GCE EASE II User manual

EASEII

DEMAND VALVE; INSTRUCTION FOR USE

ODBĚROVÝ VENTIL; NÁVOD K POUŽITÍ

VALVE A LA DEMANDE; MODE D’EMPLOI

DEMANDVENTIL; BRUKSANVISNING

VENTIL PO POTREBI; UPUTE ZA KORIŠTENJE UREĐAJA

GCE HEALTHCARE

EN

CS

FR

SV

HR

3/72

EN

1. FOREWORD

GCE EASE II low pressure medical demand valves are medical devices classified as class IIa

according to the Medical Device Directive 93/42/EEC. Their Compliance with essential

requirements of 93/42/EEC Medical Device Directive is based upon BS 4272:1996 standard.

2. INTENDED USE

The GCE EASE II low pressure demand valve is designed to be fitted to medical gas pipeline

systems or to quick connector outlet of medical gas regulator. EASE II demand valves are

intended to be used under supervision for the administration of a medical gas in response to the

patient´s inspiratory eort. The EASE II Demand valve is intended for use in the administration of

the following medical gases in the treatment and care of patients and is suitable for use in the

hospital or pre-hospital (emergency medical) environments:

• Oxygen O2

• Nitrous oxygen mixture O2/N2O - 50/50%

3. OPERATIONAL, TRANSPORT AND STORAGE SAFETY

REQUIREMENTS

Keep the product and its associated equipment away from:

• heat sources (fire, cigarettes,...)

• flammable materials,

• oil or grease (take a great care in the use of hand creams),

• water,

• dust.

The product and its associated equipment must be prevented from falling over.

Always maintain oxygen cleanliness standards.

Use only the product and its associated equipment in well ventilated area.

Before initial use the product shall be kept in its original packaging. GCE recommends use of

the original packaging (including internal sealing bag and caps) if the product is withdrawn from

operation (for transport and storage). Statutory laws, rules and regulations for medical gases,

accident prevention and environmental protection must be observed.

OPERATING CONDITIONS STORAGE AND TRANSPORT

CONDITIONS

MIN MAX MIN MAX

O2 -20 °C

+60°C

-30 °C +60 °C

O2/N2O +5 °C +60°C

10 % 100 % 20 % 70 %

600 mbar 1200 mbar 600 mbar 1200 mbar

ENGLISH

INSTRUCTION FOR USE: DEMAND VALVE EASE II

4/72

EN

In case of storage at a temperature below -20 °C or above 60°C do not operate the demand

valve until it has been allowed to change its temperature inside operating temperature limits.

For the demad valve intended to be used with mixture of gases O2+N2O, the lowest operat-

ing temperature is +5°C.

Do not use the device without being properly trained!

All gases under pressure can be hazardous and should be treated with caution.

Do NOT use oil or grease (unless specifically approved) on any part of an EASE II system.

Ensure hands are clean and free from oil and grease.

Keep system away from sources of ignition at all times.

Do NOT tamper with the equipment.

Do NOT try to connect an EASE II valve to terminal unit/quick connector of the incorrect gas

type.

4. PERSONNEL INSTRUCTIONS

The Medical Devices Directive 93/42/EEC states that product provider must ensure that all

personnel handling the product are provided with the operating instructions & performance

data.

Do not use the product without properly familiarization of the product and its safe operation

as defined in this Instruction for use. Ensure user is aware of particular information and knowl-

edge required for the gas in use.

5. PREPARATION FOR USE

5.1.CONNECTION OF THE HOSE TO THE GAS SOURCE

• Connect the supply hose

to the source of gas. For

more information regarding

gas - specific medical quick

connectors, see to Appendix

2.

• Regularly inspect the hose

during use to ensure that

the hose is not torn, bent,

twisted, or aected by

excessive pull.

• Regularly check the supply

of gas or the contents in the

cylinder.

5.2.FITTING

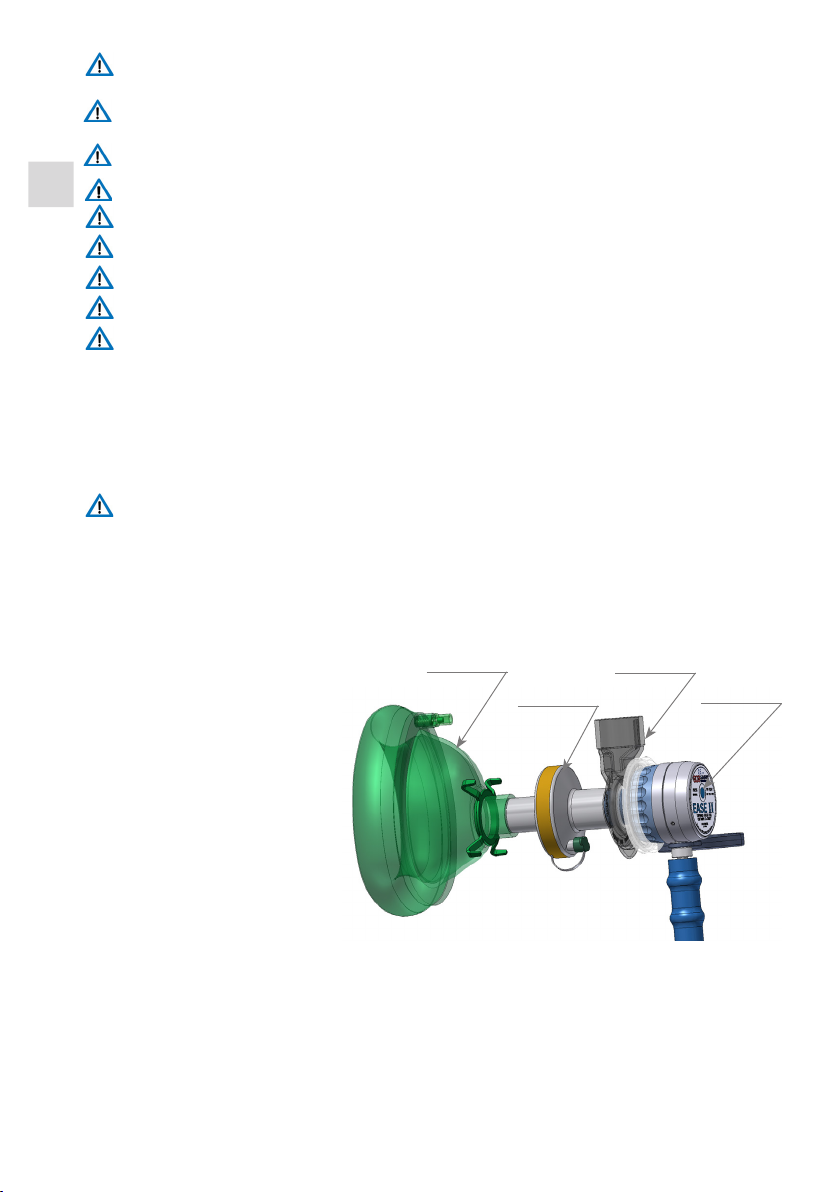

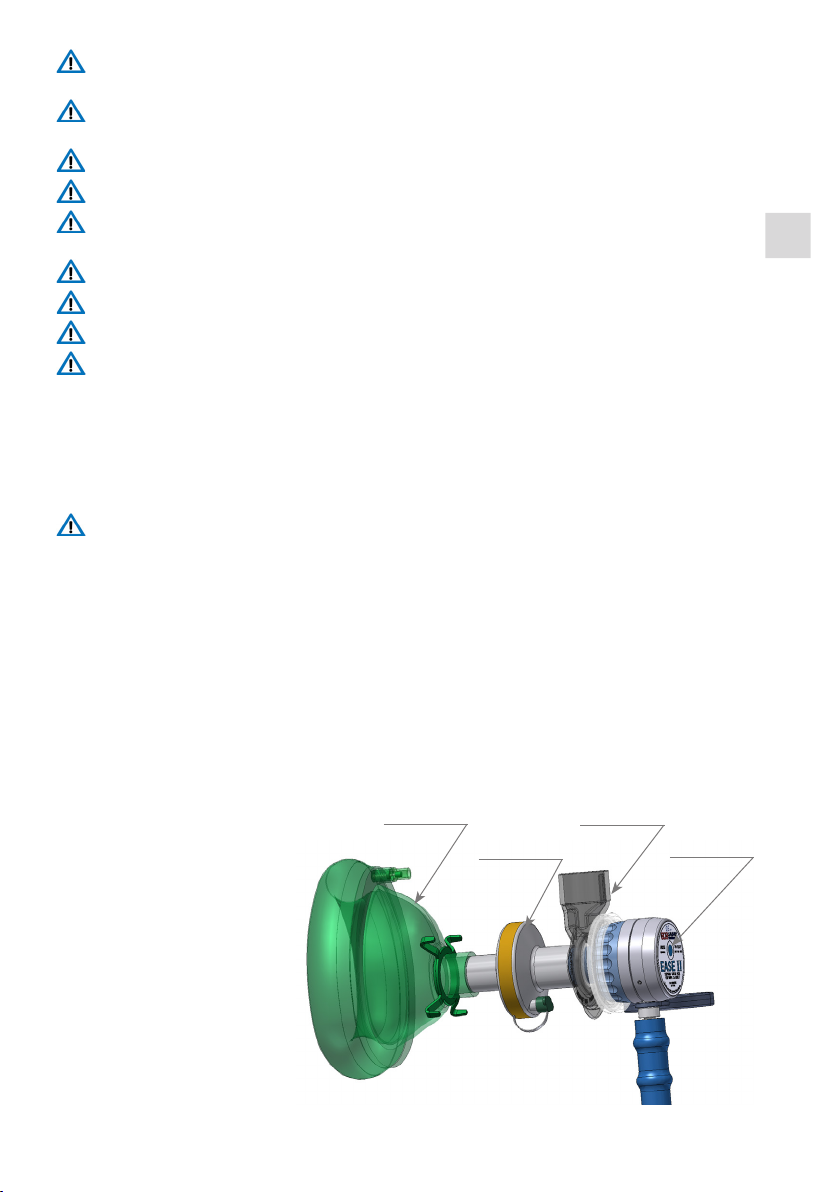

SCAVENGING ADAPTOR

• When using the scavenging adaptor, fit it to the demand valve by pushing it over the patient

port. (see Fig. 1).

• Then connect the exhalation pipe to scavenging adaptor.

NOTE: A scavenging adaptor should be fitted when EASE II for O2/N2O is used in enclosed

spaces. Failure to fit a scavenging adapter can result in supervisory personnel becoming

drowsy.

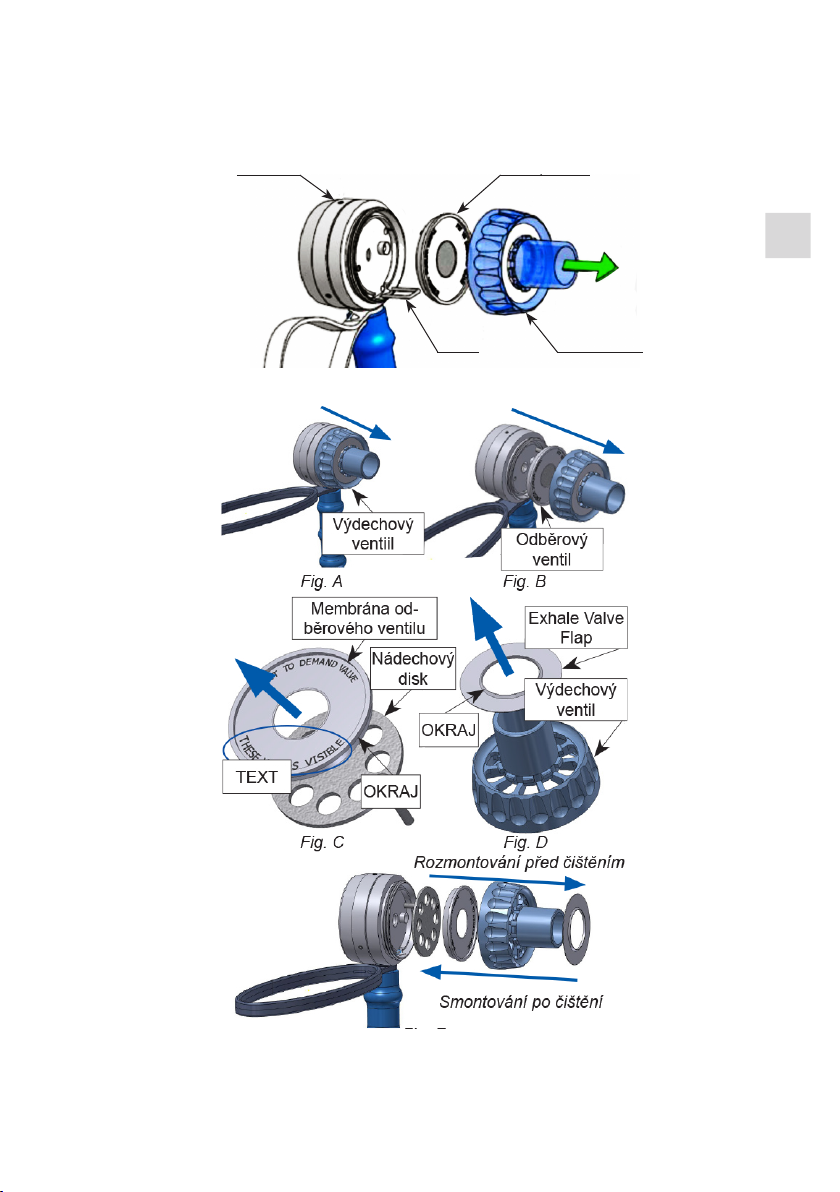

Fig. 1: Fitting scavenging adaptor, filter and mask

Test button

Scavenging

adaptor

Antibacterial

filter

Mask

5/72

EN

5.3.FITTING MASK OR MOUTHPIECE AND FILTER

Select mask or mouthpiece and filter as appropriate for the patient and fit to the demand valve

by pushing it over the 22 mm insert female tapered outlet on the patient port (see Fig. 1).

NOTE: Some patients find masks claustrophobic and may fight against the use of EASE II if

oered in this way. With such patients use of a mouthpiece is recommended.

5.4.TESTING PRIOR TO ADMINISTRATION

Units should be checked by lightly pressing the test button (see fig 1., fig.2). Gas should be

heard flowing through the mask or mouthpiece. On releasing the test button, the flow should

stop.

NOTE: If the system does not operate i.e. does not give a gas flow on depressing the test

button or the system does not stop giving flow, turn o the cylinder or disconnect from the

gas source and refer to the TROUBLESHOOTING chart in Section 9.

6. OPERATIONS

6.1.ADMINISTERING OF MEDICAL GASES

Medical gases 50/50% O2/N2O or 100 % O2should only be administered by persons trained to

do so and under qualified medical supervision.

Cylinder contents must be checked regularly during therapy and the cylinder replaced as

necessary.

1. Calmly explain to the patient purpose and operation of the demand valve. Reassure and

encourage him/her to breathe normally.

NOTE: Patients do not have to remove the mask or mouthpiece during exhalation.

2. Place the mask on the patient and support the mask over the mouth and nose, with the

patient breathing normally and not remove the mask when exhaling.

NOTE: If a mouthpiece is fitted, instruct them to hold it between their teeth, sealing on it with

their lips and to breathe through their mouth only.

3. Instruct the patient to breathe through the demand valve as required to reduce the level of

pain. (Continuous use is often unnecessary).

NOTE: Supervisory personnel can help support the mask, if should the patient is incapable

of holding it.

4. Constantly monitor the patient and the cylinder contents during administration. Check

volume of gas in the cylinder and replace the cylinder if necessary.

5. The administration of 50/50 O2/N2O may cause the patient to become drowsy. The seal

between the mouth and the demand valve will be lost and ambient air will be inhalated. The

patient will then begin to regain consciousness and an awareness of pain; and should be

encouraged to breathe the gas again.

6.2.AFTER USE

1. When treatment has been completed, close the cylinder valve and operate the test button

to de-pressurize the system or disconnect the demand valve from the wall outlet or quick

connector.

2. Clean the system as described in Section 7.

6/72

EN

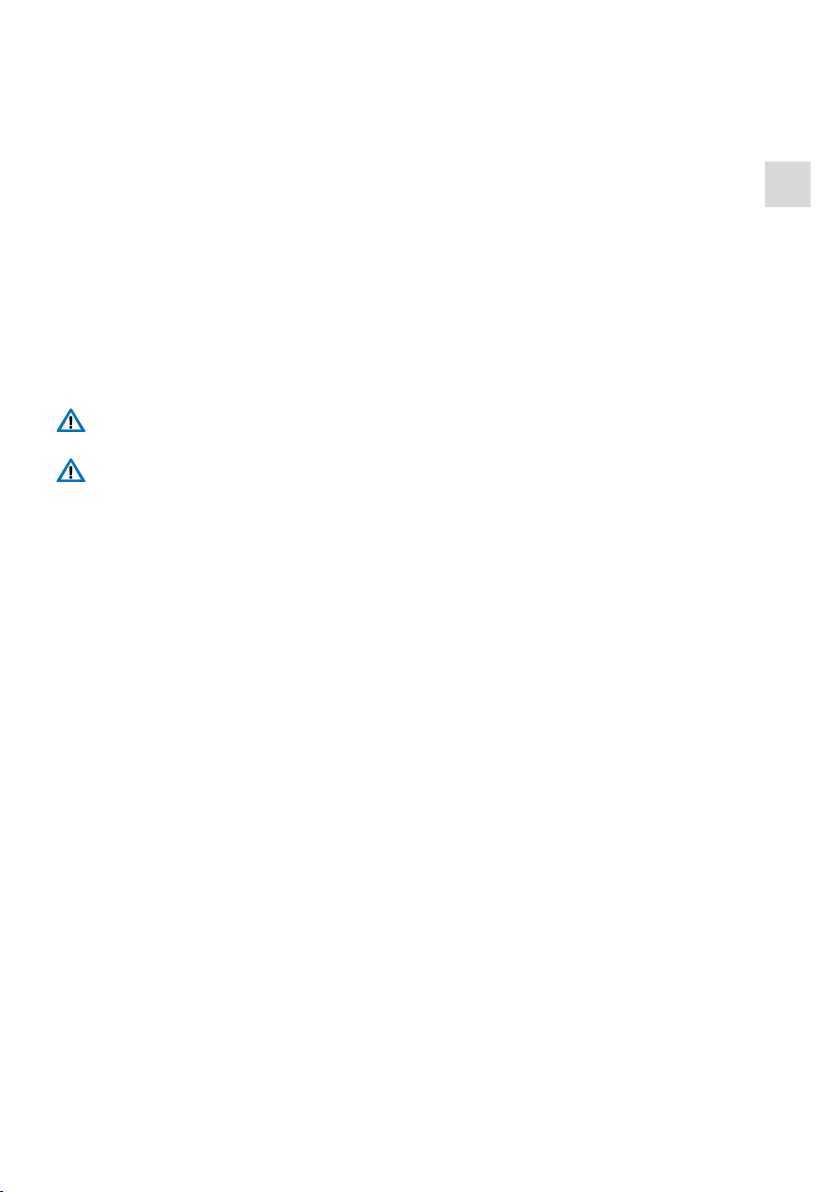

7. CLEANING

De-pressurize the system and disconnect from the gas supply prior to cleaning. Refer to the

exploded view of the demand valve parts below.

Fig. 2: Demand valve parts

U-clip Patient port

assembly

Inhalation

disc

Demand

Valve

Fig. 3: Dismantling of EASEII before cleaning

Fig. E

7/72

EN

Do not use cleaning solutions containing ammonia!

Do not expose to water or any other liquid.

Do not expose to high temperature (such as autoclave), unless it is stated otherwise.

To apply the cleaning solution do not spray it as the spray may enter into the inner parts of

demand valve and cause contamination or damage.

Do not use pressure wash as it could damage or contaminate the demand valve.

If the inner parts of the demand valve have been contaminated do not continue to use the

demand valve under any circumstances. It must be withdrawn from service.

7.1.CLEANING THE INHALATION DISC AND PATIENT PORT ASSEMBLIES

If an filter is used and bodily fluids have not contaminated the demand valve, only wiping the

demand valve with a disinfectant is necessary. Remove dirt with a soft cloth damped in oil free

soap water & rinsed with clean water. If demand valve has been contaminated by secretions,

blood, or vomit, then cleaning as outlined below is necessary.

1. Unscrew the patient port assembly from the demand valve (Fig. A) and remove the inhale

disc assembly (Fig. B).

2. Remove the silicone valve flaps from the patient port and inhale disc (see Fig.C,D). Take care

not to overstretch or damage these parts during removal.

3. If an antibacterial filter is used, cleaning is not necessary after every use. However,

recommended. If demand valve has been contaminated by blood or vomit, the cleaning is

necessary. Follow one of cleaning procedures bellow according to your preference:

a. Either wash all parts with warm water at a maximum temperature of 60°C, use an approved

disinfectant. The mechanical resistance of the components (Patient port, Inhale disc, Inhale

valve flap, Exhale valve flap), are guaranteed to 20 sterilization cycles under the cleaning

conditions mentioned below.

Example of cleaning with cold disinfectant:

Meliseptol: Remove dirt with a soft cloth damped in warm water with max. duration 30

seconds. Disinfection apply on the components (application of disinfectant for 1 minute). After

applying the disinfection, clean the components in running cold tap water. The components

shall be carefully dried with a soft non-abrasive cloth.

b. Or put the parts in an autoclave for 5 min at 134° C or for 20 min at 121° C.

After the cycle is complete, wait until parts get cool and check for damage. Assembly the

device (see section 5). The mechanical resistance of the components (Patient port, Inhale

disc, Inhale valve flap, Exhale valve flap), are guaranteed to 20 sterilization cycles under the

cleaning conditions mentioned above.

Later, the degradation of plastic substances may occur.

7.2.DISASSEMBLY OF THE DEMAND VALVE

1. Unscrew the patient port assembly from the demand valve (Fig. A) and remove the inhalation

disc assembly (Fig. B).

2. Remove the silicone valve flaps from the patient port and inhalation disc (see Fig.C,D). Take

care not to over-stretch or damage these parts during removal.

7.3.CLEANING THE DEMAND VALVE

DO NOT immerse the demand valve in disinfectant liquids.

1. Clean external surfaces of the valve with a lint-free cloth, slightly moistened in soapy water.

Dry with a lint-free cloth.

2. Disinfect the outer surface.

3. If the hose connection to the demand valve is contaminated, remove the hose from the

demand valve (see Chapter 7.4). Clean and dry the hose with a lint free cloth. Clean the hole

in the demand valve carefully with cotton moistened with clean water and disinfect.

4. If a demand valve suers internal contamination and normal cleaning is not eective, the

valve must be returned for servicing by a qualified technician.

8/72

EN

7.4.REMOVING & REFITTING THE HOSE FROM THE DEMAND VALVE

BODY

To remove the hose from the Demand Valve proceed as follows:

1. Disconnect EASE II from its gas supply and de-pressurize the system fully. If in any doubt,

contact Training and Technical Support Services at the address shown above.

2. Remove the patient port and inhalation disc assemblies. See fig 3 above.

3. Lift and remove the U-clip using a small screwdriver. See fig 2 above.

4. Pull the hose from the demand valve. Protect the hose connector from dirt and damage.

5. Reassembly is the reverse of the removal procedure. When refitting the U-clip ensure it is

fully seated.

6. Refit the patient port and inhalation disc assemblies.

7.5.CLEANING THE MASK, MOUTHPIECE, SCAVENGING ADAPTER

1. Masks for multiply use clean or sterilize according to the manufacturer’s instructions attached

to the mask. Masks for single use must be disposed after use.

2. The mouthpieces are single use only. Dispose of mouthpiece after use.

3. Scavenging adaptor can be washed in warm water (max 60°C) using approved

disinfectantwater and rinsed in clean water, or autoclaved at 121°C as preferred.

7.6.CLEANING HOSE ASSEMBLY

Hose assembly must be cleaned if contaminated or as part of regular cleaning. It is not

necessary to clean it after every use.

1. De-pressurize hose assembly and disconnect from the gas supply.

2. The external surfaces should be cleaned using a lint-free material moistened with soapy

water. Dry with a lint free material.

3. To disinfect, thoroughly wipe the outer surfaces with a disinfectant wipe.

4. Re-assemble the system and test according to the instructions in Chapter 7.7.

Please ensure that no disinfectant enters the hose, as there is risk of respiratory injuries.

7.7.REASSEMBLY OF EASEII AND TESTING AFTER CLEANING

1. Fit the hose back as described in section 7.3. if removed.

2. Place the inhalation flap back on the inhalation disc. Make sure the rim is placed over the

inhalation disk and letters “THESE WORDS VISIBLE” are up and readable - see Fig. C.

3. Place the inhalation disc assembly into the demand valve see Fig. B and D.

4. Place the exhalation flap into the patient port, make sure the rim is placed upward - see Fig.

D.

5. Screw the patient port onto the demand valve - see fig. A.

6. Test EASEII according to section 5.4. and use according to section 6.

NOTE: For cylinders with a regulator, it is recommended that the regulator be attached to the

cylinder, but with the cylinder turned OFF.

9/72

EN

8. MAINTENANCE

8.1.REGULAR CHECKS AND ROUTINE MAINTENANCE

1. T

he cylinder contents and the operation of the system must be checked regularly and prior to

use, as described in Sections 6.2.

2. Before each use, perform an audible and visual check on the hose for leaks and damage. If a

leak is detected, or if there is damage, such as cracks or abrasion in the hose outer cover the

hose must be replaced. Return the complete unit to an approved repairer for hose replacement.

3. The following components must also be checked on a regular basis for wear and tear and may

be replaced by the user as required:

• Inhalation disk

• Inhalation valve flap

• Patient port

• Exhalation valve flap

NOTE: Follow the instructions in Section 7 to change the Inhalation disc, Inhalation flap, patient

port and exhalation valve flap.

Observe the oxygen cleanliness warnings given in Section 4 when changing the cylinder seal.

All labels on the EASE II must be kept in good, legible condition by the owner and the user during

the entire product life time, replace as necessary.

All spare components must be kept in their original packaging to maintain batch / suppliers iden-

tity. All spare components must be stored in a dry, dark and clean environment by the owner/

user.

Use only original GCE components!

8.2.ANNUAL INSPECTION

EASE II must be inspected annually. No special tools or test equipment are required for the

annual inspection. The annual inspection may be carried out by the user or an approved GCE

repairer. Records of the annual inspection must be made and held for the life of the product.

See Chapter 8.3. for the annual inspection procedure and section 14 for an example of annual

inspection record sheet.

If components other than those listed in section 8.1 require replacing, the Demand Valve

complete with hose assembly must be returned to an approved GCE repairer for the work to be

carried out, as special tools and test equipment are required.

GCE approved repairers are trained by GCE to carry out servicing in accordance with the GCE

Service Manual.

A Service Manual with service and test equipment is available from GCE, s.r.o.

GCE, s.r.o. Tel : +420 569 661 111

Zizkova 381 Fax : +420 569 661 602

583 01 Chotebor http://www.gcegroup.com

10/72

EN

8.3.ANNUAL INSPECTION PROCEDURE

8.3.1.VISUAL INSPECTION

Step Procedure Comment/Action

1Depressurize and disconnect the demand

valve from the pressure supply

Use the test button on the back of the EASE

valve to depressurize the demand valve and

hose if required

2Check the demand valve serial number is

legible

If the serial number is not legible the demand

valve should be removed from service

3Check the demand valve has not exceed its 10

year life period

The first four digits of the serial number is the

year of manufacture. If the date at the time

of inspection is more than 10 years after the

manufacturing year the Demand Valve should

be removed from service and disposed of.

See 8.4.

4Check the hose has no damage to its outer

cover such as cuts, or significant abrasions.

The hose will require replacing if it has cuts, or

significant abrasions in its outer cover. Send

the demand valve to an approved GCE repairer

for hose replacement.

5Check that the hose is not kinked or miss-

shaped.

A kinked or miss-shaped hose indicates

the hose reinforcement has been damaged

and the hose should be replaced. Send the

demand valve to an approved GCE repairer for

hose assembly replacement.

6

If the hose is the type which connects to a

pipeline terminal outlet check the metal probe

connector is not damaged or worn.

A worn or damaged metal probe connector

may leak and should be replaced. Send the

demand valve to an approved GCE repairer for

hose assembly replacement.

7Check the Demand Valve body and rear cap is

not cracked or damaged.

If cracks or significant damage is evident on

the valve body or the rear cap the Demand

Valve should be withdrawn from service.

8

Check the three small grub screws securing

the Demand Valve rear cap to the main body

are in place.

If any of the grub screws are missing return the

Demand Valve to an approved GCE repairer.

9Check the label on the rear cap is in place and

in good condition

If the label needs replacing send the demand

valve to an approved GCE repairer for label

replacement.

10

Unscrew patient port assembly from main valve

body and remove exhalation valve flap from

the patient port.

See section 7 for further information on

disassembly procedure

11 Check patient port for cracks or damage. Replace patient port if damaged

12 Examine the exhalation valve flap for tears and

splits Replace exhalation valve flap if required

13 Refit exhalation valve flap to patient port.

See section 7 for further information on

refitting procedure

14

Lift inhalation disc assemble out of the Demand

Valve body. Remove inhalation valve flap from

the inhalation disc.

See section 7 for further information on

disassembly procedure

15

Examine the inhalation disc and pin. Check the

inhalation disc is flat . Check the pin is not bent

and is sitting square to the inhalation disc.

Replace inhalation disc (with pin) if required

11/72

EN

16 Examine the inhalation valve flap for tears and

splits. Replace inhalation valve flap if required

17 Refit inhalation valve flap to inhalation disc.

18

Refit inhalation disc assemble to the Demand

Valve body. Note the pin should slide easily

inside the hole in the Demand Valve body

19 Refit patient port assemble to the Demand

Valve body. Screw on hand tight only.

8.3.2.LEAK TESTING

Step Procedure Comment/Action

1Connect the demand valve to gas supply Gas will briefly flow as the Demand Valve is

connected to the gas supply, this is normal.

2Using a suitable leak detection fluid check

for leaks at:

The leak detection fluid should be compatible

with oxygen and suitable for use on plastic

components.

3The joint between the hose and hose fittings

at each end of the hose.

If a leak is found return the Demand Valve to

an approved repairer for hose replacement.

4The swivel joint between the Demand Valve

body and the hose fitting.

If a leak is found return the Demand Valve to

an approved repairer for repair.

5The connection between the hose probe

and the gas supply point.

If a leak is found here it may be due to a

worn male hose probe or a fault in the gas

supply connection. To eliminate gas supply

connection try a dierent supply point. If

leak continues hose assembly will require

replacement. Return the Demand Valve

to an approved repairer if the hose needs

replacing.

6

Unscrew the patient port assembly from

the Demand Valve body and lift out the

inhalation disc assembly.

7

While the Demand Valve is connected to

the gas supply hold the Demand Valve body

close to your ear (with outlet holes towards

your ear) and listen for leaks. No leaks

should be heard.

If a leak can be heard it indicates a fault with

either the main valve or pilot valve. Return

the Demand Valve to an approved repairer

for repair.

8Refit the inhalation disc assemble to the

Demand Valve body.

9Refit patient port assemble to the Demand

Valve body. Screw on hand tight only.

8.3.3.DEMAND VALVE OPERATION TESTING

Step Procedure Comment/Action

1Connect hose to gas supply.

Test gas may be air, nitrogen, oxygen or

N2O/O2mixture.Gas will briefly flow as the

Demand Valve is connected to the gas

supply, this is normal.

2

Press the test button. Gas should flow when

the button is pressed and stop flowing when

the button is released.

If gas flows when the button is not pressed

the Demand Valve is faulty and should be

returned to an approved repairer for repair.

12/72

EN

8.4.PRODUCT LIFE TIME

8.4.1.PRODUCT LIFE TIME AND WASTE MANAGEMENT

Maximum life time of the product is 10 years.

At the end of the product’s life time, the product must be withdrawn from service.

The owner shall put in place a relevant procedure to ensure the product cannot be used again.

The owner of the device shall prevent the reuse of the product and handle the product in

compliance with “Directive of European Parliament and Council 2006/12/ES of 5th April 2006

on waste“.

In accordance to Article 33 of REACH GCE, s.r.o. as responsible manufacturer shall inform all

customers if materials containing 0.1% or more of substances included in the list of Substance

of Very High Concern (SVHC).

The most commonly used brass alloys used for bodies and other brass components contain

2-3% of lead (Pb), EC no. 231-468-6, CAS no. 7439-92-1. The lead will not be released to the gas

or surrounding environment during normal use. After end of life the product shall be scrapped

by an authorized metal recycler to ensure ecient material handling with minimal impact to

environment and health.

To date we have no information that indicates that other materials containing SVHC of

concentrations exceeding 0.1% are included in any GCE product.

8.4.2.SERIAL NUMBER AND DATE OF PRODUCTION

Form of nine digit serial number stamped on the product is following:

YY MM XXXXX

YY: year of production

MM: month of production

XXXXX: sequence number

Example: serial number 090300521 shows the product produced in March 2009, with sequence

number 521.

9. TROUBLESHOOTING

The table below is provided as a means of correcting simple faults with the equipment. If the

suggested remedies do not rectify the fault, the equipment must be returned for inspection

and rectification by trained personnel who have completed the relevant training course (see

Section 8.2).

Symptoms Possible Cause Corrective Action

Equipment does not

deliver gas.

Cylinder valve not turned on. Check and turn on cylinder.

Cylinder empty. Check contents gauge. Fit a new

cylinder if necessary.

Quick coupling is not fully

connected.

Remove probe and re-fit to

adaptor, ensuring that it is fully

engaged.

Exhalation valve flap missing. Fit a new exhalation valve flap.

Demand valve leaks or

does not shut cleanly. Adjustment incorrect. Refer to Service Manual

Demand valve does not

stop giving flow after test

button is released.

Inhalation disc warped / damaged. Fit a replacement inhalation disc

Incorrect adjustment. Refer to Service Manual

13/72

EN

10. SPECIFICATION

Demand Valve - Meets the requirements of BS 4272 : part 2 : 1996

Gas Connection Probes by the national standards

Gas Supply Requirement 2.8 to 7.0 bar at >200 L/min

Inspiratory Resistance (at 2.8 bar

Supply Pressure)

Cracking -0,15 to -0,2 kPa

-0,2 kPa at 10 L/min.

-0,7 kPa at 200 L/min.

Expiratory Resistance Cracking Zero

At flow +0,35 kPa at 120 L/min.

Operating Temperature -20°C to +60°C when used with oxygen

+5°C to +40°C when used with 50/50 O2/N2O

Storage Temperature -30°C to +60°C

Materials Polyacetal; Polycarbonate; silicone rubber; stainless steel

Weight / Size Envelope 85 g / 50 x 50 x 63 mm

Hose Assembly

Fittings Probes by the national standards.

Pressure Working pressure 7 bar,

Burst pressure ≥56bar/23°C and ≥40bar/40°C

Material PVC, anti-static in accordance with ISO 5359

Weight 0.5kg (3m length)

Size Envelope OD 12,7 mm

NOTE: Values quoted are nominal. The manufacturer reserves the right to change

specifications without notice. Spare Parts and Accessories

10.1.ACCESSORIES PROVIDED WITH EASEII

EASE II O2/N2O demand valve are typically used with a mask, mouthpieces, filter, cylinder

thermometer and scavenging adaptor.

EASE II Oxygen demand valves are typically used with a mask, mouthpieces and filter. Acces-

sories, which is marked as disposable, or “single patient use” must not be used repeatedly.

The GCE medical range of products is constantly being developed and improved. If you require

any information or assistance, please telephone our Customer Services department. Contact is

enclosed on last page of this manual.

10.2.OPTIONAL ACCESSORIES

Those items marked by * are not manufactured by GCE.

• Bag, complete with cylinder cradle,

• Barrel bag blue,

• Cylinder cradle only,

• Disposable mouthpice - (Pack of 5)*,

• Filter single use (Pack of 100)*,

• Single use mask*

• Reusable mask*

• Thermometer for N2/N2O cylinders*

• Expiration diverter (Pack of 1)*

• Scavenging adapter (Expiration diverter)*

• Disposable filter*

14/72

EN

11. GLOSSARY

Consult instructions of use

Suitable for Hospital care use

Caution

Keep away from heat and flammable

material Suitable for Emergency care use

Keep away from oil and grease

Serial number

Humidity limit

Temperature limit Catalogue number

Keep dry Batch code

Date of manufacture Manufacturer

Fragile, handle with care Use by date

Inlet pressure (P1) Outlet pressure (P2)

12. WARRANTY

The Standard Warranty period is two years from date of receipt by the GCE Customer (or if this

is not known 2 years from time of the product manufacture shown on the product).

The standard warranty is only valid for products cu according to Instruction for use (IFU) and

general industry good practice and standards.

13. SAMPLE ANNUAL INSPECTION RECORD SHEET

Please copy this form to help with your EASEII annual checks.

See section 8.3 for details of the annual inspection procedure.

COMPANY Demand Valve SERIAL NUMBER

VISUAL CHECK TICK COMMENTS / ACTION TAKEN

Check serial number legibility

Check demand valve is less than 10 years

old

Check hose condition

SN

REF

LOT

15/72

EN

APPENDIX:

Nr 2: Quick coupling features and connecting / disconnecting procedure.

MANUFACTURER:

GCE, s.r.o. Tel : +420 569 661 111

Zizkova 381 Fax : +420 569 661 602

583 01 Chotebor http://www.gcegroup.com

Czech Republic © GCE, s.r.o.

Check body condition

Check label condition

Check the three recap screws are in place

Check patient port condition

Check exhalation valve flap condition

Check inhalation plate (with pin) condition

Check inhalation valve flap condition

LEAK CHECKS TICK Comments / Action Taken

Hose to hose fitting joints (use leak

detection fluid)

Hose to demand valve body joint (use

leak detection fluid)

Leak test Demand valve (listening for

leak with patient port and inhalation disc

removed)

OPERATION CHECKS TICK Comments / Action Taken

Test button operation

Tested By: Date:

16/72

CS

1. ÚVOD

Nízkotlaké zdravotnické ventily GCE EASE II jsou zdravotnické prostředky klasifikované jako

třída IIa podle směrnice 93/42/EHS o zdravotnických prostředcích. Jejich shoda se základními

požadavky směrnice 93/42/EHS o zdravotnických prostředcích vychází z normy BS 4272: 1996.

2. ÚČEL POUŽITÍ

Nízkotlaký odběrový ventil GCE EASE II se připojuje k systémům rozvodu medicinálního plynu

nebo k výstupní rychlospojce regulátoru medicinálního plynu. Odběrové ventily EASE II se

používají pod dohledem zdravotníka k podávání medicinálního plynu, které se řídí vdechováním

pacienta. Odběrový ventil EASE II je určen k podávání níže uvedených medicinálních plynů při

léčbě a péči o pacienty a je vhodný pro použití v nemocničním a přednemocničním (záchranná

služba) prostředí:

• Kyslík O2

• Směs oxidu dusného a kyslíku O2/N2O – 50/50%

3. BEZPEČNOSTNÍ POŽADAVKY NA PROVOZ, PŘEPRAVU A

SKLADOVÁNÍ

Výrobek, včetně příslušenství, udržujte mimo:

• zdroje tepla (oheň, cigarety, …),

• hořlavé materiály,

• olej nebo tuk,

• vodu,

• prach.

Výrobek, včetně příslušenství, musí být zajištěn proti překlopení.

Vždy dodržujte normy týkající se čistoty kyslíku.

Výrobek, včetně příslušenství, používejte pouze v dobře odvětrávaných prostorech.

Před prvním použitím musí být výrobek ve svém originálním obalu. V případě stažení z provozu

(pro přepravu, skladování) doporučuje GCE použít originální obal (včetně vnitřních výplňových

materiálů). Musí být dodržovány národní zákony, vyhlášky a předpisy pro medicinální plyny,

bezpečnost práce a ochranu životního prostředí.

PROVOZNÍ PODMÍNKY SKLADOVACÍ A TRANSPORTNÍ

PODMÍNKY

MIN MAX MIN MAX

O2 -20 °C

+60°C

-30 °C +60 °C

O2/N2O +5 °C +60°C

10 % 100 % 20 % 70 %

600 mbar 1200 mbar 600 mbar 1200 mbar

ČESKY

NÁVOD K POUŽITÍ: ODBĚROVÝ VENTIL EASE II

17/72

CS

V případě skladování při teplotě pod -20 ° C nebo nad 60 ° C nepoužívejte ventil, dokud nebu-

de povoleno měnit jeho teplotu uvnitř mezních hodnot provozní teploty.

Pro odběrový ventil určený pro použití se směsí plynů O2 + N2O je nejnižší provozní teplota

+ 5 ° C.

Nepoužívejte zařízení bez řádného zaškolení!

Veškeré plyny pod tlakem mohou být nebezpečné a mělo by se s nimi zacházet opatrně.

NEPOUŽÍVEJTE olej ani tuk (pokud to není výslovně povoleno) na žádnou součást systému

EASEII.

Zajistěte, aby ruce byly čisté a bez oleje a tuku.

Systém vždy udržujte mimo zdroje vznícení.

NEPROVÁDĚJTE nepovolenou manipulaci s přístrojem.

Hadice produktu EASEII je specifická pro daný typ plynu a nelze ji připojit k jinému typu ply-

nu, než pro který je určená.

4. INSTRUKTÁŽ PRACOVNÍKŮ

Dle medicinální direktivy 93/42/EHS má poskytovatel zařízení povinnost poskytnout všem

uživatelům a osobám manipulujícím s výrobkem návod k použití & technickou dokumentaci pro

daný produkt.

Nepoužívejte výrobek bez řádného seznámení se s výrobkem a jeho bezpečným provozem,

jak je popsáno v tomto návodu k použití. Zajistěte, aby měl uživatel odpovídající informace a

znalosti požadované pro používaný plyn.

5. PŘÍPRAVA K POUŽITÍ

5.1.PŘIPOJENÍ HADICE KE ZDROJI

• Připojte koncovku hadice ke zdroji plynu. Více informace ohledně konkrétních zdravotnických

rychlospojek viz Příloha 2.

• Pravidelně kontrolujte hadici během používání, zda není roztržená, ohnutá, překroucená

nebo vystavená nadměrnému tahu.

• Pravidelně kontrolujte přívod plynu nebo jeho obsah v láhvi.

5.2.PŘIPOJENÍ ČISTÍCÍHO ADAPTÉRU

• Pokud je v systému

zahrnut čisticí adaptér,

připevněte jej k

odběrovému ventilu jeho

natlačením na pacientský

ventil (viz Obr. 1).

• Poté připojtevýdechovou

trubku k čisticímu

adaptéru.

Pozn.: Čisticí adaptér by

měl být použit, když se

EASEII pro O2/N2O používá

v uzavřených prostorách.

Nepoužití čisticího adaptéru

může mít za následek

ospalost ošetřovatelů. Obr. 1: Montáž čistícího adaptéru, filtru a masky

Testovací

tlačítko

Čistící

adaptér

Antibakteriální filtr

Maska

18/72

CS

5.3.PŘIPEVNĚNÍ MASKY NEBO ÚSTENKY A FILTRU

Zvolte vhodnou masku nebo ústenka a filtr pro pacienta a připevněte k odběrovému ventilu

natlačením na kuželovou zásuvku o průměru 22 mm na pacientském ventilu (viz Obr. 2).

Pozn.: Někteří pacienti mohou při použití masek trpět klaustrofobií a mohou se vzpírat proti

použití EASEII, když je nabízeno tímto způsobem. U takových pacientů se doporučuje použít

ústenku.

5.4.ZKOUŠENÍ PŘED PODÁVÁNÍM

Systémy s testovacím tlačítkem by měly být kontrolovány lehkým tisknutím testovacího tlačítka

(viz obr. 1., obr.2). Měl by být slyšen plyn proudící maskou nebo ústenkou. Po puštění testovacího

tlačítka by se průtok měl zastavit.

Pozn.: Jestliže systém nepracuje, tj. při stisknutí testovacího tlačítka nedojde k průtoku plynu

nebo se průtok nezastaví, zavřete láhev nebo odpojte systém z koncové zásuvky a použijte

tabulku odstraňování poruch v článku 9.

6. POUŽÍVÁNÍ

6.1.PODÁVÁNÍ SMĚSI 50/50 O2/N2O

Směs 50/50 O2/N2O by měly podávat pouze osoby k tomu vyškolené a pod dohledem kvalifi

kovaných zdravotníků.

Během terapie by se měl pravidelně kontrolovat obsah láhve. Láhev by se měla v případě

potřeby vyměnit.

1. Poklidně vysvětlete pacientovi, co se chystáte dělat. Uklidněte ho a povzbuďte ho, aby

dýchal normálně.

Pozn.: Pacienti během výdechu nemusí masku ani náustek odstraňovat.

2. Podejte pacientovi masku a poraďte mu, jak ji má držet přes ústa a nos, aby dýchal normálně

a při výdechu masku neodstraňoval.

Pozn.: Pokud je nasazena ústenka, poraďte mu, jak ji má držet mezi zuby, že má použít rty

jako těsnění a dýchat pouze ústy.

3. Instruujte pacienta, že má dýchat přes odběrový ventil, aby se snížila bolest (nepřetržité

používání často není nutné).

Pozn.: Ošetřovatelé mohou pomoci masku podepřít, pokud by pacient nebyl schopen.

4. Během podávání neustále sledujte pacienta a obsah láhve. Kontrolujte obsah plynu v láhvi a

v případě potřeby láhev vyměňte.

5. Podávání směsi 50/50 O2/N2O může vyvolat ospalost pacienta. Tím dojde ke ztrátě těsnosti

mezi ústy a odběrovým ventilem a k vdechování okolního vzduchu. Pacient začne přicházet

k vědomí a uvědomí si bolest a měl by být vyzván, aby znovu vdechoval plyn.

6.2.PO POUŽITÍ

1. Po dokončení léčby zavřete lahvový ventil a stiskněte testovací tlačítko, aby došlo k

odtlakování systému, nebo odpojte odběrový ventil od zásuvky ve zdi nebo rychlospojky.

2. Vyčistěte systém dle popisu v článku 7.

19/72

CS

7. ČIŠTĚNÍ

Před čištěním systém odtlakujte a odpojte od přívodu plynu. Viz rozložený pohled na součásti

odběrového ventilu níže.

Obr. 2: Cásti odběrového ventilu

U-klip Výdechový

ventil

Náděchový

ventil

Odběrný

ventil

Obr. 3: Montáž EASE II pro čištěním

Fig. E

20/72

CS

Nepoužívejte čístící roztoky obsahující čpavek!

Zařízení nevystavujte působení vody ani jiné kapaliny.

Nevystavujte vysokým teplotám (např. v autoklávu), pokud není uvedeno jinak.

Pro aplikaci čistícího prostředku nesmí být použitý postřik, v opačném případě hrozí vniknutí

postřiku do vnitřních částí ventilu a jeho kontaminaci či poškození.

Pro čištění nepoužívejte tlakové mytí, mohlo by to způsobit poškození nebo kontaminaci ven-

tilu.

Pokud došlo k jakékoliv kontaminaci vnitřních částí ventilu v žádném případě jej nepoužívejte,

stáhněte jej z provozu.

7.1.ČIŠTĚNÍ SESTAV VDECHOVÉHO A PACIENTSKÉHO VENTILU

Pokud je použit antibakteriální filtr a ventil nebyl znečištěn tělesnými tekutinami, není nutné čistit

ventil po každém použití. Nečistoty odstraňte měkkým hadříkem navlhčeným v bezolejnaté,

mýdlové vodě a opláchněte čistou vodou. Pokud byl ventil kontaminován krví nebo zvratky,

čištění je nezbytné. Postupujte dle jednoho z níže popsaných postupů pro čištění:

1. Vyšroubujte sestavu pacientského ventilu z odběrového ventilu (Fig. A a vyjměte sestavu

vdechového ventilu (Fig. B).

2. Vyjměte silikonové membrány ventilu z výdechového ventilu (viz. Fig. C,D). Vyvarujte se

nadměrnému natahování a narušení silikonových membrán během demontáže.

3. Pokud používáte antibakteriální filtr, nemusíte ventil čistit po každém použití. Výrobce však

doporučuje toto čištění provést. Pokud je ventil kontaminovaný krví nebo zvratky, čištění je

nezbytné. Postupujte dle jedné z čistících metod popsaných níže:

a. Buď omyjte všechny části v teplé vodě o max. teplotě 60°C s použitím vhodného

dezinfekčního prostředku. Mechanická odolnost komponentů (Výdechový ventil, nádechový

disk, membrána odběrového ventilu, membrána výdechového ventilu) je zaručena do 20

cyklů sterilizace za níže uvedených podmínek.

Příklad čištění studeným dezinfekčním prostředkem:

Meliseptol: Nečistoty odstraňte měkkým hadříkem navlhčeným v teplé vodě s max. trvání 30

sekund. Dezinfekci aplikujte na komponenety (aplikace dezinfekčního prostředku po dobu 1

minuty). Po aplikaci dezinfekce, vyčistěte komponenty tekoucí studenou vodou z vodovodu.

Komponenty by měly být opatrně usušeny měkkým neabrazivním hadříkem.

b. Nebo umístěte části do autoklávu na 5 min při teplotě 134° C nebo na 20 min při teplotě

121°C. Po ukončení cyklu, počkejte, až části vychladnou a zkontrolujte, zda nejsou poškozené.

Smontujte zařízení (viz kapitola 5).

Mechanická odolnost komponentů (Výdechový ventil, nádechový disk, membrána

odběrového ventilu, membrána výdechového ventilu) je zaručena do 20 cyklů sterilizace za

výše uvedených podmínek.

Později může docházet k degradaci plastových látek.

7.2.DEMONTÁŽ ODBĚRNÉHO VENTILU

1. Vyšroubujte sestavu pacientského ventilu z odběrového ventilu (Fig. A a vyjměte sestavu

vdechového ventilu (Fig. B).

2. Vyjměte silikonové membrány ventilu z výdechového ventilu (viz. Fig. C,D). Vyvarujte se

nadměrnému natahování a narušení silikonových membrán během demontáže.

Table of contents

Languages:

Popular Respiratory Product manuals by other brands

ResMed

ResMed Swift FX for Her user guide

CELIMED

CELIMED U-615 instruction manual

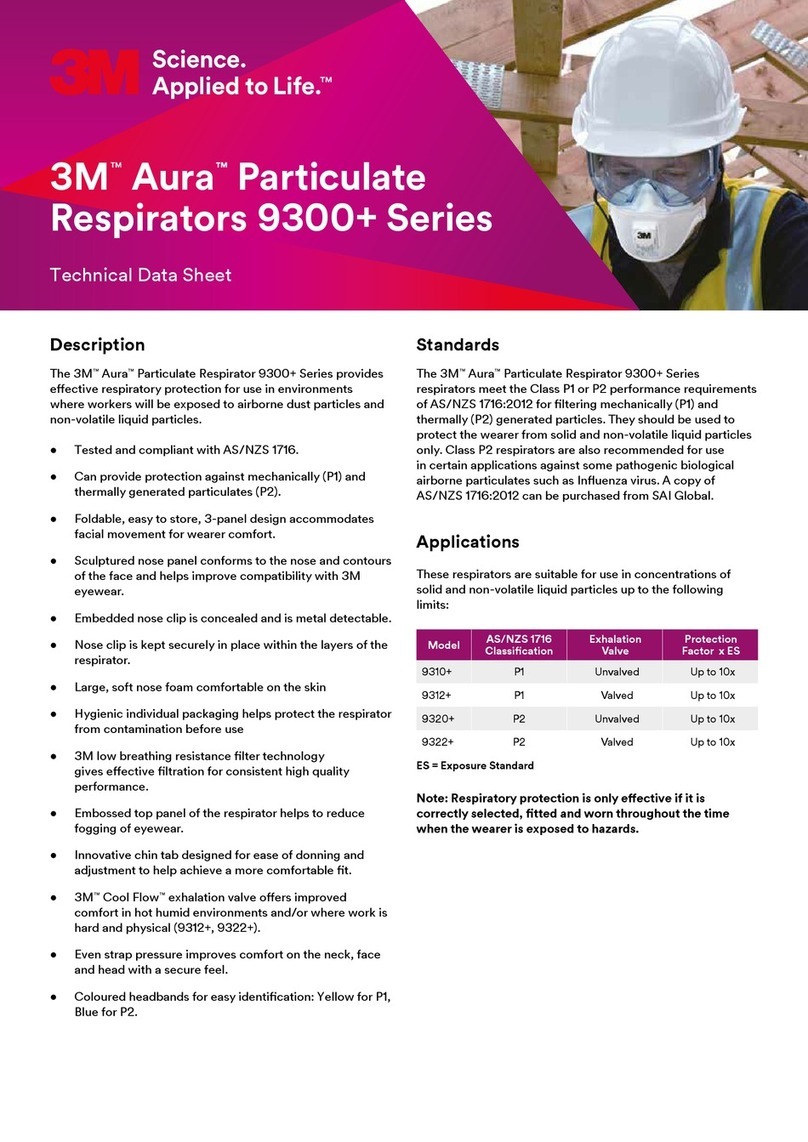

3M

3M Aura 9300+ Series Technical data sheet

Sundstrom

Sundstrom SR 90 Airline operating instructions

Kayoba

Kayoba 009449 operating instructions

PHILIPS Respironics

PHILIPS Respironics MPN-Truma MicroDrop Family instruction manual