Certication

The 3M™Aura™ Particulate Respirator 9300+ Series respirators have been produced to comply with the requirements of

Australia/New Zealand Standard AS/NZS 1716:2012 under an agreed production certication scheme operated during

manufacture in accordance with BSI.

Important

• Before use, the wearer must be trained in use of the complete product in accordance with AS/NZS 1715:2009 and other

applicable Health and Safety standards/guidance.

• Proper selection, training, use and appropriate maintenance are essential in order for the product to help protect the wearer

from certain airborne contaminants.

• Failure to follow all instructions and limitations on the use of these respirators and/or failure to wear the respirator during all

times of exposure can reduce respirator eectiveness and may result in sickness or death.

• Do not use in atmospheres containing less than 19.5% oxygen, as these respirators do not supply oxygen. (3M denition –

individual countries may apply their own limits on oxygen deciency. Seek advice if in doubt.) Do not use these respirators

for protection against atmospheric contaminants/concentrations which are unknown or at or above immediately dangerous

to life and health (IDLH) levels.

• For suitability and proper use follow local regulations and refer to all information supplied. For additional assistance, contact

an Occupational Hygienist, Safety professional or 3M TechAssist Helpline.

Warnings and Use Limitations

• Always be sure that the complete product is:

–Suitable for the application;

–Fitted correctly;

–Worn during all periods of exposure;

–Replaced when necessary.

• Before initial use, always check the product is within the stated shelf life (use by date).

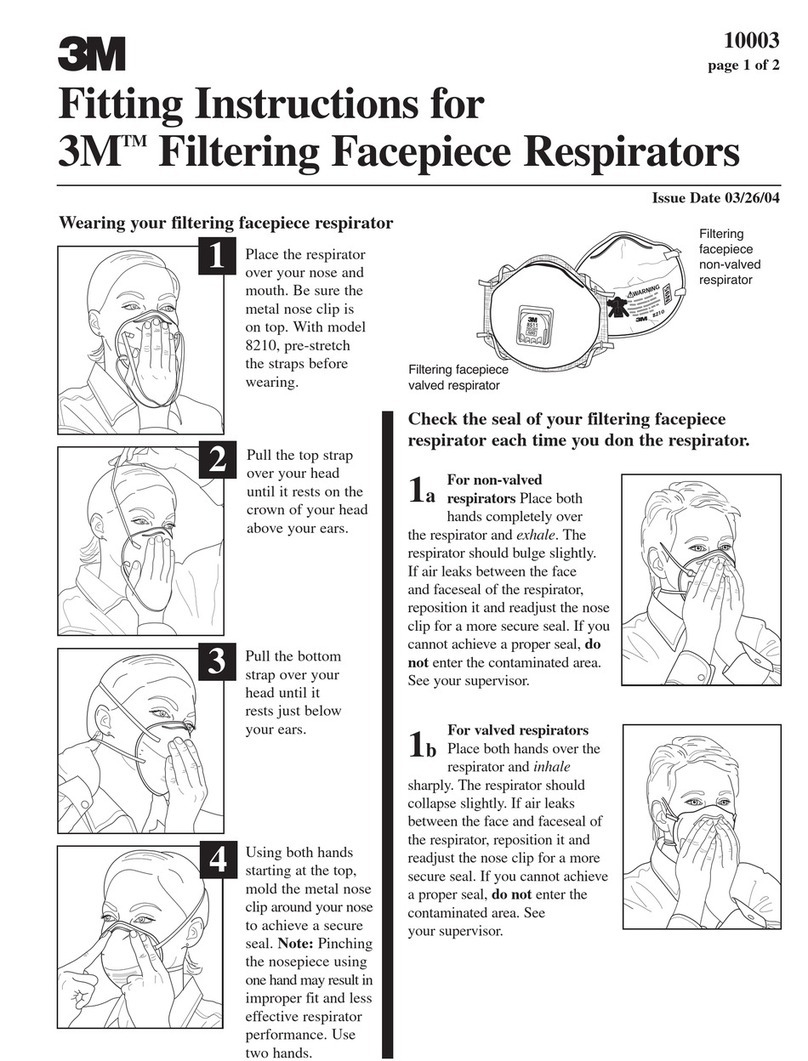

• It is recommended that t testing be conducted before assigning a respirator to an individual. If you cannot achieve a proper

t then do not enter contaminated area. See your supervisor.

• Inspect respirator before each use to ensure it is in good working condition. Examine all the respirator parts for signs of

damage including the two straps, nose clip, nose foam and staples. The respirator should be disposed of immediately upon

observation of damaged or missing parts.

• Leave the contaminated area immediately and contact supervisor if dizziness, irritation or other distress occurs.

• Do not alter, repair, wash, abuse or misuse the respirator.

• Do not use with beards or other facial hair or other conditions that prevent a good seal between the face and the sealing

edge of the respirator.

• The respirator can help protect the wearer’s lungs against certain airborne contaminants; however, it will not prevent entry

through other routes such as the skin or eyes, which would require additional personal protective equipment (PPE).

• These respirators are designed for occupational/professional use by adults who are properly trained in their use and

limitations. These respirators are not designed to be used by children.

• Individuals with a compromised respiratory system, such as asthma or emphysema, should consult a physician and complete

a medical evaluation prior to use.

• Operating Temperature Range: -20 to +50 degrees Celsius. CAUTION: Care should be taken when using these respirators at

low temperatures as excessive moisture may cause the exhalation valve to freeze.

• The ltration eciency of these respirators may decrease in the presence of oily mists.

3M™ Personal Safety Division | 3M™Particulate Respirators 9300+ Series