t-

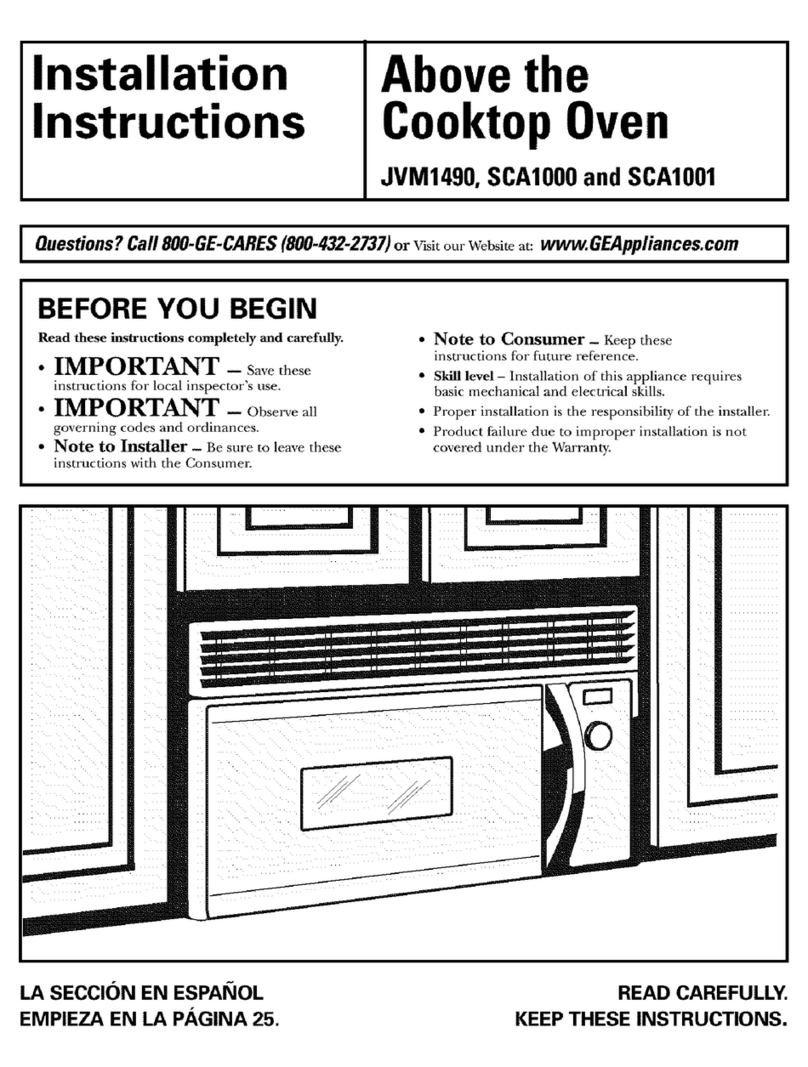

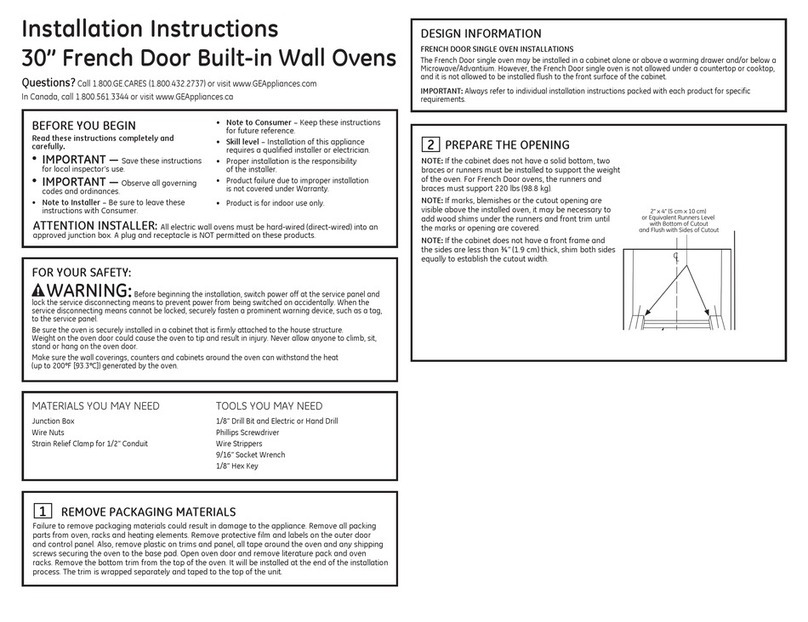

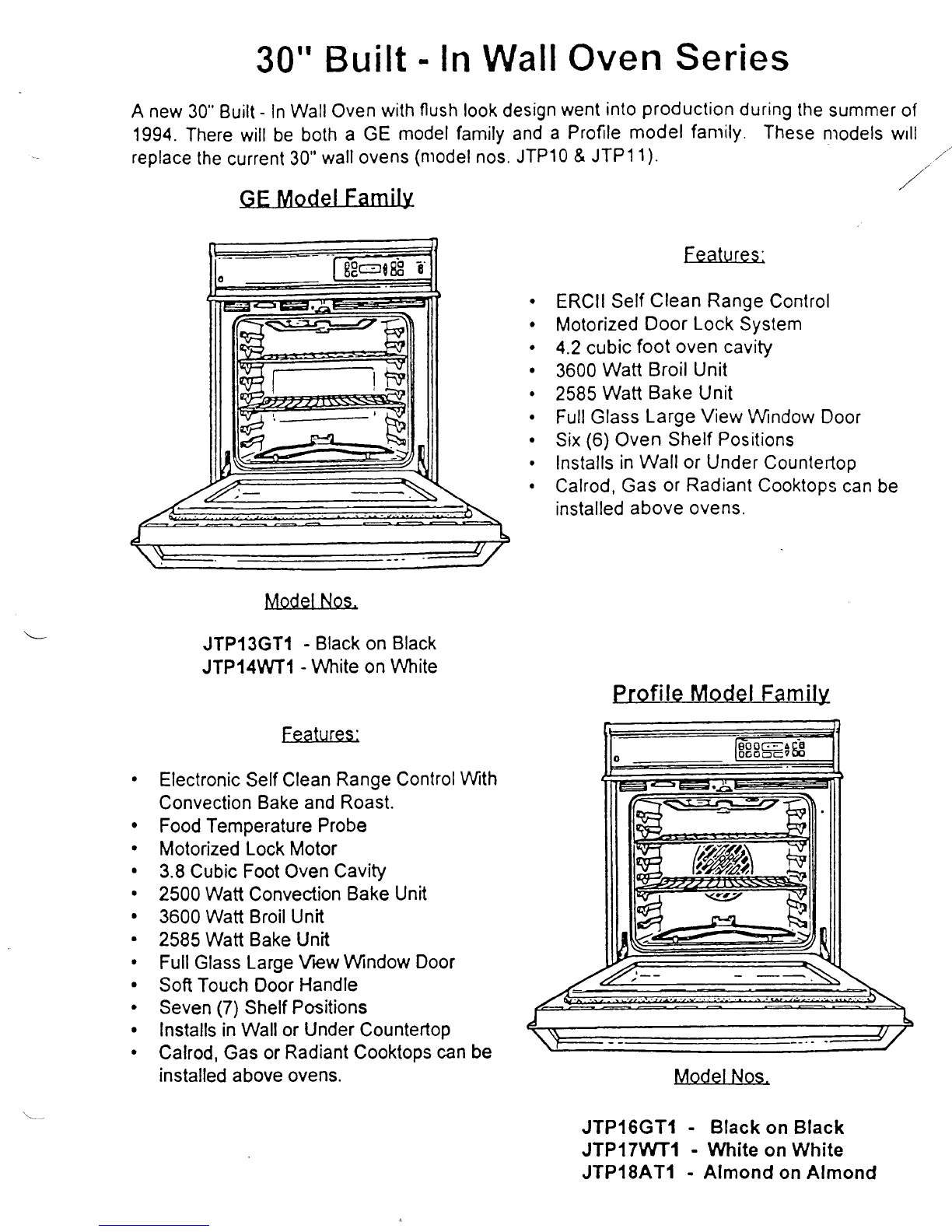

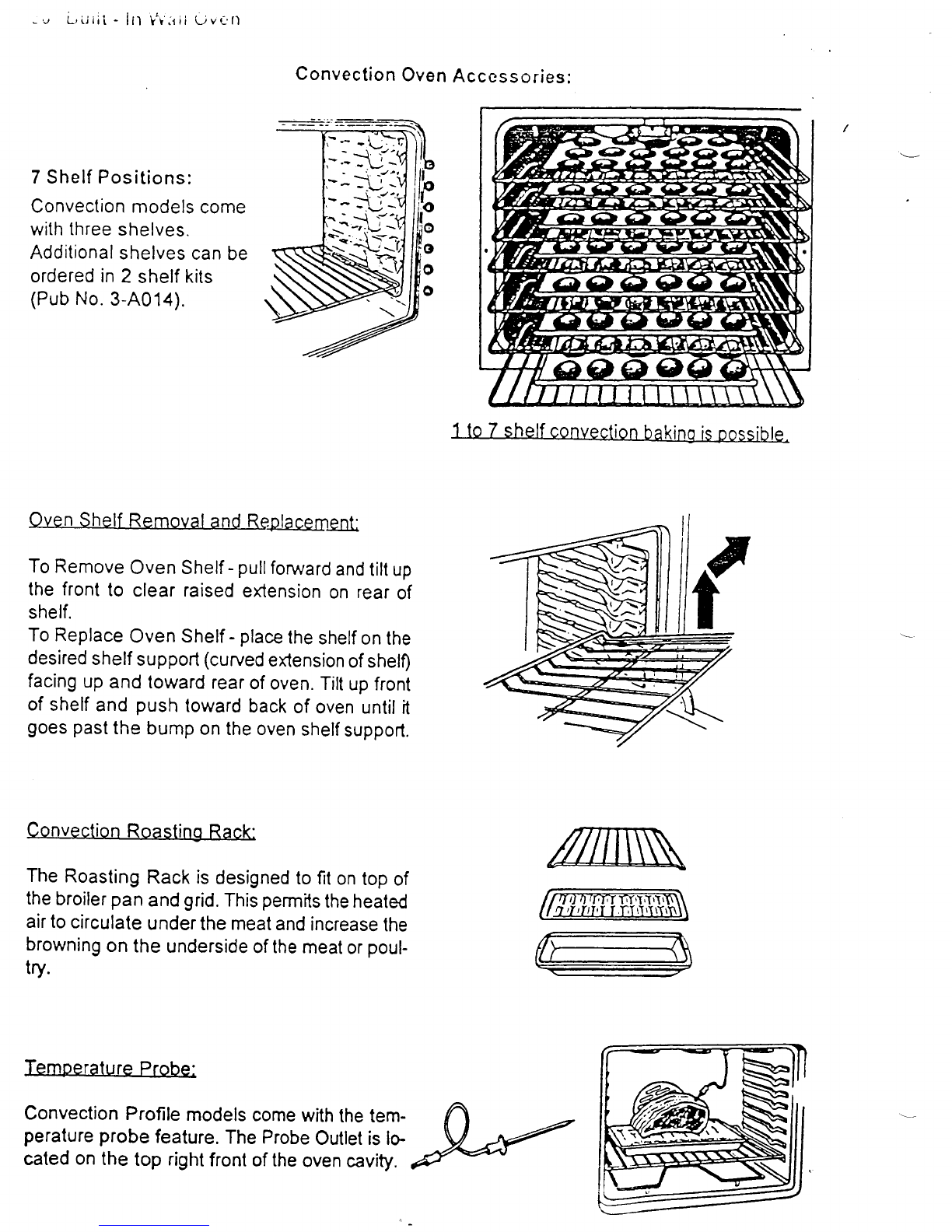

Undcrcountcr In-strlhtion for Crs or EJecrricCooltopa

(h iocbce)

t, Ya

qr

bEEb{n

HTIE f laa.rrl't-€.s

lx^irdco bfo|@d*

D<hrc inallng. coult inulLtirn inrrruffir pr(l.d rrrh FrodxL

Nc Or<n u nrd fq ur mlr un&r thc frrl\nrnl coltop

. GE !f vd !6'cLc ol rrx! !O'adi:nt <rr'ttopr

. Ct g .td 5'6r orr3rrd rnd rrJcd hrr <ciupr

Nac Gr a ckcn rolrop r* b< rnc.ncd F thg ffn. 5.< c,rl tcp rnuJhdm

irwm (o rut@t E S+c bS<l m ta<L o{*n fo rpfrutd (€ltoP ttEdc}r

Insulhtion uitb Gas

Cooktop

(io tcclee)

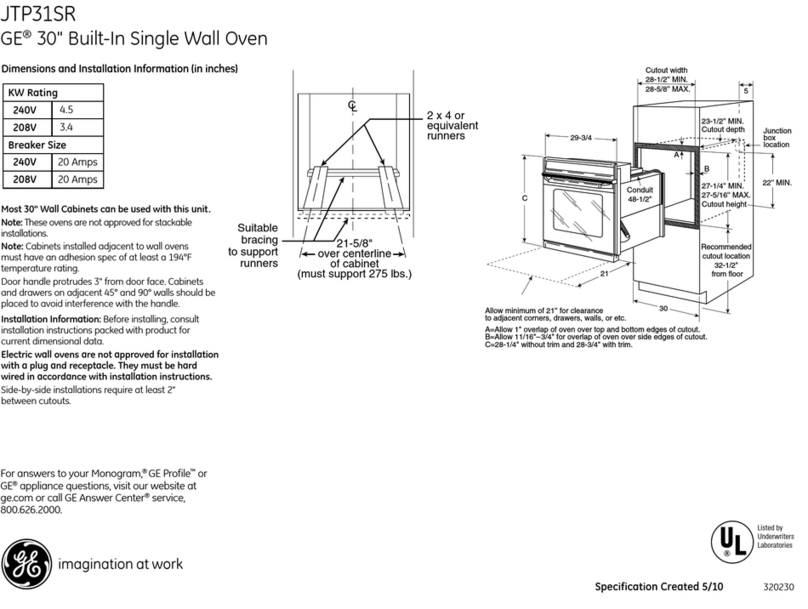

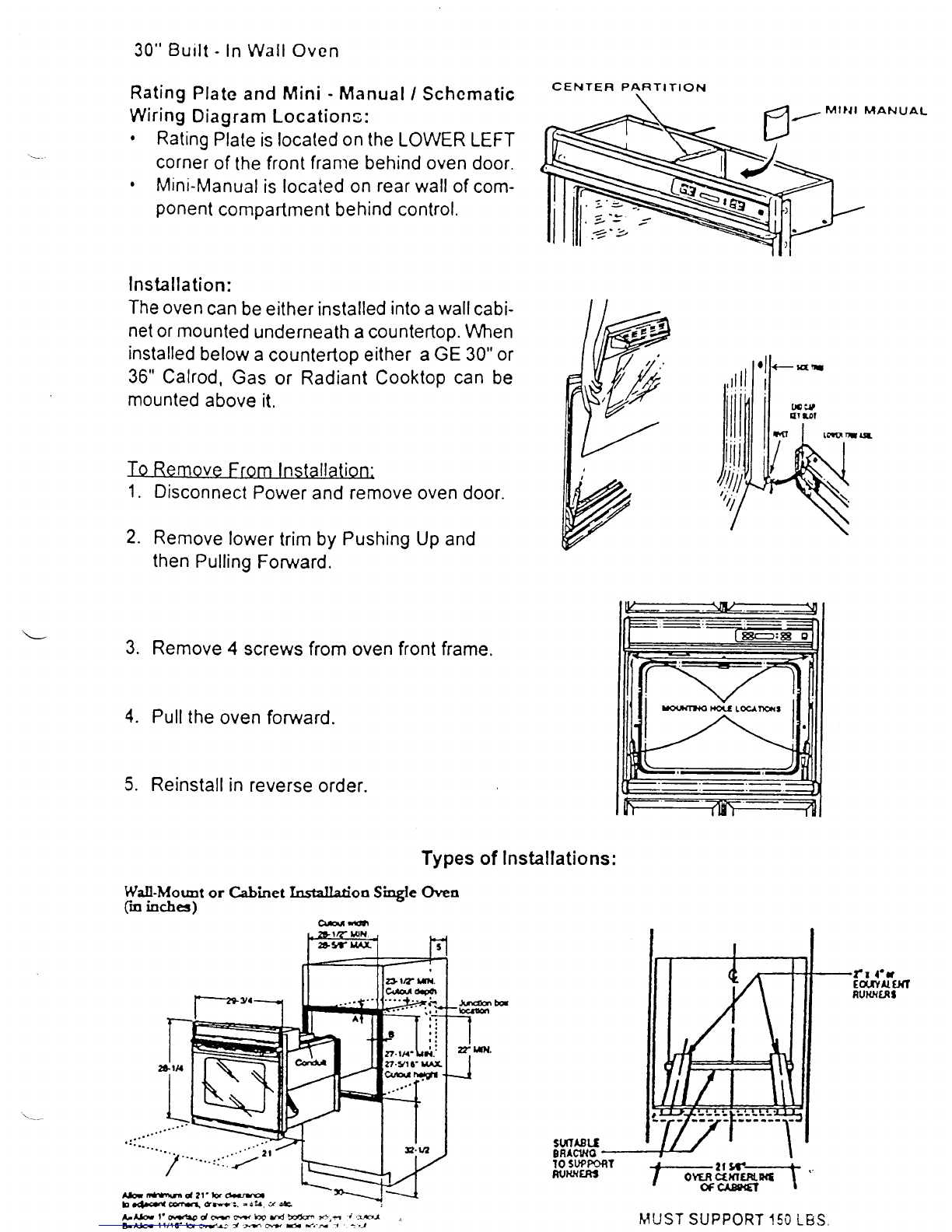

Optirnd Crr.stonllnsreJtation

for 30" R.ldjenr

(

Orrf {in inc}cs)

flrr ,' rr lr ,d^ rr

l,.r h,G 3rp brr*rn trat.,6o(.N"t.

rad r.z rr,l lurcl

!\ok. 1,, t\,r,nul'rrr,r:. rlrr lur,ro uro r{ll aor lr irrf. srh

r..r.rl a.

rd l,(l

r r?rEsJE

fie

b€aE -

q gttr

*Er66.4t

Yr EraL

J,:i"-ru Sor

vn

FtubS

O- t -t@E--4*

ahF l-*dFr-.g

\ tsv6 b.v-EtFt

ilqE4€

'T

I

-l-

J

>tzn

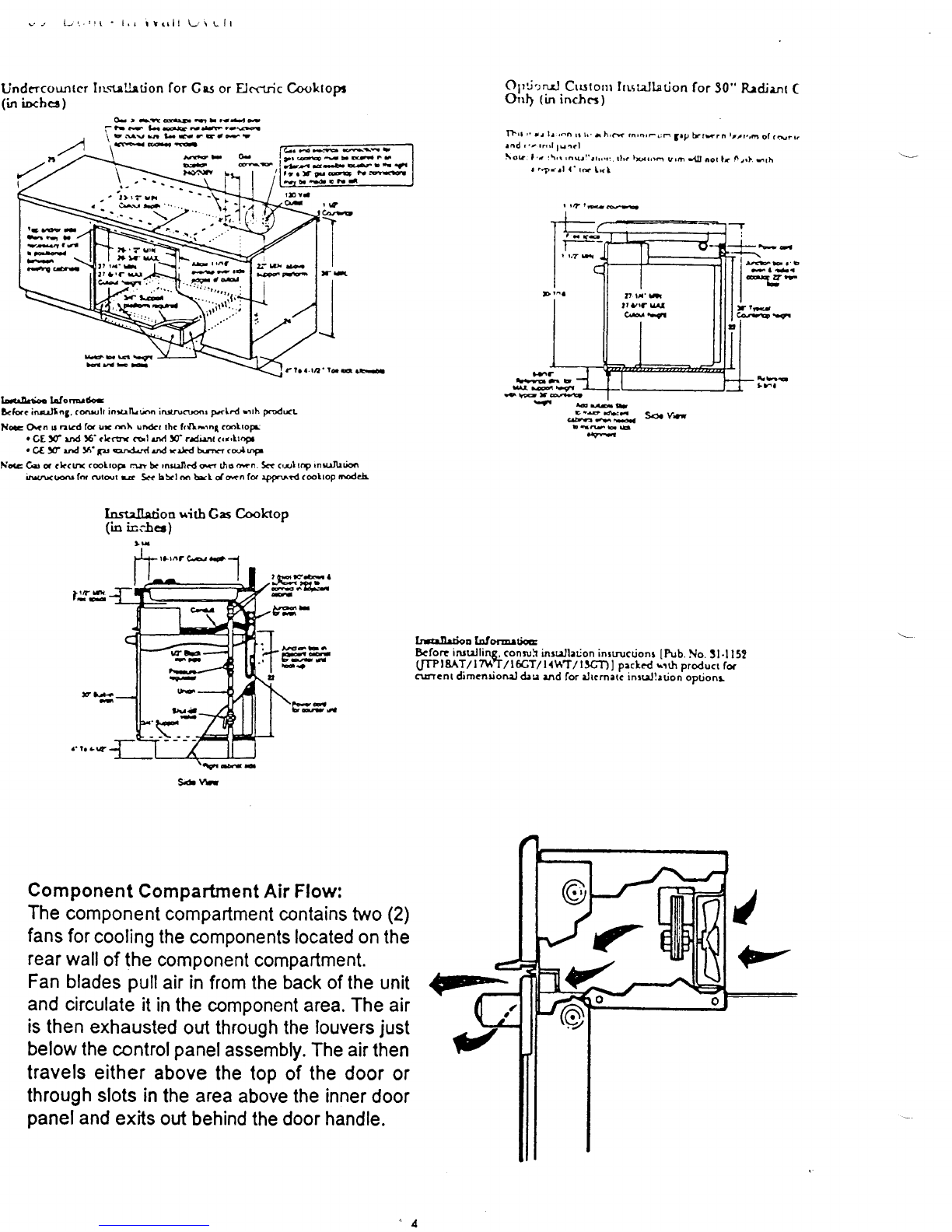

Component

Compartment

AirFlow:

The

component

compartmentcontains

two

(2)

fans

for

cooling

thecomponentslocatedon

the

rear

wall

of

thecomponent

compartment.

Fan

blades

pull

airin

fromthe

backofthe

unit

andcirculate

it

inthe

componentarea.Theair

isthen

exhausled

outthroughthe

louvers

just

belowthe

control

panelassembly.

Theair

then

travelseither

above

thetopofthedoor

or

through

slotsin

theareaabove

the

inner

door

panel

and

exitsoutbehind

thedoorhandle.

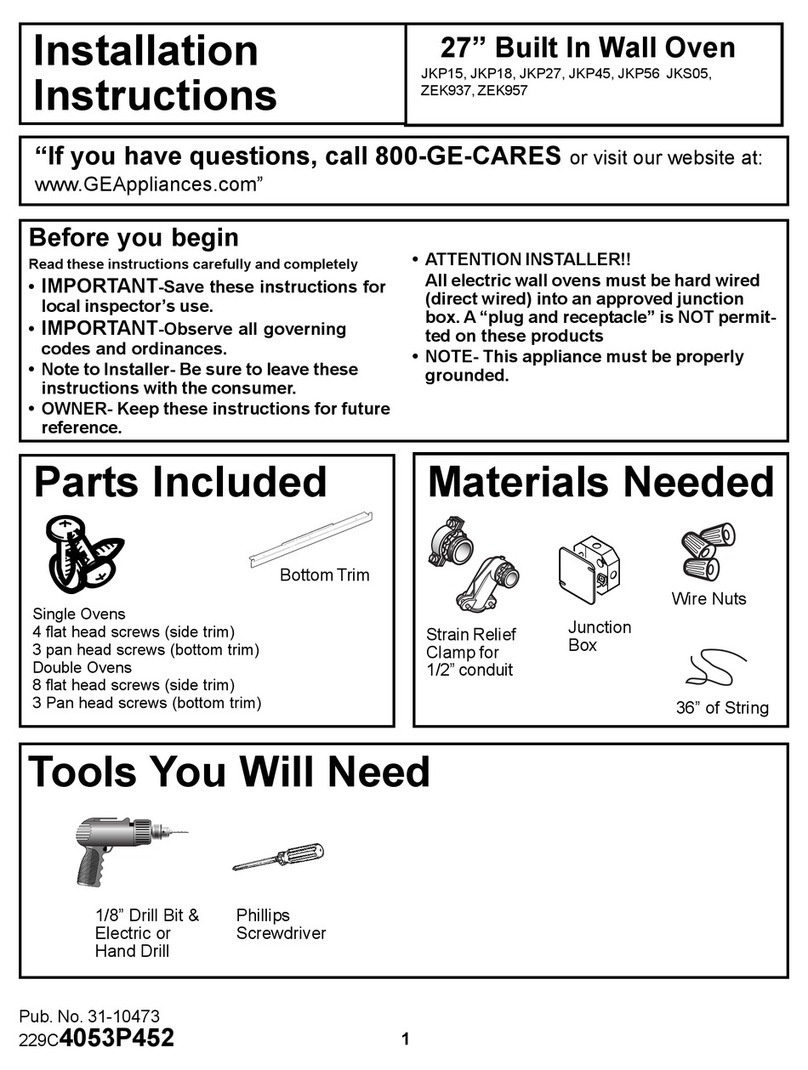

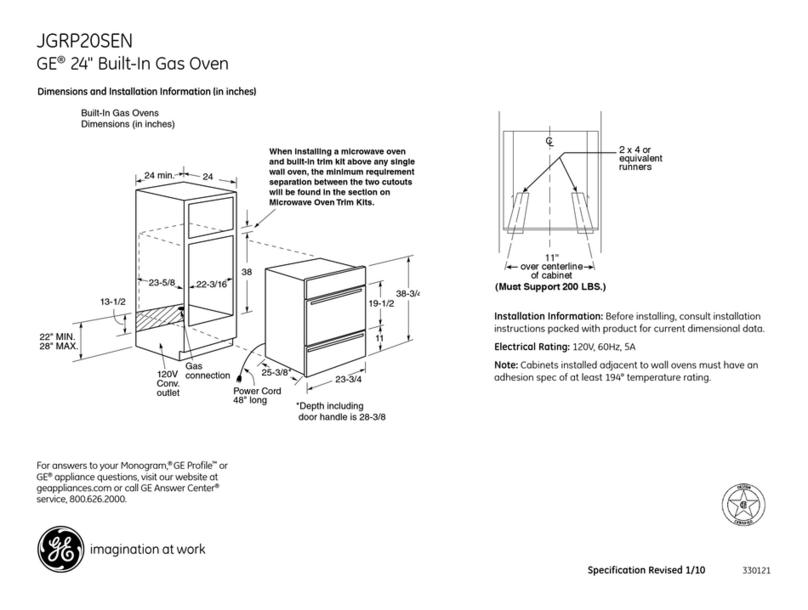

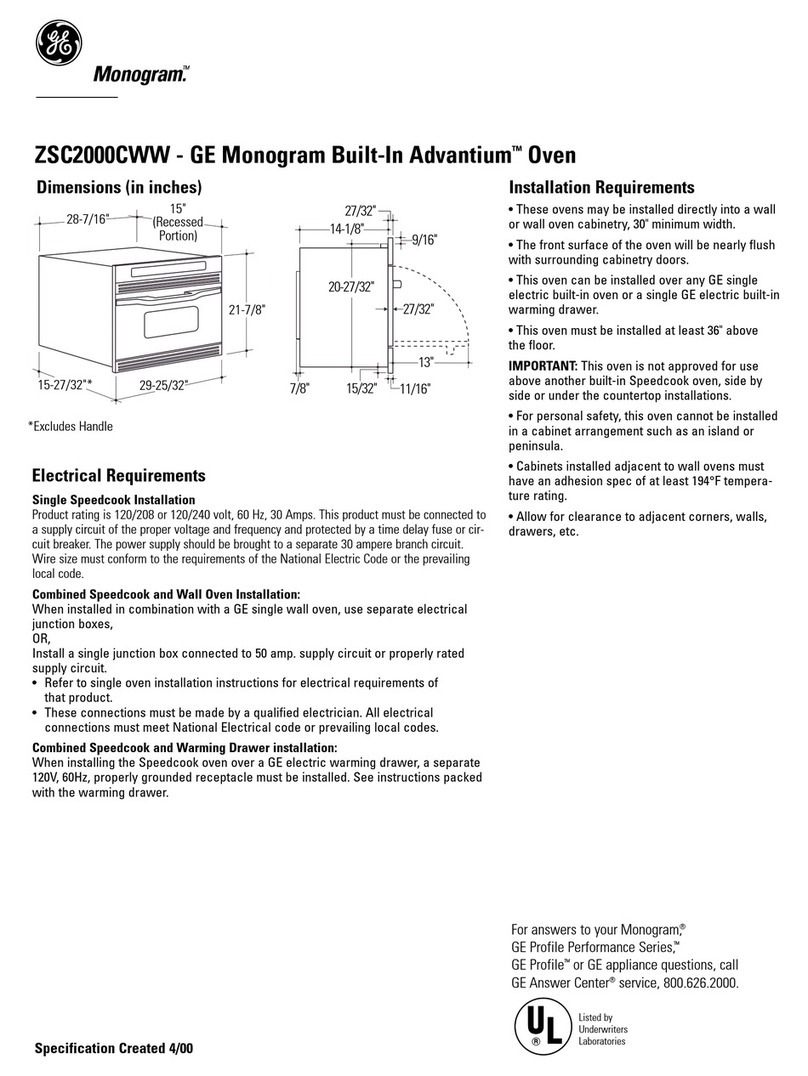

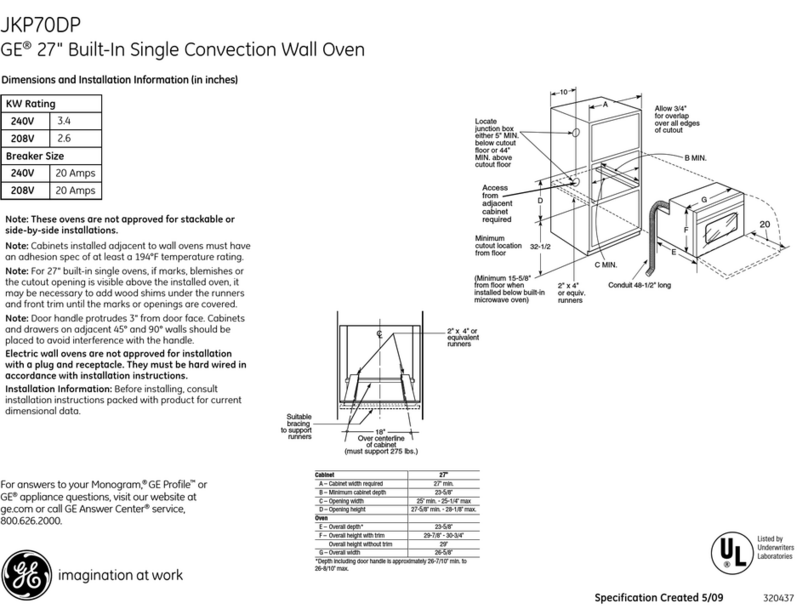

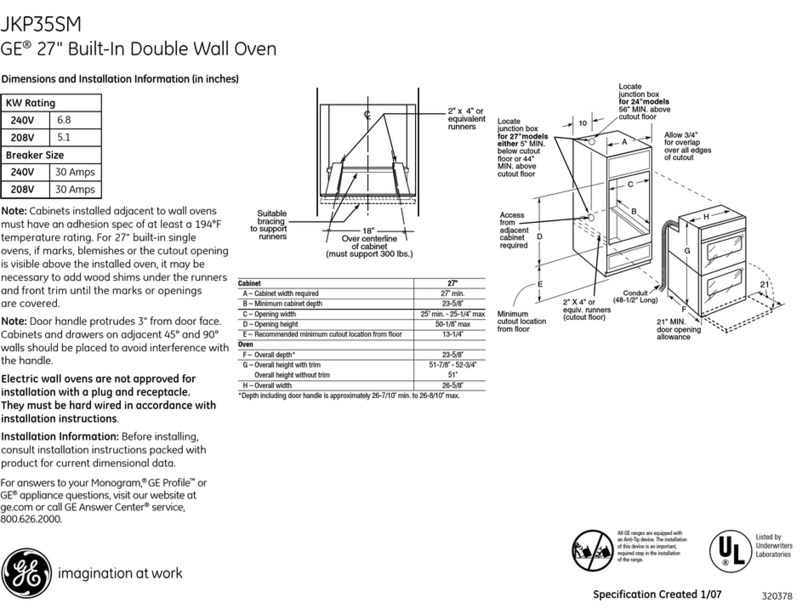

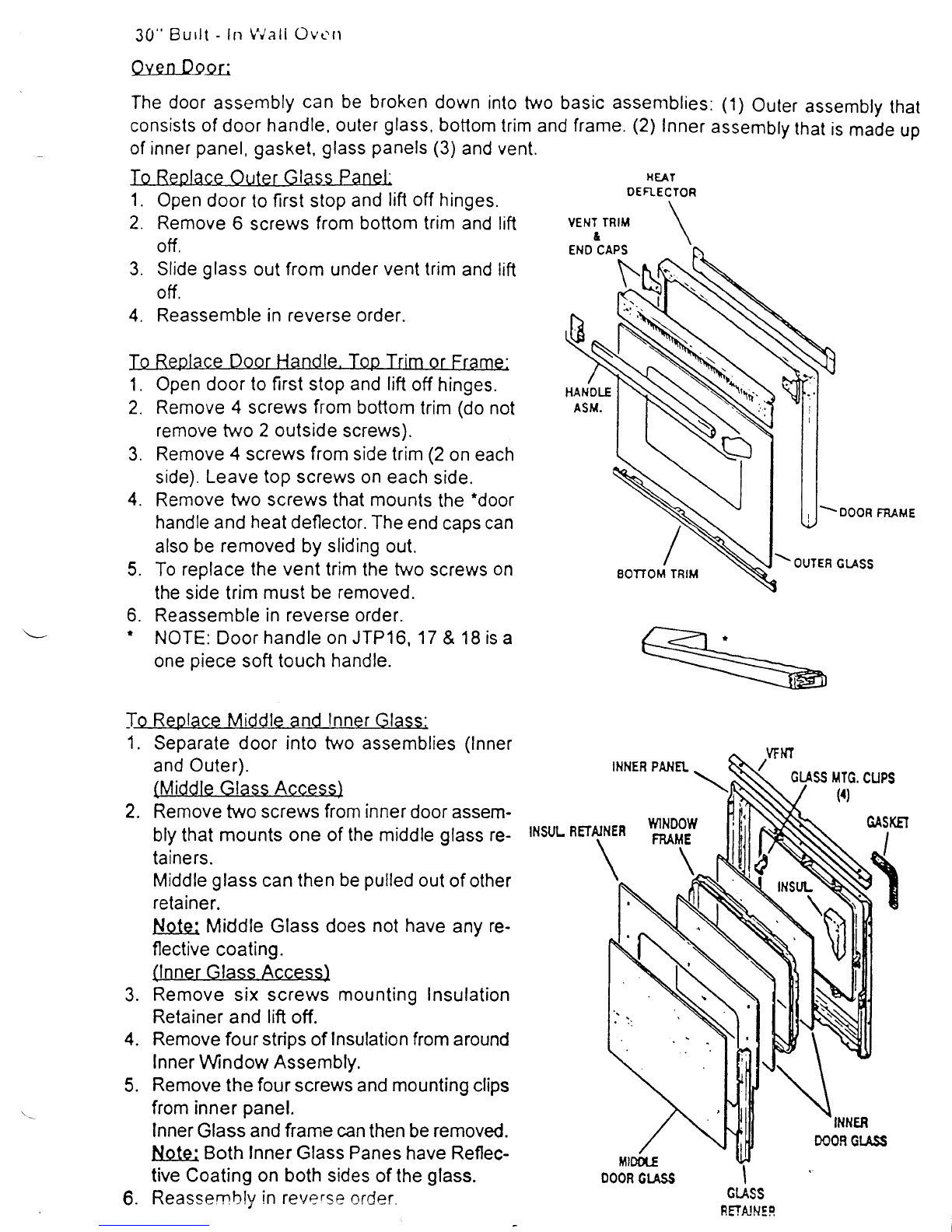

Irallrrion lalorantir

Bcfort irudling, conwh insuJlarjon

inrtrucdontIPub.

No.3l.l I5?

0m I8AT/ InAT / |6T / | lUT / lJQf) ! pacled rrrh producr for

currcnt dimenrioneld:u andfor rJrcmatiinrreJhdon

opuonr

l;-o. o

I qltF

lb

I

,rfl

Sd\Ai