– 3 –

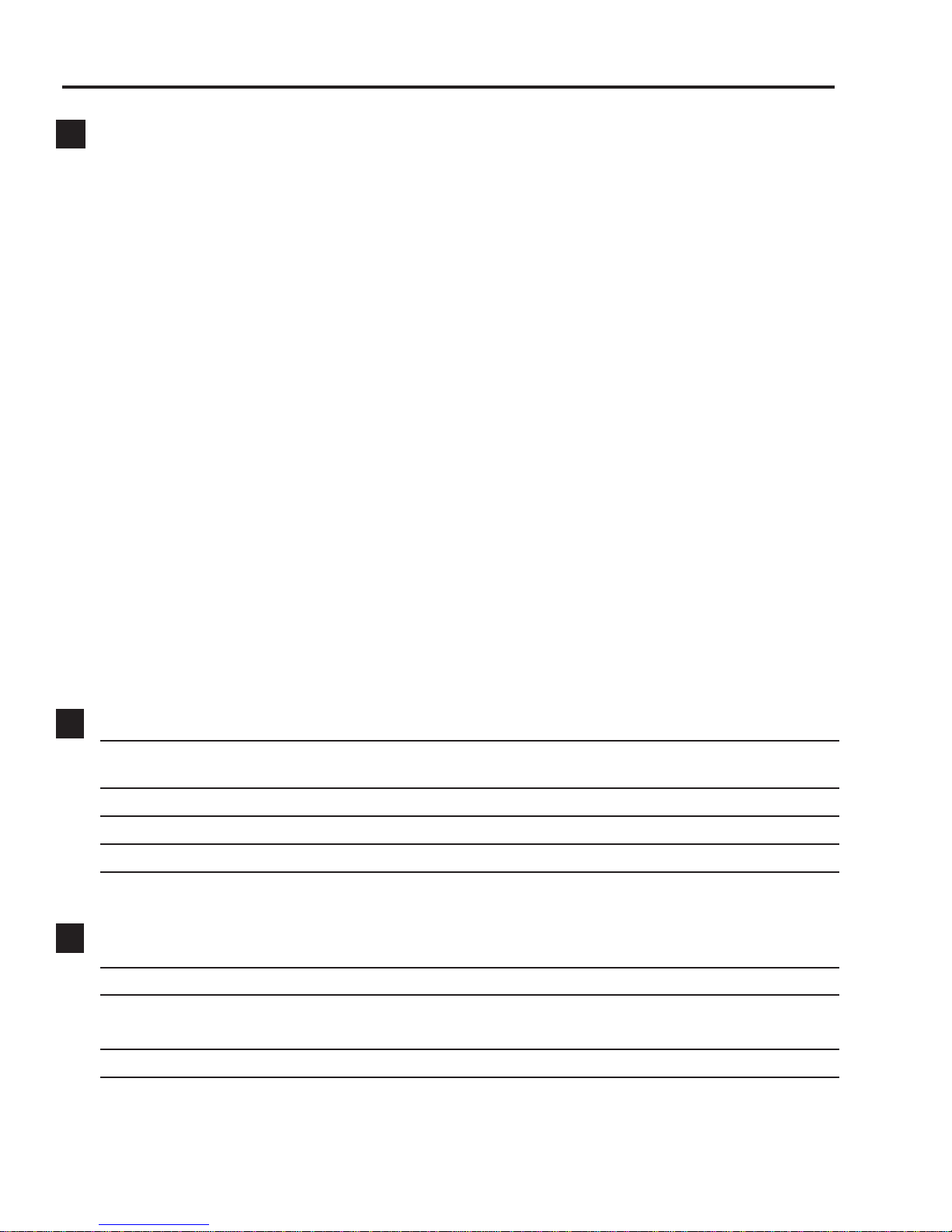

Table of Contents

Air Duct Assembly ............................................................................................................................................................21

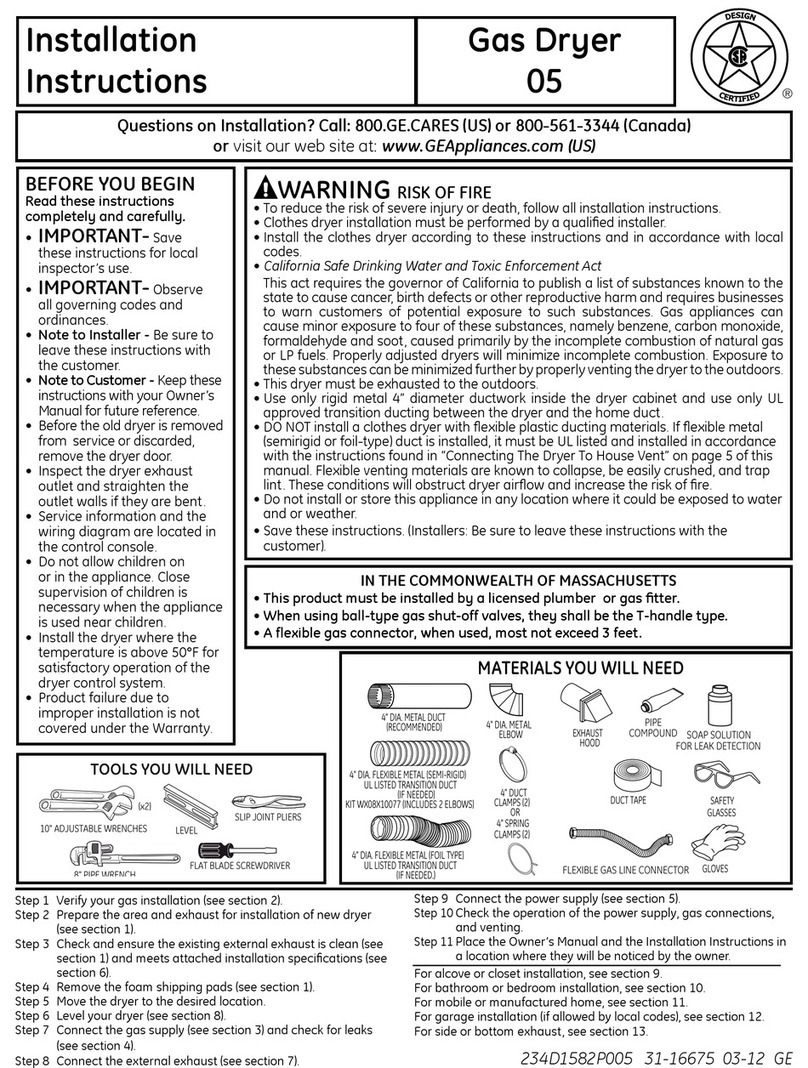

Airflow ....................................................................................................................................................................................14

Blower Wheel......................................................................................................................................................................28

Burner Assembly and LP Conversion......................................................................................................................31

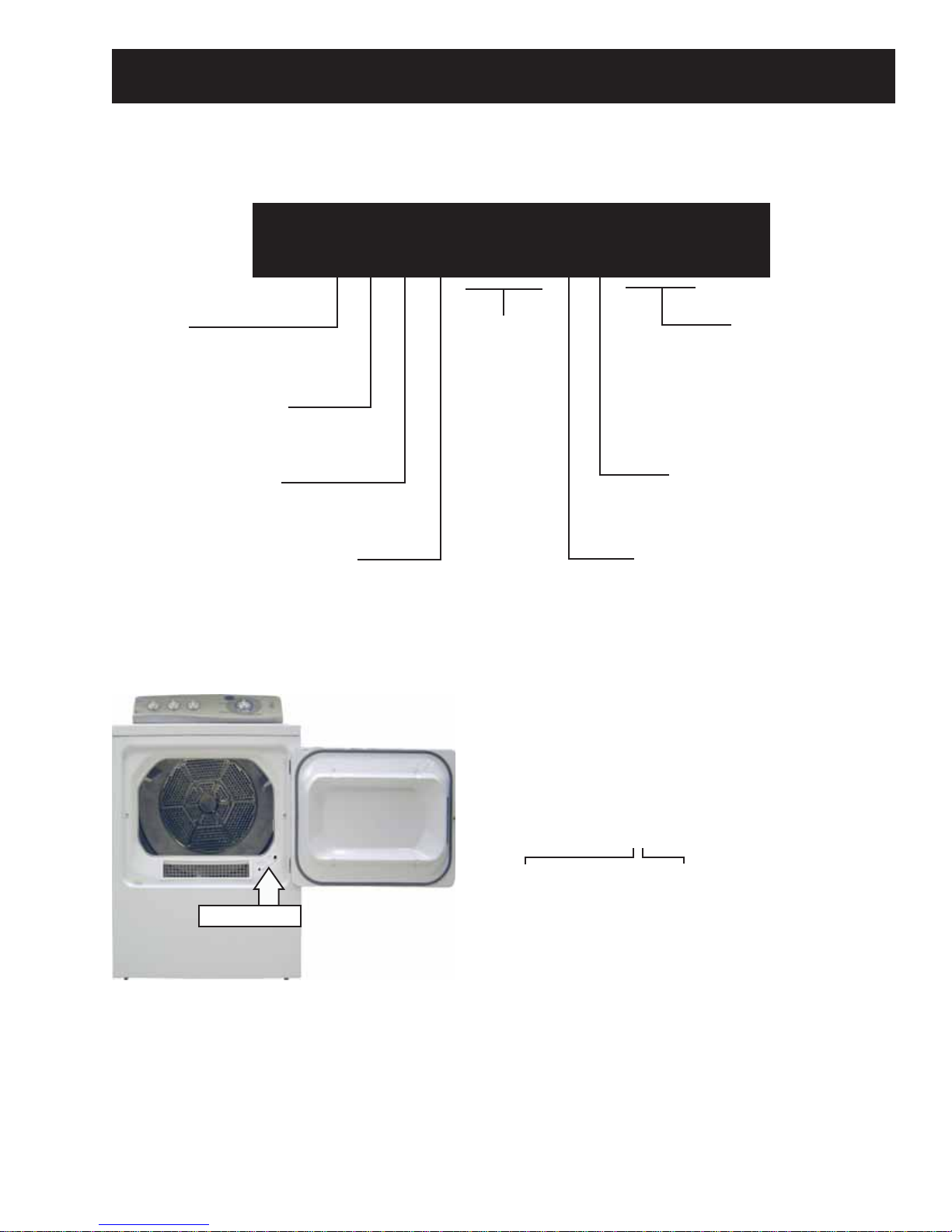

Component Locator Views...........................................................................................................................................16

Control Board Connector Locator View .................................................................................................................18

Control Features............................................................................................................................................................... 7

Control Panel.......................................................................................................................................................................19

Cycle Matrix Chart............................................................................................................................................................15

Door Switch ......................................................................................................................................................................... 22

Drive Belt...............................................................................................................................................................................24

Drum.......................................................................................................................................................................................25

Drum Light Receptacle...................................................................................................................................................22

Drum Shaft and Bearing................................................................................................................................................25

Drum Slide Assembly......................................................................................................................................................20

Dryer Components...........................................................................................................................................................19

Dryer Features...................................................................................................................................................................11

Electronic Control ............................................................................................................................................................38

Flame Detector ..................................................................................................................................................................33

Front Panel...........................................................................................................................................................................20

Gas Valve..............................................................................................................................................................................32

Gas Valve Coils...................................................................................................................................................................31

Heater Assembly...............................................................................................................................................................30

High Limit Thermostat....................................................................................................................................................37

Idler Assembly....................................................................................................................................................................26

Ignitor.....................................................................................................................................................................................33

Ignitor Circuit Operation................................................................................................................................................34

Inlet Control Thermistor.................................................................................................................................................35

Inlet Safety Thermostat.................................................................................................................................................35

Introduction......................................................................................................................................................................... 4

Moisture Sensor ................................................................................................................................................................23

Motor ......................................................................................................................................................................................28

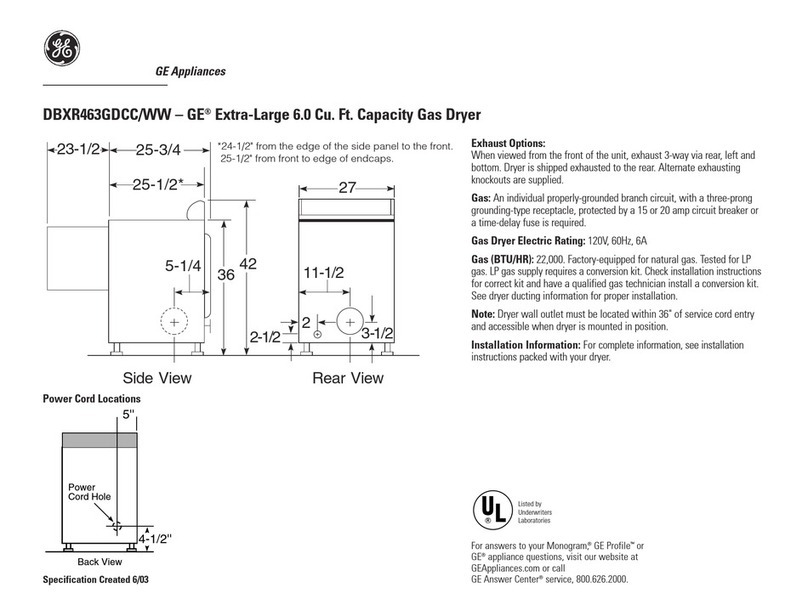

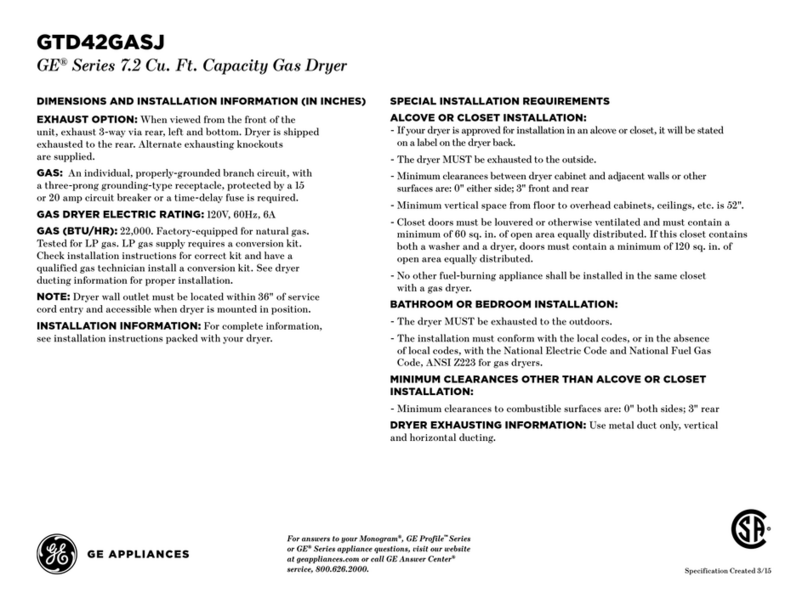

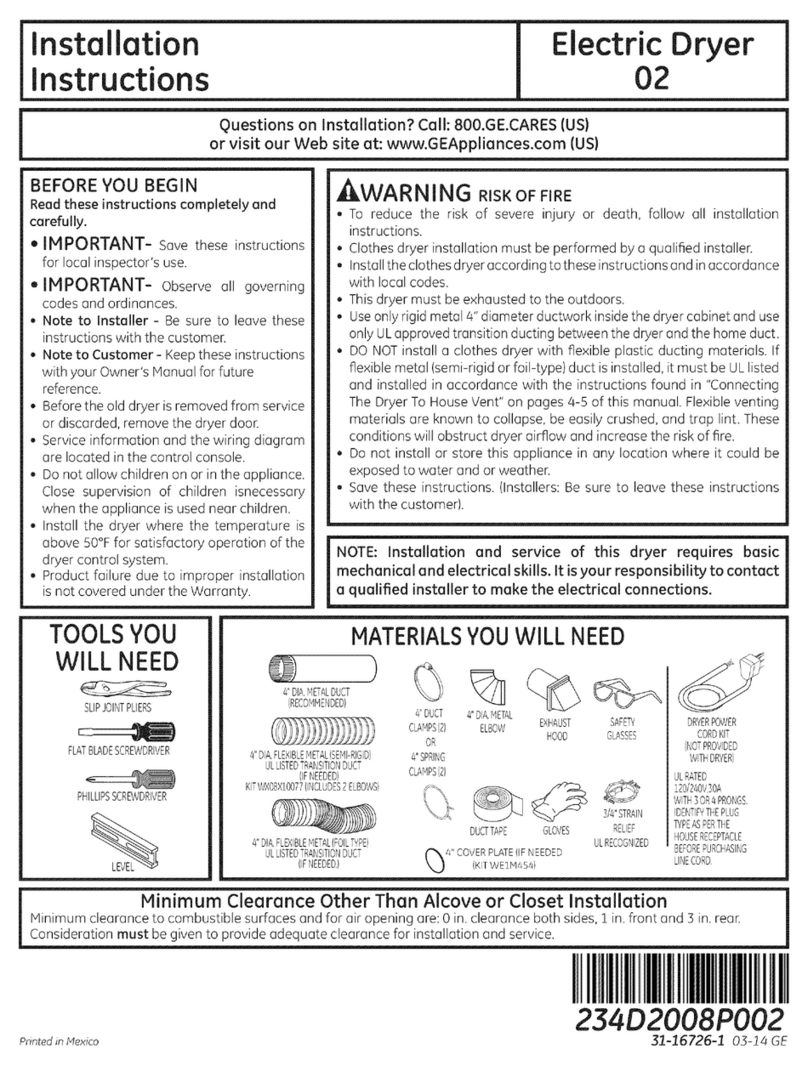

Nomenclature .................................................................................................................................................................... 5

Operation Overview.........................................................................................................................................................13

Outlet Control Backup Thermostat...........................................................................................................................37

Outlet Control Thermistor .............................................................................................................................................36

Reversing the Door ..........................................................................................................................................................12

Schematics and Wiring Diagrams............................................................................................................................43

Service Test Mode.............................................................................................................................................................39

Steam Nozzle......................................................................................................................................................................21

Top Panel ..............................................................................................................................................................................19

Troubleshooting ................................................................................................................................................................39

Warranty ..............................................................................................................................................................................45

Water Inlet Valve ..............................................................................................................................................................26

Water Line Connection .................................................................................................................................................. 6