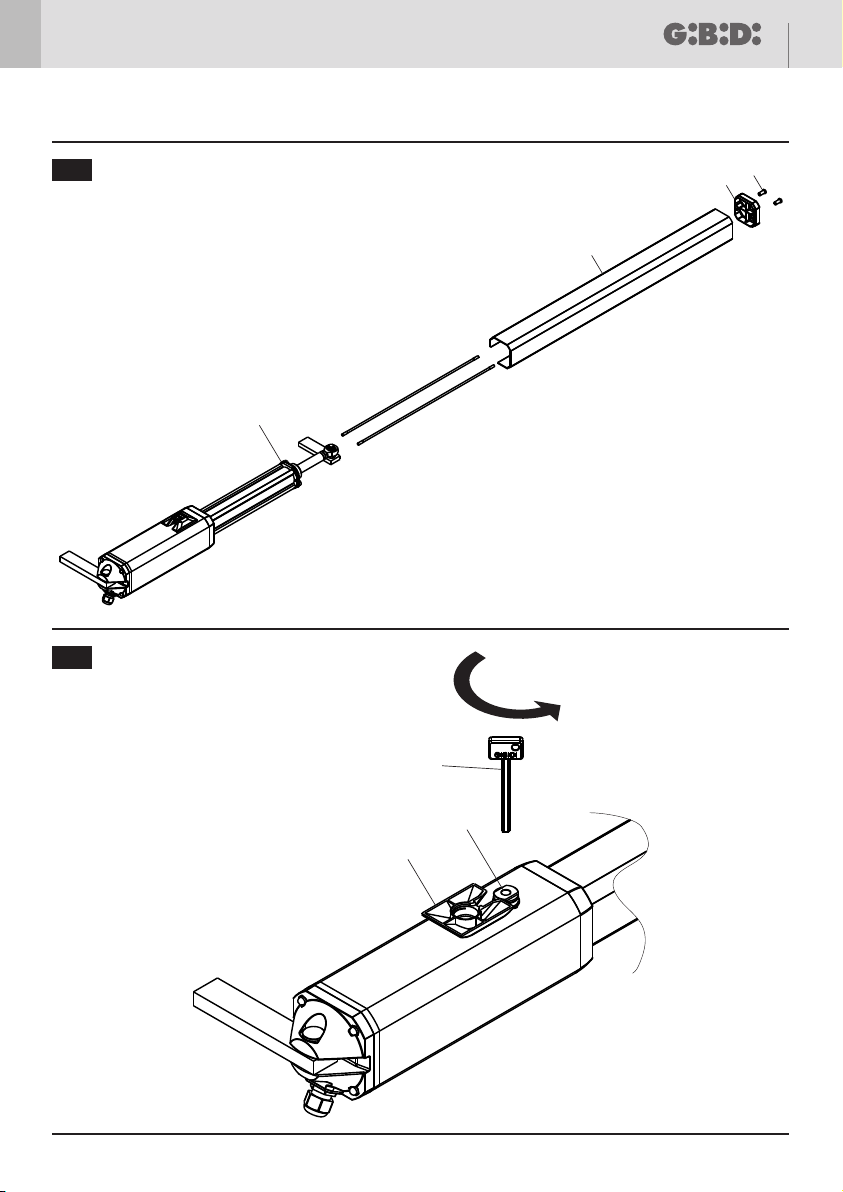

10 OPERATOR INSTALLATION -

1 - Check the fixing point most suitable for the front bracket of the operator [5] and mark it.

2 - Indicate the point on the pillar with a spirit level to fix the rear bracket [5].

3 - Find the fixing point of the rear bracket in function of quotas A-B [4].

WARNING: if the pillars or walls are big, you must make a niche [7], so that quotas A, B, E are met.

4 - Fix the rear bracket:

• Weld (if it is an iron pillar), previously checking the column thickness. If it is less than 5mm, provide a

reinforcing plate of such size that it allows making the welds on the edge of the column.

• If it is a concrete pillar, you must make a plate 5 mm of thickness with no. 4 holes. Weld the bracket in the

middle of the plate and fix it with some screws.

5 - Power the operator [9], bring the rod completely forward, then make it go back for 5-10 mm.

6 - Fix the front bracket on the operator [8].

7 - ring the leaf in closing position against the mechanical stops and fix it with a clamp.

8 - Mount the operator on the rear bracket with the pin provided [8].

9 - Put the front bracket in the point previously marked at point 1, check the levelling of the operator with a spirit level

and mark the exact fixing point of the front bracket [5-6].

10 - Remove the operator from the rear bracket.

11 - Remove the front bracket of the operator.

12 - Fix the front bracket in the point marked.

Fixing the front bracket:

• Weld (if it is an iron gate), previously checking the tubular thickness, where we are going to weld

the bracket. If it is less than 5mm, provide a reinforcing plate of such size that it allows making the welds

on the edge of the tubolar.

• If the gate is made with a material different from iron, you must make a plate 5 mm of thickness with no. 4 holes.

Weld the bracket in the middle of the plate and fix it with some through screws.

13 - Assemble the operator on the brackets [8].

14 - Screw the tension rods [10]

15 - Lightly lubricate the seal [10], insert the carter [10] [10].

16 - Fix all with the two screws provided à [10].

WARNING:

• Make the welding operations with the operator not assembled on the brackets.

• In case of heavy and/or buffered gates, it is necessary to strenghten both brackets with reinforcing hard metal

plates (not provided ).

• Before definitively fixing the brackets, make some manual tests of gate opening and closing, to check the

installation quotas.

À for 4-5 mm on the operator head.

Ä Á and the head Â

12 THRUST ADJUSTMENT -

13 CONVERSION FROM IRREVERSIBLE TO REVERSIBLE OPERATOR -

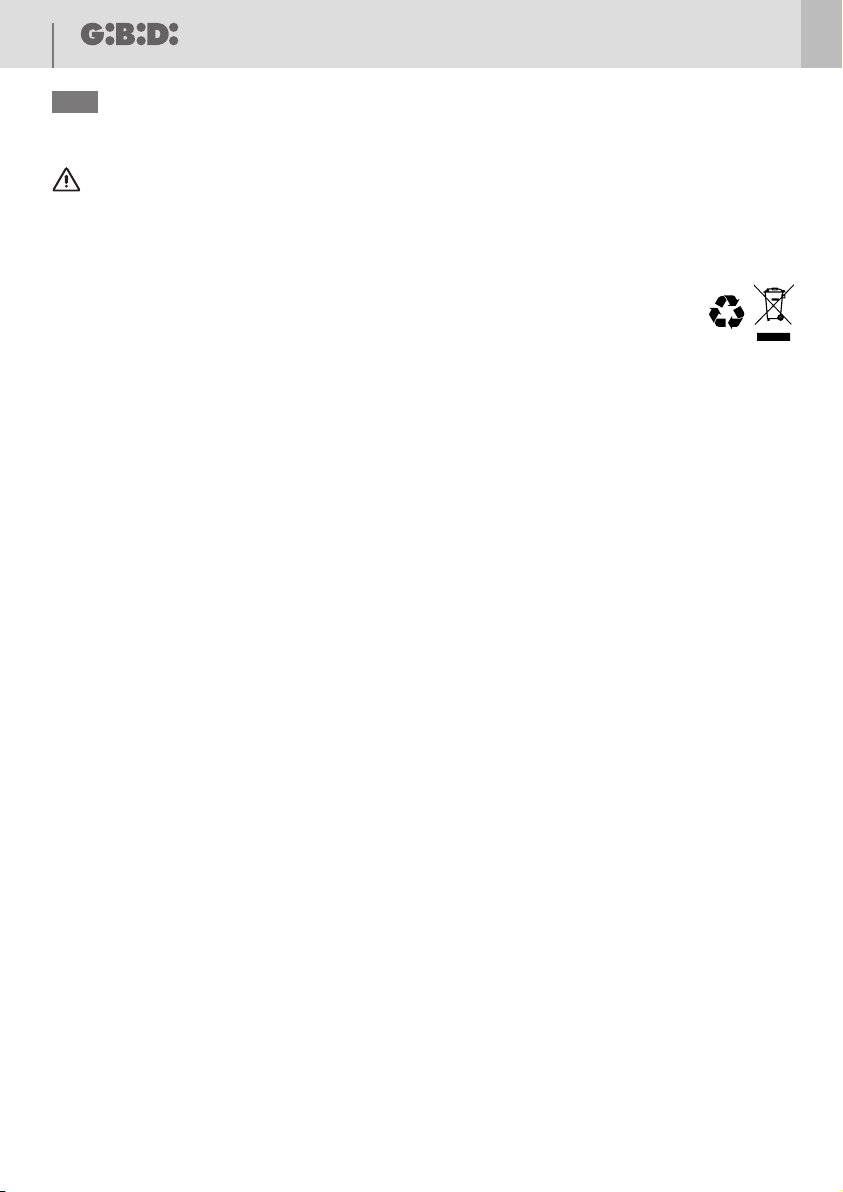

11 MANUAL MANOEUVRE (UNLOCKING DEVICE) -

Unlocking device with hexagonal key [11]:

Turn the cover À and lift it, turn the unlocking key Á anti-clockwise by 2 turns and carry out the manual

manoeuvre.

To reset turn the key Á clockwise until it stops without forcing it, replace the cover into its original position.

Unlocking device with personalised key [12]:

Push the cover  in the arrow direction, insert the key À in the cylinder Á, turn the key clockwise, turn the

unlocking key à anti-clockwise by 2 turns and carry out the manual manoeuvre.

To reset turn the key à clockwise until it stops without forcing it, turn the key À anti-clockwise, replace the cover

into its original position.

WARNING: carry out the operations for the manual manoeuvre with the motor off.

[ ]

In order to increase the thrust, turn the valves À and Á clockwise with a screwdriver 13 ; in order to decrease

the thrust, turn the valves anti-clockwise.

In detail :

[ ]

• The valve À 13 adjusts the OPENING thrust.

[ ]

• The valve Á 13 adjusts the CLOSING thrust.

WARNING:

When you adjust the thrust, turn the valves smoothly and gradually without unscrewing or

completely screwing them, keeping in mind that the operators are provided with the thrust already adjusted in

its best way during testing mode.

The operator is equipped with pressure control labels both for right and left version, already attached to the

motor.

TOP EVO operator is manufactured and sold as IRREVERSIBLE, if you need you can transform it into

reversible in opening or closing or both in opening and closing.

[ ]

The reversibility of the operator is controlled by the cursors  and à 13 , turning them clockwise until they are

blocked the operator is irreversible, turning them anti-clockwise the operator becomes reversible.

In detail with the operator installed on LEFT leaf:

[ ]

• The valve à 13 controls the reversibility in OPENING.

[ ]

• The valve  13 controls the reversibility in CLOSING.

UK

30 TOP EVO 31

TOP EVO

UK

10 OPERATOR INSTALLATION -

1 - Check the fixing point most suitable for the front bracket of the operator [5] and mark it.

2 - Indicate the point on the pillar with a spirit level to fix the rear bracket [5].

3 - Find the fixing point of the rear bracket in function of quotas A-B [4].

WARNING: if the pillars or walls are big, you must make a niche [7], so that quotas A, B, E are met.

4 - Fix the rear bracket:

• Weld (if it is an iron pillar), previously checking the column thickness. If it is less than 5mm, provide a

reinforcing plate of such size that it allows making the welds on the edge of the column.

• If it is a concrete pillar, you must make a plate 5 mm of thickness with no. 4 holes. Weld the bracket in the

middle of the plate and fix it with some screws.

5 - Power the operator [9], bring the rod completely forward, then make it go back for 5-10 mm.

6 - Fix the front bracket on the operator [8].

7 - ring the leaf in closing position against the mechanical stops and fix it with a clamp.

8 - Mount the operator on the rear bracket with the pin provided [8].

9 - Put the front bracket in the point previously marked at point 1, check the levelling of the operator with a spirit level

and mark the exact fixing point of the front bracket [5-6].

10 - Remove the operator from the rear bracket.

11 - Remove the front bracket of the operator.

12 - Fix the front bracket in the point marked.

Fixing the front bracket:

• Weld (if it is an iron gate), previously checking the tubular thickness, where we are going to weld

the bracket. If it is less than 5mm, provide a reinforcing plate of such size that it allows making the welds

on the edge of the tubolar.

• If the gate is made with a material different from iron, you must make a plate 5 mm of thickness with no. 4 holes.

Weld the bracket in the middle of the plate and fix it with some through screws.

13 - Assemble the operator on the brackets [8].

14 - Screw the tension rods [10]

15 - Lightly lubricate the seal [10], insert the carter [10] [10].

16 - Fix all with the two screws provided à [10].

WARNING:

• Make the welding operations with the operator not assembled on the brackets.

• In case of heavy and/or buffered gates, it is necessary to strenghten both brackets with reinforcing hard metal

plates (not provided ).

• Before definitively fixing the brackets, make some manual tests of gate opening and closing, to check the

installation quotas.

À for 4-5 mm on the operator head.

Ä Á and the head Â

12 THRUST ADJUSTMENT -

13 CONVERSION FROM IRREVERSIBLE TO REVERSIBLE OPERATOR -

11 MANUAL MANOEUVRE (UNLOCKING DEVICE) -

Unlocking device with hexagonal key [11]:

Turn the cover À and lift it, turn the unlocking key Á anti-clockwise by 2 turns and carry out the manual

manoeuvre.

To reset turn the key Á clockwise until it stops without forcing it, replace the cover into its original position.

Unlocking device with personalised key [12]:

Push the cover  in the arrow direction, insert the key À in the cylinder Á, turn the key clockwise, turn the

unlocking key à anti-clockwise by 2 turns and carry out the manual manoeuvre.

To reset turn the key à clockwise until it stops without forcing it, turn the key À anti-clockwise, replace the cover

into its original position.

WARNING: carry out the operations for the manual manoeuvre with the motor off.

[ ]

In order to increase the thrust, turn the valves À and Á clockwise with a screwdriver 13 ; in order to decrease

the thrust, turn the valves anti-clockwise.

In detail :

[ ]

• The valve À 13 adjusts the OPENING thrust.

[ ]

• The valve Á 13 adjusts the CLOSING thrust.

WARNING:

When you adjust the thrust, turn the valves smoothly and gradually without unscrewing or

completely screwing them, keeping in mind that the operators are provided with the thrust already adjusted in

its best way during testing mode.

The operator is equipped with pressure control labels both for right and left version, already attached to the

motor.

TOP EVO operator is manufactured and sold as IRREVERSIBLE, if you need you can transform it into

reversible in opening or closing or both in opening and closing.

[ ]

The reversibility of the operator is controlled by the cursors  and à 13 , turning them clockwise until they are

blocked the operator is irreversible, turning them anti-clockwise the operator becomes reversible.

In detail with the operator installed on LEFT leaf:

[ ]

• The valve à 13 controls the reversibility in OPENING.

[ ]

• The valve  13 controls the reversibility in CLOSING.

UK

32 TOP EVO 33

TOP EVO

UK

14 ELECTROLOCK MOUNTING -

15 FINAL CHECKS -

16 MAINTENANCE -

[14a] [14b]

Refers to pictures and . The electrolock must be installed on leaves longer than 2.5 m.

ÀElectrolock.

ÁElectrolock fixing plate.

ÂBolt hooker.

ÃBolt hooking rabbet.

ÄBolt.

ÅKey cylinder (on request).

ÆGate.

Power the automatic system:

• If installed, check the correct reading of the limit switches (optional), manually moving the leaf.

Run one or more opening and closing complete cycles checking:

• The correct operation of safety devices;

• The regular movement of the leaves;

• The solidity of the foundation plate;

• That the automatic gate complies with the essential safety requirements required by the Machinery Directive

(2006/42/CE)

Carry out periodic checks on the gate with particular attention to:

• Check the hinges;

• Check the correct operation of safety devices;

• Unlock the operator and verify there is no friction points during the whole stroke;

• Check the self-lubricating bushing.

Periodically check the correct functioning of anti-crushing safety and the efficiency of the unlocking system which

allows the manual operation (see the relevant paragraph).

The safety devices installed must be checked at least each six months.

Gi.Bi.Di. S.r.l. reserves the right to modify the technical data without prior notice, depending on product

development.

In the event of any malfunction, cut the power of the system and call in a qualified technician (installer).

During out of service, activate the manual release to allow manual opening and closing.

17 MALFUNCTIONING -

EU Declaration of conformity

The manufacturer: S.r.l.

Via Abetone Brennero, 177/B,

46025 Poggio Rusco (MN) ITALY

declares that the products:

are in conformity with the following Directives:

•2014/30/UE;

•2014/35/UE;

and that the following harmonised standards have been applied:

•EN 61000-6-2:2005; EN 61000-6-3:2007 + A1:2011

•EN 60335-1:2002 + A1:2004+ A11:2004 + A12:2006 + A2:2006 + A13:2008 + A14:2010

+ A15:2011; EN 60335-2-103:2003 + A11:2009;

The parts of the product which are subject to the following standards complyWwith them:

•EN 13241-1:2003 + A1:2011; EN 12445:2002; EN 12453:2002; EN 12978:2003

+A1:2009.

Moreover declares that the product must not be used until the machine in which it has been

incorporated has not been declared in accordance with 2006/42/CE Directive.

Date 13/12/2021

GI.BI.DI.

HYDRAULIC OPERATORS TOP 291E(R)(/S)-391E(R)(/S)-441E(R)(/S)

The legal Representative

Michele Prandi

The UKCA declaration of conformity is avaible

at http://conformity.gibidi.com

This manual suits for next models

8

Table of contents

Other GBD Gate Opener manuals