1-3

with the NEC or Canadian Electrical Code. The

connection shall be made by a UL listed or CSA

certified closed-loop terminal connector sized for

the wire gauge involved. The connector is to be

fixed using the crimp tool specified by the

connector manufacturer.

Do not perform a megger test

between the Drive terminals or on the control

circuit terminals.

The Drives are an IGBT drive

which develops an adjustable frequency via pulse

width modulation. While this does not present a

problem on 200-240 VAC applications, it may on

380-480 VAC applications. When using the

Drives on 380-480 VAC, get the motor

manufacturer's approval that his insulation system

can withstand the voltage spikes (up to twice the

dc bus voltage 2 x 621 VDC for a 480 VAC power

source of the Drive, in conjunction with the long

motor cable lengths). If the insulation system

does not meet this limit, utilize a RLC filter.

Because the ambient

temperature greatly affects Drive life and

reliability, do not install the Drive in any location

that exceeds the allowable temperature. Leave

the ventilation covers attached for temperatures

of 40 degrees C or below, and remove the

ventilation port side and top covers for

temperatures of between 40 (104° F) and 50

(122° F) degrees C. If the covers need to be

removed, another type of enclosure may be

required for safety purposes.

If the Drive’s Fault Alarm is

activated, consult the TROUBLESHOOTING

section of this instruction book, and after

correcting the problem, resume operation. Do

not reset the alarm automatically by external

sequence, etc.

Be sure to remove the desic-

cant packet(s) when unpacking the Drive. (If not

removed these packets may become lodged in

the fan or air passages and cause the Drive to

overheat.)

CAUTIONS

This product is suitable for use

on a circuit capable of delivering not more than

1,000 (1HP or less) or 5,000 (2 HP or more) rms

symmetrical amperes.

AC input fuses to be customer supplied and may

be branch circuit protection fused. The maximum

allowance fuse ratings per TABLE 4.

Do not connect power supply

voltage that exceeds the standard specified

voltage permissible. If excessive voltage is

applied to the Drive, damage to the internal

components will result.

Do not connect power supply to

the output terminals (U, V, W). Connect power

supply only to the power terminals (L1, L2, L3).

Do not connect power supply to

the breaking resistor connection terminals (P (+),

DB). Never short-circuit between P (+) – DB

terminals, and do not connect any resistance with

an ohm and/or wattage value less than standard

application breaking resistor.

Do not connect a power supply

to the control circuit terminals (except 30A, B, C,

maximum rating 250 volts, 0.3A ac/dc).

For RUN and STOP, use the

FWD-CM (forward) and REV-CM (reverse)

terminals. Do not use a contactor (ON/OFF)

installed on the line side of the Drive for RUN and

STOP.

Do not use a switch on the

output side of the Drive for ON/OFF operation.

Do not connect power factor

correcting capacitors on the output side of the

Drive.

Do not operate the Drive

without the ground wire connected. The motor

chassis should be grounded to earth through a

ground lead separate from all other equipment

ground leads to prevent noise coupling. The

grounding connector shall be sized in accordance

1-4

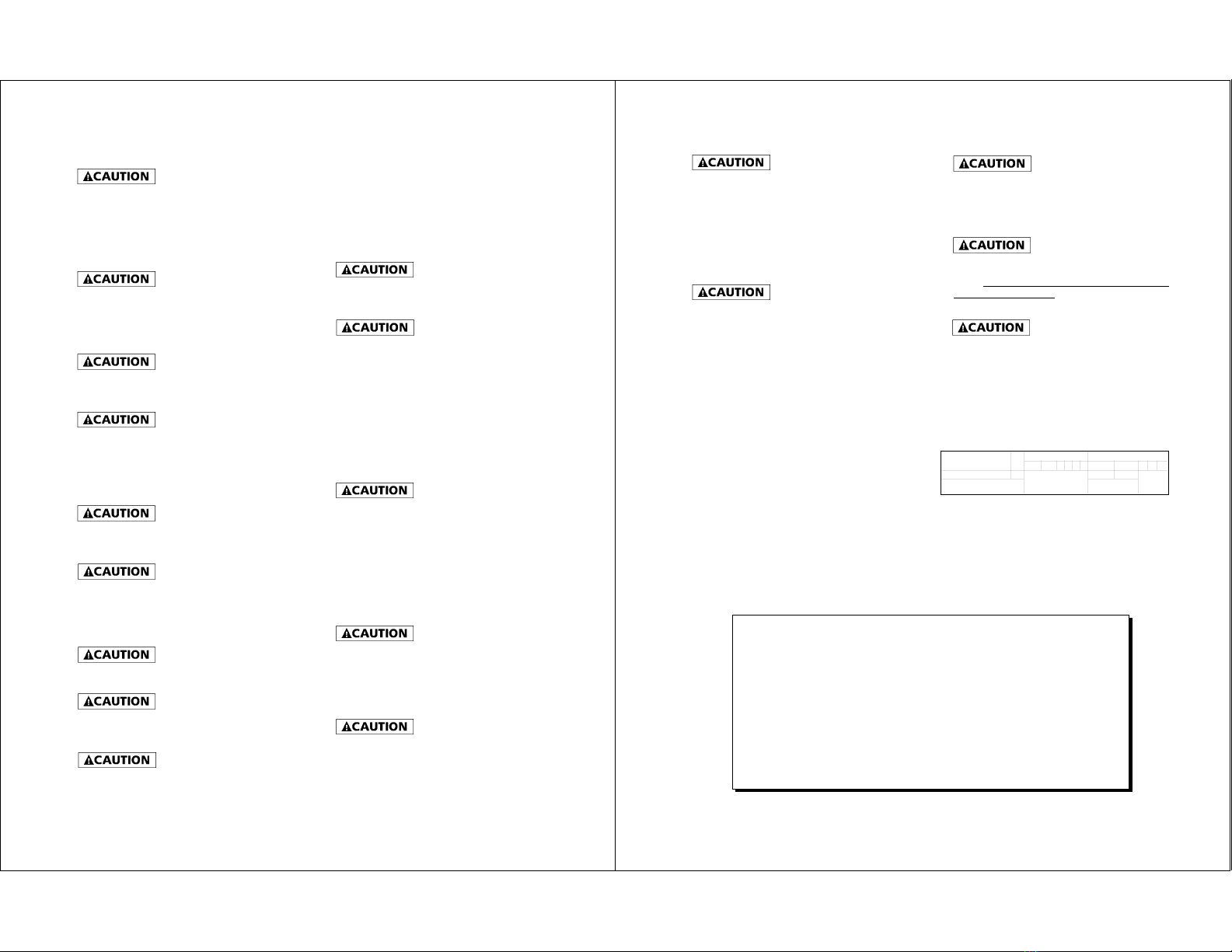

UL/CSA Drive Caution Label

Use 60/70°C copper wire only. Use Class 1 wire only.

Suitable for use on a circuit capable of delivering not more than 1,000

(1HP or less) or 5,000 (2 HP or more) rms symmetrical amperes.

WARNING: HAZARD OF ELECTRICAL SHOCK. DISCONNECT INCOMING

POWER BEFORE WORKING ON THIS CONTROL.

ADVERTISSEMENT: RISQUE DE CHOC ELECTRIQUE COUPER

L'ALIMENTATION AVANT LE DEPANNAGE DE CETTE COMMANDE.

CAUTION: DANGEROUS VOLTAGE EXIST UNTIL CHARGE "CRG" LIGHT IS OFF.

ATTENTION: PRESENCE DE TENSIONS DANGEREUSES TANT QUE LE

VOYANT N'EST PAS ETEINT.

WARNING: MORE THAN ONE LIVE CIRCUIT. SEE DIAGRAM.*

AVERTISSEMENT: CET EQUIPEMENT RENFERME PLUSIEURS CIRCUITS

SOUS TENSION. VOIR LE SCHEMA. SA523154-01

*See diagram on page 4-6.

CAUTIONS (continued)

NOTE:

① When terminal operation mode (Function code

F_02 setting is 1) - RUN and STOP are being

controlled byamaintainedcontact(e.g.,selector

switch, toggle switch, etc.) which is connected

between the terminal CM and FWD or REV:

•Closing/openingthemaintainedcontactstarts/

stops the Drive.

➁ Function code F_02 setting can be changed only

when connection between the terminals CM and

FWD or REV is open. (i.e. STOP MODE).

Drive ships with shorting bar between

terminals FWD-CM.

NOTES

AC induction motors require

that they be sized based on the applications speed

range and associated torque requirements for the

motor-Drive system; this is to avoid excessive

motor heating. Observe motor manufacturer's

recommendations when operating any ac induction

motor with the Drive. Also observe motor

manufacturer's recommended voltage/torque boost

at lower operating frequencies.

The available power source con-

nected to the Drive is not to exceed 500KVA. If the

ac power source is greater than 500KVA and the

Drive's rated (HP) is less than 10% of the power

source'sKVA;aclinereactorswillhavetobeinstalled

in L1, L2 & L3 power leads of the Drive.

The Drive must be mounted on

a building or enclosure wall that is constructed of

heat resistant material. While the Drive is operat-

ing, the temperature of the Drive's cooling fins can

rise to a temperature of 90°C (194°F.)

If the Drive protective function

is activated, consult Section 8 "Troubleshooting",

and after correcting the problem, resume opera-

tion. Do not reset the alarm automatically by

external sequence, etc.

Be sure to provide fuses, as

specifiedon"ApplicationofWiringAndEquipment"

in Section 4, on line terminals of Drive. Provide

power line disconnect or contactor as needed.

➂ Total wiring between the Drive and the motor must

not exceed the length shown below.

➃ Error in current detection may increase when;

a) A specially designed motor is used.

b)A Drive'scapacity is2 Hpratings orgreaterthan

the motor capacity.

Function 200V Series 400V Series

F_12 data

Hp 1/4 1/21235 1/2 1 2 3 5

F_12 = 0, 1, 2 or 3 538 ft. 754 ft.

F_12 = 4 – 15 1076 ft. 213 ft. 1076 ft.