TOC TABLE OF CONTENTS

MULTILINK ML600 ETHERNET COMMUNICATIONS SWITCH – INSTRUCTION MANUAL TOC–I

Table of Contents

1: INTRODUCTION GETTING STARTED ............................................................................................................1-1

INSPECTING THE PACKAGE AND PRODUCT ...................................................................... 1-1

ORDERING ..........................................................................................................................1-2

ORDER CODES ..................................................................................................................... 1-2

SPECIFICATIONS ................................................................................................................1-3

TECHNICAL SPECIFICATIONS .............................................................................................. 1-3

ENVIRONMENTAL SPECIFICATIONS .................................................................................... 1-4

PHYSICAL SPECIFICATIONS ................................................................................................. 1-4

APPROVALS AND WARRANTY ............................................................................................ 1-4

2: PRODUCT

DESCRIPTION

OVERVIEW ...........................................................................................................................2-1

INTRODUCTION TO THE ML600 ........................................................................................ 2-1

DESIGN ASPECTS ................................................................................................................. 2-1

FEATURES AND BENEFITS ...............................................................................................2-3

FRAME BUFFERING AND LATENCY .................................................................................... 2-3

ADDITIONAL FEATURES AND BENEFITS ............................................................................ 2-3

APPLICATIONS ...................................................................................................................2-5

DESCRIPTION ........................................................................................................................ 2-5

WINDMILL APPLICATION .................................................................................................... 2-5

INDUSTRIAL NETWORKING APPLICATION ......................................................................... 2-6

TRANSPORTATION SURVEILLANCE SYSTEM ...................................................................... 2-6

3: INSTALLATION PREPARATION ....................................................................................................................3-1

LOCATING THE ML600 ...................................................................................................... 3-1

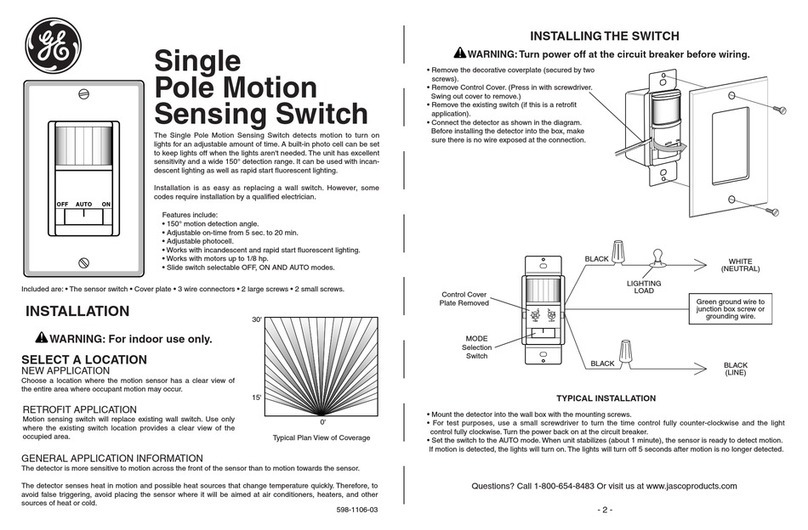

ELECTRICAL INSTALLATION ...........................................................................................3-2

POWER REQUIREMENTS ...................................................................................................... 3-2

CONNECTING DC POWER .................................................................................................. 3-2

CONNECTING ETHERNET MEDIA ..................................................................................3-3

DESCRIPTION ........................................................................................................................ 3-3

CONNECTING TWISTED PAIR ............................................................................................. 3-3

CONNECTING ST-TYPE FIBER OPTICS (TWIST-LOCK) ...................................................... 3-3

CONNECTING SC-TYPE FIBER OPTICS (SNAP-IN) ............................................................ 3-4

CONNECTING SINGLE-MODE FIBER OPTICS .................................................................... 3-4

4: OPERATION FUNCTIONALITY ................................................................................................................4-1

DUAL-SPEED AND SWITCHING FUNCTIONALITY ............................................................. 4-1

SWITCHING, FILTERING AND FORWARDING .................................................................... 4-1

ADDRESS LEARNING ............................................................................................................ 4-2

AUTO-CROSS (MDIX), AUTO-NEGOTIATION, AND SPEED SENSING ............................. 4-2

STATUS LEDS...................................................................................................................... 4-2

ALARM CONTACT ................................................................................................................. 4-2

POWER BUDGET CALCULATIONS WITH FIBER MEDIA .................................................... 4-3

TROUBLESHOOTING .........................................................................................................4-5

OVERVIEW ............................................................................................................................ 4-5

BEFORE CALLING FOR ASSISTANCE .................................................................................. 4-5

WHEN CALLING FOR ASSISTANCE .................................................................................... 4-5