GBD KUDA 150 Guide

I UK

Operatore elettromeccanico lineare

ISTRUZIONI PER L’INSTALLAZIONE

Electromechanical linear operator

INSTRUCTIONS FOR INSTALLATIONS

KUDA

KUDA 150 - (15000/DX-15000/SX)

KUDA 200 - (22000/DX-22000/SX)

KUDA

10

UK

In the event of an operating fault or failure, cut the power upstream of the control unit and call Technical Service.

Periodically check functioning of the safety devices. Any repairs must be carried out by specialised personnel

using original and certified materials.

The product may not be used by children or persons with reduced physical, sensorial or mental capacities, or

lacking experience and knowledge, unless appropriately instructed.

Do not access the circuit board for adjustments and/or maintenance.

WARNINGS FOR THE USER

CAUTION: IMPORTANT SAFETY INSTRUCTIONS.

It is important to follow these instructions in order to safeguard persons.

Keep this instruction booklet

9

UK

The KUDA operator for swing gates is an electromechanical device that transmits motion to the gate by means of a

worm screw. It is locked when the motor is not running, it is necessary to install locks

.

if fitted on blind/flush panel

doors

INTRODUCTION

WARNINGS FOR THE INSTALLER

Before proceeding with installation, fit a magnetothermal and differential switch with a maximum capacity of 10A

upstream of the system. The switch must guarantee omnipolar separation of the contacts with an opening

distance of at least 3mm.

All the packaging materials must be kept out of reach of children since they are potential sources of danger.

The manufacturer declines all responsibility for proper functioning of the automated device if failing to use original

GIBIDI components and accessories suitable for the intended application.

When installation has been completed, always carefully check proper functioning of the system and the devices

used.

This instruction manual addresses persons qualified for installation of “live equipment”, therefore, good technical

knowledge is required exercised as profession in compliance with the regulations in force.

Maintenance must be performed by qualified personnel.

Before carrying out any cleaning or maintenance operation, disconnect the control unit from the mains.

This product has been designed and constructed solely for the use indicated in this document. Any other use may

cause damage to the product and be a source of danger.

Verify the intended end use and take the necessary safety precautions.

Use of the products for purposes different from the intended use has not been tested by the manufacturer and the

operations performed are therefore on full responsibility of the installer.

Mark the automated device with visible warning plates.

Warn the user that children and animals must not play or stand near the gate.

Adequately protect the danger points, for example, using a sensitive frame.

Check proper installation of the earthing system; connect all the metal parts of doors, gates, etc. and all the

system components equipped with earthing plate.

Exclusively use original spare parts for any maintenance or repair.

Do not make any modification to the components of the automated device unless expressly authorised by GIBIDI.

Gi.Bi.Di. Srl reserves the right to change the technical data without prior notice in relation to product development.

WARNING: IMPORTANT SAFETY INSTRUCTIONS.

It is important for the safety of persons to follow these instructions.

Keep this instruction manual.

KUDA 11

UK

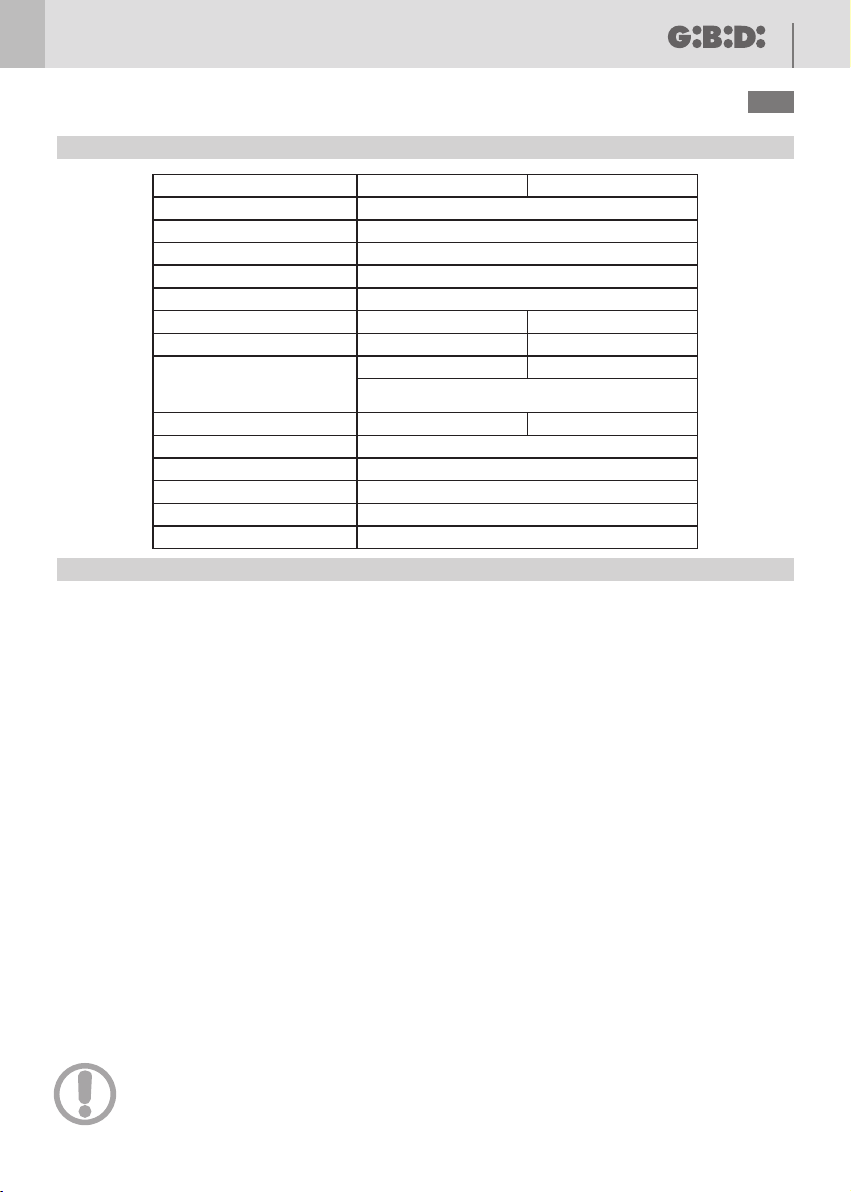

Encoder

KUDA 150

24 Vdc

100 W (~1000 N)

4 A (~1000 N) MAX

360 mm

24 Vdc 2600 rpm

1000 N

-20°C + 60°C

IP 44

If fitted on blind/flush panel doors

it is mandatory to use an electric lock

Integrated into the motor

intensive

20 mm/s

KUDA 200

1500 N

2 m 2.5 m

400 mm

150 Kg 200 Kg

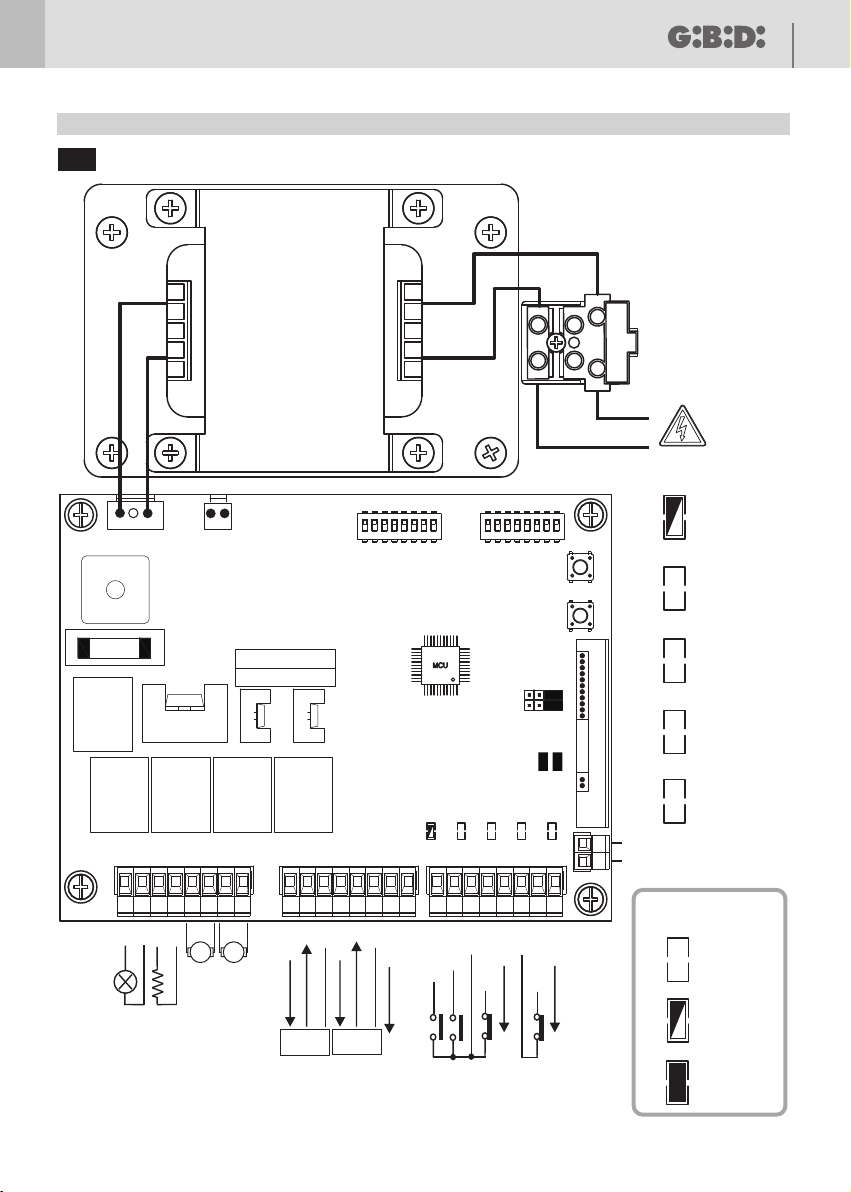

Electric system setup

Set up the electric system as shown in fig.1 referring to the electric system regulations and other national regulations

in force. Keep the mains power connections clearly separated from the service connections (photocells, sensitive

frames, control devices, etc.).

The main components are:

1- Antenna; screened coaxial cable

2- Electronic control unit container

3- Electric lock; 1 mm² 2-core (2x1) cable

4- Key selector; 0,5 mm² 3-core (3x0,5) cable

5- 24Vdc operators:

- 1,5 mm² 2-core (2x1,5) cable power supply WHITE = + YELLOW = -

for a cable length of 6 m max., over it’s necessary increase the cable section.

-0,5mm² 3-core (3x0,5) encoder cable.

6- Omnipolar magnetothermal and differential switch with minimum contact opening of 3 mm

220-230V/50-60Hz control unit power line: min. 1,5 mm² 3-core cable (3x1,5)

(adhere to the regulations in force)

7- 24V flashing light; 0,75 mm² 2-core (2x0,75) cable

8- Connector blocks

9- Photocell transmitter; 0,5 mm² 2-core (2x0,5) cable

10- Photocell receiver; 0,5 mm² 4-core (4x0,5) cable

A- Opening mechanical end-stop.

B- Closing mechanical end-stop.

ELECTRICAL EQUIPMENT

Supply voltage

Power absorbed

Current absorbed

Electric motor

Useful travel

Max thrust/traction force

Operating temperature

Frequency of use (%)

Degree of protection

Maximum leaf length

Linear velocity

Operator

Type Irreversible electromechanical with worm screw

TECHNICAL DATA

Maximum leaf weight

CAUTION: It is important that an omnipolar magnetothermal and differential switch with a

minimum contact opening of 3 mm be fitted upstream of the control unit.

KUDA

12

UK

Check that the gate structure is in conformity with the regulations in force and that the gate movement is linear

without friction.

Preliminary checks:

• Check that the gate structure is sufficiently robust.

• In any event, the actuator must push the leaf at a reinforced point.

• Manually check that the leafs move without force along their entire travel.

• Check that the gate opening and closing end-stops A-B fig.1 have been installed.

• If the gate is not a new installation, check the state of wear of all the components, and repair or replace the

defective or worn parts.

The reliability and safety of the automated device is directly dependent on the condition of the gate structure.

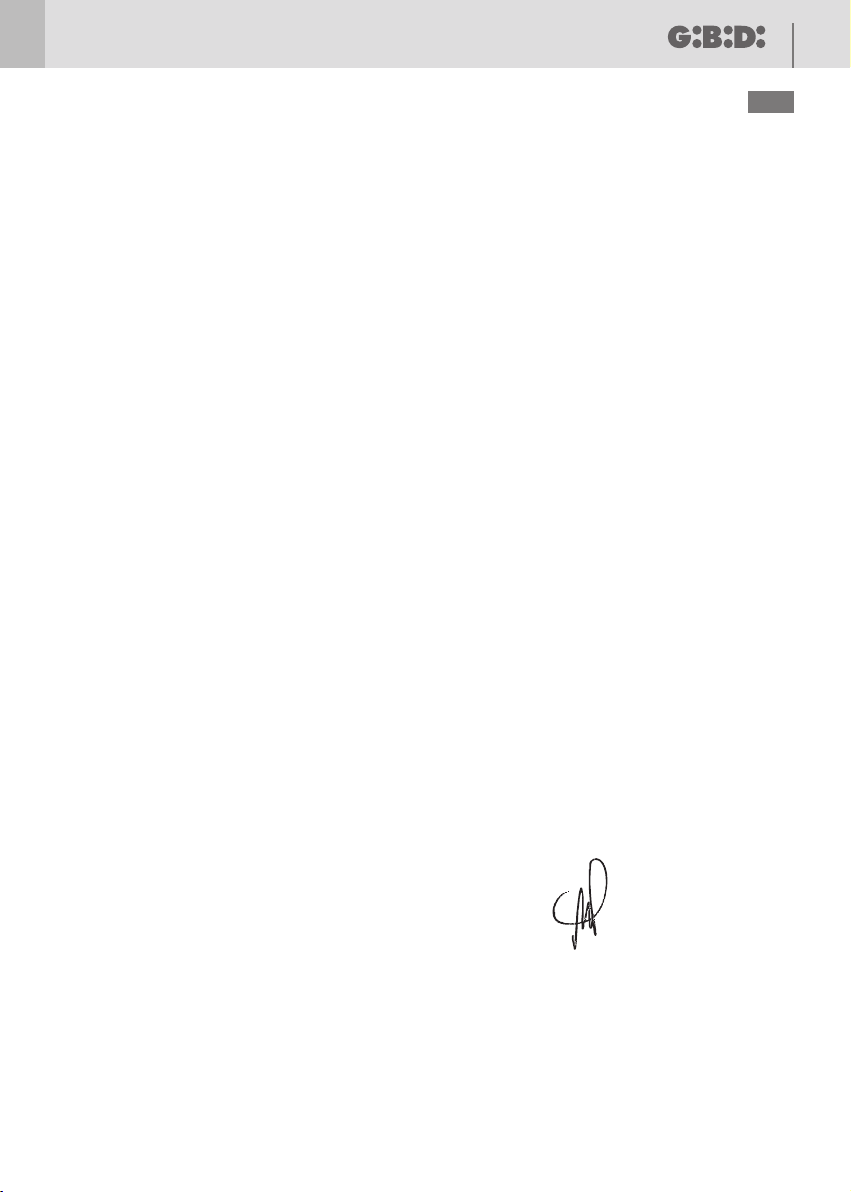

Refer to 6 for possible installation dimensions.

The difference between A and B must not exceed 50 mm; greater differences cause irregular gate movement

(the traction/thrust force and the movement speed vary during the manoeuvre).

fig.

PRELIMINARY WARNINGS

INSTALLATION DIMENSIONS

Preliminary checks:

For proper functioning of the automated device, the existing or new gate structure must meet the following

requirements:

The individual leafs must have a maximum length of 2 metres (KUDA 150) or 2,5 meters (KUDA 200)

The leaf structure must be robust and rigid

The leafs must move smoothly and uniformly without irregular friction along their entire travel

The existing hinges must be in a good condition

The mechanical end-stops A-B fig.1 must be fitted

fig. fig.

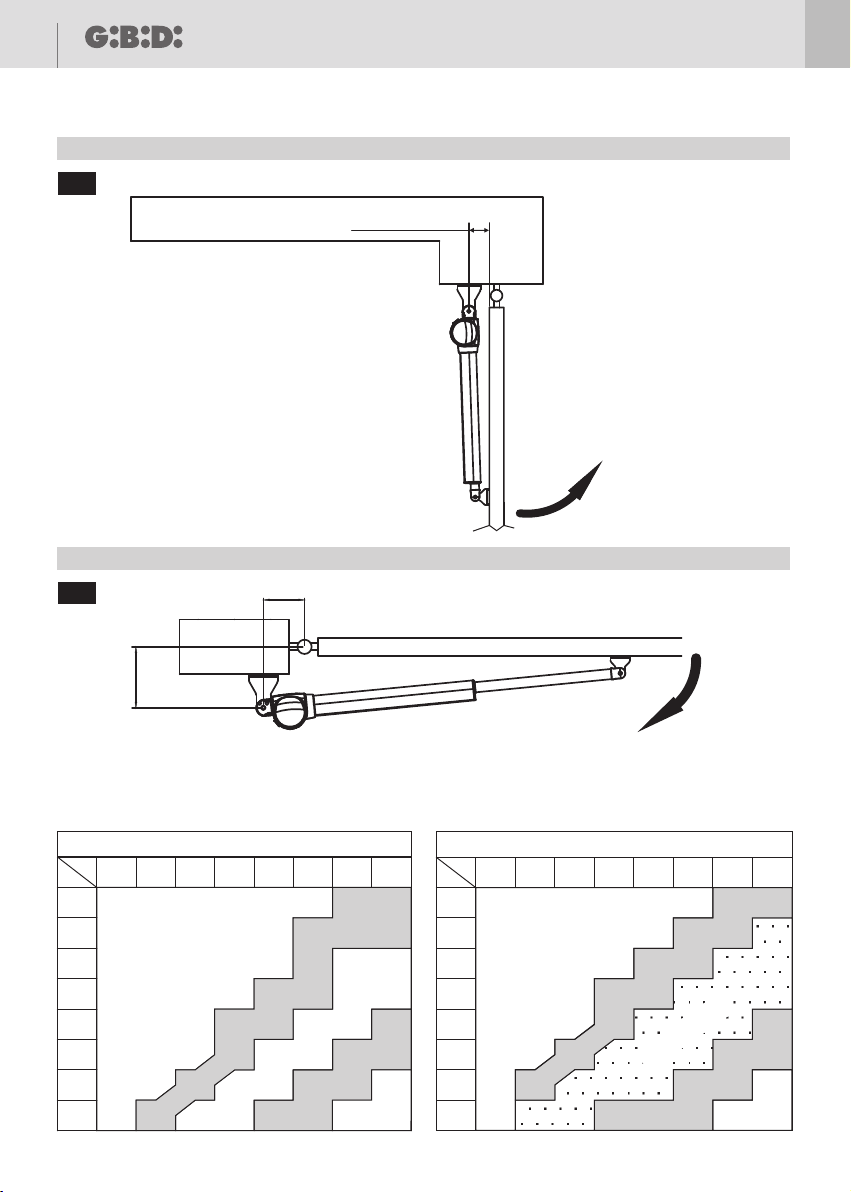

4 - Fasten the rear bracket to the pillar fig.7a .

5 - Fit the operator on the rear bracket using the pin provided fig.7b .

6 - Fasten the front bracket on the operator fig.8a .

7- Unlock the operator (see unlocking device), pull out the operator rod fully then push it inside for 20 mm.

8 - Move the leaf to closed position against the mechanical end-stop B fig.1.

Installing the operators

1 - Find the most suitable point where to fasten the front bracket of the operator and mark it.

2 - Using a spirit level mark the point on the pillar where to fasten the rear bracket .

3 - Identify the point where to fasten the rear bracket in relation to the dimensions A-B 6 and in relation to 3-4-5.

CAUTION: Where there are big pillars or walls, a niche must be made so that the dimensions A and B are

respected.

OPERATOR INSTALLATION

13

UK

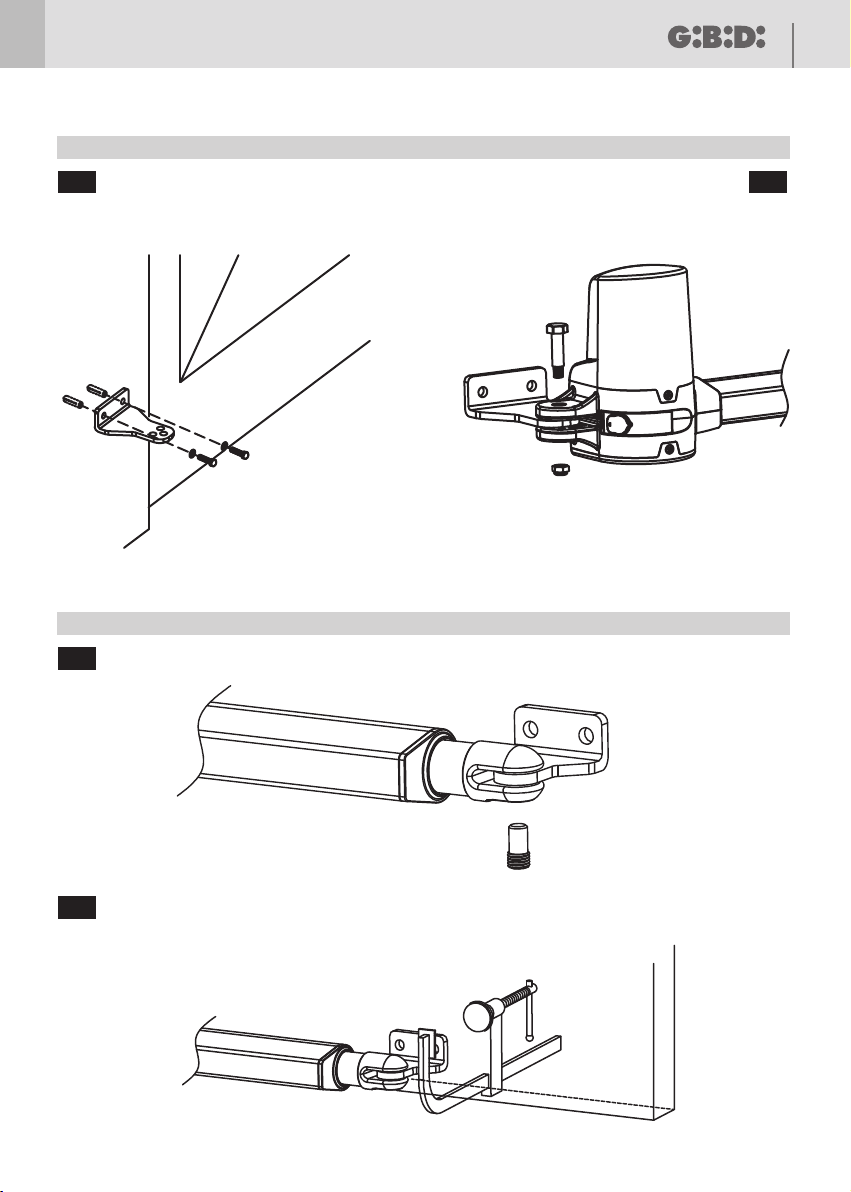

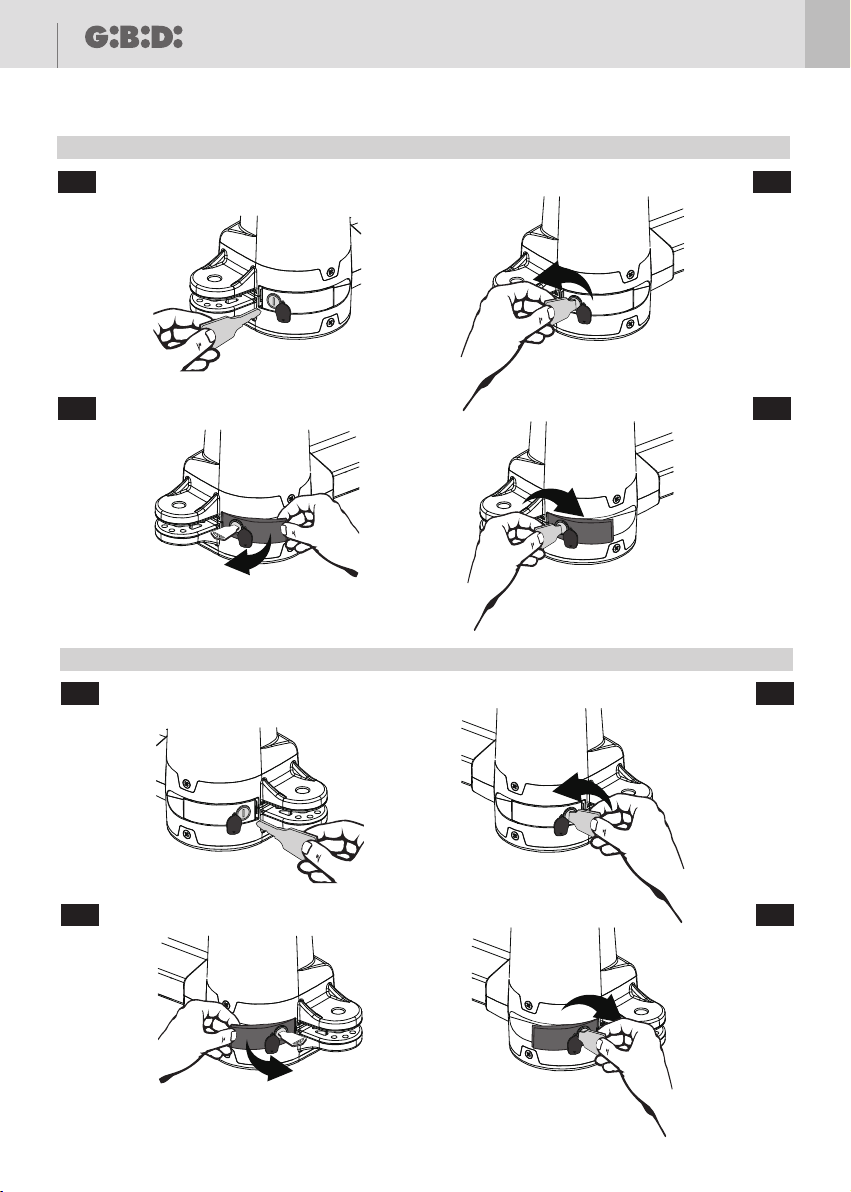

If the gate needs to be operated manually because of a power failure or operator malfunctioning:

Remove the rubber plug fig.9a-9e .

Insert the release key to the release slot fig. 9a-9e .

Turn the release key as shown in fig.9b-9f .

Pull out the release bar and keep it pulled out fig.9c-9g .

Turn the release key to its original position to fix the release bar fig.9d-9h .

Move the gate manually only in the event of a power failure.

UNLOCKING DEVICE

If you need to install an electric lock, refer to figures 11 and 12 .

1) ELECTRIC LOCK

2) ELECTRIC LOCK FASTENING PLATE

3) BUSHING

4) END-STOP FOR BUSHING

5) SPRING LATCH

6) THROUGH CYLINDER (ON REQUEST)

7) GATE

fig. fig.

INSTALLING THE ELECTRIC LOCK

Power the system and run a complete opening and closing cycle checking that:

• The safety devices function properly;

• The gate moves smoothly;

• Good hold of the fastening brackets;

• That the power cable moves freely;

• The gate assembly conforms to EN 12453 and EN 12445;

• For further details and information on the reference standards, visit our site: www.gibidi.com

FINAL CHECKS

9 - Fix the front bracket to the leaf with a clamp fig.8b .

10- Use a spirit level to check that the operator is perfectly level.

11 - Remove the operator from the front and rear bracket .

12 - Fasten the front bracket .

13- Unlock the operator (see unlocking device).

14 - Fit the operator on the brackets.

15 - Manually open and close the gate to its full opening and closing travel. The gate must move smoothly without

friction and the lead nut must not reach the mechanical end-stop during opening or closing. If otherwise, adjust

the bracket positions.

It is recommended to leave at least 40-50 mm of cable free.

OPERATOR INSTALLATION

KUDA

14

UK

Periodically check the gate structure, in particular:

- Check functioning of the hinges;

- Check that the leafs are correctly balanced. Excessive inclination of the leafs will result in faster wear of the

operator fastening brackets. Do the test by unlocking the operator and checking that the leafs do not move on their

own;

- Check good functioning of the safety devices;

- Unlock the operator and check that there are no points of friction along the entire travel;

- Check that there is no dirt or debris on the worm screw, and if so, clean and then lubricate the worm screw with

lubricating grease.

- Periodically check proper adjustment of the operator thrust force and the efficiency of the unlocking device for

manual operation (see the relative paragraph).

- The safety devices installed on the system must be checked every six months.

For any unresolved malfunction, cut the power to the system and call in a qualified technician (installer). In the

period when the gate is out of service, activate the manual unlocking device to allow manual opening and

MAINTENANCE

MALFUNCTIONING

KUDA 15

UK

CE Declaration of conformity

The manufacturer:

GI.BI.DI.

Via Abetone Brennero, 177/B,

46025 Poggio Rusco (MN) ITALY

Declares that the products:

ELECTROMECHANICAL GEARMOTOR KUDA 150-200

Are in conformity with the following CEE Directives:

•

EMC Directive 2004/108/CE and subsequent amendments;

and that the following harmonised standards have been applied:

•

•

Date 26/05/14

S.r.l.

Directive and subsequent amendments;LVD 2006/95/CE

•

EN60335-1,

EN61000-6-1, EN61000-6-3

Moreover declares that the product must not be used until the machine in which it has

been incorporated has not been declared in accordance with 2006/42/CE Directive.

The legal Representative

Michele Prandi

KUDA

KUDA 150 - (15000/DX-15000/SX) Operatore elettromeccanico lineare

DISEGNI E SCHEMI

Electromechanical linear operator

DRAWINGS AND DIAGRAMS

I UK

KUDA 200 - (22000/DX-22000/SX)

KUDA

2

991

IMPIANTO TIPO / TYPICAL INSTALLATION

1

2

3

4

5b

5a

6

7

8

8

10

10

9

9

A

A

B

5a 5b

LEFT OPERATOR-MOTOR 2

OPERATORE SINISTRO-MOTORE 2

RIGHT OPERATOR-MOTOR 1

OPERATORE DESTRO-MOTORE 1

B

922

DIMENSIONI OPERATORE / OPERATOR DIMENSIONS

98mm

46mm

93mm

400mm

799mm

29mm

KUDA 200

170mm

98mm

170mm

93mm

640mm

360mm

46mm

674mm

KUDA 150

29mm

765mm

KUDA 3

48

35

15

94

82

20

50

17

Ø9

17mm

15mm

993

STAFFE / BRACKETS

Ø9

991

APERTURA VERSO L’INTERNO / INWARD OPENING

994

Min

150mm

KUDA 150 MAX 120mm

KUDA 200 MAX 150mm

CHIUSURA / CLOSING

KUDA

4

991

APERTURA VERSO L’ESTERNO / OUTWARD OPENING

995

Min 70mm

APERTURA / OPENING

991

QUOTE INSTALLATIVE / INSTALLATION DIMENSIONS

996B

A

β°

120 130 140 150 160 170 180 190

120

130

140

150

160

170

180

190

B

A

β>120°

β=110°-120°

β=100°-110°

β<90°

β=90°-100°

210

β<90°

β=90°-100°

β=110°-120°

β>120°

β=100°-110°

140 150 160 170 180 190 200

140

150

160

170

180

190

200

210

B

A

KUDA150 KUDA200

KUDA 5

991

STAFFA POSTERIORE / REAR BRACKET

997a

991

STAFFA ANTERIORE / FRONT BRACKET

998a

991997a 991997a991997b

991998b

KUDA

6

991

MANOVRA DI SBLOCCO OPERATORE SINISTRO / LEFT MOTOR UNLOCK MANEUVER

999a 991999b

991999c 991999d

991

MANOVRA DI SBLOCCO OPERATORE DESTRO / RIGHT MOTOR UNLOCK MANEUVER

999e 991999f

991999g 991999h

KUDA 7

6

5

3

4

7

2

1

3

4

5

6

4

3

5

1

2

7

991

COLLEGAMENTI ELETTRICI / ELECTRICAL CONNECTIONS

9910

.

991

COLLEGAMENTO ELETTROSERRATURA / ELECTRIC LOCK INSTALLATION

9911 9919912

12 3 4 5 8

6

7

J4

9 10 11 12 13 16

14

15

J5 Motore 1 / Motor 1

GND

S1

5V

M1-

M1+

12 3 4 5 8

6

7

J4

9 10 11 12 13 16

14

15

J5

Motore 2 / Motor 2

GND

S2

5V

M2-

M2+

I UK

Apparecchiatura elettronica

ISTRUZIONI PER L’INSTALLAZIONE

Electronic control unit

INSTRUCTIONS FOR INSTALLATIONS

PC200 - (AS06050)

PC200

PC200

Red warning LEDs for N.C. contacts and for programming.

Buttons on the circuit board for programming and learning the radio controls.

Automatic run time learning with simplified procedure.

Onboard radio receiver that can store up to 200 radio controls.

Control of the radio transmitter channels via jumpers.

Deceleration during opening and closing.

Deceleration speed adjustable via DIP switch.

Stop and motion inversion after intervention of the safety devices.

Anti-crushing function both at normal speed and in deceleration.

Amperometric reading of motor absorption for the anti-crushing function adjustable via DIP switch.

Pedestrian operation with fixed opening of 5 seconds.

Two N.C. inputs programmable via DIP switch as photocell 1, photocell 2, N.C. frame or as opening device.

Two possible operating logics: step-by-step with stop or condominium selectable via DIP switch.

Gate phase shift time adjustable via DIP switch.

Programming of automatic closing and pause time via DIP switch.

Provision for use with buffer batteries.

Soft-Start and Soft-Stop to limit mechanical shock.

2 - TECHNICAL SPECIFICATIONS/FUNCTIONS

1 - TECHNICAL SPECIFICATIONS

SC230 / AS05710

230 VAC single-phase 50/60 Hz

2

24 Vdc

24 Vdc 10W max

Integrated

-20°C +60°C

ENCODER

12 Vdc 10W max

Electronic control unit for automation

of a double swing gate with 24VDC motors

Control unit

Power supply

No. of motors

Motor power supply

Flashlight

Radio receiver

Operating temperature

Run time

Accessory power supply

Type

WARNINGS: This product has been tested by GI.BI.DI. for full compliance with the requirements of the directives in force. GI.BI.DI. S.r.l. reserves the right to

change the technical data without prior notice in relation to product development.

DISPOSAL: GI.BI.DI. advises recycling the plastic components and to dispose of them at special authorised centres for electronic

components thus protecting the environment from polluting substances.

CAREFULLY READ THESE INSTRUCTIONS BEFORE PROCEEDING WITH INSTALLATION.

Thank you for choosing GIBIDI.

UK

11

PC200

991

INSTALLAZIONE APPARECCHIATURA / CONTROL BOARD INSTALLATION

991

2

PC200

991993991992

SW1SW2

ON

1 2 345 6 78

OFF

ON

1 2 345 6 78

OFF

F1 20A

+

-

BAT 24V

24Vac

K5

K2 K3 K4K1

Q17

J2J1

DB1

R59

R60

Q11

Q14

PHASE

NEUTRAL

PED (NO)

START (NO)

GND

+12Vdc

PHOT2 (NC)

+12Vdc

PHOT1 (NC)

GND

GND

+12Vdc

GND

GND

+5Vdc

S2

17 18 19 20 21 2422 239 10 11 12 13 16

14

15

+5Vdc

S1

12 3 4 5 8

6

7

JP3

JP1 JP2

LIT

LIT

M2M1

S2

S3

SYS-learnRF-learn

ENCODER

M1

ENCODER

M2

LED1 LED2 LED3 LED4 LED5

ANTENNA

24Vdc

10W MAX

LED1

SYS-learn

LED2

START-PED

LED3

LED4

PHOT1

LED5

PHOT2

RF-learn

LED STATUS

ON

OFF

FLASHING

25 26

J4 J5 J3

J7

RX

SCHEMA ELETTRICO / ELECTRICAL CONNECTIONS

J10

+-+-

+-

+-

LAT

LAT

3

GND

1 2 1 2

PC200

3

COLLEGAMENTO ALIMENTAZIONE / POWER SUPPLY CONNECTION

PHASE

NEUTRAL

230Vac

PHASE

NEUTRAL

INTERRUTTORE DIFFERENZIALE

RESIDUAL-CURRENT DEVICE

INTERRUTTORE MAGNETOTERMICO

OVERCURRENT CIRCUIT BREAKER

J10

4

COLLEGAMENTO MOTORE / MOTOR CONNECTION

.

4

12 3 4 5 8

6

7

J4

9 10 11 12 13 16

14

15

J5

Motore 2 / Motor 2

GND

S2

5V

M2-

M2+

12 3 4 5 8

6

7

J4

9 10 11 12 13 16

14

15

J5 Motore 1 / Motor 1

GND

S1

5V

M1-

M1+

Other manuals for KUDA 150

1

This manual suits for next models

1

Table of contents

Other GBD Gate Opener manuals

Popular Gate Opener manuals by other brands

Casanoov

Casanoov RANGER B150 instruction manual

ATA

ATA NeoSlider NES-500 manual

GFA

GFA ELEKTROMAT KE 20.24-40,00 installation instructions

tau

tau EASY Use and maintenance manual

tau

tau ARM200 Series Use and maintenance manual

Motorline professional

Motorline professional LINCE400 User's and installer's manual