– 3 –

Table of Contents

Safety Information..........................................................................................................................................................................2

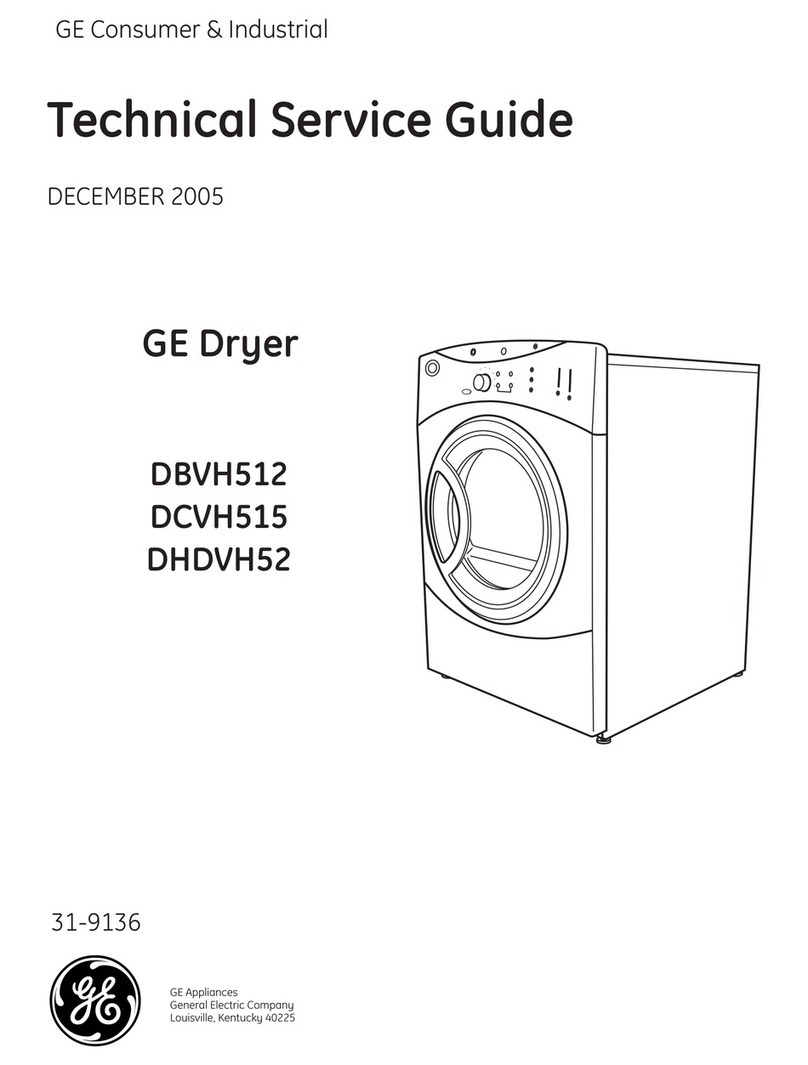

Nomenclature...................................................................................................................................................................................5

Model Number..........................................................................................................................................................................5

Introduction........................................................................................................................................................................................6

Control Features.............................................................................................................................................................................7

Operating Instructions..................................................................................................................................................................8

Operating Instructions (continued).........................................................................................................................................9

Dryer Features..................................................................................................................................................................................12

Communication................................................................................................................................................................................13

Reversing the Door Swing...........................................................................................................................................................14

Component Locator Views..........................................................................................................................................................16

Electric Model ...........................................................................................................................................................................16

Gas Model ..................................................................................................................................................................................17

Control Board Connector Locator View................................................................................................................................18

Dryer Components..........................................................................................................................................................................19

Control Panel...........................................................................................................................................................................19

Control Board Assembly ...................................................................................................................................................20

Top Panel..................................................................................................................................................................................21

Front Panel...............................................................................................................................................................................21

Door Switch.............................................................................................................................................................................22

LED Drum Light......................................................................................................................................................................22

Front Bulkhead ......................................................................................................................................................................22

Drive Belt and Drum............................................................................................................................................................23

Drum Rollers............................................................................................................................................................................24

Moisture Sensor ....................................................................................................................................................................25

Belt Switch................................................................................................................................................................................26

Blower Wheel..........................................................................................................................................................................26

Drum Motor.............................................................................................................................................................................27

Long Vent Motor....................................................................................................................................................................28

Heater Assembly...................................................................................................................................................................28

Burner Assembly and Gas Conversion.......................................................................................................................29

Gas Valve .................................................................................................................................................................................29