4

Installation Preparation

IMPORTANT

(Please read carefully.)

The power cord of this appliance is equipped with

DWKUHHSURQJJURXQGLQJSOXJZKLFKPDWHVZLWK

a standard three-prong grounding wall receptacle

to minimize the possibility of electric shock. The

customer should have the wall receptacle and

FLUFXLWFKHFNHGE\DTXDOL¿HGHOHFWULFLDQWRPDNH

sure the receptacle is properly grounded and has

correct polarity.

• Where a standard two-prong wall receptacle is

encountered, it is the personal responsibility and

obligation of the customer to have it replaced

with a properly grounded three-prong wall

receptacle.

Do not, under any circumstances, cut or remove

the third (ground) prong from the power cord.

Do not use an extension cord or adapter plug with

this appliance. Follow National Electrical Code or

prevailing local codes and ordinances.

Location of Rating Label: on front of chassis of

vent system.

This downdraft vent must be supplied with 120V,

60 Hz. and connected to an individual, properly

grounded branch circuit, protected by a 15- or

20-ampere circuit breaker or time-delay fuse.

A properly grounded 3-prong receptacle should be

located within reach of the vent’s two-foot power

cord.

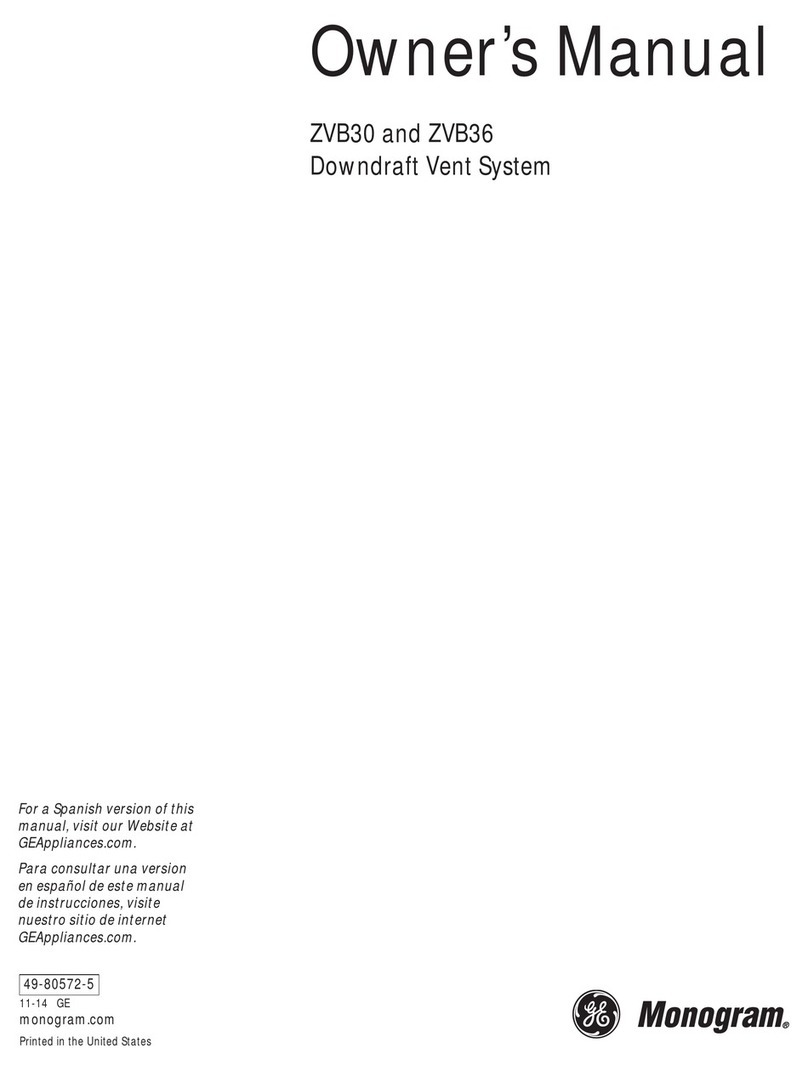

• Gas Cooktops

If this vent is installed in combination with a GE or

Monogram gas cooktop, it may operate from the

same duplex outlet.

• Electric Cooktops

If this vent is installed in combination with a GE

or Monogram electric cooktop, the vent must

operate from a separate 120V outlet.

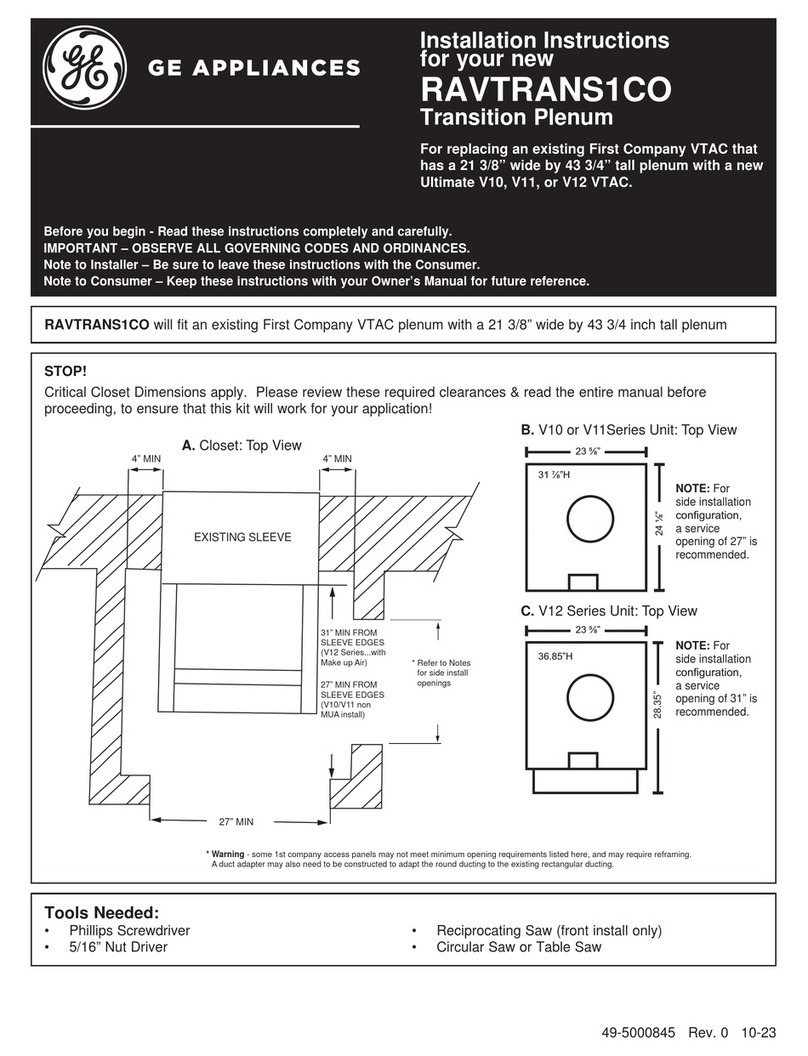

Locate the receptacle inside the cabinet on the right

VLGHZDOOVHHLOOXVWUDWLRQ7KHUHFHSWDFOHFDQQRWEH

placed on the back of the cabinet wall where it may

interfere with the downdraft plenum.

The downdraft vent power cord is to be routed

beneath the cooktop and routed away from heat

generated by the cooktop.

Ensure that the cooktop is installed per

manufacturer’s installation instructions.

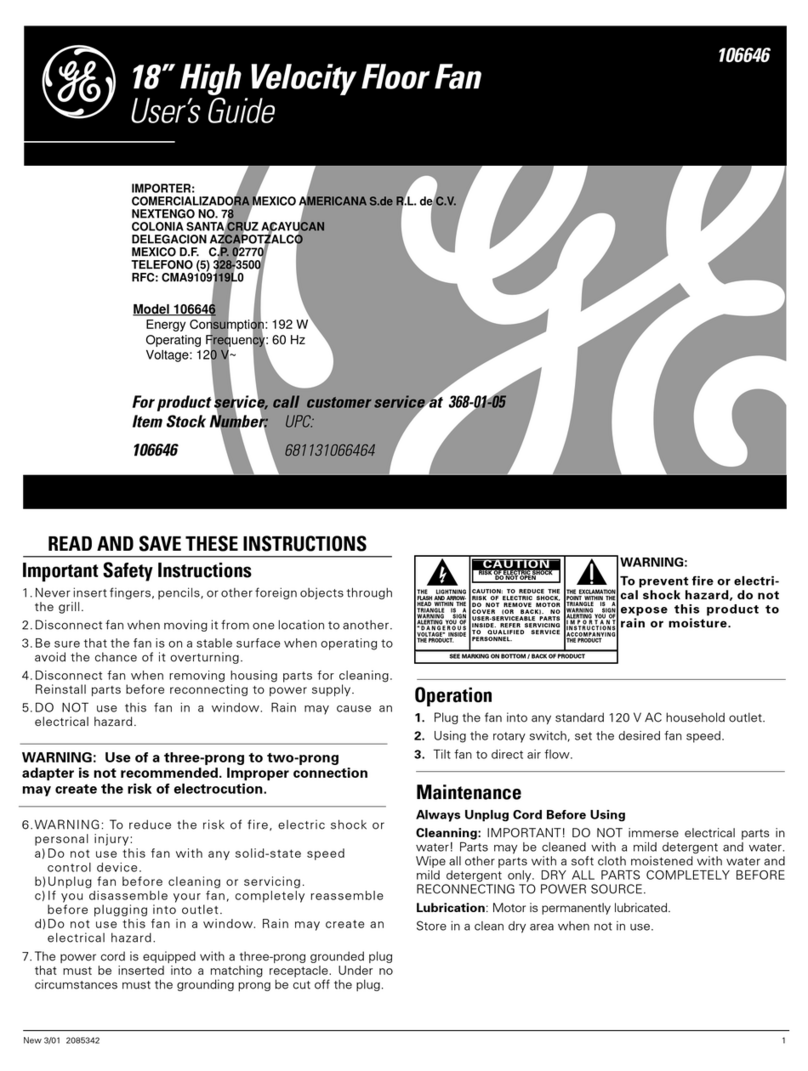

POWER SUPPLY Locate the Gas or Electrical

Connection Only Within the

Shaded Area

DO NOT Locate

Gas or Electrical

Connections within

this Area

FXWRXWZLGWKIRUPRGHOV

FXWRXWZLGWKIRUPRGHOV

29-1/2"

12" Electrical

Outlet 12"

Above

Cabinet

Floor