Medical Solutions 6000 Series User manual

5640.A

TEMP 2

FLUID WARMER

OPERATORS MANUAL

6000 Series

Medical Solutions, Inc

3901 Centerview Drive, Suite L

Chantilly, VA 20151

800-435-7600

703-834-0039 (Fax)

5640.A

2

TEMP 2Fluid Warmer

Read and understand the Operators Manual before using the TEMP 2FLUID WARMER.

Intended Use

The TEMP 2Fluid Warmer is designed to store, warm and maintain the temperature of

I.V. and irrigation fluid bags or bottles prior to their use.

It is suggested that each facility should contact the fluid manufacturer to obtain the

manufacturer’s specifications for time and temperature for the fluids being

warmed.

Unit Description

The TEMP 2Fluid Warmer is a mobile unit consisting of one cabinet with two internal

shelves. A central temperature controller is used to control the independent heating of

each shelf. The controller will display two temperatures in its display. The top display

number (in red) will indicate the temperature of the top shelf heater plate. The bottom

display number (in green) will indicate the temperature of the bottom shelf heater plate.

During the time that the controller is directing the unit to warm, a light will illuminate in

the upper left corner of the display.

The Documentoris designed to assist in the compliance with JCAHOstandard MM

2.20 and the fluid manufacturer’s specifications for time and temperature.

JCAHO is a registered trademark of the Joint Commission on Accreditation of Healthcare Organizations

Important Labels or Directions

Model/Serial Number label

Caution: Replace fuses as marked.

Caution: Electric shock hazard, do not remove protective panel. Refer servicing to Qualified

Personnel.

Caution: Verify temperature of warmed items before use.

Danger: Risk of explosion if used in the presence of flammable anesthetics.

Warning: Unit not intended for blood or blood products.

Caution: Unit may tip when exposed to a 10-degree angle

5640.A

3

Specifications

Classification Class 1

Dimensions 14” (wide) x 19” (deep) x 33 ¾” (tall)

Capacity Each Shelf

12 – One Liter Bags, or

6 - Three Liter Bags, or

2 - Five Liter Bags

Design Floor model with 2 locking casters

2 non-locking casters

Construction Electro Galvanneal Steel

Temperature Control Specifications

Temperature Setting Range Ambient to 120F

Factory Preset Temperature 104°F

Ambient Operating Conditions

Storage Temperature -40º to +80º C (-40º to +176º F)

Humidity Conditions 0 to 90% up to 40º C non-condensing

Ambient Operating Temperature -10º to +55º C (+14 to 131º F)

Atmospheric Pressure During Minimum of 16.288 in. Hg

Transporting

Electrical Requirements

Power Requirements 110 / 120 VAC, 60 HZ

Fusing 2 each 5 Amps Mains

2 each 3 Amps Heaters

2 each 0.5 Amps Documentor Outlet

Amperage Consumed 4 Amps

Heater Wattage 2 each 250 watt heaters

Thermal Cutout Temperature 140º F Manual Reset (plate temperature)

The TEMP 2System has not been evaluated for compliance for Electro-magnetic compatibility

(EMC).

5640.A

4

Set-up Instructions

1. Remove the TEMP 2from the shipping box; check before operating to ensure that all of the

packaging material and manuals are removed from the cabinet.

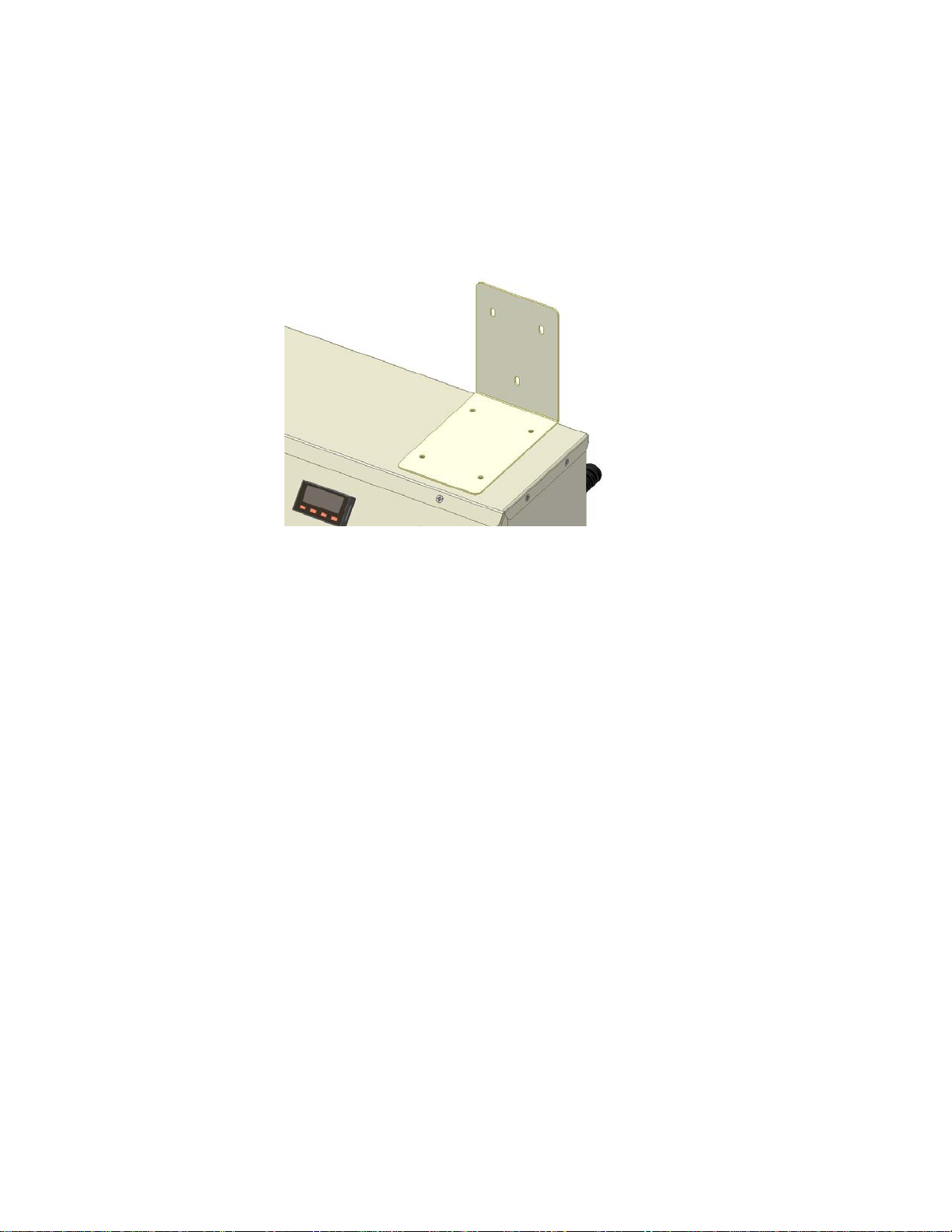

2. Locate The Documentorand remove it from the shipping box. Attach The Documentorto

the TEMP 2following the instructions below.

3. Remove the 4 screws in the top of the TEMP 2. Align the four holes in the TEMP 2

Time/Clock Mounting Bracket and secure using these 4 screws.

4. Remove the 3 screws in the back of The Documentor. Attach The Documentorto the

mounting bracket using these 3 screws.

5. Plug the Documentorinto the Hospital Grade Receptacle located on the back of the TEMP

2.

6. Move the TEMP 2to the desired location, check that power switch is off and plug the

power cord into an approved outlet.

DocumentorInstructions

1) Prior to loading the cabinet with bags, use the Documentorto label the bags with a future

date that follows the manufacturer’s recommendation for the length of time a bag is to be

warmed.

“Future Date Label”

To create a future date label: (See the DocumentorResetting Instructions for adjusting the

clock date)

i) Hold the Label sheet face up.

ii) Line up the arrow on the Documentorunder the words “Remove Fluid By:” on the

label

iii) Push the label sheet towards the arrow until the Documentoris activated.

iv) Place a label on each IV bag for documentation and compliance purposes.

2) Load the labeled bags of solution into the TEMP 2®through the door.

5640.A

5

Operating Instructions

1. Turn the unit on by pressing the power switch. The switch will illuminate when energized.

The controller will perform a self-test then will display the current temperature of the shelf

heater plates. The factory temperature setting is 104 degrees F. To change the temperature

setting, follow the instructions below.

2. The controller will display 2 temperatures in its display. The top display number (in red) will

indicate the temperature of the top shelf heater plate. The bottom display number (in green)

will indicate the temperature of the bottom shelf heater plate. During the time that the

controller is directing the unit to warm a light will illuminate in the upper left corner of the

display.

3. To change the temperature setting, follow the instructions below.

TO CHANGE THE SET POINT

PRESS THE INDEX KEY (LEFT MOST KEY) TO VIEW SET POINT ONE (SP1).

TOP SHELF.

PRESS THE INDEX KEY TWICE (LEFT MOST KEY) TO VIEW SET POINT TWO

(SP2). BOTTOM SHELF.

PRESS THE UP OR DOWN ARROW KEYS TO CHANGE THE SET POINT.

PRESS THE ENTER KEY (RIGHT MOST KEY) TO ACCEPT NEW SET POINT.

PRESS THE INDEX KEY.

3) The shelves will operate independently from each other. When one shelf is not in use

decrease the set point for that shelf (below ambient temperature) to reduce operating cost.

4) Reload the TEMP 2after removing the bag.

NOTES:

The TEMP 2may be left on continually without harm to the unit. It is suggested that each

facility should contact the fluid manufacturer to obtain the manufacturer’s specifications

for time and temperature for the fluids being warmed.

The TEMP 2is not intended for Blood or Blood Products.

In the event that fluid should spill inside the cabinet – unplug the unit to prevent an

electrical shock hazard and refer to step #4 of the Cleaning instructions.

5640.A

6

Documentor™Resetting Instructions

TO CHANGE THE DATE:

1. Plug Documentor™ into an electrical outlet.

2. Press and hold blue RESET button located on the bottom of the Documentor™.

3. While holding down the RESET button, press and hold the • right button on the front

panel.

4. While holding the • right button, release the RESET button.

5. When Prog appears in the display, release the • right button, Prog finishes.

6. Tap the • right button again. The display will show 0000 and the 1st digit will flash.

7. Tap the left button until the number 8 appears then Tap the • right button twice so the

third 0 is flashing.

8. Tap the left button until the number 8 appears in the third position then Tap the

• Right button.

9. Tap the left button until the number 8 appears in the fourth position. The display

should read 8088 then Tap the • right button.

10. When the display flashes all four digits, Tap the • right button

11. The display flashes P1(date).

12. Tap the • right button, the small digits on the left, representing the year, will flash.

13. Tap the left button until the desired number appears then Tap the • right button. The

digits representing the month should flash.

14. Tap the left button until the desired number appears then Tap the • right button. The

digits representing the day should flash.

15. Tap the left button until the desired number appears then Tap the • right button.

16. When the desired date is set Tap the • right button until the display flashes P1 (date).

17. Tap the blue RESET to return to the standard display.

TO CHANGE THE TIME:

18. Follow steps 1-11.

19. Tap the left button, when the display flashes P2 cloc, Tap the • right button.

20. The hour format will flash (12 or 24). If necessary, tap the left button until 24 flashes.

Tap the • right button

21. The hour digits will flash; Tap the left button until the desired setting is achieved. (the

hour must be set in military time 3:05 pm = 15:05) Tap the • right button

22. The minutes digits will flash; Tap the left button until the desired setting is achieved.

Tap the • right button twice.

23. The display will flash P2 Cloc, Press and release the blue RESET button.

5640.A

7

Cleaning Instructions

1. Turn the TEMP 2off and disconnect it from the power source.

2. Wipe down the cabinet with a damp cloth using a general hospital cleaner (i.e. Isopropyl

Alcohol) as needed, following the manufacturers instructions for the cleaner.

3. Avoid contact with the electrical connections and the electrical components.

4. In the event that excessive fluids enter the cabinet, disconnect power to the unit and refer to

qualified service personnel. Remove the service panel (qualified person) and remove any

liquid and/or dry components. Perform any necessary hospital electrical safety checks before

returning the TEMP 2to service.

Trouble Shooting

1. If the unit fails to warm, check the following:

a. Check to see that the TEMP 2is plugged in and the power switch is on.

b. Check the set point setting so that the controller is calling for the unit to operate.

2. If the unit overheats, call Medical Solutions, Inc.

3. Contact Medical Solutions, Inc. for technical assistance at 800-435-7600.

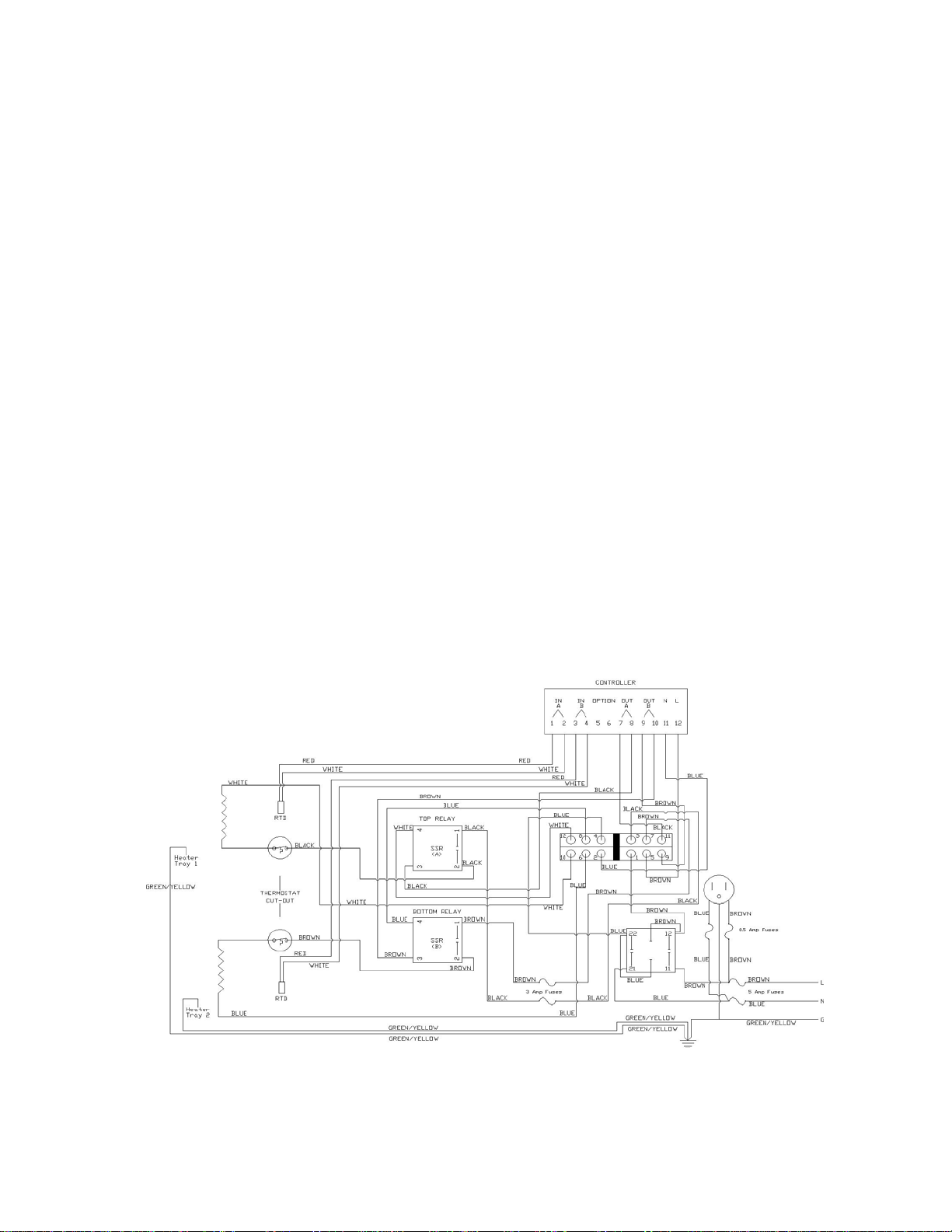

Electrical Schematic

5640.A

8

Service Panel Location and Removal

Remove the top plate to access the electrical compartment.

5640.A

9

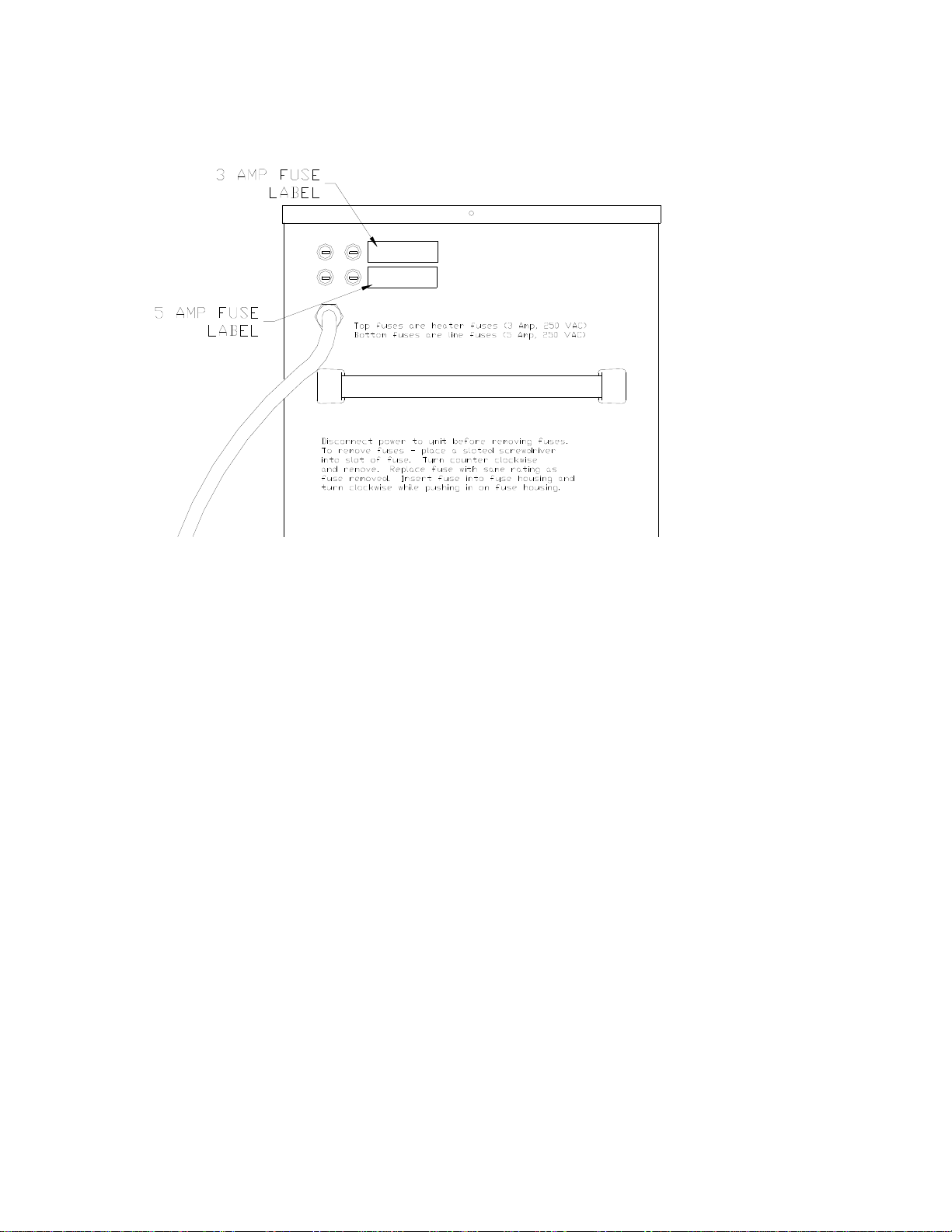

Fuse removal instructions

5640.A

10

Preventive Maintenance Plan

The TEMP 2temperature controller should be verified every five (5) years. Medical Solutions,

Inc. requires the use of the following items to accurately measure the bag temperature for

verification.

Fluke 51II Digital Thermometer

6” Long .093” Diameter Type T Needle Thermocouple

(with the Thermocouple calibrated to the Thermometer)

With the outer wrap still on a three liter IV fluid bag, pierce the bag through the needle injection

port on the bag with an 18ga needle to make it easier to insert the Thermocouple. Insert the

Thermocouple through the pierced needle injection port. Place the fluid bag onto the center of

the bottom shelf. Load the top shelf with an additional three liter IV fluid bag. Feed the

Thermocouple wire attached to the Fluke Thermometer out of the cabinet positioning the probe

in the center of the bag. Close the door.

Turn the power on to the TEMP 2. Adjust the temperature controller set point temperature to

104F for both shelves. Allow the unit to operate for a minimum of 6 hours before verifying the

temperatures. After the allotted time, compare the temperature reading on the controller to the

temperature reading on the Fluke Thermometer, the two temperatures should be within two

degrees Fahrenheit of each other. If the two temperature readings are within two degrees

Fahrenheit of each other, the temperature controller has been verified. If they are not, please

contact Medical Solutions, Inc. at 800-435-7600.

Repeat the calibration process for the top shelf of the TEMP 2.

If a Fluke Digital Thermometer is not available an alternative method to verify the controller is

to use a glass laboratory thermometer. Place 1 three liter IV bag onto the center of each of the

shelves. Turn the power on and adjust the temperature controller set point temperature to 104F

for both shelves. Allow the unit to operate for a minimum of 6 hours before verifying the

temperatures. Remove the bag and place the end of the glass thermometer on the top and in the

middle of the bag. Fold the bag over the thermometer and hold for approximately two minutes

or until the mercury stops moving. If the reading on the thermometer is between 100.4F and

105.8F the temperature controller has been verified. If they are not, please contact Medical

Solutions, Inc. at 800-435-7600.

Repeat the calibration process for the other shelf of the TEMP 2.

5640.A

11

LIMITED WARRANTY

For one year from the date of shipment to the Buyer (the “Warranty Period”), MSI warrants that the Equipment

provided to the Buyer shall be free from defects in workmanship and material. In the event of a breach of this

warranty during the Warranty Period, MSI shall, at its option, repair or replace the Equipment, and Buyer’s remedies

are limited to such repair or replacement. MSI DISCLAIMS ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT SHALL MSI BE LIABLE FOR DIRECT, INDIRECT, PUNITIVE, ECONOMIC,

CONSEQUENTIAL OR OTHER DAMAGES, INCLUDING BUT NOT LIMITED TO LOST PROFITS.

To enable MSI to administer the Warranty properly, Buyer shall (1) register the Warranty using the form provided

below, and (2) promptly notify MSI of any claim hereunder. As a condition to the Warranty, Buyer shall use and

maintain the Equipment according to the provisions of the Operator’s service manual.

IMPORTANT: THIS IS YOUR TEMP 2®WARRANTY REGISTRATION

Please register your warranty by filling out this page and send it to Medical

Solutions, Inc. within 30 days of purchase.

A. Hospital Name:

B. Mailing Address:

C. City: State: Zip Code:

D. Contact Name:

E. Date Purchased:

F. Serial Number:

G. Department Purchased For:

COPY THIS PAGE AND MAIL TO:

Medical Solutions, Inc.

3901 Centerview Drive, Suite L

Chantilly, Virginia 20151

Fax number 703-834-0039

This manual suits for next models

1

Table of contents

Other Medical Solutions Medical Equipment manuals

Popular Medical Equipment manuals by other brands

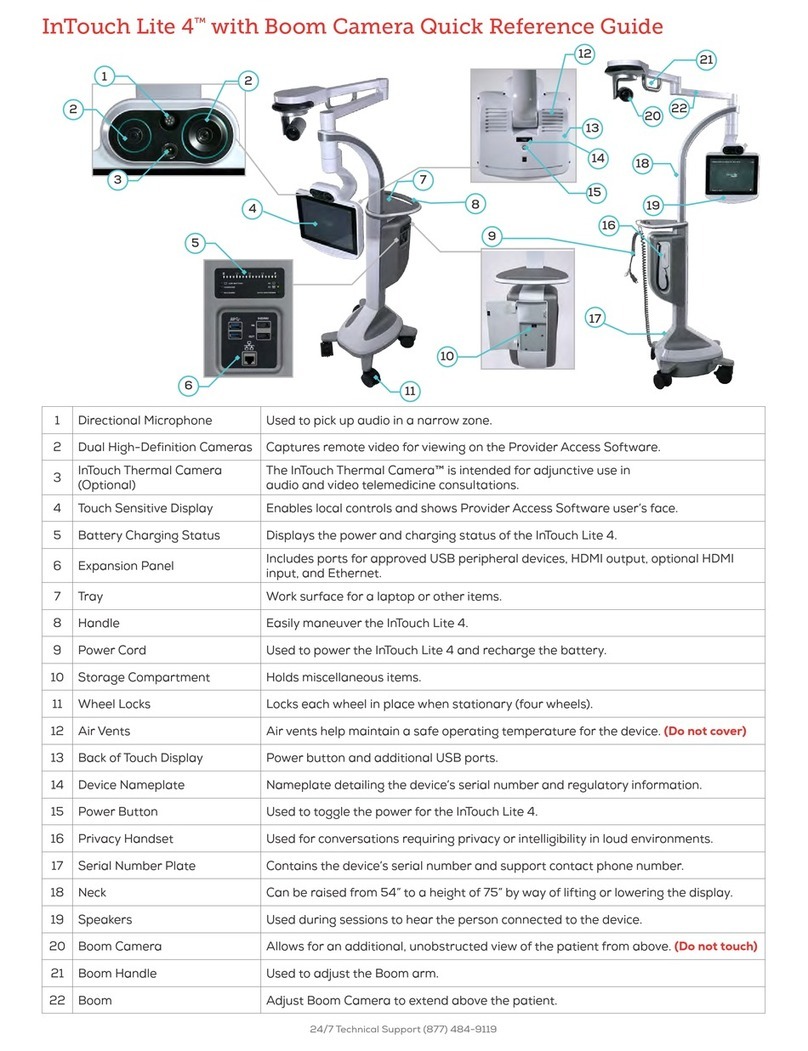

InTouch Health

InTouch Health InTouch Lite 4 Quick reference guide

burmeier

burmeier ARMINIA II instruction manual

Optopol

Optopol REVO nx user manual

ResMed

ResMed Ultra Mirage Clinicians Guide

Olympus

Olympus BX3-SSU instructions

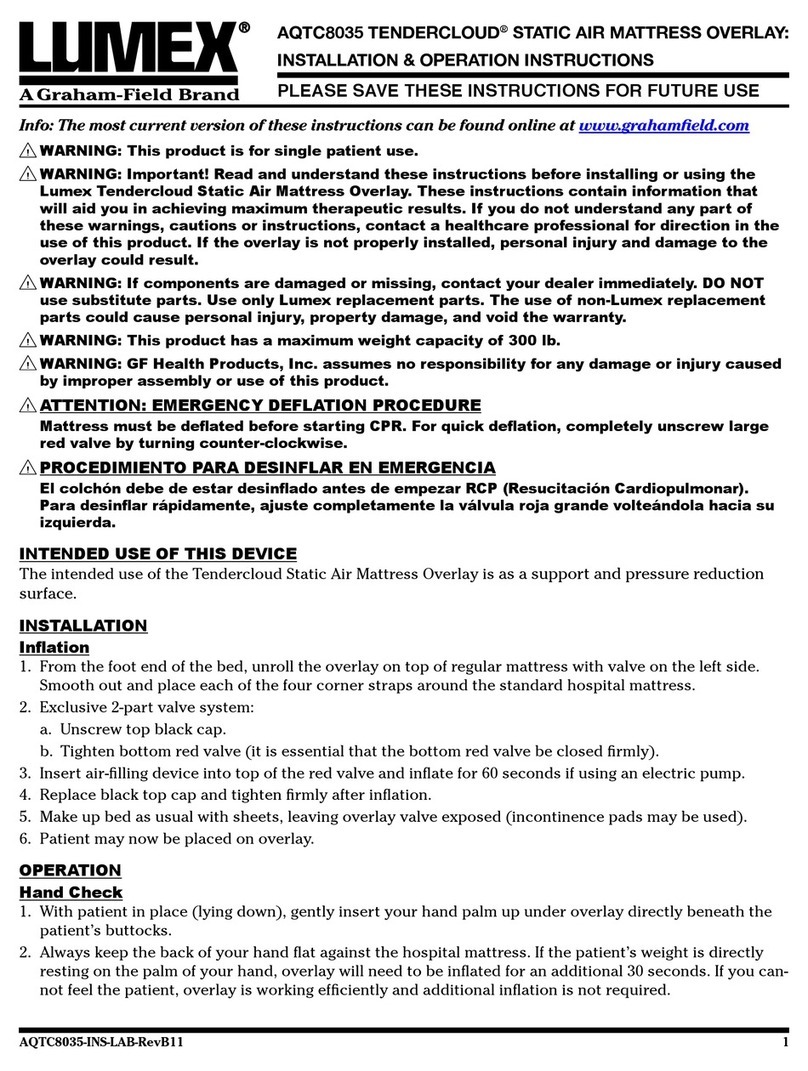

Graham Field

Graham Field LUMEX TENDERCLOUD AQTC8035 Installation & operation instructions

Promeba

Promeba PB-410 Series user guide

Otto Bock

Otto Bock AxonArm Ergo 12K501 Instructions for use

Gentherm

Gentherm Electri-Cool II Operation and technical manual

Mirion Technologies

Mirion Technologies BIODEX ECONO 058-726 Operation manual

NanoVibronix

NanoVibronix PAINSHIELD MD user manual

Aspira

Aspira P1211EM Instructions for use