Installation Instructions

AVERTISSEMENT:AFIN DE

REDUIRELERISQUED'INCENDIE,DECHOCS

ELECTRIQUESOUDEBLESSURESCORPORELLES,

VEUILLEZVOUSCONFORMERAU×RECOMMANDATIONS

SUIVANTES:

A. L'installation et le c6blagedoivent _trefaits par une ou des

personnesqualifi6es et en conformit6 6 tousles codes et

normes applicables,g compris lesnormes en mati@rede

coupe-feu.

B. Letirage d'airdolt @tresuffisant pour permettre une

combustion ad@quateet 1'6vacuationpar leconduit

(chemin@e)desgaz de 1'6quipementde combustion afin

de pr6venirle refoulement. Conformez-vous aux lignes

direatricesdu fabricant de 1'6quipementde chauffage

et aux normes de s6curit6, comme cellespubli@espar

I'associationnationale contre lesincendies(National Fire

ProtectionAssociation,NFPA)et I'associationam6ricaine

desing6nieursen appareilsde chauffage,de rdrig@ration

et de climatisation (AmericanSocietgfor Heating,

Refrigerationand Air Conditioning Engineers,ASHRAE),

ainsiqu'aux codes desautorit6s de votre r@gion.

C. Lorsquevous percezou coupez lesmursou lesplafonds,

prenezsoinde ne pasendommager lesills @lectriquesni

lesautres appareilsqui g sont dissimul@s.

D. Leconduit de lahotte dolt toujours @treventil6 vers

I'ext6rieur.

• Lescodes peuvent diff6rersuivant lesr6gions.L'installation

desconnexions61ectriqueset de la mise6 la terre dolt

seconformer aux codes applicables.EnI'absencede code

@leatrique,I'installationde 1'6ventdolt sefaire en conformit6

la norme ANSI/NFPA70-1990 du code national de

1'61ectricit6(National ElectricalCode)ou 6 son @dition

la plus r@cente.

CAUTION:TOreduceriskof fire and to

properlg exhaust air,besureto duct air outside.

Do notvent exhaust air into spaceswithin walls

or ceilingsor into attics,crawl spacesor garages.

ATTENTION:,,faut prendre soin

d'installer un conduit vers I'ext6rieur pour r6duire

le risqued'incendie et pouvoir @vacuerI'air

correctement. IIne faut pas 6vacuer I'airdans

I'espaceentre lespatois d'un mur,un plafond ou un grenier,

un espacesanitaireou un garage.

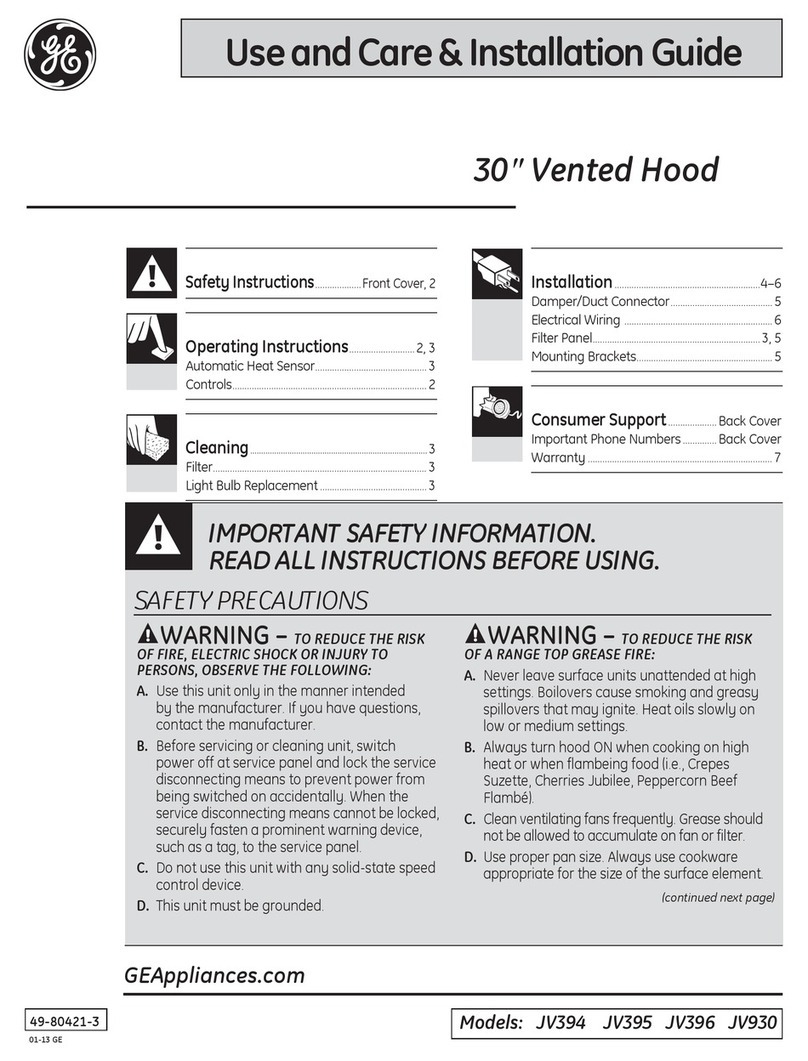

WARNING:ToREDUCETNERISK

OFA RANGETOPGREASEFIRE:

A. Never leavesurface units unattended at high settings.

Boiloverscause smoking and greasg spilloversthat maU

ignite. Heat oilsslowlUon low or medium settings.

B. Alwagsturn hood ONwhen cooking at high heat or when

flambeing food (i.e.CrepesSuzette,CherriesJubilee,

PeppercornBeefFlamb@).

C. Cleanventilating fans frequentlg. Greaseshouldnot be

allowed to accumulate on fan or filter.

D. Use proper pan size.Alwags usecookware appropriate for

the sizeof the surface element.

AVERTISSEMENT:AFIN DEREDUIRELE,RISQUED'UNFEUDEFRITURESUR

LACUISINIERE:

A. Nelaissezjamaissanssurveillanceles6bments decuissonde

votrecuisini_reIorsqu'ilssontr6gl6s_ unetemperature6levee.

Lesd6bordementscauserontde lafum6eet les6claboussures

de graissepeuventprendrefeu.Faiteschaufferleshuiles

lentement6 unetemp6raturebasseou mogenne.

B. Metteztoujourslahotteen marcheIorsquevouscuisinez6

unetemp6rature_lev6eouIorsquevousfaitesflamberdes

aliments(p.ex.,cr_pesSuzette,cerisesjubil6,flamb6de bceuf

au poivre).

C. Nettogezlahottede ventilationr6guli_rement.Evitezdelaisser

lagraisses'accumulerdonslahotte oulefiltre.

D. Utilisezune casserolede labonnedimension.Utiliseztoujours

descasserolesetdespo_lesd'unetaillequicorrespondaux

616mentsde lacuisini_re.

WARNING:ToREDUCETNER,SKOF

INJURYTOPERSONSINTHEEVENTOFA RANGE

TOPGREASEFIRE,OBSERVETHEFOLLOWINGa:

A. SMOTHERFLAMESwith a close-fittinglid,cookiesheet

or metaltrag,thenturn offthe burner.BECAREFULTO

PREVENTBURNS.Iftheflamesdo notgo outimmediatelg,

EVACUATEANDCALLTHEFIREDEPARTMENT.

B. NEVERPICKUPAFLAMINGPAN-Youmagbe burned.

C. DONOTUSEWATER,includingwet dishclothsortowels-

a violentsteamexplosionwillresult.

D. Usean extinguisherONLYif:

1)Youknow gouhaveaClassABCextinguisher,andgou

alreadgknowhowto operateit.

2)Thefireissmallandcontainedintheareawhereitstarted.

3)Thefiredepartmentisbeingcalled.

/4)Youcanfightthefirewith gour backtoan exit.

aBasedon "KitchenFiresafetUTips"publishedbg NFPA.

AVERTISSEMENT:AFINDE REDUIRE

LESRISQUESDE BLESSURESCORPORE,LLESEN CAS

D'UNFEUDE FRITURESUR LACUISINIERE,

VEUILLEZSUIVRELESRECOMMANDATIONS

SUIVANTESa:

A. ErOUFFEZLESFLAHMES_ I'aided'uncouvercleajust6,

d'unet61e6 biscuitsou d'unplateaum6tallique,puis6teignez

1'_16mentchauffant.PRENEZGARDEDENEPASVOUSBRULER.

Silesflammesnes'_teignentpasimm6diatement,EVACUEZ

LESLIEUXETAPPELEZLESPOMPIERS.

B. NESOULEVEZJAMAISUNECASSEROLEENFEU.Vousrisquez

devousbn31er.

C. N'UTILISEZJAMAISD'EAU,gcomprisde layettesou de

serviettesmouill6es.Uneexplosiondevapeurviolentepourrait

en r6sulter.

D. UtilisezunextincteurSEULEMENTsi:

1)Voussavezquevotreextinateurestde cat_gorieABCet

voussavezd_j6commentlefairefonationner.

2)Lefeuestpetitetcontenu_ I'endroito6 ila commenc&

3)Lespompiersant6t6appel6ssurleslieux.

/4)Vous_tesenmesuredecombattreI'incendiesachantquela

sortiedesecourssetrouvedirectementderrierevous.

aReprisdu <<KitchenFiresafetgTips>>(conseilsen cosd'incendie

donsla cuisine)publi6parla NFPA.