– 3 –

Table of Contents

AC Line Filter........................................................................................................................................................................17

Agitator..................................................................................................................................................................................13

Belt...........................................................................................................................................................................................20

Brake Test............................................................................................................................................................................. 36

Component Locator Views...........................................................................................................................................12

Control Panel ......................................................................................................................................................................14

Control Timer ......................................................................................................................................................................14

Control Features...............................................................................................................................................................10

Cover/Lid Assembly.........................................................................................................................................................19

Diagnostics and Service Information...................................................................................................................... 30

Drain Pump..........................................................................................................................................................................20

Front Panel...........................................................................................................................................................................19

Harness Fuse ......................................................................................................................................................................23

Inverter/Motor.................................................................................................................................................................... 22

Inverter/Motor Error Codes..........................................................................................................................................33

Inverter/Motor Test..........................................................................................................................................................35

Leveling Legs ......................................................................................................................................................................13

Lid Switch .............................................................................................................................................................................18

Mode Shifter Coil Test .....................................................................................................................................................35

Motor and Drive System................................................................................................................................................ 5

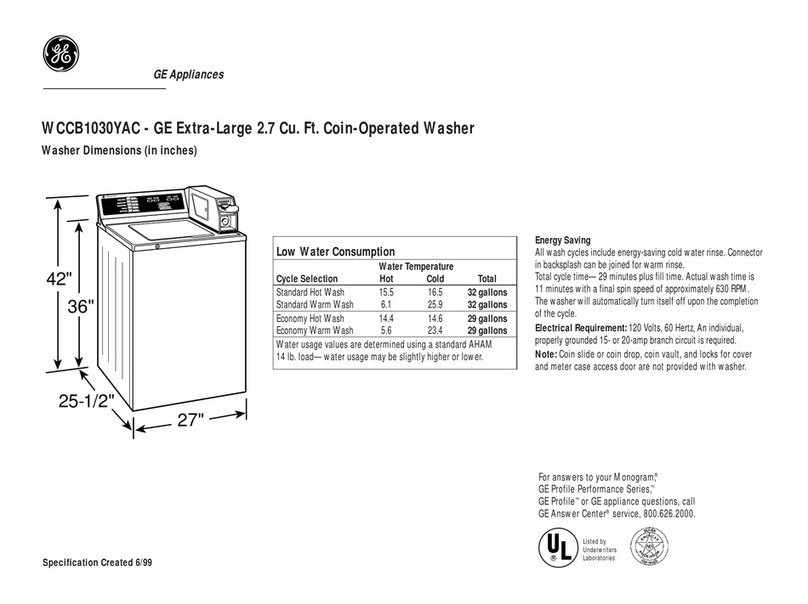

Nomenclature .................................................................................................................................................................... 4

Schematic ............................................................................................................................................................................37

Shaft and Mode Shifter Assembly ............................................................................................................................ 26

Shaft and Mode Shifter Overview ............................................................................................................................. 6

Shipping Rod.......................................................................................................................................................................13

Suspension ..........................................................................................................................................................................23

Temperature Selector and Options Switches...................................................................................................... 16

Tub Assembly .....................................................................................................................................................................24

Tub Cover.............................................................................................................................................................................. 24

Warranty ..............................................................................................................................................................................38

Washer Components......................................................................................................................................................13

Water Level Switch ..........................................................................................................................................................15

Water Valve.........................................................................................................................................................................17