Contents

GFK-1322A vii

Chapter 1 Overview.......................................................................................................... 1-1

LONWORKS Network Overview ....................................................................................1-3

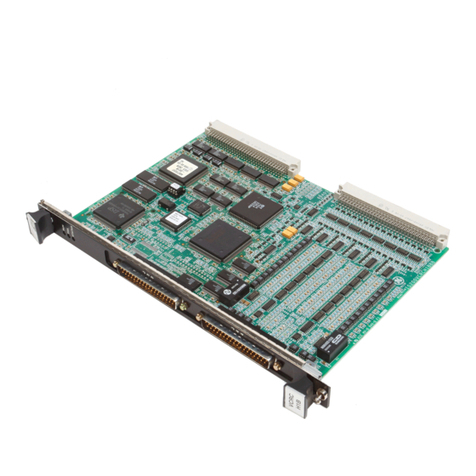

Bus Interface Module Overview ....................................................................................1-5

Controls and Indicators...........................................................................................1-6

Connectors .............................................................................................................1-7

Functional Characteristics.......................................................................................1-8

Configuration .........................................................................................................1-8

Diagnostics.............................................................................................................1-8

What You Need to Operate the Bus Interface Module....................................................1-9

Chapter 2 Operation......................................................................................................... 2-1

Overview of Operation..................................................................................................2-2

Architecture............................................................................................................2-2

Operating Modes ....................................................................................................2-4

Powerup Sequence........................................................................................................2-4

Sweep Operation...........................................................................................................2-6

Chapter 3 Hardware Installation..................................................................................... 3-1

Rack Location for the Bus Interface Module..................................................................3-2

Module Installation and Removal ..................................................................................3-3

Module Installation.................................................................................................3-3

Module Removal.....................................................................................................3-3

Network Installation......................................................................................................3-4

Network Wiring Guidelines.....................................................................................3-4

Terminating the Network ........................................................................................3-4

Connecting a Programmer.............................................................................................3-6

Chapter 4 Configuring the LBIM.................................................................................... 4-1

Overview......................................................................................................................4-2

Using the LBIM Configuration Software.......................................................................4-4

Installation and Startup...........................................................................................4-4

Editing a Configuration...........................................................................................4-5

Module Configuration...........................................................................................4-6

Reference Configuration.....................................................................................4-11

Field Definitions..........................................................................................4-11

Defining Variables.............................................................................................. 4-13

Menu Commands................................................................................................4-18

File Menu ....................................................................................................4-20

Tools Menu..................................................................................................4-20

Binding Network Variables .........................................................................................4-23