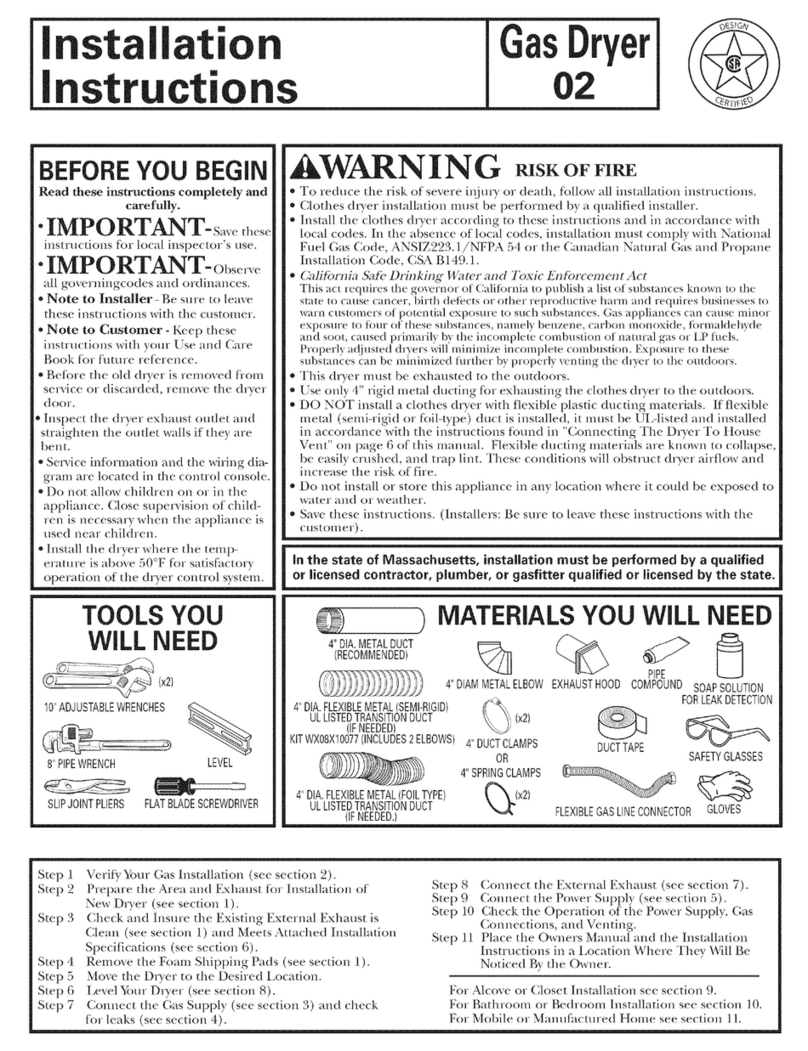

Installation Instructions

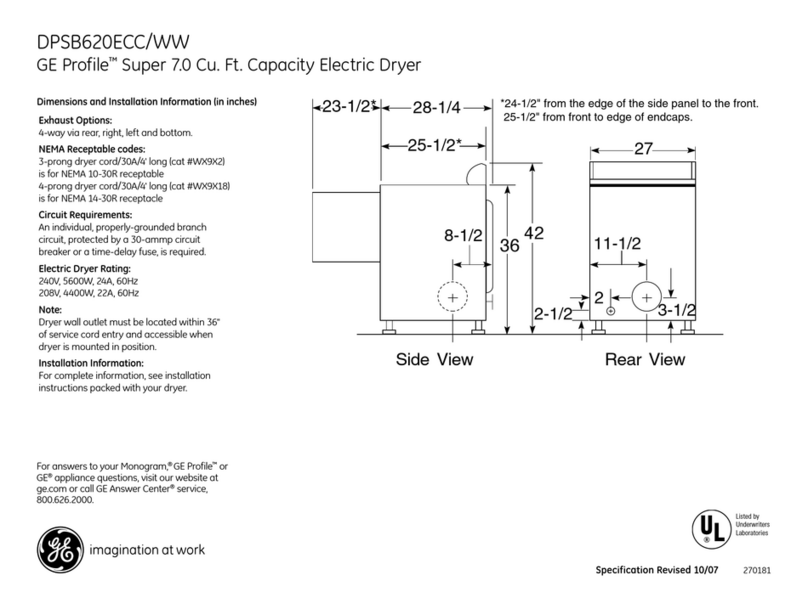

CONNECTING DRYER USING 4-WIRE CONNECTION

• Remove the cover near the power cord entry hole.

• Install 3/4" ULrecognized strain relief to power cord entry

hole. Bring power cord through strain relief.

• Connect two HOT lines to outer screws (L1 & L2)of

terminal block.

• Connect NEUTRAL(white) line to center screw (N)of

terminal block.

REMOVE GROUND STRAPAND DISCARD

KEEP GREEN GROUND SCREW

GREEN

0

strain relief

bracket

3/4", UL

strain relief

• Attach ground wire of the power cord with the green

ground screw (hole above strain relief bracket).

• Tighten all terminal block screws securely.

• Properly secure power supply cable to strain relief.

• Reinstall the cover.

_ZIWARNING: Onlg a 4-conductor cord shall

be used when theappliance is installed in a location

where grounding through theneutral conductor is

prohibited. Grounding through the neutral isprohibited

for the new branch-circuit installations, mobile homes,

recreational vehicles, and areas where local codes

prohibit groundingthrough the neutral conduction.

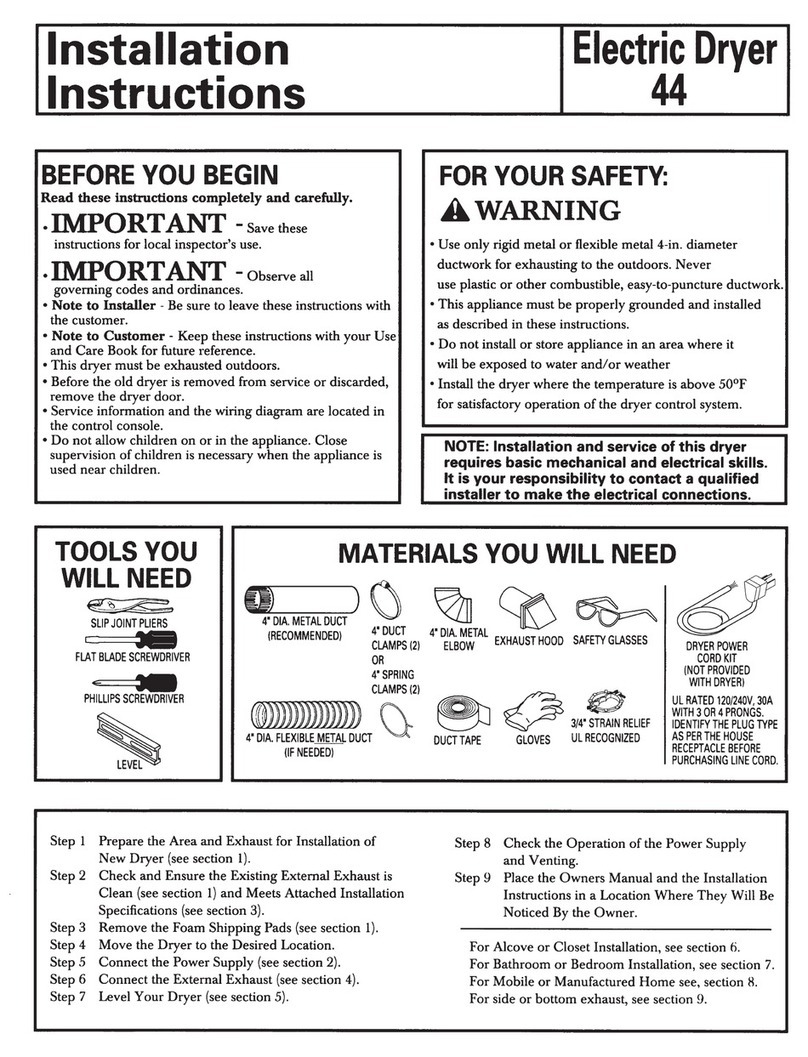

4 #10 AWG MINIMUM COPPER CONDUCTORS OR 120/240V 30A

POWER SUPPLY CORD KIT MARKED FOR USE WITH DRYERS&

PROVIDED WITH CLOSED LOOP OR SPADE TERMINALS WITH

UPTURNED ENDS (NOT SUPPLIED).

I I

OFTHETERMINAL BLOCK.

EXHAUST INFORMATION

WARNING -TO REDUCE THE RISK

OF FIRE OR PERSONAL INJURY:

• This clothes dryer must be exhausted to the outdoors.

• Use only 4" rigid metal ducting for home exhaust duct.

• Use only 4" rigid metal or UL-listed flexible metal (semi-

rigid or foil-type) duct to connect the dryer to the home

exhaust duct. It must be installed in accordance with

these instructions and local codes.

• Do not terminate exhaust in a chimney, a wall, a ceiling,

gas vent, crawl space, attic, under an enclosed floor,

or in any other concealed space of a building. The

accumulated lint could create a potential fire hazard.

• Never terminate the exhaust into a common duct with

a kitchen exhaust system. A combination of grease and

lint creates a potential fire hazard.

• Do not use duct longer than specified in the exhaust

length table. Longer ducts can accumulate lint, creating

a potential fire hazard.

• Never install a screen in or over the exhaust duct. This

will cause lint to accumulate, creating a potential fire

hazard.

• Do not assemble ductwork with any fasteners that

extend into the duct. These fasteners can accumulate

lint, creating a potential fire hazard.

• Do not obstruct incoming or exhausted air.

• Provide an access for inspection and cleaning of the

exhaust system, especially at turns and joints. Exhaust

systemshallbe inspectedand cleanedat leastoncea year.

• In special installations, it may be necessary to connect

the dryer to the house vent using a flexible metal (foil-

type) duct. A UL-listed flexible metal (foil-type) duct

may be used ONLYin installations where rigid metal or

flexible metal (semi-rigid) ducting cannot be used AND

where a 4" diameter can be maintained throughout

the entire length of the transition duct. In Canada and

in the United States, only the flexible metal (foil-type)

ducts that comply with the "Outline for Clothes Dryer

Transition Duct Subject 2158A" shall be used.

_ZlLWARNING- BEFOREPERFORM,NGTH,S

EXHAUSTINSTALLATION,BESURETO DISCONNECTTHE

DRYERFROMITSELECTRICALSUPPLY.PROTECTYOUR

HANDSAND ARMSFROMSHARPEDGESWHENWORKING

INSIDETHECABINET.BESURETOWEARGLOVES.

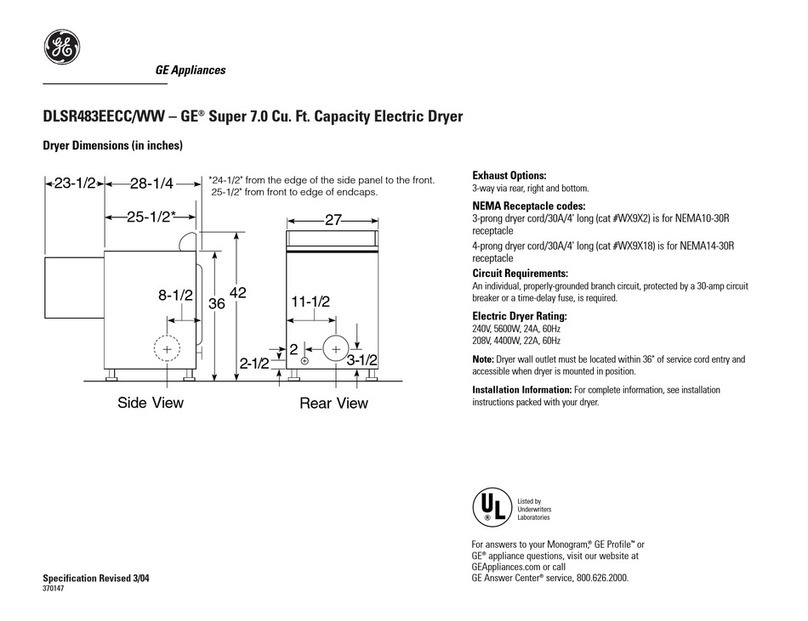

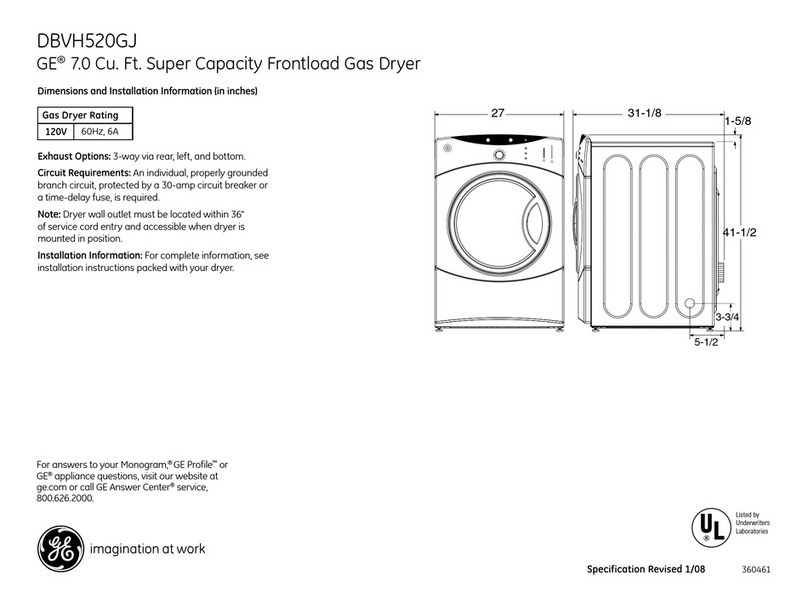

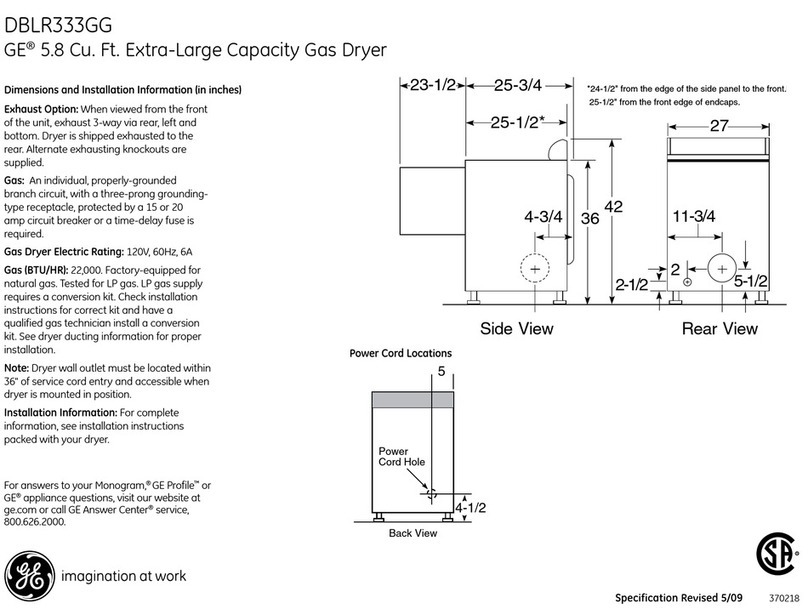

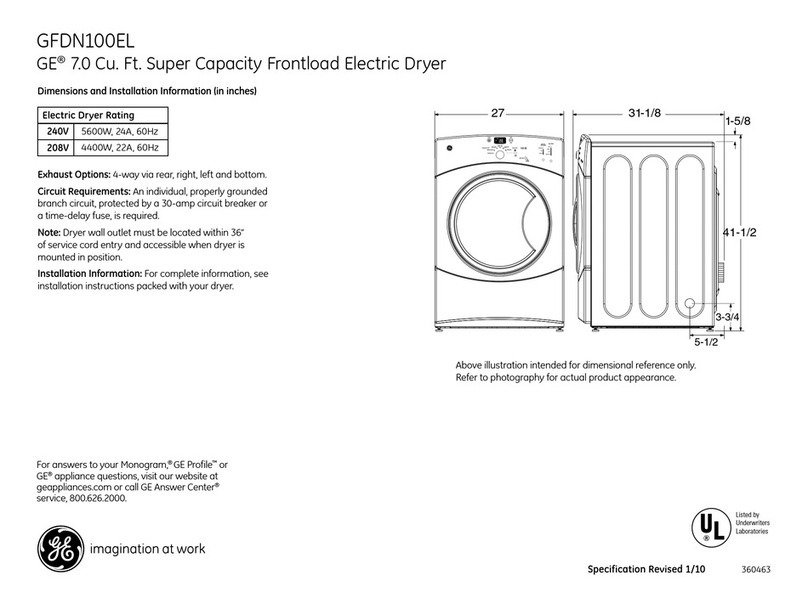

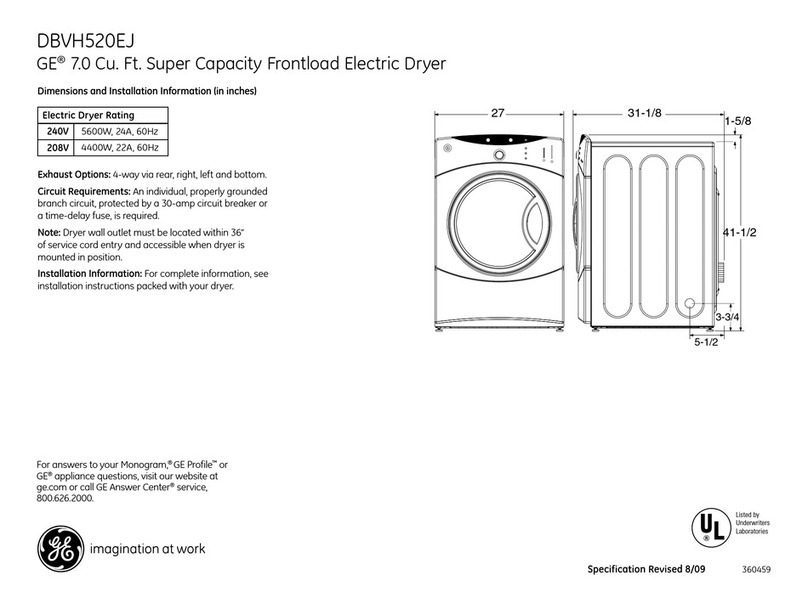

REAR EXHAUST LOCATION

The dryers comes ready for rear exhausting. Units have

separate exhausts. ; NOTE:Add

to vertical

dimension

the distance

between

cabinet

bottom to

floor surface.

13/4"_

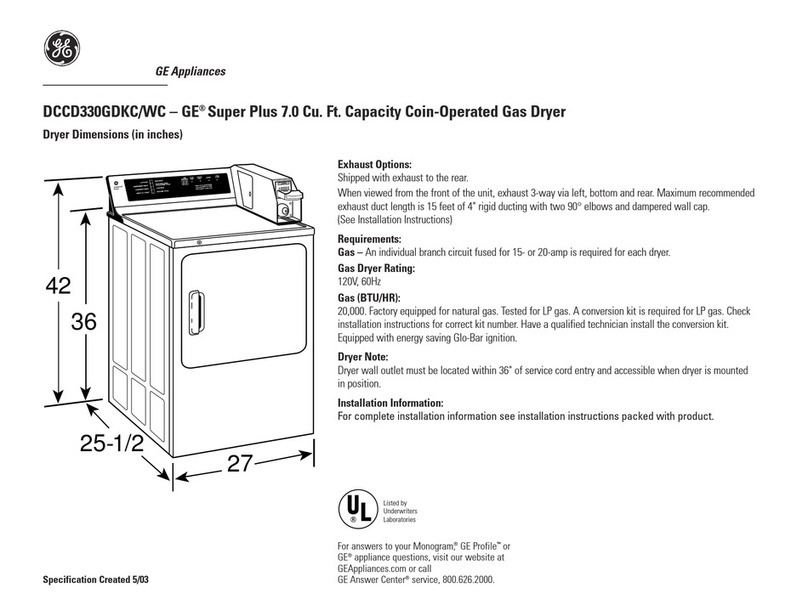

EXHAUST LENGTH

The MAXIMUM ALLOWABLEduct length and number of

bends of the exhaust system depends upon the type of

duct, number of turns, the type of exhaust hood (wall cap),

and all conditions noted below. The maximum duct length

for rigid metal duct is shown in the table below.

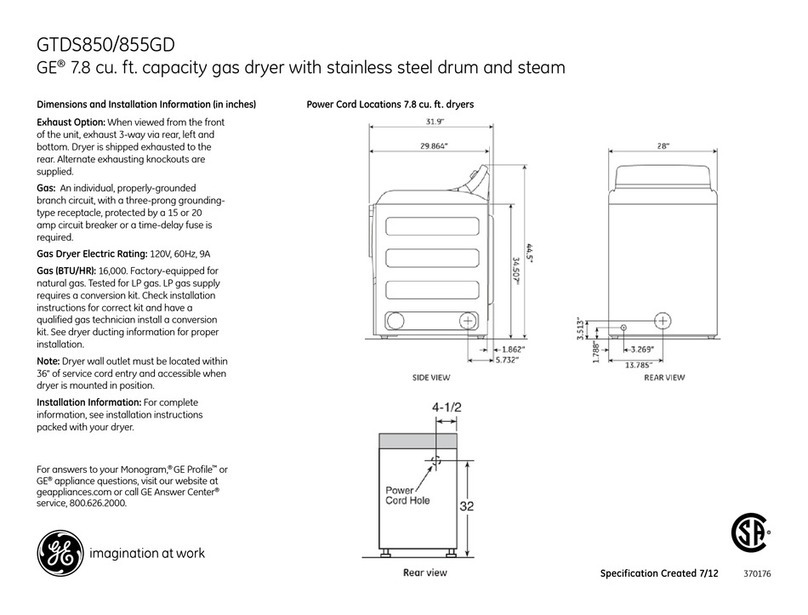

RECOMMENDEDMAXIMUMLENGTH

ExhaustHoodTypes

Useonlyfor short

Recommended run installations

4" DIA.

I

_I 4" _ _ 14 2-1/2"

1'4o.of 90° Elbows Rigid IVletal Rigid IVletal

0 45 ft. 3O ft.

1 35 ft. 20 ft.

2 25 ft. 10 ft.

More than two 90°turns is not recommended. Thetotal

length of flexible metal duct shall not exceed 8 ft. (2.4m). In

Canada and in the United States,the required exhaust duct

diameter is4" (102 mm).