Technical

Gas Type Oxygen

Input Voltage

12~30v DC – 24v nominal

Optional Mains 230/115vAC 50/60hz

Nominal 30mA – 120mA full alarm

Output Standard

Analogue 4~20 mA (250 ohms max) – sink/source

(source mode – standard)

Option 1~5v output – solder G

CV–Sensor Cable 3 core screened

Alarm Relay

Main relay S.P.C.O. 3A/230v AC

Fire Alarm panel signalling – cut F

Trip Indicator LED – trip point selectable 10% to full scale

(Auto reset)

On board sounder

Auxiliary output DC volts – standard–as input volts 24v

DPM – gas readout display – (zero and span potentiometers used

only for DPM setting)

www.gds–technologies.co.uk

SET UP PROCEDURE

Installation

Siting of the equipment should be chosen with regard to the

following points:

1. Safe area use only (not hazardous zone)

2. Away from sources of heat and with room for adequate air

circulation.

3. Within easy reach for operating and maintenance personnel.

4. Connecting cables to be electrically shielded.

5. For further information regarding sensor location see our website

www.gds–technologies.co.uk.

Note: Sensor cables should not be run in the same ducting as power

cables.

Removing Lid (30J)

Using a 2.5mm Allan key withdraw the two lid screws until they clear

the lid bezels. Push the lid up until it is stopped by the circuit board

located inside the enclosure; pull one side to remove the lid.

Mounting

Direct wall mount – use M4 or No.8 screws through the membrane

of the 4 stand–os. Where the stand–os are to be removed (rotate

each stand–o using pliers) drill at mounting points marked C or

utilise knock out slots.

For surface mount box drill at points B (2 o)

For conduit box xing drill at points A (2 o)

Supply Input

Ensure that the supply is correct for the voltage rating of the

indicator. Ensure that the supply is OFF before making any

connections and wire only in accordance with the terminal detail.

Calibration (factory set)

1. Connect a digital voltmeter (miIIivolt range) to the X and Y test

terminals, the CV is preset in the current source mode.

2. Remove the sensor terminal connector from the PCB J4 or yellow

wire and adjust the 4mA potentiometer for 4mA (4mV).

3. Where a digital panel meter is tted to the CV card the reading

may be adjusted by the DPM Zero potentiometer.

Reconnect the cell and allow reading to stabilise adjust the DVM

reading to 17.3mV (20.8% ambient oxygen) using the 20mA

potentiometer.

Where a Digital panel meter is tted the display may be adjusted by

using the DPM S potentiometer (span).

Alarm Trip Point Adjustment (factory set)

This level will normally be set at 23% for oxygen.

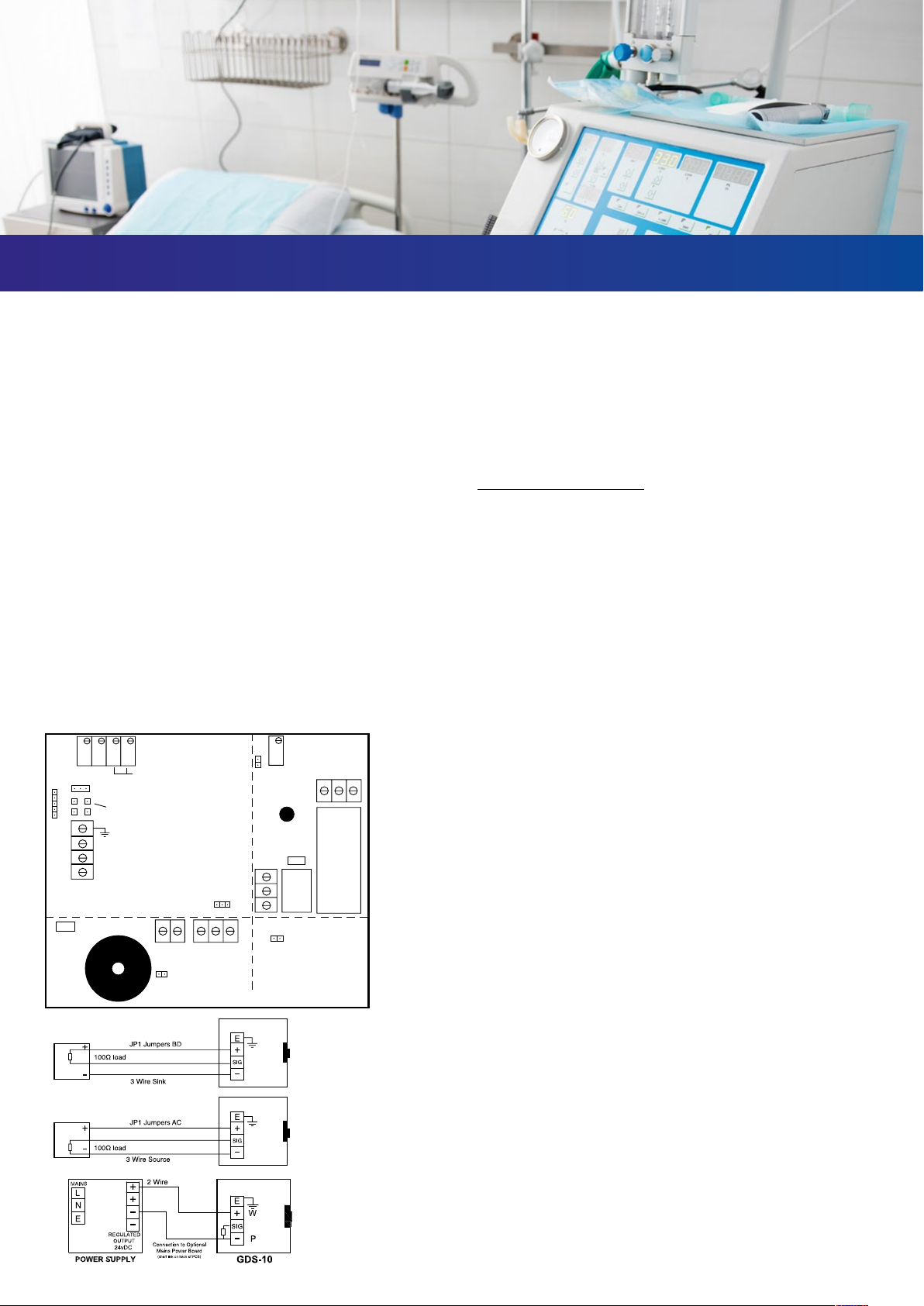

1. Connect the DVM as above, using the 20mA potentiometer adjust

for the required trip level (OM DPM).

2. Adjust the alarm level potentiometer until the alarm LED just

comes on.

3. Using the 20mA potentiometer re–adjust the DVM to 17.3mV.

The above adjustment may be carried out in house by connecting

the CV transmitter directly to a DC power supply and connecting a

100Ω load resistor. See diagrams on left.

Should a full board be required to operate on a 2 wire 4-20mA loop

then the alarm relay / LED must be disabled – remove JP2.

A

B

C

D

XP

-

-

+

-

+

+

YW

PYW

SENSOR

FIELD TERMINALS

TO GDS

ALARM PANEL

PCN149

E

Y

20mA

4mA

TP2

TP4

TP1

RV3

JP1

RV4

TP3

WY P

No CNc

NC

C

NO

-+

Sensor Terminal

Sounder Mute

Sounder

FULL CV BOARD

T

RELAY

BOARD

CV

TRANSMITTER

EOL

Output Signal

Adjust

Test Points

Alarm Level

Adjust

Alarm

LED

JP2

20mA

4mA

Span

Zero

DPM

E

A

JP1

-+

WYR

-+

J4

JP3

JP4

XY

B

C

D

W+

Y SIG

P -Field Terminals

to GDS Alarm Unit

U5

LK1

A L

SAFE AREA BOARD EExd BOARD

-

+

-

+

E

SIG

-

+

-

+

E

SIG

JP1 Jumpers BD

JP1 Jumpers AC

3 Wire Sink

100Ω load

100Ω load

3 Wire Source

2 Wire

24vDC

24v DC

Output

WY P

No CNc

NC

C

NO

-+

+

Sensor

Terminal

Sounder

RELAY

BOARD

Sensor

Terminal

EOL

Output Signal

Adjust

Test Points

Alarm Level

Adjust

Alarm

LED

JP2

20mA

4mA

Span

Zero

DPM

E

A

JP1

-+

WYR

-+

J4

JP3

JP4

XY

B

C

D

W+

Y SIG

P -Field Terminals

to GDS Alarm Unit

U5

LK1

A L

T

1A

Relay

RL2

3A

Relay

RL1

24v DC

Output

+

-