Intended Use .............................................................................................................................................................. 3

Safety instructions and safety devices ........................................................................................................................ 4

Technical data HOFFMANN Frame Joiner ................................................................................................................... 6

Noise level at the machine ......................................................................................................................................... 7

Warranty Statement................................................................................................................................................ 8

EC Declaration of Conformity ..................................................................................................................................... 9

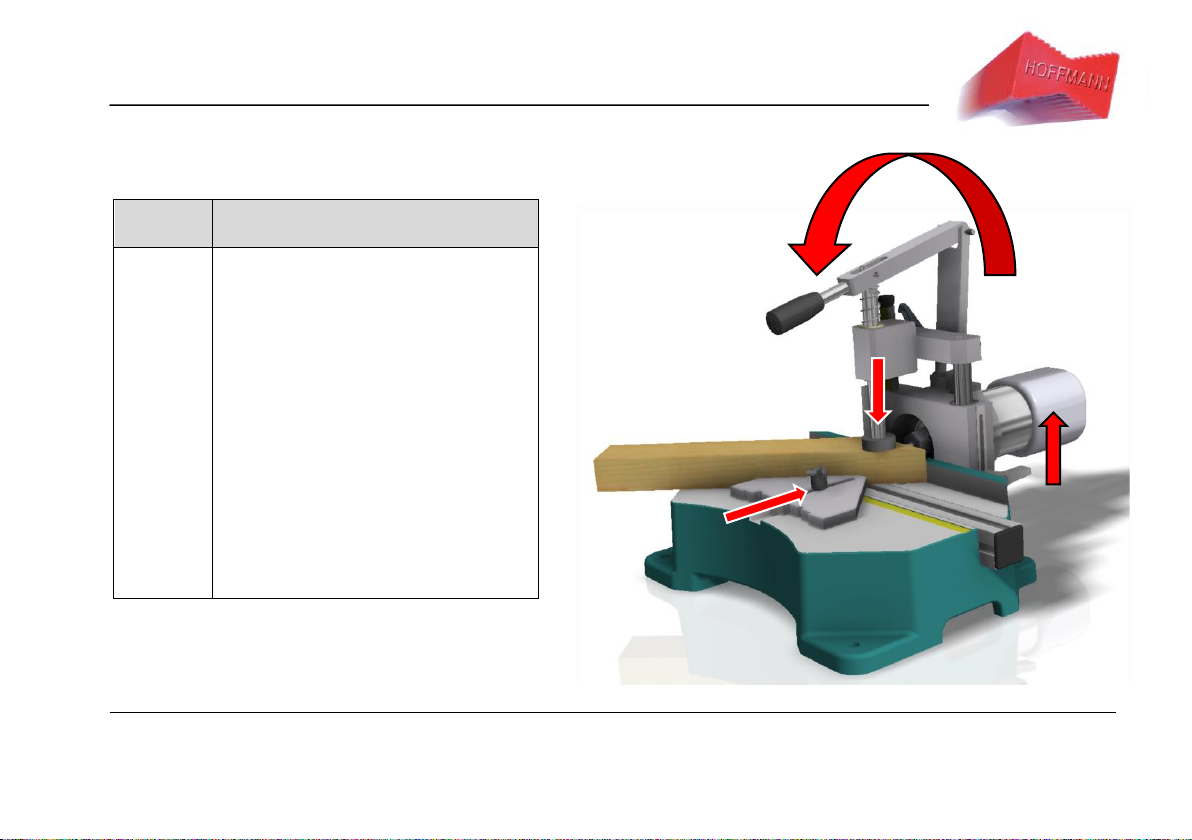

Function and operation of the machines ...................................................................................................................10

Scope of delivery, transport and storage ...................................................................................................................11

Cutter change and cutter adjustment........................................................................................................................15

Adjusting the routing groove length ..........................................................................................................................18

Malfunctions and troubleshooting ............................................................................................................................22

Machine plan Hoffmann Frame Joiner.......................................................................................................................23

Parts list Hoffmann Frame Joiner...............................................................................................................................24

Warranty and liability ...........................................................................................................................................25