8

DRYER OPERATION

The dryer drum rotates clockwise at 48 – 54 rpm

as viewed from front. On electric models, air is

drawn into the heater housing and across the

open coils of the electric heater. On gas models,

air is drawn into the combustion chamber and over

the burner flame. The air is then pulled through

the tumbling clothes, picking up moisture and lint.

Lint is filtered out as air passes from the drum,

across the filter screen and into the blower duct,

where it is discharged out the vent. The bias

control thermostat, according to the setting of the

fabric selector switch, controls the air temperature.

The length of the drying cycle is controlled by the

number of minutes selected on the timer or auto-

matically controlled by the timer, in conjunction

with the thermostat, for the type of fabric selected

(automatic dry cycles).

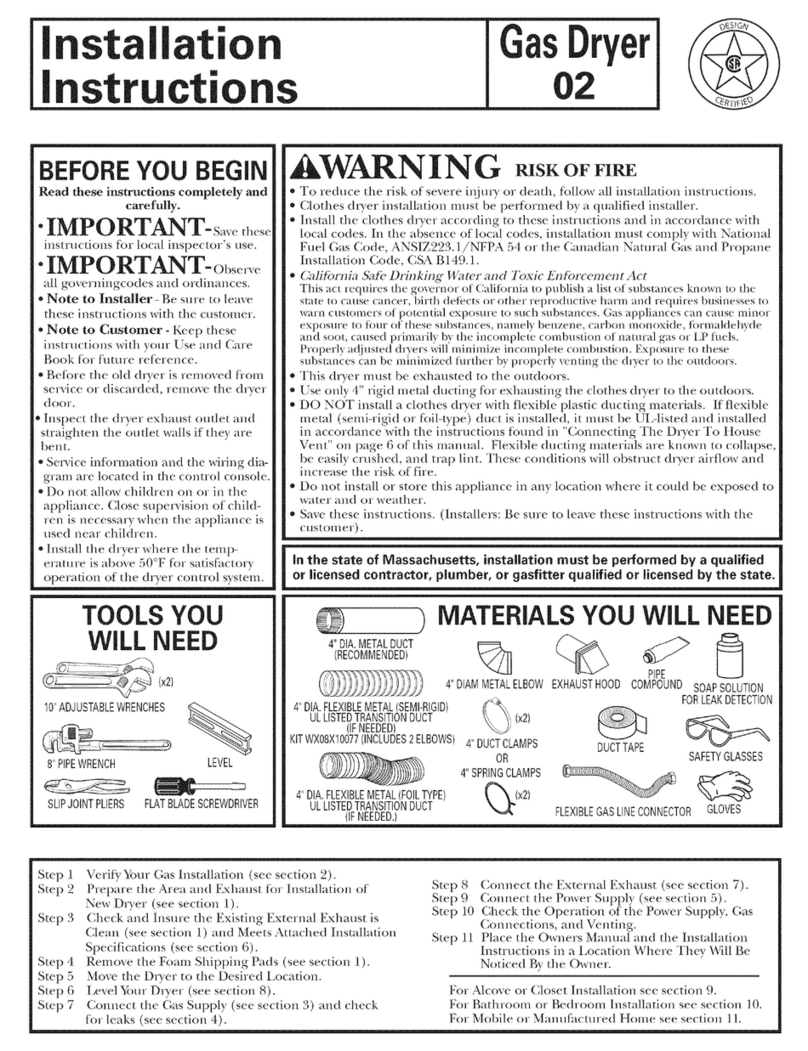

ACCESSINGTHE DRYER COMPONENTS

Top Panel Removal

The top panel is held in place by two spring clips

locatedat the front ofthe dryerandtwotabs located

at the back. To release the clips, use a stiff putty

knife inserted between the top and front panel at

the locations shown at right. Holding the putty knife

in a horizontal position, push in on one spring clip to

release that edge of the top. Repeat with the other

clip, lift the top at the front and disengage it from the

tabs at the rear.

Front Panel Removal

The remove the front panel, disconnect power and

remove the top panel. Once the top panel is off,

remove the two Phillips screws, one on each side,

located on the top inside edge of the front panel.

Disconnect the two wires from the door switch.

2 Phillips screws

Starting at the top edge, pull the front panel forward.

3guideclips align the front panel tothesides. Once

the clips are released, lift the front panel to remove.

Guide Clips

Air Duct

Front Panel Air Duct

The front panel air duct is glued to the front panel.

Should the air duct need to be replaced, an air duct

seal will also be required. The foam air duct seal is

gluded to the air duct and seals between the duct

and the opening for the blower wheel on the blower

housing. To replace the air duct or install a replace-

ment front panel, remove the front panel, remove

the lint filter, remove the 2 Phillips screws from the

lint trap cover and remove the lint trap cover. Using

a sharp knife, cut the adhesive between the air duct

and the front panel. If reinstalling the original front

panel, use a putty knife to remove as much of the

old adhesive as possible. Apply adhesive along the

edgeoftheairductandpositionitonthefrontpanel.

Air Duct Seal

Commerical Dryer

PERMAMENTPRESS

HIGHHEA

TWITH

COOLDOWNCYCLE

LOWHEA

T

RESUMEHEA

T

1.

2.

Addcoinsforextradrytime.

Add coins for extra dry time.

Ifdryerdoorisopenedduring

If dryer door is opened during

cycle,pushPRESSTOST

ART

buttonagaintoresumecycle.

button again to resume cycle.

SYNTHETICKNITS

PRESSTOST

ART

OPERA

TING

COTTONS

HEA

TW

ASH